How to break rails without sawing

Maintenance of the railroad bed involves cutting out worn out sections of rails with special equipment. In this material we will talk about how to saw the rail at home (or garage) conditions, what tools are more effective, how to act in each case and what are the advantages of one or another method.

Despite the apparent complexity of the operation, it is not difficult to cut a metal element into small sections. To do this, you can use one of the following tools:

Each method is complicated in its own way, but the expected result (the rail cut into pieces) will be obtained. Now for more details about each technique.

Cutting with a sewing needle

This method was popular in the last century, when there were no more convenient devices to cut metal rails. in this case the workpiece is not sawn but broken.

- The rail is placed by its edges on two supports with the base facing downwards;

- A thick sewing needle is placed perpendicular to the piece at the suggested breaking point;

- a strong and precise blow is made with a sledgehammer at the point where the needle touches the rail, cutting it in half.

- experience is needed. it’s not easy to hit the right spot accurately;

- The fishing line for the trimmer of the fracture (cut) sometimes turns out to be a curve;

- Only one precise blow is required; if several unsuccessful attempts are made, the sheet integrity will be destroyed.

Using a chisel

Here, too, the metal workpiece is divided not by cutting, but by punching.

- set the rail as in the paragraph above;

- all around the perimeter with a chisel and hammer (mallet) perform notches of low depth (1-2 mm);

- hit the notches with a sledgehammer, the rail is split.

Advantages and disadvantages of the method repeat the above mentioned, but it takes a little more time.

Cutting rail with a hacksaw

It is a popular method, but time-consuming. It is important to know a few requirements for the saw blade:

- the handle is comfortable, is not horizontal, but vertical, with a slight tilt to the side of the stroke “from itself”;

- there is a spraying on the teeth of the blade;

- the teeth are in a “pull away” direction;

- When working, move the blade so that the contact area of the teeth with the cutting surface is maximum;

- select the blade according to the density and hardness of the rail material.

How to cut a rail using a hacksaw? The sequence is as follows:

- the rail is placed on a horizontal surface;

- If you need a precise cut, it is worth using a chisel to make notches on the base;

- Saw through the base on both sides to the neck of the rail;

- Place a stop notch under the kerf;

- Make a pointed blow with a sledgehammer.

There are other ways to divide the notched rail into two parts. For example, to drop it from a height, if there is a manipulator-loader at hand.

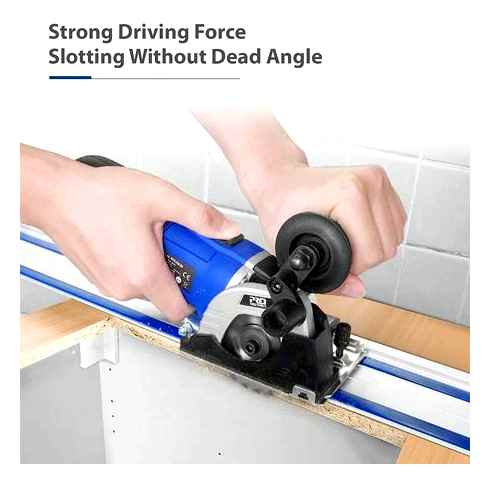

Using an angle grinder

Professional tool will save time on sawing the rail. Experienced people say that two discs 150 mm in diameter are enough to saw a classical railroad rail (P65, P75).

The work is performed similarly. the base is sawed on both sides, followed by a blow with a sledgehammer. The operation takes 5-10 minutes.

- Risk of injury (disc could bite and break, flying sparks in the eyes, etc.).д.);

- Noise at work;

- high meaningless);

- the method is bad for home conditions because of the dust, dirt, metal shavings generated.

application of rail cutters

One more method of quick splitting the rails into fractions, which is not quite suitable for home conditions, but deserves consideration. The rail cutter is a professional equipment used for various types of products. It is usually used on railroad tracks for quick roadbed restoration to avoid train delays. Here are two devices to give you an example.

