How the cutter to cut a circle of small diameter

As I wrote earlier, the hand router has the widest range of abilities. Now consider carefully one of these necessary abilities. cutting circles. Quite often in the manufacture of furniture, well, and just for domestic purposes, there is a need to produce a full circle (for example, for the lid of the table) or part of the circle (for example, an arch or other decorative elements of furniture). This can simply be done with only 1 hand router.

To make a circle we need: a workpiece for the circle of suitable size, a cutter for a straight groove and a parallel stop for the cutter (usually comes with the cutter itself). The workpiece for the circumference can be made of plywood or board. It is better to have the cutter’s working area not less than the thickness of the workpiece.

Place the workpiece on the workbench: put under it a scrap of plywood, for example, so as not to cut the desktop. The workpiece itself secure with screws: clamps will prevent the movement of the cutter with small-sized workpieces. Let’s put the milling machine in a parallel stop, which we fix in the center of the future circle with a screw, so the whole structure can rotate around the central point.

Using the parallel stop we secure a suitable radius of the circle and start turning the cutter around. With every revolution of the router we lower it by several mm. Depending on the thickness of the workpiece, after a certain number of circles our circle is ready.

In this case I milled a tabletop for a small table with a cross section of about 400mm. The workpiece is a board, glued from a board 30mm. As you can see in the photo. from the screw in the center of the workpiece remains a hole. not a failure, it can be putty or just make this side the underside of the table top.

Another example. making not the whole circle, but only a part. In this case it is necessary to strengthen the workpiece and the milling machine separately, but the principle is exactly the same.

I am sure that this method of production circles for you need!

Thank you for your kind attention! Fortune in the craft to all!

Read new posts before everyone else. subscribe to the channel in Telegram!

Communicate and ask questions to the creator of the blog !

Plywood (and to a lesser extent other sheet materials, such as particleboard or oriented chipboard) has significant decorative potential. In the presence of a fairly common tool and certain abilities to cut out of plywood can actually do anything. But that acquired as a result of such a carving parts look pretty representative, the master should have in stock a few tricks. Specifically about them, and we’ll talk in our article. Crooked sawing is difficult only at first glance

Circular and elliptical milling cutters

It is better to have a two-bar circular cutter.

Generally speaking, circular saws are a very common tool. There are a huge number of proprietary and homemade devices for milling circles, varying in size and ease of use. Circulators usually have a mechanism for changing the radius of the circle. It is usually made in the form of a screw with a pin on the end, moving along the groove of the device. A pin is inserted into the center hole of the workpiece.

When it is necessary to mill a circle of small cross-section, the pin must be under the router base, and for such cases, use other devices attached to the bottom of the router base.

Circular motion of the cutter is quite easy to achieve with a compass. But often we are faced with the need to perform elliptical contours. when cutting in mirrors or glass rounded shape, the device windows or doors arch type, etc.п. WEGOMA (Germany) device PE60 is created for milling of ellipses and circles.

Circle Cutting Jig for a Trim Router. Cutting Circles in Wood

It is a base in the form of a plate fixed to the surface by vacuum suction cups 1 or by screws if the surface does not allow fixing by suction cups. Two shoes 2, sliding on intersecting slideways, provide elliptical movement of the milling cutter. When milling a circle only one shoe is used. Fixture set includes two mounting rods and bracket 3, by means of which the connection of the cutter with the platen is made. Grooves on bracket allow installing the cutter in such a way, that its bearing surface and the base plate are in the same plane.

As can be seen from the photo above, the cutter was used instead of a jigsaw or bandsaw, and, thanks to the high rotational speed of the cutter, the quality of the machined surface comes out even higher. Also, in the absence of a manual circular saw, the cutter can replace it as well.

Selecting the tool

When starting to work with sheet materials, many masters only have an idea of how to make a straight saw. Therefore, the question of how to cut a smooth circle out of plywood, many may be stumped. And indeed, an ordinary or circular saw with the task can not cope. Figured sawing in most cases is done with these tools: Manual jigsaw

- Hand-operated jigsaw. The most common tool used for sawing. With a jigsaw, even the narrowest work can be done with their own hands, but here for thick material or longish kerfing it is actually not suitable.

