Training

Preparatory work is happening very quickly. First, the tools are selected so as not to run in search. You will need:

- Tape measure, building meter or ruler.

- Simple pencil, nail, screw. Any object that leaves a visible mark.

- Knife. Stationery or construction (it is more reliable).

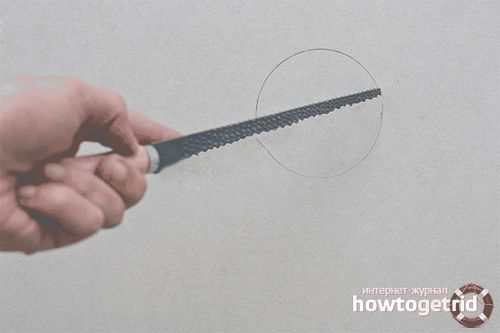

- Hacksaw. Preferably narrow, but with a stiff blade. You can take the one intended for cutting knots.

- A hammer. The most common.

- Special plane. Easily replaced with a file or medium grit sandpaper.

- Drill. If there is a special nozzle-cutter for it, it will be great.

Then the drywall lettering is laid on a flat surface. For example, on the floor. Experts can cut drywall by weight, I do not recommend this technique for beginners. Fraught with damage to material.

If there is no space on the floor (this happens during repairs), then the letter is placed on two stools. Strictly the same height. And they start.

How to cut a circle in drywall

If you have a drill with a special attachment at hand, then small round holes can be drilled very easily. The cutter is pressed against the letter strictly perpendicularly, then the drill is turned on and slowly pressed from above. In total, it turns out a little dusty, but perfectly even.

Do NOT drill round holes or mowing lines of complex configuration (waves, patterns). Here you will have to act with a hacksaw on the principle of cutting out an inner piece. Drill out the fishing line, insert the canvas. Then they saw on the drawn.

Naturally, it is inconvenient to do such work on the floor. You can put drywall on the table so that the cut protrudes beyond the edge of the tabletop.

Some craftsmen cut a round hole in the cardboard with a knife, and then knock it out using the usual method. Beginners are NOT advised to try to repeat this procedure. Without proper skills in drywall, an ugly gap with torn edges turns out instead of a perfect circle.

Council. DO NOT attempt to cut openwork mesh or intricate patterns with thin lines in drywall. The material may simply not stand up. The letter is strong only with a large pattern of wide lines.

Description of the cutting process

Use a tape measure to measure the desired distance. Draw a mark with a simple pencil. Once again, they will double-check everything, because there will be no possibility to fix the work.

Then they take a clerical knife and cut the cardboard along the mowing line of the marking. If there is any doubt about the hardness of the hand, then you can cut along the guide. It is very convenient for this to use the rest of the profile for fastening to the wall or a long building level. Sometimes one effort is not enough, after all, drywall is a fairly durable material. Then cut through several times.

DO NOT strive to immediately cut drywall with a knife. It’s impossible. There is a hammer for such work. All you need is that several times it will lightly hit the cut on the back of the sheet. The plaster base will crack safely exactly along the cut line.

All that remains is to turn the letter upside down and cut the second layer of cardboard with a knife. All is ready.

For a better joint of the pieces, the cut must be cleaned. Sometimes quite large notches remain there. Aesthetically, they DO NOT interfere, because all the same, the seam will be putty. But connection accuracy can be affected.

Chamfering. This is the name of this procedure. It can be easily done with sandpaper or a large file. But we recommend purchasing a special plane for such purposes. over, it stands very democratically.

Cleaning the incisions is performed with smooth movements, without strong pressure. Don’t try to achieve perfect smoothness. It is enough to remove large rags.

Someone will ask: why was a hacksaw needed? For cutting through holes. You can’t just knock them out with a hammer. Practice shows that drywall writing breaks anywhere, but not on the markup. For through holes, the execution technique is slightly different.

A hole is drilled in the sheet along the mowing line of the marking so that the hacksaw blade fits. Then, with the same hacksaw, cut out three sides of a square or rectangle. The fourth side cannot but get dusty. It is enough to cut through the cardboard on one side with a knife, and then knock out the Unnecessary piece with a hammer. The cardboard on the other side is also cut with a knife.