Rail cutting machine РМ5ГМ

- The cutter is a hacksaw blade with a length of 400 or 450 mm, which resembles a sabre saw;

- There is a gripper for fixing the products;

- the presence of hydraulic pressure allows to apply maximum force to the contact point during the working stroke and unloading during idle (reverse) stroke.

Time to cut one P65 rail into 2 pieces. about 11 minutes. The device weighs 90 kg, has dimensions of 1465x505x460 mm, so it is not suitable for home conditions.

Husqvarna K 1260 (Partner K-1250 Rail) Saw

- power almost 6 kW (higher than RM5GM power);

- Working body. a cutting disc with a diameter of 350 or 400 mm (the principle of work. like an angle grinder);

- weight without additional equipment. 20 kg.

The device is 5 times faster to cut the same P65 than the machine considered earlier. Compact size, relative lightness and efficiency make it ideal for home use. The only disadvantage of the equipment is its high weight.).

Which method to choose

To make a decision, it is necessary to take into account a number of factors. Costs of work (money and time), noise, duration of the process, the need for outside help. From the point of view of safety the way of cutting with a sabre saw looks attractive. In terms of speed. angle grinder or rail cutter.

The latter tool is expensive for most craftsmen, so it is recommended to take two ways. with a sabre saw (metal saw) or an angle grinder with cutting discs. Being aware of how to quickly saw the rail, the user can quickly achieve the desired result.

For disposal of worn-out sections of rail track, long scrap rail, pre-sectioning of long steel bars and other massive long meters (which can not be placed in the working area of the alligator shears) use cold-breaking machines. For them, the question of how to break the rail is not technologically difficult.

What way to choose

To make a decision, it is necessary to consider a number of factors. Among them. the cost of the work (finances and time), noise, duration of the process, the need for outside help. From a safety standpoint, cutting with a saber saw looks attractive. In terms of speed. angle grinder or rail cutter.

The latter tool is expensive for most craftsmen, so it is recommended to adopt two ways. with a saber saw (metal saw) or an angle grinder with cutting discs. Being aware of how to quickly saw the rail, the user can quickly achieve the desired result.

Railroad maintenance involves cutting out worn rail sections with special equipment. In this material we will talk about how to saw the rail at home (or garage) conditions, what tools are more effective, how to act in each case and what the advantages of one or another method.

Possible ways of cutting rails

Despite the apparent complexity of the operation, to divide the metal element into small sections is not difficult. To do this, you can use one of the following tools:

Each method is complicated in its own way, but the expected result (cut into parts of the rail) will be obtained. Now for more details about each technique.

Cutting with a Sewing Needle

The method was popular in the last century, when there were no more convenient devices for cutting metal rails. In this case the workpiece is not sawn, but broken.

- the rail is placed by its edges on two supports with the base downwards;

- a thick sewing needle is placed at the intended breaking point perpendicular to the product;

- With the sledgehammer a strong and precise blow is made at the point where the needle touches the rail, cutting it in half.

- experience is needed. it is not easy to hit the right place precisely;

- the line for the trimmer of the chop (cut) sometimes turns out crooked;

- it is necessary to make only one precise blow; in case of several unsuccessful attempts, the integrity of the blade will be damaged.

Using a chisel

Here, too, the metal workpiece is divided not by cutting, but by punching.

- install the rail as in the paragraph above;

- all around the perimeter with a chisel and a hammer (mallet) make notches of a small depth (1-2 mm);

- the place of the notches a blow is made with a sledgehammer, the rail is split.

Advantages and disadvantages of the method repeat the above mentioned, but it takes a little more time.

Cutting the rail with a hacksaw

A popular way, though energy-consuming. It is important to know a few requirements for the saw blade:

- the handle is comfortable, located vertically, not horizontally, with a slight tilt to the side of the stroke “from me”;

- On the teeth of the blade there is a dusting;

- the teeth are in the direction “from yourself”;

- when working, move the blade so that the area of contact of the teeth with the cutting surface is maximum;

- choose the blade according to the density and hardness of the rail material.