- Electric jigsaws. Two varieties of devices can be used here:

- Plain, with a vertically arranged saw;

- Art, in which the role of the cutting element makes the iron blade.

Ordinary electric jigsaws for you will need when working with a thick board, for example, in the manufacture of their own hands made beds. But if you are looking for a method how to cut letters from plywood or make other complex elements (for example, parts of a child’s construction set), then it is ideal to use a model with a band saw. Design for artistic sawing

Tip! Naturally, there are several varieties of saws and blades for each type of jigsaw. The right choice of cutting element is a prerequisite for high quality workmanship.

- Not counting jigsaws for curved cuts, you can use a furniture router. Despite all the difficulty in operation, it is many times superior to most models of saws for plywood in terms of the quality of the holes made. With the help of a router, you can make a wonderful rocking chair out of plywood sheets with your own hands.

Tips for cutting

Selecting the tool

Beginning to work with sheet materials, many craftsmen only have an idea of how to perform a straight line sawing. Therefore, the question of how to cut a straight circle of plywood, many may be stumped. And indeed, an ordinary or circular saw is not enough to cope with the task. Shape sawing is most often done with these tools: Hand jigsaw

- Hand jigsaws. The simplest tool used for sawing. Even the thinnest work can be done with the jigsaw, but for thick material or long cuts it is practically useless.

- Jigsaws. Here you can use two varieties of devices:

- A standard jigsaw with a vertically arranged saw blade;

- Artistic, in which the role of the cutting element is performed by a steel blade.

Ordinary electric jigsaws you will be useful when working with thick plywood, for example, when making a bed with your own hands. But if you are looking for a way to cut letters out of plywood or to make other complex elements (for example, parts of a child’s construction set), it is best to use a model with a band saw. Model for artistic sawing

Tip! Naturally, there are several varieties of saws and blades for each type of jigsaw. The right choice of cutting element is a prerequisite for high quality products.

- In addition to jigsaws for curvilinear cutting, you can use a furniture router. Despite all the difficulty in operation, it is many times superior to most plywood saw models in terms of the quality of the holes made. With the help of a router you can make a wonderful rocking chair out of plywood sheets with your own hands.

Also do not forget about improvised devices, but about their use, we will talk in the appropriate section.

Tips for cutting plywood

Cutting from plywood has several nuances that the craftsman needs to take into account:

- Firstly, you can only saw on dry material. High humidity increases the resistance of plywood, so excessive force either causes delamination of the veneer or breaks the saw.

- You should change your saw or cutter blade as soon as you see the first signs of bluntness.

- If we cut plywood with a jigsaw, we want the main cutting lines to be aligned with the grain of the veneer in order to get cleaner edges. But it is easier to work across fibers with a hand saw: there will be few chips, but there is less risk of jamming the saw or its deviation from the planned line.

A file for rough work: the edges of the workpiece will need to be filed

Advice! When transferring patterns for veneer-cutting to the workpiece, try to place the template in such a way that the elements to be removed are in areas with defects: knots, chips, stains, etc.д.

Shape cutting technology

Jigsaw

As we noted above, the jigsaw will come in handy if we are looking for how to cut a word out of plywood or make other details of complex shapes:

Figured carving with a jigsaw: photo of the finished product

- If the design has through sections. we make a thin drill start holes.

- Insert saw or jigsaw blade into the hole. Secure free saw end with fixing screw or clamp.

- Make a kerf along the planned line, pressing the workpiece to the workbench. The saw moves either automatically (with electric shape jigsaws) or manually.

After all circular elements are sawn through, remove unnecessary parts and finish the ready piece with a file or emery board. Ready hole

Cutter

A furniture router is great for sawing out thick plywood. Of course, it is not possible to make a complex shape with his help, but to cut an arc or a circle. easily:

- Regular ruler, which is part of the router, we fix in the center of the circle with a self-tapping screw.

- If the ruler is not long enough, you can assemble a simple bracket from a metal profile or wooden slats.