In the same way, corner squares and rectangles are cut out in drywall. One side is cut with a hacksaw, the other. With a knife and a hammer.

Council. There will be very few jagged edges at the cut if you hold a knife or hacksaw perpendicular to a drywall sheet. The lower the blade tilts, the larger the rags will turn out later.

How to cut drywall at home

07.01.2019 0299 Views

- 1 Preparation

- 2 Description of the cutting process

- 3 How to cut a circle in drywall

- 4 Useful tips

- 5: how to cut drywall with a knife

Many people align the walls and ceiling with drywall at home. Fast, convenient, perfectly straight. But the sheets are large and do not always fit exactly the size. Or you have to make a hole for an outlet, a lamp, attach a small piece.

Cutting professionals have special power tools, but they are always obscenely expensive. What should ordinary people do? How to cut drywall at home? In fact, it’s not as scary as you think. If desired, everything is quite doable in a few minutes. And the most popular tools will be needed.

Helpful hints

- Some people manage to cut drywall at home with an angle grinder. We do NOT recommend doing this. There will be a lot of noise and plaster dust. With a simple knife and hammer, it turns out much cleaner and more accurate. And you will NOT need somewhere to get personal protective equipment and the ability to work with a power tool.

- Glasses, plates and saucepan lids serve as excellent templates for marking circles. Just pick the right size and draw the line of the circle. This is in case there is no compass at hand.

- The jigsaw greatly simplifies most drywall work. Its blade is thin and stiff, with small teeth. With such a tool, you can drink even a square, even a dragonfly, any shape and configuration on drywall. If your farm does NOT have such a miracle of technology, then you can rent it. Many construction firms Provide power tool rentals.

- First, all the cuts are made and only then the drywall sheet is fixed to a permanent place. If the cut is made on an already fixed sheet, then in case of a possible error, you will have to remove the structure and attach a new sheet.

- It doesn’t matter which side you cut the drywall from. Facial or purl. It breaks equally well on both sides.

- If you have to cut a large sheet alone, then it is inconvenient to lift it with one hand and knock with the other with a hammer. Then they put a block on the floor and just break the drywall on it just along the cutting line of the cut.

- Some sources recommend using your own knee instead of a hammer. If you have a couple of new ones in stock, then you can knock out unnecessary pieces with them. True, humanity invented the hammer a long time ago. Try to use it anyway, and leave your knees for other purposes. For example, for the fifth point of a beloved woman, let him sit on them.

How to cut drywall at home? Very simple. Precise measurement and firm hand. These are the main components of a known success. And everything will work out with a bang.

Mounting knife

In this method, we need a drill and, in fact, an assembly knife.

To cut drywall with a mounting knife, you must measure the required size of drywall in length or width. We also need a metal ruler. We apply it to the cut mowing line. Then a cut of this material is made. The process itself is quite simple, It does not take much time. A sloppy edge left after a cut can be corrected with a planer. It is recommended when drywall is broken on the table, so that the edge protrudes by one or two centimeters, and when cutting on the floor, place any object resembling a block under it.

When cutting drywall by one person, a fairly convenient method is to cut a part on one side, after which the drywall is gently turned over to the other side and continues to cut on the other side. This method allows, if necessary, to cut thin strips of drywall with minimal damage.

The better to cut?

Drywall cutting is done by various types of tools, some of them are:

- Assembly knife;

- Hacksaw;

- An electric jigsaw is a hand-held power tool that sprays various types of materials using the reciprocating motion of the saw blade.

Let’s consider each of them separately.

Hacksaw

This tool will only allow us to cut out small shapes such as a circle, square, rectangle, rhombus and others. For best results, a fine-blade hacksaw is recommended.

Damn the shapes we need of the appropriate size, and then use a drill to make a hole corresponding to the size of the blade of our hacksaw. Then we cut out the shapes we need. Just as in the previous method, you can use a plane or a file to achieve neat edges if the size of your parts is too pic. It is recommended to use a hacksaw for metal, but if it is not available, it is possible to use a hacksaw for wood.

