Required tools and materials

Foam boards are a thick and highly porous material, they consist of more than 95% air, and it is difficult to cut them from the habit. How to cut the foam depends on the type of cut, the availability of the tool and the amount of cutting work.

How and with what to cut foam with a guarantee of dimensional accuracy? Ordinary foam. terminology and material characteristics

In a broad sense, foam is considered an extensive class of cellular (foamed) plastics based on polyurethane, polyvinyl chloride, urea, phenol and even formaldehyde. All these materials are united by a minimum density and an internal structure in the form of frequently located and small gas cavities. However, in practice, you have to deal with the only type of foam. low-pressure polystyrene foam, abbreviated PSV.

Only it has an affordable cost, all other cellular plastics in production are much more expensive and are rarely used in construction and repair business. The international name for low-pressure polystyrene foam (PSV) is the brand name styrofoam, patented by the development company BASF back in the 50s of the XX century. The abbreviation EPS is often used in the documentation for imported foam. For practical purposes, it is important to know that all these terms. styrofoam, PSV and EPS. denote ordinary foam plastic that is familiar from childhood.

The structure in the form of small gas pores and the significant dimensions of the slabs determine the main operational advantages of foam:

- Excellent thermal insulation from any side of the house. You can perform foam insulation inside the room, you can carry out this procedure outside, you can combine external and internal thermal insulation, and the cost of such a “double” protection will still be lower than the estimate for the newfangled roll insulator;

- Excellent acoustic protection of premises. In fact, sound comfort is achieved already during heat-insulating works. if frost cannot penetrate the foam layer, then loud sounds are all the more impossible;

- Environmental Safety. Styrofoam is absolutely non-toxic, including on opened cut lines and with prolonged use. Some varieties are allowed to come into contact with food, which is regulated by European quality standards (!). over, the foam is safe for repairs, there is not the slightest need to try the walls pasted over with it;

- High resistance to mold, moisture, microorganisms, fungi, algae and other unwanted companions of human life. In order to enhance the durability of such consumer qualities, cutting the foam with your own hands must be done accurately and competently;

- Ease of installation due to the miniature weight. This quality greatly simplifies the transportation and laying of the foam, however, when working outdoors, pay attention to the Possible “wind difficulties”. the foam blank will be easily carried away by even a weak Breeze.

Of course, before any introduction of foam, the Potential Complications must be considered. Firstly, this material is destroyed by the action of most technical fluids. from acetone and gasoline to white spirit and enamel solvents. This destruction is intense even with the vaporous action of technical fluids on the foam.

Secondly, it is necessary to pay special attention to the expected operating temperature of the surface covered with foam. Already at 50 ˚C. 60 ˚C, some types of foam boards begin to crumble, their internal bubbles combine into extensive gaps and cavities. Painting of surfaces insulated with foam plastic must be thought out in advance, otherwise the thermal comfort of the entire room will suffer from toxic nitro paints.

Sawing rules

Before getting dusty, choose a method, as well as accessories and tools.

- Scotch;

- Masking tape;

- Pencil, ruler;

- Sandpaper.

- Hacksaw;

- Cutters;

- A circular saw;

- Tire;

- Jigsaw;

- Sawing machine.

How chipboard dusts without chips step by step:

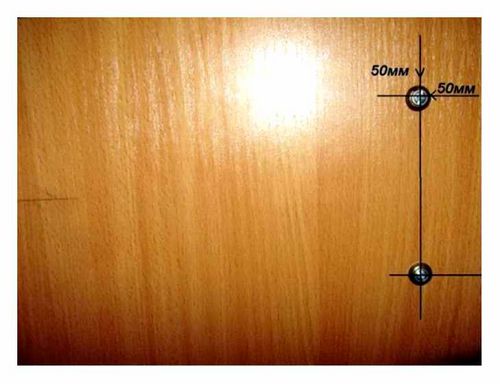

- Place dots on the end part of the chipboard. You need to determine in advance what type of cutting will be made. straight or curly. Their cutting technique is different.

