Cutting instruction

If you follow the instructions in everything, your foam rubber will be cut perfectly. So let’s go:

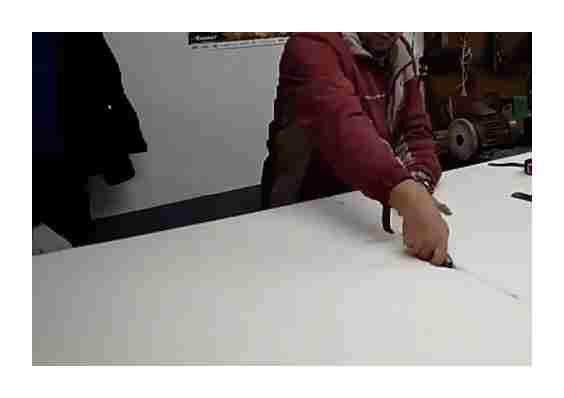

- Since we decided to cut the foam rubber on a lining, and not on linoleum or parquet, the first thing we do is lay it. Plywood first, then a sheet of cardboard.

- On top we lay a layer of foam rubber that we want to cut. We make sure that the line of the future cut falls on the lining.

- We take a ruler and, in accordance with the given dimensions, draw a line along which the future cut will pass.

- We remove the ruler. If we cut along a ruler and press down on it at the same time, then the cut will turn out to be even, but the edge will be the same depressed as in the case of the scissors. If you decide to cut along a ruler, then in no case press on it.

Good advice on how to cut the foam so that the edge is perfect. If you feel that the knife has begun to make peculiar hooks during the wiring, it means that in some place the blade has become dull and, without cutting through, begins to tear the foam rubber, forming a strip of foam burrs. In this case, replace the blade with a new one immediately. It is best to do this without waiting for this to happen. We made five or six wires, changed the blade. They can then be used again for any other purpose, but they will no longer be suitable for cutting foam rubber. A simple cutting of foam rubber with a knife is clearly shown in this video.

What’s the problem with scissors?

The problem is that when cutting with scissors, the structure of the foam rubber along the edges of the cut is broken. The edges are depressed and no longer straighten to their original position. So scissors for even cutting will not work either.

Bad tips for thin wire

It is better not to listen to these advice. Even if the cutting of foam rubber takes place on the street, you risk breathing in the most dangerous toxins so that you will ruin your health at once. The thing is that foam rubber is not ordinary plastic. To give it a foamy structure, various kinds of toxic impurities are added to the polymers, which are absolutely not dangerous in the usual solidified state and at room temperature, but instantly turn into the strongest poison upon strong heating.

Yes, in production this material is cut by means of hot nichrome threads. But there people work in protective clothing and respirators, or even stay in a protected operator’s booth with an excellent hood. And since you are going to cut the foam rubber at home, in the absence of such means of protection, you risk poisoning not only yourself, but also your loved ones.

Plus, this method is only suitable for straight cuts. To make a curly one, you still have to take up a knife.

Preparing tools for cutting foam rubber

So, how to cut foam rubber at home so that the edges are as smooth as possible and close to those obtained during production cutting? To do this, you will need to prepare the following tools and consumables:

- Actually, the foam itself, which we are going to cut.

- Lining for foam rubber, which we will cut. It is clear that if we lay it out on linoleum or on the parquet floor of an apartment, these same materials will end, since they will all be scratched by a knife. As a lining, it is best to use a sheet of plywood with cardboard laid on it, so that the tip of the knife does not blunt against the hard plywood. Cardboard can be used by opening any suitable size cardboard box.

- It is desirable to have a knife from the category of construction. They are also called linoleum knives. He comes with a whole clip of removable blades, which can be changed in case of dullness. It is better to use a branded European rather than a Chinese knife, since the steel of the “Chinese” is of low quality, and such a blade will become dull after the very first wiring.

How to cut foam rubber at home: expert advice

Foam rubber is a great thing. Soft, comfortable and harmless. Most often, mattresses and padding for upholstered furniture are made from it. It comes in varying degrees of rigidity and thickness. But regardless of what elasticity and thickness it has, it should only be cut with a knife. How to cut foam rubber with a knife, and why you need to do it only with this tool, you will learn from this article.

about curly cutting

How to cut foam rubber smoothly along curved lines? Here everything is the same as in the case of straight cutting. The only thing is that the angle of inclination of the knife towards you should be increased to the maximum, otherwise the cut out parts will “mow” a little along the edges, as if you were holding the plane of the knife blade non-vertically in relation to the plane of the foam rubber. That’s all. Nothing complicated. The main thing. have patience and a branded knife, and the edges of the cuts you get as a factory.