- Rotating the cutter at a fixed radius, select the groove around the circumference, resulting in a nearly perfect hole.

A router arm: it can be used to cut a disc of almost any diameter

Please note! When calculating the diameter of the circle, you must take into account the dimensions of the working cutter. Your device manual will tell you the exact numbers.

Not only can circles be cut this way, but also individual arcs. to create grooves for furniture brackets, for example.

By any means necessary

For shaped elements it is desirable to have special devices, but to make a round hole in a board of glued veneer can be necessary to any craftsman. Here’s how to cut a circle out of plywood if you have nothing handy. Well, almost nothing:

- For cutting from plywood a wooden bar with two nails is used.

- One nail is driven through the bar into the workpiece, exactly into the center of the hole to be made.

- We hammer the second nail into the slat so that the edge protrudes at least 5-10 mm on the underside. The distance from the first nail must be the same as the hole radius.

- Turning the slat, we draw a furrow on plywood with the spike, deepening it with each turn.

- Instead of the stick, you can use a strong cord. The working principle remains the same.

The sharper the nail, the faster the hole will be made. It should be noted that, though the price of such a device is low, it should be used only when other methods are not available: the edges are still far from ideal.

A special router

A milling machine with a loudspeaker usually already comes with nozzles for cutting circles. It is quite convenient, but not always the diameter of the nozzles corresponds to the required diameter of the future circle. So it makes sense to make a little extra work on the router with your own hands.

The improvement is made by making simple overlays. For this, you need to prepare Fiberboard and laminate. These materials will serve as spacers, which will hold the screw that adjusts the diameter. Make markings on the materials with the desired diameter and cut them out with a jigsaw or ordinary knife. Make sure the templates are perfectly aligned.

Now you need to mount these pads to the router. First remove the protective cover, then put on a circle made of fiberboard, which is fixed with countersunk head screws. They fit rather easily flush. On top of this is attached a layer of laminate, which is also fixed with screws, but already smaller. Make sure their heads do not protrude.

During the work, you need to take into account one important point. As a rule, any router has its own size. Therefore, it is by no means allowed that the edges of the future hole, marked on the slots and fitted with screws, do not coincide with the cutting edge of the milling machine. The center of the circle and the mounting center screw should perfectly match, the edge with the edges of the circle should also be at the same level.

It is very important to be able to correctly match the distance between the center of the cutter and the center of the set screw. So, if you are going to cut a hole, this distance should be slightly less (about the thickness of the cutter edges). And if you need the circle itself, not the hole, it’s best to take a little extra distance.

So, method one is covered. It’s not that difficult to do, if you’re careful and have some carpentry skills. But still experts say that the work with standard circles, which are in the appropriate attachments of the router, is simplified several times.

Shape-cutting techniques

Jigsaw

As we noted above, the jigsaw will come in handy if we are looking for how to cut a word out of plywood or make other parts of complex shapes:

Jigsaw shape carving: photo of the finished product

- If the construction has through areas. make start holes with a thin drill.

- Insert a saw or jigsaw blade into the hole. Secure the free end of the saw with a fixing screw or clamp.

- We make a cut along the planned line, pressing the workpiece to the workbench. The saw moves either automatically (with electric shape jigsaws) or manually.

After all the arc elements are sawn through, we remove unnecessary areas and process the finished piece with a file or emery cloth. The finished hole

Cutter

The furniture router is ideal for cutting out thick plywood. Of course, you can’t make a complex shape with it, but you can cut an arc or a circle with it:

- Secure the standard ruler included in the router to the center of the circle with a self-tapping screw.

- If the length of the ruler is not enough, you can assemble a simple bracket from a metal profile or wooden slats.

- Rotating the cutter along a fixed radius, the groove is picked out along the circumference, resulting in a nearly perfect hole.

router arm: you can use it to cut almost any diameter disc

Please note! When calculating the diameter of the circle, the dimensions of the working cutter should be taken into account. Instructions for the machine will tell you the exact figures.

Not only circles but also individual arcs can be cut in this way. for example to make grooves for furniture brackets.