- Connect the dots in the fishing line and stick the adhesive tape on top. Dust chipboard with laminated coating, preferably with the introduction of adhesive tape. It will reduce cracks when cutting, as the wood board is subjected to strong pressure with increasing temperature.

- Saw a board. The accessory is installed at the desired angle to achieve extremely smooth edges. The process should take place smoothly, rhythmically and without strong pressure.

- Finish irregularities and edges, if necessary, with a file and a rasp. The edges can be veneered with matching color. This will protect them and look prettier.

Only after placing all the necessary tools on the table, you can start cutting.

Circular saw

The tool is a table with a toothed disk for chipboard. Among the craftsmen, it is called a circular saw. Cuts through wood better than a jigsaw. A good chipping-free result is possible by sketching the guide lines and securing the circular saw to the board. Chips should NOT appear where the saw cuts into the board. But the opposite side can be cut with fragments.

Spraying with a panel saw

The workpiece is placed on the table and fixed in a motionless state. The necessary markings are made on the sheet and the saw unit is turned on. When the disc reaches a sufficient speed, the table moves forward along with the wooden plates and hits the disc.

- Tile position;

- Cut depth;

- Cutting angle.

Chipboard cutting machines are divided into 3 types:

- Lungs. for 5 hours of continuous work;

- Medium. up to 10 hours;

- Heavy. up to 20 hours.

What the cutting machine consists of:

- The bed is the mount on which the entire mechanism rests. A heavy bed will add stability to the instrument and eliminate vibration. This is important for a quality cut.

- Saw unit. consists of 2 flat metal discs. The first one pre-saws the slab, and the second one finally cuts through it.

- Work tables. Three take part in the process at once. The first is for the location of the unit, the second is for feeding the sawn-off plates (movable), the third is for supporting the sawn-off parts.

- Carriage. allows the movable table to move. In this case, the workpiece is fixed with a stop and rulers in the required position.

Methods for cutting chipboard without chips

It is necessary to dust the laminated board with a special machine (format-cutting). But his) when it comes to home use. An alternative can be budget options (hacksaw, jigsaw, etc.), which will take more time when cutting, but require less cash investment.

Undercut sawing

The process requires a tire. a persistent ruler. It is fixed on the board with clamps. Trimming is carried out according to the marking. The tire is installed along the mowing line, and the slot is made 10 mm deep. The second cut is made through. With this method, there will be no chips on both sides, since the laminate has already been cut from the bottom side.

Some elements used in design ideas are not cut straight, but curved. In this case, a mixed type of chipboard cutting is used.

Using a router

Milling cutter is a power tool for manual woodworking. Suitable for grooving, curving, edging and drilling. Before its introduction, a sheet of wood is sawn with a jigsaw, stepping back 3 mm from the marking. It is necessary to dust with a cutter together with a bearing, which form the cutting depth to the required level. This is a laborious process that only experienced professionals can do. High probability of cutting the board crookedly.

How to cut chipboard without chips at home

Chipboard. chipboard. It is used in the manufacture of furniture and decoration. Affordable price is the main feature. In modern wood production, laminated boards are used. They are made from coniferous and deciduous-wood materials. They are distinguished by their strength and ease of processing. Incorrect cutting process can lead to breakage and cracks. To avoid this, you should know what to do to cut chipboard without chips at home.

Jigsaw

In order to smoothly saw off chipboard with a jigsaw without chips, you need to choose a device with a minimum size of teeth. It is used for small areas of tiles, with smooth movements without pressure at a low speed. If you are using the jigsaw for the first time, some cracks may appear on the back of the hob. With continued use, the quality of the cut will improve.

Using a hacksaw

Dusting with a hacksaw at home is hard enough. First, you need to cut the measuring line with a knife and glue tape on it. This will protect the top layer from damage. The tool will aim at an angle of 30 degrees. Gently, without strong pressure, move the hacksaw back and forth. To cut chipboard without chips with a hacksaw at home, choose devices with the finest teeth. In case of damage, the place of cutting must be passed with a file, guiding it from the edge to the center. Finally, rub with sandpaper (fine-grained) and hide the defects under a flexible profile.

How to cut a chipboard with a jigsaw without chips?