Cutting process

- Freeing up space, removing all things that might interfere.

- Place the foam sheet. Mark the line of the cut with a ruler and marker.

- We take a knife with a blade of the required length (along the width of the foam rubber) and carefully make an incision on one side.

- We tilt the plane of the blade towards ourselves to get an even cut.

- If the blade clings to the foam, then it is dull. Then it must be changed, otherwise it is possible to spoil the material.

- In the event that you were unable to cut through a thick sheet of foam rubber the first time, don’t worry. Spread the line of the cut with your hands, put the knife down and drag again.

In order to make curly cutting, you should act in exactly the same way. Only increase the angle of inclination of the knife towards you as much as possible so that the mowing line bends are even.

For cutting material such as foam, get everything you need and be patient.

What to look for

Foam rubber is not just a type of plastic, but plastic with the addition of various kinds of chemical impurities, toxic polymers, which impart porosity to this material.

At room temperatures, foam rubber is absolutely harmless to humans, but as soon as the material is heated, it immediately becomes toxic. Therefore, it is impossible to use a heated metal thread or wire for cutting foam rubber at home, as some amateurs advise.

In production, foam rubber sheets are cut this way, but workers must use protective masks, and in the production workshop where this operation takes place, powerful ventilation is installed.

Ordinary household scissors are also not helpers for cutting foam rubber. The edges of the material cut in this way lose their porous structure.

How to cut foam rubber at home

Foam rubber is a modern material that is soft, comfortable, hypoallergenic. It is used as a filler for mattresses, furniture, it is made of different density and thickness.

So, what to cut? Here are the tools you need to cut the foam:

- we use cardboard or plywood for lining to preserve the surface of the table or floor where this operation will be performed;

- construction knife with adjacent blades;

- ruler or template;

- marker for drawing a section.

1 comment: How to cut foam rubber at home

I thought that cutting the foam rubber on my own, at home, would be difficult. But, judging by the description in the article, everything is quite simple. We will try.

Introducing the toolbox

The obligatory list of tools for cutting gypsum fiber with your own hands includes three groups of objects

Devices for applying markings on a sheet of gypsum board. a simple pencil, tape measure, long ruler.

Cutting and sawing devices themselves.

- Knife. You can cut GVLV with a clerical knife, as well as with a specialized construction knife with a double-sided replaceable blade (suitable for denser materials).

- Hacksaw. It is better if it is a tool for processing metal than wood.

- Electric jigsaw. Ideal for cutting rounded elements. Least of all, high-quality saws for metal with a fine notch leave chips at the ends of drywall.

- Electric drill. Needed for making holes. For gaps of large d, round crowns (which cut into the core of the door snap locks) and feather drills are required.

Edging attachments:

- roughing plane;

- chamfering planer.

This list clearly shows how the home craftsmen cut drywall. Of course, it is far from complete. The arsenal of experienced craftsmen may include professional equipment, for example, a special cutter for GVL. However, for those who are working with the material for the first time, this set is quite enough. To better understand how to cut drywall correctly, you need to clearly understand the structure of this material.

The structure and purpose of drywall

Plasterboard sheets are a layer-by-layer combination of two types of materials. gypsum (inner content) and sheets of thick cardboard glued to it on both sides. It is clear that if the cardboard layers are damaged, it is not difficult to cut the rest.

Therefore, in order to be able to quickly cut a sheet of gypsum board, it is not enough to know the best way to cut drywall. It is important to know the basic principle of this action: after the continuous even cutting of drywall is carried out, the second step immediately follows. breaking the sheet.

Sawing drywall, like any solid porous material, is not difficult. It also lends itself well to drilling.

The functions of the material make it possible to differentiate it into varieties: moisture-resistant, fire-resistant, standard, increased strength (for example, gypsum board or gypsum board made using Knauf technology), acoustic gypsum board, etc.