How to cut the rail with a hacksaw? The sequence is as follows:

- lay the rail on a horizontal surface;

- If a precise cut is required, it is worth using a chisel to make notches on the base;

- Saw through the base on both sides to the neck of the rail;

- put a stop under the place of the notch;

- make a point blow with a sledgehammer.

There are other ways to divide a notched rail into two parts. For example, to drop it from a height, if there is a manipulator-lift handy.

Use of angle grinder

Professional tool will save time for sawing the rail. Experienced people say that two discs with a diameter of 150 mm is enough to saw a classic railroad rail (P65, P75).

The work is carried out similarly. the base is sawed on both sides, then followed by a blow with a sledgehammer. The operation takes 5-10 minutes.

- traumatic hazards (disc can “bite” and lead to a breakage, flying sparks get in the eyes, etc.).д.);

- working noise;

- high pointless);

- the method is bad for home conditions because of the formation of dust, dirt, metal chips.

Use of rail cutters

Another method of quickly dividing the rails into fractions, which is not quite suitable for home conditions, but worthy of consideration. Rail cutter. it is a professional equipment used for different types of products. Usually used on railroad tracks to quickly repair the bed to avoid train delays. For example, below we will consider two devices.

Rail Cutter PM5GM

- Cutter is a hacksaw blade with length of 400 or 450 mm, than the equipment reminds a saber saw;

- there is a gripper for fixing the products;

- hydraulic clamping allows to apply maximum force to the point of contact in operating stroke and unloading in idle stroke (back stroke).

Time to cut one P65 rail into two parts. about 11 minutes. The device weighs 90 kg, has the dimensions 1465x505x460 mm, so it is not considered suitable for home conditions.

Cutting machine Husqvarna K 1260 (Partner K-1250 Rail)

- power of almost 6 kW (higher than that of PM5GM);

- Working body. a cutting disc with diameter of 350 or 400 mm (the principle of work. as at the angle grinder);

- weight without additional equipment. 20 kg.

The device is 5 times faster to cut the same P65 than the machine considered above. Compactness, relative lightness, efficiency make it possible to use it for cutting products at home. The only disadvantage of the equipment. high ).

When sawing is required?

Thermal processing makes rails particularly hard. Over time, they can fail. Nevertheless, the used rails continue to retain their useful qualities and are of value on the construction market: they are successfully used as beams, supports and floor slabs.

For example, a private home is being built where rails with a standard length of 12.5 m are selected for beams. In a room, a rail from an adjoining room projects more than one metre out of the wall. Because of the difference in the floor level of the two rooms, the projecting rail must be shortened. The challenge is to trim it, ideally flush with the wall.

It is not uncommon to find such long objects in a garden plot, which have never been used in the household before. Often the owners in the process of remodeling or landscaping are faced with the need to dismantle the rail. The question arises as to how to cut the rail at home. What is the best and most effective tool to use?

possible ways to cut rails with your own hands

There are many options for solving the problem. from, it would seem, quite mystical grandfather’s and at the same time inexpensive, to the most modern, using specialized equipment, but financially expensive. Here will go to use such improvised means, devices and tools, such as:

If we remember the high strength of rolled steel, the operation of dividing the longitudinal piece into fragments seems incredibly difficult. However, using any of the listed devices, you can prove the opposite.

Possible ways to cut the rail

Despite the apparent complexity of the operation, to divide the metal element into small sections is not difficult. To do this, you can use one of the following devices:

Each method is difficult on its own, but the expected result (cut to size) will be obtained. Now. details of each technique.

Sewing needles

- the rail is ribbed on two supports with the base downward;

- a thick sewing needle, perpendicular to the product, is placed at the specified breaking point;

- the sledgehammer makes a strong and precise blow to the point where the needle fits, causing the rail to cut in half.

- experience is needed. accurately hit the right spot;

- the hair growth trimmer line (slice) sometimes gets bent;

- you only need to make one accurate shot; after several unsuccessful attempts the integrity of the canvas will be compromised.

Chisel to use

- place the rail as indicated above;

- the perimeter is notched with a chisel and hammer (hammer) to a shallow depth (1-2 mm);

- the sledgehammer strikes the slot, the rail is broken.