Using improvised means

For shaped elements it is desirable to have special devices, but to make a round hole in a board of glued veneer can be necessary to any craftsman. Below we will tell you how to cut a circle out of plywood when you don’t have anything handy. Well, almost anything:

- Plywood cutting uses a wooden block with two nails.

- One nail is hammered through the bar into the workpiece, exactly into the center of the hole being made.

- We hammer the second nail into the slat so that the edge protrudes on the underside by at least 5-10 mm. The distance from the first nail must be equal to the radius of the hole to be made.

- Rotating the slat, we draw a furrow in the plywood with the nail point, deepening it with each turn.

- Instead of the stick, you can use a strong cord. The working principle remains the same.

The sharper the nail, the faster the hole will be made. It should be noted that, although the price of such a device is low, it is worth using it only when other methods are not available: the edges are still far from ideal.

We hope that thanks to the above information the question of how to cut a figure out of plywood will not cause you difficulties. Of course, figurative carving on sheet material requires a certain skill and accuracy, but with the right tools, even a beginner should not have any special difficulties. In the video presented in this article you will find more information on this topic (also learn how to make a box of plywood with your own hands).

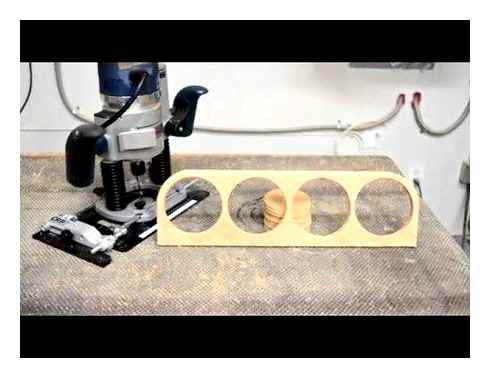

Cutting round shapes out of wood, plywood or chipboard used to be a problematic job. I bought a Bosch Pof 1200 AE. Of course, you can do a lot with this machine, but for now I’ll focus on circles, namely, on cutting a hole for the speaker.

I got the idea for my work from this article. It tells in a very clear way how to make a sampling on the loudspeaker. Basically everything is the same, but I made some changes and a little bit about these changes.

There is a device in my router to cut circles, but it is only good for diameters from 21 cm, but in the case of the speakers there are 5 cm instances. So I made a special overlay for a quick hand. It consists of two parts: 1. base part made of laminate; 2. spacer to hold the screw, which sets the radius of the circle, it is made of fiberboard. The overlay is cut out with the expectation of a diameter of up to 23 cm.

The main part is screwed to the router with the layer and the standard cover removed beforehand. Countersunk head screws, flush, of course. The screw, which is used to set the radius, I also chose a countersunk screw and also set it flush. The bottom of the cutter without a pad has a ribbed surface and for this purpose, so that the screw that marks our screw does not fall out, I put a layer of fiberboard.

Now we would like to stop on a surface marking for a cutting circle. The proverb “Measure twice, cut once” is very useful here. The point is that to expose the cutter (now I mean the cutting element, not the machine itself) you have to not align it to the center of the circles you have marked out.

The picture above shows how to cut it. For example you have to cut a round hole (under the speaker) with diameter 100 mm and radius 50 mm. The center (our screw), around it will rotate the cutting head, so the center of the future hole coincides with the center of the screw and it does not need to move anywhere, t.е. Whatever its thickness, we do not take this value into account. But the cutter head, in my case has a diameter of 8 mm, and if you set it on the marking line, we end up with a hole larger than we need, namely: cutter 8/2=4 mm, radius 504=54 mm, diameter 5454=108 mm. To avoid this, I set the calculated distance taking into account the diameter of the cutter: cutter 8/2=4 mm, radius 50-4=46 mm. The distance between the center of the set screw and the center of the cutter will be 46 mm. So I end up with a diameter of 100 mm. 4646=92, 928mm cutter = 100mm. If you need to cut a desired circle rather than a hole, the scheme is the same, only the opposite should be calculated with a reserve.