Despite the large assortment of GK, panels of any of its varieties lend themselves well to dividing into parts by means of the available material at hand.

Standard cut

Cutting the sheet in a straight line is the easiest way to cut. It boils down to the following:

GVL is placed on a hard and flat surface. Then mark the future cutting line of the cut.

Whichever knife is chosen, they should be cut strictly, placing a ruler on the side. An uneven cut is guaranteed if you decide to handle without a ruler. Cutting begins from the back (there is a thicker cardboard layer). The front part of the Civil Code is somewhat different, as it is intended for finishing work. When cutting, they try to deepen the knife as much as possible into the plaster content.

At the end of the process, the GK is turned over and bent in the direction of the solid (without the mowing line of the cut) side. Gypsum that is not hit by the knife will break in the required direction. The cardboard is cut from the opposite side along the formed mowing line of the fold.

It is not particularly important which side to start cutting drywall. However, on a flat, dense surface, this is much easier to do than when holding the GL in weight.

Before you cut drywall with improvised devices, you should familiarize yourself with two more types of simple cutting, feasible for independent implementation.

Double-sided cutting. Most often, cutting in the form of any rectangle is performed in this way. With a hacksaw, one of the sides is sawed, the other is simply cut with a blade. After that, the material is cracked, and the cardboard is cut from the opposite side (as in a simple cut). The finished cut is polished to perfection using an edging planer.

Cutting on uneven mowing lines. To cut material along uneven lines, you must first prepare a drawing.

Drywall cutting

Newbies in the construction business do not know how and how to cut drywall in the best way. After all, any work, whether it is the creation of a ceiling structure, partitions or a complex decorative element, requires knowledge of the rules for cutting gypsum board and strict adherence to them in practice. Different tools are used for these purposes. It all depends on the chosen cutting method. So, how to cut drywall at home, the recommendations below will tell you.

What is this article about

The nuances of making circles

Circles in the ceiling structure are made primarily for the installation of luminaires. The easiest way is to cut a circle of a given diameter in the gypsum fiber with a blade. And gently knock out the middle part with a hammer. However, it will be easier to carry out what was conceived would be a drill with special equipment. a cylindrical nozzle. The same one that is used when cutting into the door of the lock mechanism with a latch.

Cut to specified geometry

Figured cutting of drywall is used in the situation of creating unique shapes for a specific structural element. This procedure is more complicated, and you cannot do without basic experience and a sufficient arsenal of tools.

When curly cutting, the material is first also marked out. If you need to draw a circle, but there is no compass at hand, then they arm themselves with a needle and thread and a tied pencil.

For curly cutting of HA in different situations, we will apply one of the methods described below.

Option one. Describes the process when a hacksaw is selected as the tool. Manipulating a hacksaw is akin to working with a serrated knife and a handle. Using a drywall hacksaw, you can cut out fragments with any non-trivial shapes (for example, butterflies or flowers).

Option two. An electric drill with a cylindrical nozzle allows you to create even circles of small diameter in drywall. The circle is not marked here, but limited to a mark in the desired area.

Option three. For cutting GVL with an electric jigsaw, a clear marking of the contour of the required shape is performed. Priority in the choice of a jigsaw is given when the diameter of the circle to be made must be greater than the diameter of the crown of the electric drill, and the rounded mowing lines of forms are not limited to a circle.

Option four. The most primitive, when the choice of tool comes down to a knife and a hammer. Drywall is cut along the outlined border. At the same time, they try to press on the blade as hard as possible.

Then the HA is placed on a flat surface with a depression. over, the detachable part of the element must fall into this hole. It is less effective to support the sheet against the wall. Then hit with a hammer in the middle of the fragment to be separated. The part to be removed should break. A layer of cardboard is cut from the bottom, leveling the ends as necessary. The GC masters strongly discourage people with no experience from using this technique. Since you have to spend a lot of drywall sheets for stuffing your hand and working out the pressure.

Choice of methods for cutting HA

What method of cutting drywall to resort to will become clear after studying the options available for these purposes.

How and how to cut drywall at home

Gypsum cardboard is a very fragile material, which accordingly requires a careful and careful attitude towards itself. The main and big mistake in construction, where drywall is used, is its incorrect cutting, which leads to its deterioration and you have to buy out too much.