Advantages and disadvantages of the methodology repeated above, it will take a little more time.

Cutting rail blades

- the handle is comfortable, not horizontal, but vertical, tilted slightly toward the “distance”;

- There is a spray on the nail of the canvas;

- The teeth are spaced “apart.”

- during operation, move the blade so that the contact area of the tooth with the cutting surface is as large as possible;

- choose a blade according to the density and hardness of the rail material.

How to cut the rail with a hacksaw? Consistency:

- lay the rail on a horizontal surface;

- if you need a precise cut, use a chisel to make notches in the base;

- through the base on both sides to the rail neck;

- put a stop;

- Perform a sledgehammer blow.

There are other ways to divide the rail into two parts. For example, lower it from a height, if there is a forklift with a loader at hand.

Using a grinder

The work is done in a similar manner. The base is fed from both sides, followed by a blow with a hammer. The operation will take 5-10 minutes.

- risk of injury (disc can “bite” and cause injury, sparks from flying sparks can enter your eyes, etc). д.);

- noise at work;

- high senseless);

- The method is harmful to the home due to the formation of dust, dirt, metal chips.

RM5GM rail machine

- Blade blade of 400 or 450 mm acts like a cutter than piston dust-like equipment;

- there is a hobby for fixing the products;

- The presence of hydraulic pressure allows you to apply maximum force to the point of contact in motion and unload at idle (backward).

Time to cut one P65 rail into 2 pieces is about 11 minutes. The device weighs 90 kg and has dimensions of 1465x4505x460 mm, so it is not considered suitable for home use.

Husqvarna Grid K 1260 (Rail K-1250 Rail)

- Output power of about 6 kW (above RM5GM;)

- working body. cutting disc diameter of 350 or 400 mm (the principle of operation is the same as for the grinder);

- Weight without accessories. 20 kg.

The unit cuts the same P65 5 times faster than the machine discussed earlier. Compactness, relative lightness, and economy allow it to be used for slicing products at home. The only disadvantage of the equipment is its high ).

Possible ways to cut the rail

Despite the apparent complexity of the operation, it is not difficult to divide the metal element into small sections. You can use one of the following devices to do this:

Each method is difficult on its own, but the expected result (cut in half) will be obtained. Now. more about each technique.

Sewing Needles

- the rail is provided with ribs on two supports with the base downward;

- A thick sewing needle perpendicular to the product is placed at a given breaking point;

- A sledgehammer makes a strong and precise blow to the point where the needle fits, causing the rail to cut in half.

- experience is necessary. definitely didn’t hit the right spot;

- hair growth trimmer line (slice) is sometimes obtained curved;

- you only need to make one precise shot; after several unsuccessful attempts, the integrity of the canvas will be compromised.

Chisel to use

- set the rail as indicated above;

- on the perimeter with a chisel and hammer (hammer) are made notches of shallow depth (1-2 mm);

- sledgehammer strikes the slot, the rail is broken.

Advantages and disadvantages of the methodology repeated above, it will take a little more time.

Cutting rail blades

- the handle is comfortable, not horizontal, but vertical, tilted slightly towards the “distance

- there is spray on the nail of the canvas;

- the teeth are positioned at “distance”;

- during operation, move the blade so that the contact area of the tooth with the cutting surface is as large as possible;

- choose a blade depending on the density and hardness of the rail material.

How to cut rail with a hacksaw? Sequence:

- lay the rail on a horizontal surface;

- if you need a precise cut, use a chisel to make notches in the base;

- through the base on both sides to the rail neck;

- put a stop to it;

- Make a blow with a sledgehammer.

There are other ways to split the rail into two pieces. For example, lower it from a height, if there is a forklift with a loader at hand.

Using a grinder

The work is carried out in a similar way. the base is fed from both sides, followed by a blow with a hammer. The operation takes 5-10 minutes.

- risk of injury (the disc can “bite” and cause injury, sparks from flying sparks can enter the eyes, etc. д.);

- Noise at work;

- high pointless);

- The method is harmful to the house because of the formation of dust, dirt, metal shavings.