Laminated chipboard is one of the most popular materials, which is used in the independent manufacture of furniture. Speaks about its advantages and disadvantages for a long time. But it is much more important to find out how chipboard dusty with a jigsaw without chips.

What else do you need to know?

When it is planned to saw off everything without chips on one side, let us use saws with both upper and lower teeth arrangement. Most craftsmen prefer small, straight-toothed nail files. Such devices chip less material, but at the same time they work pretty well. After the saw cut, it is best to process the ends with emery stretched on even bars. If there are no ready-made small suitable colors, you can mix different crayons, like paints in the artist’s palette, and get a new color.

In order to cut without errors and, moreover, quickly, you must always take into account the brand markings. There is no generally obligatory designation standard yet, however, almost all firms strictly follow the classification developed by Bosch specialists. Or at least indicate it along with their own abbreviations and terms. For cutting wood and wood-based products, CV saws (sometimes referred to as HCS) are well suited.

Some inscriptions indicate in which mode the tool works normally:

Basic. a simple blade that allows you to make a high quality clean cut;

Speed. a device whose teeth are set (this allows you to cut faster)

Clean. a canvas that has not been cut (usually gives the cleanest cut).

If the workpiece is thick, preferably a saw blade with large incisors that DO NOT cut, then the deviation from the vertical will be minimal. The longitudinal (in relation to the fibers) cut is most often made with helical saws. For transverse, a straight blade is better. When you plan to make a blank for furniture, it is advisable to choose a less productive, but more accurate tool. Since most of the pollen produced now cuts the material when it is pulled in, the workpiece will need to be machined from the INSIDE.

Features and recommendations

Experts and experts advise to carry out this kind of work with the help of electric Jigsaw already after that an ordinary hand hacksaw is too rough. It doesn’t cut the material straight enough. The correct sequence of steps is as follows:

Preparation of tools (ruler, jigsaw, measuring tape, awl or other sharp device for drawing on chipboard)

Addition of THESE tools (if necessary) Square for laying right angles;

Measurement of the desired part (with a reserve of 0.2 cm so that you can fit)

Drawing a line along the ruler;

Actually sprayed along the laid mowing line;

Completion of the saw cut with sandpaper;

With very poor quality of the end. rubbing it with a fine, similar in tonality to chipboard.

Completing of the work

When the saw is selected, you also need to properly cut the laminated board at home. Experts recommend dusting along the guide (a rail clamped in clamps is also suitable). If you use a new, unworn blade, you can cut the chipboard as cleanly as a circular saw. It is advisable to turn on the jigsaw at the lowest speed possible. This will significantly increase the resource of each used saw.

The canvases themselves are placed at right angles to the sole of the jigsaw. The easiest way to adjust the angle is with a square or protractor. Important: the straight line passing through the cutting edge of the tool must be parallel to the rigidly fixed part of the jigsaw. It is recommended to use special inserts to reduce the chance of splitting. But in order for them to work more efficiently, they usually cut the laminated layer on the side where the blade will come out.

For how to cut a chipboard with a jigsaw without chips, see the following.

Tools and materials

If possible, it is best to spray chipboard with a hand mill, using homemade guides. This method is NOT very convenient when cutting large sheets, because when working with this tool, a table is required. In addition, this method often requires changing the cutters. But as a result, you will get cleanly processed, “chamfered” edges.

Electric jigsaw. The most popular tool for sawing chipboard

Some craftsmen use a jigsaw in their work, however, in the absence of skill, it is difficult to cut smoothly, and chips can form.

If such methods do not suit you, then for cutting chipboard at home, prepare for work:

- A hacksaw with fine teeth (one that is best suited for metal work). At the same time, the teeth must be divorced by 1/2 of the blade thickness and hardened;

- Paper adhesive tape;

- File for rough processing of the cut mowing line;

- Sandpaper for finishing the cut line.

How to cut chipboard without chips?

Before we start spraying chipboard, especially laminated chipboard, cut the line with a sharp tool, along which we will cut and glue paper tape with a sticky layer along it. This will help minimize damage to the decorative chipboard layer.