But in fact, there is nothing difficult about it. Once I even had to give advice and carry out instructions over the phone, while driving. People were faced with the fact that it was necessary to cut sheets of gypsum cardboard at home to different sizes, as a result, they solved this problem and got out of it.

How to cut drywall. tools

Let’s agree right away that we will talk about the most important and ordinary things. The tools described in various books are not so cheap and, in fact, they are needed by people who are professionally involved in repairs.

If you are not a professional or you need to make some minor repairs, then you can use the following kit:

- The first is a tape measure and a pencil. Almost every self-respecting man has these things. There are no requirements for them. The only thing is that the pencil must be sharpened, and the tape measure at least three meters.

- The second is a metal ruler. It is desirable that the longer the better. If there is no ruler, then you can take it as an ordinary flat metal profile. The profile may remain when assembling the frames.

- The third is the knife. If you choose a knife, you can use one of two options. You can take an ordinary clerical knife, not too flimsy construction, or a special one with changing blades.

- The fourth is a hacksaw. The saw can be any, ordinary for wood, even “dull”. The main thing is that it is not wide. The best option for this is a knot saw.

- One of the professional tools, perhaps, is a roughing plane, designed for processing the edge of the cut. It is not advisable to replace it with any kitchen object such as a grater or a file. It is better to purchase such a plane, because the price is not so high for it.

Now is the time when we will talk about what can be made of drywall at home.

How to properly cut drywall

Its essence lies in the fact that this sheet is reduced to a certain size. This task is very easy and affordable to perform. To do this, mark the desired dimensions with a pencil on both sides and put a ruler or profile and cut the top layer of drywall with a knife.

It is not necessary to cut the cardboard along the mowing line drawn with a pencil, it is better to attach a ruler and do it along it. Use the knife to cut 2-3 times to make the cut deeper. And only then the cut will turn out to be even and neat, it is possible that the cardboard can break in the right place for you.

Then put a sheet of cardboard with an edge, and approach it from the side where it is not cut and lightly knock on it. After a couple of blows, the drywall will break in the right place, clearly in size. There is little to do. cut off the cardboard (paper on the other side), which also holds the two halves together. Everything, the work is done, you can think that you have coped with this work.

Such a cut is needed if there are any obstacles during the construction of the structure, for example, you need to cut out a sheet for a window, door, etc. To do this, at home, you need to cut a square or rectangle on one side. It will not be difficult for you to do this.

Saw on one side with a hacksaw, on the other, cut the cardboard, as we described above. And everything is ready. It remains only to process the edge with a plane.

How to cut round holes

Almost always, these types of holes are used for cutouts for an outlet, chandeliers in the ceiling, lamps, and more. There are two options for doing this. The first is to take a special nozzle with which holes are made for the lock in the door. Such a nozzle is pushed onto a drill, and after that a hole is cut.

With the second option, you will not need a drill, but just a hammer and a cut out circle of the desired size. You need to attach this circle and gently hit with a hammer. Of course, the effect will be worse than with the nozzle, but it can also be quite amiss.

This type of cut is usually used in toilets or shower rooms, since there are a large number of pipes and other plumbing units. The biggest challenge is calculating the dimensions of the cutouts. First, it is advisable to check the contour several times on which the cutout will be applied.

If it is more than necessary, then there will be many problems with the fastening of the sheet to the frame. If not suitable in size, then it will take your time to fit.

Next, you need to make a plan of your actions. Take a few more looks at your resulting drawing. Usually, in many cases, all flaws in curvature are a hybrid of straight lines and a semicircle. For straight lines and semicircles, you have your own tools. Use a hacksaw in areas where you are sure to make a cut, and all uneven bends and roundness are cut out thanks to the knife.

That’s all, now you know how to cut drywall at home. There is really nothing complicated about it. Everyone knows that experience can come only with practice.

Introducing the toolbox

The obligatory list of tools for cutting gypsum fiber with your own hands includes three groups of objects

Devices for marking on a sheet of gypsum board. a simple pencil, tape measure, long ruler.

Cutting and sawing devices themselves.

- Knife. You can cut GVLV with a clerical knife, as well as with a specialized construction knife with a double-sided replaceable blade (suitable for denser materials).

- Hacksaw. It is better if it is a tool for processing metal than wood.