This process can be described in more detail as follows. The drywall letter is laid on a flat surface (you can use a stack of drywall sheets). Next, the necessary measurements are made, and the dimensions are applied with a pencil (or any other object) on a baking sheet. Marks are made on both sides of the sheet, starting from the edge of the sheet. Then they are connected to each other, forming the desired line or figure. In some cases, a marking thread is used. Mowing lines are marked on both sides of the drywall.

The next step is directly cutting drywall. The length of the blade of our tool does not have to exceed the thickness of the sheet. The sheet is cut with a knife (preferably several times to achieve the best effect), turning the letter over to the other side. Then he knocks on the cut mowing line several times, and cut the rest of the drywall with the same knife.

Features:

Drywall is a very young material used in construction work. It gained wide popularity due to its harmlessness, versatility, good sound insulation. GKL itself, as the name implies, consists of two sheets of thick cardboard and gypsum, placed between them. The standard width of one sheet is one hundred and twenty centimeters. Since drywall is large, during construction work it is necessary to resort to cutting it.

For cutting on drywall, we need a tape measure to obtain the desired dimensions (a ruler can also be used), a pencil, a pen (or any other similar tool), with which we will apply the shapes we need on a baking sheet, a tool for the cut itself (hacksaw, angle grinder , jigsaw, cutter), a roughing planer (for processing edges after cutting), a saw (can be circular or circular), or a drill with a crown. The cut of drywall, although it does NOT present any difficulties, but its incorrect spraying leads to a large waste of material, and, accordingly, to an unnecessary waste of money.

A brief process for cutting drywall is as follows. First, the drywall is cut, after the break. Also, the simple composition of drywall is easy to drill, which is necessary for making various holes.

This type of material is divided into various types depending on the endowed functions:

- Moisture resistant;

- Standard;

- Fire resistant;

- Acoustic;

- Increased strength.

Moisture resistant drywall is needed when used in rooms with an increased amount of vapors in the air. Fire-resistant plasterboard is used wherever there are fireplaces and near open flames.

Initially, drywall was used only for leveling surfaces.

There are three standard types of writing:

- 3000×1200 mm;

- 2500×1200 mm;

- 2000×1200 mm.

Depending on the type of drywall, their thickness also differs, which affects the complexity of cutting.

Ceiling drywall has a thickness of 9.5 millimeters, wall. 12.5 mm, arched. 6.5 mm.

Consider a few features when cutting drywall:

- It is necessary to place the drywall letter on a flat and stable surface as it is very flexible.

- If the drywall lettering is large, then the cutting must be done gradually.

- Make sure it is dry before placing the letter on the work surface. Wet writing will be unusable.

- It is recommended to cut from the side that will be located in the walls. This will allow you to later hide Possible defects formed during cutting.

- Protect eyes and respiratory organs with personal protective equipment.

Jigsaw

To achieve the desired effect, we apply the correct shapes or patterns to the lettering of gyrsokarton. Next, I place it on two stools (or any other supports) placed on both sides of the sheet. Then, using a jigsaw, we cut out the figures we have applied.

When cutting round holes, it is recommended to draw them with a compass, and when cutting out, drill a hole inside the circle. The edges after cutting drywall need minimal processing, which also saves us time and effort, being a significant plus.

How to cut drywall?

- Features:

- The better to cut?

Each of us has made repairs at some time in our lives. And many do it every couple of years. To insulate our home or create beautiful figures on the ceiling, in the bathroom or any other room, we often use a material such as drywall. And many of those who prefer to make repairs with their own hands wondered whether it is possible to cut drywall on their own at home, and how difficult it is.

Most often, the owners resort to the help of strangers (specialists), while spending a lot of money. This article will help you cope with this process yourself, rather than waste time looking for specialists, and will help you Get exactly the result you want.

Algorithm for cutting plasterboard with a stationery knife

It is worth starting by laying the letter on a flat surface and carrying out the markup. For marking with a tape measure, measure the distance that must be cut off, and put dashes indicating the places where the cut passes. To achieve a straight cut, marks must be made in several places, after which he will impose a level or rule on them after drawing a straight line with a pencil.