If chips still could not be avoided, we first process the spray with a file, working in the direction from the edges to the center, and then with a fine-grained sandpaper. It is also possible to mask all defects by applying a flexible profile where possible.

Sawing chipboard. methods and methods of processing

[Contents] If you have tried spraying chipboard at home at least once, then you know for sure that this work is by no means simple and requires not only skill, but also a good tool. It is especially difficult to process laminated chipboard, when sawing which often a lot of chips are formed. That is why, many craftsmen, faced with such a problem, come to the conclusion that it is better to spray chipboard when buying, especially since many trading organizations provide such services and the price for them is quite acceptable.

Sawing of chipboard is carried out with the introduction of precise panel-sawing machines, which will help to obtain blanks of a given size and shape.

In addition to cutting sheets, you will be helped to calculate and PROVIDE in the form of a visual file several options for competent and economical cutting of sheet material (using Special computer programs) and, if necessary, perform edging. However, if for some reason you prefer to do this work yourself, before sawing the chipboard you will have to do some preparatory work.

Shaped cutting

Curved surfaces of a given configuration It is even more difficult to obtain at home, while you will have to additionally spend money on purchasing a router, which will help you get rid of chips and notches formed when you cut chipboard.

To cut chipboard, you need to follow these steps:

- Having marked out the contours of the necessary part on the chipboard sheet, cut it out with an electric jigsaw, trying to get dusty. Retreating just a couple of millimeters from the intended cut mowing line;

- We make templates of the design radius from fiberboard or plywood and carefully grind the ends with sandpaper;

- Attached the template to the part to be trimmed, clamp it with clamps and process it with a manual copying cutter with a bearing, absorbs excess material exactly into the intended mowing line.

It does not matter which cutter (with two or four knives used). The only condition is that the knives must cover the cut thickness to be processed along the entire height. After processing, it remains only to stick the edge on the part. How it’s done. look at:

What you can’t cut chipboard

If the volume of work is large enough, and the quality requirements are small, some craftsmen advise dusting the chipboard at home using a grinder (an angle grinder, commonly called an “angle grinder”). In doing so, they use a disc designed for working with wood. To make cutting easier, a guide bar is fixed along the mowing line of the cut with the help of clamps. Spray chipboard using an angle grinder can sometimes be seen on.

How to cut porcelain stoneware glass cutter

The technology of cutting tile material with the introduction of a manual glass cutter is not much different from the previous method. The only differences are that, instead of a carriage moving along the guides, you have to cut porcelain stoneware with a small tool held in your hand.

In fact, this is ideal if you want to cut material at home. Instead of a frame fixture, a regular table, a metal ruler and the glass cutter itself are used. In order to cut porcelain stoneware, it is enough to lay a ruler on the mowing line of the marking and draw a diamond along the mowing line of the cut.

To break the material, the tiles are laid on the table so that the scratch line coincides with the edge of the tabletop, pressed on top with a board and with a sharp movement break the material into two halves. For home conditions, there is no easier way, but in order to master the technique, you need to practice cutting on the waste of porcelain stoneware or glass.

The advantage of this method is the simplicity and the minimum amount of equipment required. It is easier to store a manual glass cutter with a diamond at home than a tile cutter. The disadvantage of this method is that it is necessary to learn how to draw a line with a diamond along the markings at a constant speed, and the main thing is to do it continuously, in one motion, while accurately metering the force applied to the surface of porcelain stoneware.

In addition, it is very difficult to cut glass cutter material without chips, therefore, if possible, it is best to use a diamond, and not a carbide roller.

How does porcelain stoneware dusty with a circular saw

Porcelain stoneware tiles can be cut and cut without any problems using a more powerful cutting tool, such as a hand-held circular saw. Engine speed and power allow you to cut almost everything at home, from wood to metal profiles.

In order to cut porcelain stoneware, the tool must be retrofitted:

- First, the standard carbide-tipped dust disc must be replaced with a diamond disc;

- Secondly, a bandage ring is placed under the disk mounting, thanks to which it is possible to damp vibrations and uncontrolled bending of a thin and flexible diamond wheel.