3 Комментарии и мнения владельцев: Circle or circle cutting with a router

A metal hacksaw is well suited for making holes in wood. Its interchangeable blades make it possible to work with almost any material. However, note that the depth of cut is limited by the arc of the jigsaw, so cutting a circle further than 40 cm from the edge of the workpiece becomes virtually impossible. When sawing, drive the blade as carefully as possible to prevent it from tilting. Otherwise the blade will be damaged.

It is often necessary to mill a circular recess for the speaker flange and/or grill. This should be done after marking the center, but before you cut the circular hole. If the hole is shaped, you need to use interchangeable shaped soles and overhead templates. Also it is convenient to mold the ports of the bassinverter with milling cutters: outside rounding with a jointer cutter (semistap), inside on half of the facade thickness there is a step with depth of the wall thickness of the port with a trimming cutter with a bearing (the depth of the cutting is selected by changing the bearing).

Observations from my practice. Small diameter circles up to 120 mm inclusive should be sawed with a crown. If you have an inexpensive set of heavy-duty bits, you can easily make your own AC. Or restore the acoustics of the USSR while bringing it into the 21st century by introducing new ports under the banana.

And if sawing holes for the MF and HF with a drill is not a problem, the LF must be sawed with a mill or a jigsaw. The drill has “indisputable” advantage comparing to a jigsaw and crowns, it can saw recesses for flanges of speakers so the speaker sank into the faceplate. Neither the jigsaw nor the crown is capable of this in principle.

The advantage of the crown is the accuracy of the circle to perfection, even a beginner will make a new panel for 15AC with 10 and 25 speaker drums.

The jigsaw is an outsider as far as accuracy and is not capable to saw circles less than 50mm in diameter (FI/terminal), the saw blade “walks” in the material so that the circle on the back side may differ in diameter from the front one, a lame result is guaranteed.

But they have a fourth competitor “three-legged ballerunner” it dances a fouetté up to 250mm (35/50/75hdn) with an ideal trajectory. Who was born in the USSR knows “this dancer” by sight. The only problem is its rarity and difficulty to use.

How to draw ellipses

The ellipse is quite a complex shape, but to draw it on paper, you only need two buttons, a piece of string and a sharpened pencil.

Fix two buttons on the surface of the workpiece at some distance from each other. Take a piece of rope, tie both ends with a knot and hook the rope to the heads of the buttons. Now use a pencil to guide the line for the trimmer, which the stretched rope allows you to describe. You can change the shape of the ellipse as you like.

The distance between the two focal points of the ellipse is indicated by the buttons. If you guide the pencil within the limits given to it by the rope, the outline of an ellipse will appear on the paper.

The shape of the ellipse may be larger or smaller, thicker or narrower, depending on the distance between the buttons and the length of the rope.

How to cut perfect circles with a Jasper Circle Guides router

Almost every joiner encounters a project in which he or she needs to cut a perfect circle. Whether you’re building a special speaker cabinet for your car or home or building a round table, having the right tools to cut the circles can make a big difference.

You can draw a circle with a jigsaw, then use the template and flush cutter on the router to clear it. Or you can use the fixture on a band saw to cut a circle.They all work to some degree, but are not as easy to use or as accurate as the hand router and Jasper Circle Guide.

Designed with details that make it easy to mill perfectly straight circular cutouts. The smaller Jasper Model 200 Circle guide makes 256 different size cutouts from 2 1/4″ to 18″ diameter in 1/16″ increments. It is designed for use with 1/4 inch diameter. router bit.

The larger Jasper Model 300 machine makes 184 different circular discs ranging in diameter from 7 to 52 3/4 inches in 1/4-inch increments. It uses a 1/2-inch diameter cutter. You can use other sizes of cutters, but you have to do some math to be able to set the fixture to the right radius before you cut a circle. As with the Model 200, if you want to make a round cut instead of a disc, you need to consider the diameter of the drill.

Setting

The Jasper circular guides replace the base plate on most routers (we recommend using a plunge router). Mounting screws appropriate for your router are included. The process for installing and centering the ring guide is the same for the 200 and 300 models.