- Electric jigsaw. Ideal for cutting rounded elements. Least of all, high-quality saws for metal with a fine notch leave chips at the ends of drywall.

- Electric drill. Needed for making holes. For gaps of large d, round crowns (which cut into the core of the door snap locks) and feather drills are required.

Edging attachments:

- roughing plane;

- chamfering planer.

This list clearly shows how the home craftsmen cut drywall. Of course, it is far from complete. The arsenal of experienced craftsmen may include professional equipment, for example, a special cutter for GVL. However, for those who are working with the material for the first time, this set is quite enough. To better understand how to cut drywall correctly, you need to clearly understand the structure of this material.

4 ways to cut drywall in shape

List of tools that you need to work:

- electric drill;

- special attachment. crown.

Saw pieces can be easily removed from the crowns through the side slot.

It is best to cut a circle in drywall, for example, for a built-in lamp, using an electric drill and a special cylindrical nozzle for drilling round holes. a crown. These cylindrical nozzles are available in various diameters and applications. To cut a circle, use the wood and plywood attachment. They are called circular saws or drills. It is also convenient if there is a set of such saws, for example, if you need to make a hole for spotlights of various models or for round sockets of various diameters.

List of tools for work:

- pencil or marker (for marking);

- jigsaw.

If you don’t have a crown, you can use a jigsaw. Before starting work, a circle is marked on drywall, then a hole is drilled in the center of this circle, into which we insert the jigsaw blade. Cut out, going along the previously marked contour of the circle. Thus, we get a perfect circle. It is also advisable to use a narrow file with fine teeth when cutting with a jigsaw. At the same time, it should be noted that you do not need to cut too quickly, but the speed of the jigsaw is better to set to maximum.

- pencil or marker (for marking);

- drywall hacksaw.

Drywall cutting diagram.

In addition to the above tools, in order to cut an even circle, you can use a special hacksaw for cutting drywall. This tool is very simple and easy to use and can also be used for straight cutting. All you need to do is just mark the circle in advance with a pencil or marker and then cut along the markings.

If there are no special tools

List of tools that you need to work:

- pencil or marker (for marking);

- ruler (for measuring the radius of the hole);

- drywall knife;

- hammer.

All the methods described earlier can be used if you have the appropriate tool at hand. But what to do if there are simply no such tools and devices, but you still need to cut a hole?

In this case, you need to use the following method. All we need for this is a drywall knife and an ordinary hammer.

The actions are performed as follows:

- Mark the center of the future circle and measure the radius.

- We apply the markup.

- With a knife we draw along the markings so that we cut through the drywall as deeply as possible.

- we put a sheet of drywall on a surface in which there is a recess, so that the circle that we cut out is above this recess.

- after which we hit with a hammer at the marked center of the circle with sufficient force so that the drywall breaks through the slot made.

- cut off excess pieces, trim the edges and cut off the bottom layer of cardboard.

Drywall Cutting Tools.

This method is very, very simple, does not require special tools, but its use requires skill. It is quite dangerous, in the absence of experience and a beginner will have to spoil more than one sheet of drywall before working it out. The blow should not be too strong, otherwise the material will simply break, but not too weak.

The depth of the slot made in the first stages of preparation is important. The deeper the cut, the less effort will have to be made in order for the sheet to break off in the right place. If the circle you want to cut is large enough, then it would be better to cut the cardboard inside the outline into segments.

Double-sided cut

Quite often, when fastening a sheet to a profile in difficult places, it is required to make a double-sided cut. This method is used when decorating window openings, doorways, if necessary, bypass beams and other complex structures. What is the best way to cut drywall in this case? First you need to make a rectangular or square hole. You can cut it using such a simple tool as a hacksaw, or a sharp knife. The cutting process is easy:

- first you need to mark up the sheet with a simple pencil and ruler;

- on the one hand, the sheet must be cut with a hacksaw, and on the other, using a knife;

- now the drywall breaks, it is cut off from one side.

After that, it is necessary to carefully process the edge with a roughing planer to get even edges. When the sheet is cut, you can fix it in the required place using self-tapping screws. Joints and seams after installation are putty, pre-glued with a special mesh.