Alteration of the saw for porcelain stoneware

The process of sawing material is not much different from working on an electric tile cutter.The only difference is that the engine power is noticeably higher. Therefore, you need to carefully control the supply of the diamond wheel with minimal effort, otherwise the porcelain stoneware quickly overheats and splits.

If you want to cut large quantities of porcelain stoneware, then there is no better option than an electric machine

This method of cutting porcelain stoneware is considered the most productive, but at home it is used for short-term cutting of a small amount of material. You can work only in the yard, in the garage, in the barn, but in no case inside the living space. The amount of dust that is generated when cutting even a small amount of material is about an order of magnitude higher than all other cutting methods. The only indisputable advantage of this option is that with the help of a circular and a diamond wheel, you can cut porcelain stoneware at 45 degrees.

Cutting porcelain stoneware tiles at home

Anyone who prefers to make repairs or do minor work with their own hands must have had to cut porcelain stoneware at home. In the first tests, spraying porcelain stoneware tiles is more difficult than in the case of cutting tiles. It turns out a lot of scrap, but in general, the process itself is not much different from working with high-quality ceramic tiles.

The line of the cut should be marked with an allowance for finishing

How to cut porcelain stoneware tiles at home

In terms of technology, there are two main ways to cut porcelain stoneware. To do this, you can use various tools and devices, but, regardless of the number and type of technical equipment, porcelain stoneware is still cut in two ways:

- Mechanical spray of ceramic granite massif. In this case, the cutting line is sampled with an abrasive tool;

- Injection method. A deep scratch is cut on the surface of the porcelain stoneware along the future mowing line of the division. Further, a bending or shear force must be applied to the porcelain stoneware, and the tile splits exactly according to the marking.

At home, you can use both methods, depending on the available tool, the amount of work and the thickness of the material. In addition, the complexity of the cut line configuration must be taken into account. For example, if you want to cut a tile that is large enough in size at home, which simply does not fit into the tile cutter, then you will need to look for a diamond cutting wheel and an angle grinder. For cutting at home, this is one of the most reliable ways.

I laid the tiles on the drywall lettering, you can cut the porcelain stoneware with an angle grinder in almost any trajectory, it is only important not to rush and evenly pressing the edge of the disc to the surface of the porcelain stoneware. Otherwise, you can easily overheat the tile at the cut point, which will lead to a pinch.

Professional advice

Oddly enough, but the greatest number of problems arise not even with the drive or the tool used to process porcelain stoneware, but directly with the diamond disc. The main complaint about a diamond is its rapid loss of cutting ability. As a result, with an increase in feed and force, the edge of the wheel heats up and begins to lose diamond powder. If you try to cut at home in this mode for at least 10-20 seconds, then there will be nothing left for an expensive disc.

In this case, before each cut, the edge is cleaned and restored; at home, this can be done on an ordinary red brick by performing several small cuts. This removes the soft material adhering to the diamond strips.

Experienced craftsmen, before cutting porcelain stoneware tiles, soak the material for 10-15 minutes in water. Artificial granite absorbs moisture very poorly, but a small amount of water still remains on the edge of the slab. As a result, the first time the cutting edge touches the surface, a beautiful, chip-free entry hole is guaranteed.

Features of cutting porcelain stoneware

It should be noted that the spraying of a very dense and hard porcelain stoneware slab is sometimes even easier at home than in the case of ceramic tiles. Anyone who does not believe can try to cut overheated ceramics made on old Soviet or Chinese equipment at home. In comparison, the spraying of porcelain stoneware tiles does not look so problematic.

It is quite possible to cut porcelain stoneware without chips, although some masters argue that it is impossible to achieve this in principle. If this were really the case, then most of the walls and steps tiled with porcelain stoneware tiles would be with wide seams, curves and unattractive.

It’s not even about the hardness of porcelain stoneware. The technology for the manufacture of artificial granite is such that as a result of pressing and deep firing, material is obtained practically without internal stresses, and this is the guarantee of high quality mowing line sawing.