The equipment comes with a 1/4-inch diameter alignment pin that is used to make sure the fixture is centered on the mill. So the first step is to install the alignment pin in the 1/4″ collet on the milling machine

Each circular guide includes a 1/4″ diameter centering disc that is pressed into the larger center hole of the circular guide. After removing the base plate from the router, align the mounting holes on the circular guide with those on your router before loosely installing the appropriate screws.

Now plunge the router so that the centering pin goes through the hole in the centering disc. Tighten the mounting screws to attach the circular guide to the router.

If you’re using a Model 200 Circle Guide, replace the alignment pin with a 1/4-inch diameter cutter. /2″-diameter. router bit. While you do this, remove the alignment disc from the circular guide. Just remember to reinstall the disk when you save the Circle Guide.

Understanding the circular guide weights

The key to cutting precise circles and notches is in the scales printed on the circle guides. They may seem a little confusing at first, but once you take a few minutes to understand how they work, using the scales will become your second nature.

But before I go into detail, I should mention one thing. The 200 Circle Guide was primarily designed for use by auto sound professionals who build custom speaker cabinets.Thus, the pivot hole readings on the scale refer to the diameters of the cutouts, not the size of the disc. You can use the Model 200 to make circular disks for small countertops, for example, but you will need to consider the diameter of the cutter (more on that later).

The Model 200 circular guide scale is designed to cut holes of a given diameter. (Click to enlarge the image.) To cut discs, the arbor hole value is equal to the desired disc diameter plus twice the drill diameter (1/2 inch if using a 1/4 inch diameter).router bit).

The first and most obvious thing to know is the diameter of the notch you want to make. Let’s use the 8-15/16 inch diameter circle example printed on the Model 200 guide above. You look at the bottom of the printed scale to see an integer number of inches, which in our case is 8 inches. Then you follow the curved grid line over that number until you reach the fractional part marked on the left side of the circle guide, or 15/16 inches in our case. The point where the two lines intersect is the center of the circle, and the pivot point will be located the pin.It’s that simple!

The process I just described creates a round cut or hole with the diameter selected for the pivot hole value. If you want to create a disc of a particular diameter, you need to use quite a bit of arithmetic. All you have to do is add twice the diameter of the drill bit from the desired hole size. This tells you where to find the center pin on the pivot hole scale.

In our example, instead of a cutout, we want to create an 8-15/16 inch diameter disc, and we are using a 1/4 inch.router bit. The double diameter of the cutter is 1/2 inch. Just add 1/2 inch to 8-15/16 inches to get 9-7/16 inches. You must place the center pin in place for 9-7/16″ to create an 8-15/16″ diameter disc.

How to mill the holes for the furniture hinges

Applied hinges are located at a certain distance from the edge of the panel. When using a hand router to cut a blind hole for a cup, it is more convenient to use a fixture (template) with a thrust ledge that facilitates positioning on the furniture board.

Drawing of a template for mortising a furniture hinge.

The template is designed for the insertion of a standard hinge with a cup of 35 mm in diameter. For products with other fitting dimensions, calculate hole diameter and position stop according to the distance from the middle of the hinge to the edge of the panel.

Cut out pieces of the fixture from plywood and secure the bar with glue and small nails.

To punch the hole, secure the template to the furniture board by resting the bottom bar against the end. Set the milling depth on the tool to 11.5 mm and cut a recess in a few passes.

Similarly easy to calculate and prepare templates for other holes. The minimum size of the recess to be cut out according to the considered technology is limited by the caliber of the copying ring, and the maximum. by the size of the router base.

Articles :

Discuss how to work with a dust-free peorator. Also: disadvantages when using a vacuum cleaner, how to avoid dust when drilling a wall and drilling the ceiling.

The article examines the process of making simple holders, stands and shelves for hand tools in the home workshop.

Router Circle Cutting Jig

Examines options for homemade side stops for a carpenter’s workbench. A drawing is presented and the order of making one of the.

Master class for replacing a failed nickel cadmium battery in an electric screwdriver with a modern lithium polymer battery.

Step-by-step instructions with photos show how to make a simple tapping screw with your own hands.