Drywall Sheet Cutting Tools

Drywall is a very durable material, but in order to securely fix it to the ceiling or wall, it must be properly cut. GKL sheets are somewhat fragile, that is, in order to cut them along an even mowing line without splitting the plate, you will have to use special, albeit fairly simple tools. After that, using the profile and self-tapping screws, you can proceed with the installation.

So how do you cut drywall? Many manufacturers recommend using special equipment for this, but its cost is quite high, so it is quite possible to get by with a minimum set that allows you to quickly and efficiently cut sheets before attaching them to a profile. You can limit yourself to the following set: Roulette, a simple pencil. this is the minimum set required for marking on the surface of the sheet. It is better to take a three-meter tape measure, made of metal, the pencil should be sharply sharpened.

The marking itself is very simple, according to preliminary measurements. It is better to take a long ruler, but if it is not there, then you can use a regular profile, the scraps of which may remain after installing the frame. Knife. There are several options here: the most common stationery sharp knife with a strong body or a special construction knife with replaceable blades, which has a comfortable handle for work. When cutting like this, make sure that the blade is sharp and it is recommended to use protective gloves.

For cutting drywall sheets, a saw for wood or a hacksaw with which knots are cut is excellent.

It must be narrow, so as not to damage the stove during operation. Also, when cutting, the sheet must first be fixed so as not to break it. Rough planer. Probably, this is the only professional tool that must be used when cutting sheets of gypsum board. The plane is used to clean the cut edges. Many believe that such work can be done using the most ordinary kitchen grater, file, sandpaper, but when installing a multi-level ceiling or large niches, partitions, it is recommended to use a plane

The structure and purpose of drywall

Gypsum plasterboards are a layer-by-layer combination of two types of materials. gypsum (inner content) and sheets of thick cardboard glued to it on both sides. It is clear that if the cardboard layers are damaged, it is not difficult to cut the rest.

Therefore, in order to be able to quickly cut a sheet of gypsum board, it is not enough to know the best way to cut drywall. It is important to know the basic principle of this action: after the continuous even cutting of drywall is carried out, the second step immediately follows. breaking the sheet.

Sawing drywall, like any solid porous material, is not difficult. It also lends itself well to drilling.

The functions of the material make it possible to differentiate it into varieties: moisture-resistant, fire-resistant, standard, increased strength (for example, gypsum board or gypsum board made using Knauf technology), acoustic gypsum board, etc.

Despite the large assortment of GK, panels of any of its varieties lend themselves well to dividing into parts by means of the available material at hand.

Drywall cutting methods

Before making a hole in the drywall, you need to know what kind of material it is. Drywall is a material that is a two-layer sheet of cardboard and a core of hardened gypsum with fillers. This material is intended for cladding, creating partitions, used when installing ceilings in rooms with normal air humidity.

How to cut perfect a circle of cardboard

Holes in drywall may be needed when installing switches, sockets and lights.

There are three types of drywall: ordinary, moisture resistant and fire resistant. The moisture resistant type is used when working in rooms with high air humidity, for example, a bathroom. Fire-resistant, respectively, for fireplace portals and other places where open fire is present nearby. In addition to the above listed types, there is also a gypsum fiber sheet, which is highly durable, and acoustic, which has increased sound insulation.

There are several ways to cut drywall.

Each of them is used for different cases. The most common way is to cut the sheet in a straight line. But it also happens that it is necessary to cut out a circle or other shape.

Cut after installation of gypsum board

Of course, it is more convenient to cut material that has not yet been fixed. But in practice, there are situations when cutting off the excess is required after mounting the sheets to the frame. Such trimming is due to the fact that the sheathed surfaces meet window slopes or corners on their way.

The sheet is fixed on the wall, leaving a small margin of size. Already on the wall, remove excess centimeters.

It is important to make sure that the HA is securely fixed to the frame. The incision is made on the side that is in contact with the wall. The cutting movements are repeated several times, following the markings. At the same time, they try to “squeeze out” unnecessary parts of the material. The sheet is cut from the other side.

Having studied these methods, beginners will understand how to cut drywall with a minimum set of tools at home. If you need to cut large quantities of HA, these options will not work. The best solution would be to turn to professionals.

When installing drywall sheets, it is necessary to use tools that will allow you to cut all the plates evenly and efficiently. We will find out how to cut drywall, what tools can be used for this.

Drywall cutting scheme.