In order to accurately and accurately cut porcelain stoneware at home, you need to fulfill only two conditions:

- Choose the right cutting mode, ensure constant and uniform pressure with the cutting tool on the line of the cut of porcelain stoneware;

- Choose the right tool for your specific cutting conditions.

It is clear that at home the possibilities for cutting the material are significantly limited, but even in an apartment it is quite possible to cut porcelain stoneware without a tile cutter, although initially the amount of dust generated when working with electric machines is frightening.

Water cutting of porcelain stoneware

The most efficient and at the same time accurate method of sawing very hard natural and artificial granites is the Waterjet system. It allows you to cut out entire designs and 3D images. The system is powerful enough to cut porcelain stoneware up to 200 mm thick. At home, such equipment is not used for obvious reasons.

Cutting with the introduction of water can be done on a hydromechanical machine. The use of water or water emulsion can significantly lower the heating temperature of the tool and the porcelain stoneware itself. The result is less wear and better surface quality. The emulsion is applied to the edge of the wheel, but not to the surface of the ceramic.

The diamond wheel, mounted on the rotor of the engine, is fed along the guides of the machine along the surface of the porcelain stoneware, the coolant is supplied from a special reservoir directly to the cutting zone. This method is considered the most harmless, since almost all dust is washed off with water and removed from the surface of porcelain stoneware. It is clear that it is possible to cut material in this way if at home it is possible to find a separate room, for example, in a garage or in a barn.

Such machines have very high characteristics and cutting speed, therefore, if you plan to cut porcelain stoneware of complex shapes and sizes at home, then using a hydromechanical machine will be the best option.

How to cut porcelain stoneware with a jigsaw

Quite an unusual way of cutting porcelain stoneware slabs. Using an electric or hand jigsaw to cut very dense and hard material always raises some doubts for beginners. Nevertheless, it is quite possible to cut ceramics and porcelain stoneware with a jigsaw even at home, but only if certain requirements are met:

- The tool must be prepared for cutting porcelain stoneware. A thin, necessarily soft material is glued to the sole, you can use paper or rubber. This is done in order not to scratch or damage the front surface of the plate;

- The second step is to turn off the pendulum vibration-movement on the hacksaw blade feed mechanism, otherwise the saw will cut with chips on porcelain stoneware;

- A special type of diamond-coated hacksaw blade is used for sawing tiles.

In addition, the slab itself must be securely fixed on the countertop with clamps, and a rubber strip must be placed under the porcelain stoneware to reduce vibrations. The method for cutting porcelain stoneware is quite simple and does not require special skills, ideal for use at home. It is valuable that curly cutting of porcelain stoneware is very easy to perform with a jigsaw.

You can also cut tiles with a hand jigsaw, sometimes at home there is simply a second tool, however, it will take several times more time, but it is possible to get a very accurate and high-quality cut. In this case, the side edges of the hacksaw blade are ground off, and emery powder is fed into the seam during sawing.

Curved sprayed porcelain stoneware

It is believed that this method is the cleanest of all mechanized options, which is especially important if you have to work at home, without a hood and vacuum cleaner.

How to cut porcelain stoneware tiles with a tile cutter

A tabletop or floor device for cutting all types of tiles is a small frame with rails installed at the top and a carriage with a carbide head. The carriage is driven by a lever or electric drive. Simple and convenient mechanism at home.

At home, the tile cutter turns out to be the most affordable tool for cutting porcelain stoneware

Before cutting the porcelain stoneware, the tiles are laid on the frame and fixed with plastic or metal stops. This is necessary so that the material does NOT move during the cut. Next, bring the head to the edge of the tile to touch and push the lever away from you, the carriage with a diamond or carbide tip travels evenly over the tile surface, leaving deep scratches behind.

There remains only a slight, but sharp movement of the fracture of porcelain stoneware into two parts. One way to cut porcelain stoneware with a hand-held tile cutter is shown in:

- It is very easy and comfortable to cut porcelain stoneware at home, you can master the cutting technique even with minimal experience and qualifications;

- A minimum amount of dust is formed, which is very valuable at home, especially if you plan to lay porcelain stoneware tiles on a small area of the floor or wall.