RM5GM rail machine

- Blade blade with a length of 400 or 450 mm acts as a cutter than the equipment resembling piston dust;

- have a hobby for fixing products;

- The presence of hydraulic pressure allows you to apply maximum force to the point of contact in motion and unload at idle (backward).

The time required to cut a single P65 rail into two pieces is approximately 11 minutes. The device weighs 90 kg and has dimensions of 1465x4505x460 mm, so it is not considered suitable for home use.

Grid Husqvarna K 1260 (Rail K-1250 Rail)

- output power of about 6 kW (above RM5GM);

- operating unit. cutting disc with a diameter of 350 or 400 mm (the principle of operation is the same as for the grinder);

- Weight without additional equipment. 20 kg.

The device cuts the same P65 up to 5 times faster than the previously mentioned machine. Compactness, relative lightness, cost-effectiveness allow it to be used for slicing products at home. The only disadvantage of the equipment is its high ).

Which way to choose

A number of factors must be considered in order to make a decision. Among them. costs of work (money and time), noise, duration of the process, the need for outside help. From a safety standpoint, cutting with a sabre saw looks attractive. In terms of speed. angle grinder or rail cutter.

The latter tool is expensive for most craftsmen, so it is recommended to take two ways. with a sabre saw (metal hacksaw) or an angle grinder with cutting discs. Knowing how to saw a rail quickly, the user will be able to quickly achieve the desired result.

Found possible duplicates

put it to your throat and breathe in your ear, any hide anywhere in your town is yours

I made a knife with this blade, great steel and the sharpening lasts a long time. But I’d rather not use it as a throwing knife. the steel is really quite fragile.

Yeah, no need to throw it against the wall) ohh how I liked this iron kolhoztuning into a long knife, that I’m already completing a kitchen tool, a kitchen tool single sided and about to start folding

I’m the only one who knows that a freshing knife should have a blunt tip so it doesn’t burrow into the meat?

The skin is trimmed from the inside, on the meat side, so as not to cut the hair. And with this shape of the blade will burrow into the meat.

Dear Sir, you see. such knives are made either with a sufficiently large angle at the tip, or with a sufficiently sharp one, but, to compensate for this, they scrape this very tip higher than on ordinary knives. Then you get a rk longer than the standard and a normal convexity. If you don’t need to pierce the skin, you’ll never pierce it

Conditions for Cutting Rails

For such work on dismantling and repair work of rail constructions allowed experts who have received prior training, have the necessary professional knowledge and skills. At application of the equipment at which there is a sawing of rails, it is necessary to apply requirements on safety of work with tools, accurate handling with it.

If an electric cutting tool is used, then it is necessary to have the appropriate training and authorization to work with this equipment. Masters working with this type of electric tool have electrical safety group more than II.

If the work will be carried out on the rail-cutting or rail-drilling machines, then the master must know perfectly their device, the principle of operation, to be able to change the modes of cutting, comply with safety rules for carrying out these works.

How is the cutting of rails

Nowadays a lot of techniques are known for rail sawing which include both tried and tested methods and innovative methods with application of modern equipment. They differ from each other in the level of safety, the accuracy of the cut, labor costs, how to connect additional tools, other.

In order to choose the best option, you need to objectively assess the tasks and choose the right options for their solution. After that, it is necessary to take into account the necessary safety requirements for such actions.

Conditions for rail cutting

For such work on the dismantling and repair work of rail structures allowed to specialists who have received prior training, have the necessary professional knowledge and skills. When using equipment in which the cutting of rails takes place, it is necessary to apply the safety requirements for working with tools, careful handling.

If power tools are used for cutting, then appropriate training and an authorization to work with this equipment must be passed. Masters working with this type of electric tool have an electrical safety group more than II.

If the work will be carried out on the rail-cutting or rail-drilling machines, then the master must know perfectly their device, the principle of operation, to be able to change the modes of cutting, to comply with safety rules for carrying out these works.