An electric tile cutter resembles a circular saw for processing and sawing wood. In order to cut porcelain stoneware, you just need to set the size of the cut strip, after which you can saw in unlimited quantities.

Home compact electric tile cutter

The disadvantages of the device include the fact that only material of a certain shape and size can be cut, for example, it is very difficult to cut off a thin strip of porcelain stoneware or make an incision of a non-standard, curved shape.

A thin strip of porcelain stoneware is easier to cut with an angle grinder

Hacksaw

Beginners are usually interested in: is it possible to cut and how to cut cellular polycarbonate with a hacksaw or a hand saw? In the event that there is no experience, it is advisable NOT to use these tools: the canvases along the cuts may crack. Work best with power tools. But both beginners and experienced professionals need to fix polycarbonate sheets well so as not to allow vibration and stress in the material, which is also fraught with bad consequences.

Electric jigsaw

A household, most ordinary electric jigsaw is also quite suitable for working with polycarbonate letters, only you need to install a file with fine teeth on it, otherwise the material will tear, not cut. This tool, like the angle grinder, is quite easy to use, but in order to be completely confident in the quality of work, it is advisable to also practice in advance. An electric jigsaw is very much in demand, especially when you have to cut monolithic polycarbonate of complex decorative shapes or do it by rounding.

When only one letter needs to be cut, the risk of cracking increases significantly. To prevent damage to the material, you need to work only with a very well sharpened tool. There are craftsmen Who, when working with polycarbonate, use scissors. This is also perfectly acceptable. The main thing is that the tool used does NOT break the structure of the canvases.

Stationery knife

Perfectly cuts polymer plastic canvases and a stationery knife. over, even beginners can cope with this. The main thing is that the knife is of good quality, and the work is not done in a hurry. the blade of such tools is very sharp and it is impossible not only to make an incorrect cut, but also to get seriously injured. The stationery knife is suitable for honeycomb sheets with a thickness of 4-6 mm, but with 8 mm it is already quite difficult to work with. On thicker sheets, cutting polycarbonate is almost impossible, therefore, experts recommend using a knife only where it is necessary to trim the material, and even then, on leaves up to 10 mm.

How and how to cut polycarbonate at home?

Cloths of polymer plastic, more familiar to everyone under the name polycarbonate, are becoming more and more popular every day. It is no coincidence: the relative cheapness and excellent properties of the material brought it to one of the first places in sales. It is also of great importance that almost anyone can work with it, if there is a desire. But since this is a new material, not everyone knows how to correctly and how to cut polycarbonate at home in order to get a high-quality cut and NOT spoil the material.

Laser cutting

In addition to the listed methods, you can also cut with a laser. But, to work with a laser machine, you need to have the Appropriate skills. In addition, not every master has such a tool, therefore, laser cutting of polycarbonate is available only to those who deal with polycarbonate professionally. But, if there is an opportunity to perform the work with a laser, you must definitely use it, since this guarantees:

- High speed of work;

- Lack of defects;

- Excellent cutting quality;

- Cutting accuracy: when working with a laser, the dimensional accuracy is maintained up to 0.05 mm;

- During work it is not necessary to fix sheets.

Any cutting material designed for working on metal or wood can be applied to the blades of solid polycarbonate, even a standard cutter for metal.

Tools

Angle Grinder

The very first tool that almost everyone has and that can work with polycarbonate is an angle grinder. over, it is not at all necessary to use an expensive tool: even an inexpensive and small angle grinder will do all the work perfectly. To make even cuts, you need to set the circle 125, intended for metal. The only thing you need to pay attention to is experience, since the tool is distinguished by high revolutions, and if you did NOT have to work with it before, it is advisable to practice cutting from this material before cutting the polycarbonate. Where can I get them? Contact the craftsmen who are engaged in the manufacture of polycarbonate structures.

How to cut correctly?

Before cutting polycarbonate, experts prepare the workplace well beforehand. It is necessary:

- Remove all foreign objects from the site: branches, pieces of planks and boards, even small pebbles. Ideally, the place should be clean. This is necessary so that there are NO dents, scratches and other damages on the polycarbonate canvases. It is best to pave the working area with sheets of chipboard, fiberboard or another suitable material for this purpose.

- Use a marker and a long ruler or a second object on the panels to mark up. If you have to move along the canvases during this, it is necessary to lay a wide board and walk only on it so that dents do NOT appear on the polymer surface.

- Before cutting polycarbonate to size, it is necessary to put boards under both sides of the markings applied with a marker, the size of which should NOT be less than 4 × 10 × 220 cm.On top of the canvas, in the same places, boards are again placed and, only then, you can will move on them.

- If the cut is made on an even mowing line, you can work with an angle grinder, rounded parts go through with an electric jigsaw, and if you need to make a slight adjustment, a clerical knife will do.

- If the work is performed on material with a laminated or mirror surface, it is very important to correctly position the canvas in the workplace: the laminated or mirror coating must be returned upwards. What is better for this kind of polycarbonate dust? The same tools as other types of material, but using a hacksaw is not acceptable: mirror or laminated layers can peel off.

- When working with canvases of cellular polymer plastic, if the cut is made along the length of the sheet, the markings can be omitted: the honeycombs themselves will serve as a guide. Thanks to this, it will not even work on the surface of the material.

- After completing the sawing work of honeycomb blades, it is necessary to blow out all the seams with compressed air to remove dust and chips that have got inside.

And most importantly, before cutting polycarbonate with an electric jigsaw or an angle grinder, you need to wear safety glasses to protect your eyes from microparticles and dust. And one more thing. you should always remember the popular wisdom, which says that before you cut it off, you need to measure it seven times. this will help save both money and time.

What makes plexiglass dusty at home

The need to dust plexiglass does not arise very often when it comes to home use, but sometimes you still have to think about what tools may be needed in such a situation.

If you decide to make your own plexiglass, then you will need to master the skills of working with this material. The most common acrylic is 8 mm thick. It should be noted that spraying or cutting off organic glass is not at all difficult, because this material lends itself well to all processing methods. Below we will consider how you can saw plexiglass at home Using the available tools.

Methods for cutting plexiglass

If you decide to start making some products from acrylic or maybe you need to repair a product that has it, then you may well need to use it to remove the deformed element. The following methods are available at home:

- Use a hacksaw for metal. Plexiglass with a thickness of 8 mm can be easily cut with this tool, but be prepared for the fact that the cutting site will turn out to be sloppy, additional grinding with a file or a file is required.

- You can use a cutter. The method looks like this: on the plexiglass element, which needs to be cut off, press a metal ruler, then a cutter is carried out a couple of times. The thickness is cut in half and it is neatly smashed.

- A circular saw will also work, it will easily handle 8 mm or thicker organic glass. Some craftsmen use cutters for metal, the thickness of which is from 0.5-1 mm. In the process of working with cutters, they quickly work, this leads to the release of smoke, while the surface becomes Rough, and due to the high temperature it can foam. To avoid this result, the dust must be cooled during operation. To do this, you can install a container with water on one side of the cutter and from there feed it through a plastic hose. By organizing such cooling, you can achieve a neat and transparent cut.

- If necessary, cut an 8 mm or other sheet of plexiglass not along an even mowing line, you can use a nichrome thread.

This will require building a small cutting tool. The nichrome thread will need to be thoroughly warmed up, for this it is connected to a 24V transformer or less. When the thread is heated, it can cut acrylic along a predetermined path. - Another method to cut 8mm Plexiglas or other parameters is to use a slotted screwdriver. I attached its end to the cut, the blade is heated with a 25W soldering iron. When the temperature reaches the melting point of the material, draw a straight line along the guide fence with a sharp movement. After that, the part is simply broken off, it will be very easy to do.

As you can see from the above information, cutting plexiglass at home is a completely simple task. Home craftsmen use the listed methods, and also adapt and come up with more convenient and accessible methods. So you can use a jigsaw, and if the thickness of the material is less than 2 mm, even an ordinary stationery knife can handle cutting.

Regardless of the chosen method of cutting or sawing plexiglass, in order to obtain a neat cut point, it is recommended to grind and then polish it.