The next stage is cutting the outer layer of cardboard, for this, the clerical knife is pulled out to a distance of no more than 1.5 cm from the body, after which a cut is made with the corner of the blade, and you need to cut it strictly according to the marked mowing line.

After the top layer has been cut, the letter must be placed on the edge so that the cutting line is parallel to the floor. It is necessary to locate it from the uncut side. Further, crouching down a little and making an emphasis with your knees in the area of the cut, pull the upper part of the sheet towards yourself, thus breaking it. After that, the letter is lowered to the surface, cut side down, bent at an angle of 900 and the second layer of cardboard is cut along the corner. Cutting the sheet with a clerical knife is over.

Description of the process using various tools

First, let’s look at how to cut drywall in the most popular way.

Why cut drywall

The plasterboard cutting technique is used in all finishes using this material. The fact is that drywall sheets have standard dimensions and it is impossible to fit them to the dimensions of the wall without trimming, it does not already mean finishing some more complex structures.

Also, knowledge of how to cut drywall will come in handy when creating multi-level ceilings, making arches and design elements of complex geometry. Gypsum sheets lend themselves well to processing and you can cut out a part of almost any shape from them, if you know how to do it.

Making a hole for round lamps

Using a drywall saw, it is convenient to cut holes for lamps or switches, but in order to achieve an ideal even shape of a circle, it is better to use special drill bits for this. In order to cut a circle with such a nozzle, it is enough to mark only the center of the circle, install a crown of the required diameter and set a centering drill in the marked place to drill.

Cut out a curved line segment

If you need to cut a curly section, you can use a drywall saw. Work on a curvilinear cut, at home, is best done by laying the sheet on several stools or setting the letter on one edge. That is necessary for the free movement of the saw, without fear of touching it with any obstacle that can bend it.

Further, they begin to take their time to cut out a curly cut. If you need to process a large number of sheets, you can speed up the process by using a jigsaw with a saw for edge cutting on the laminate for cutting.

Drywall lends itself well to mechanical cutting, since it has a low density.

Cutting drywall at home without building skills

You have a renovation and want to do it yourself, but don’t know how to cut drywall at home. Look for someone who can tell you how to do this. Stop looking! Read the article and get down to business!

At first I would like to note why drywall should be cut in general.

How to cut drywall. Tools

We will immediately agree that we will talk about the most fundamental and ordinary things. The tools that are described in various books are not cheap for centuries and, in fact, they are needed by people who are professionally engaged in repair.

If you are NOT a professional or you need to make some minor repairs, then you can use the following kit:

- First. This is a tape measure and a pencil. Practically, these things are present in almost every self-respecting man. There are no requirements for them. The only thing is that the pencil must be sharpened, and the tape measure at least three meters.

- Second. This is a metal ruler. Preferably the longer the better. If there is a ruler, then you can take it as an ordinary flat metal profile. The profile may remain when assembling the frames.

- Third. This is a knife. If you choose a knife, you can use one of two options. You can take an ordinary clerical knife, and not too flimsy construction, or a special one with changing blades.

- Fourth. It’s a hacksaw. The saw can be any, ordinary for wood, even “dull”. The main thing is that it is NOT wide. The most optimal option for this. Knot saw.

- One of the professional tools, perhaps, is a roughing plane, designed for processing the edge of the cut. It is NOT advisable to replace it with any kitchen object such as a grater or a file. It is better to buy such a plane, because the price is not high for centuries.

Now the time has come when we will talk about what can be made of drywall at home.

How and how to cut drywall at home

Gypsum plasterboard is a very fragile material, which accordingly requires a careful and careful attitude to itself. The main and big mistake in construction, where drywall is used, is its incorrect cutting, which leads to its damage and it is necessary to outbid excess.

But in fact, there is nothing difficult about it. Once I even had to give advice and conduct instructions over the phone, while Driving. People were faced with the fact that it was necessary to cut sheets of gypsum plasterboard at home into different sizes, as a result, they solved this problem and got out of it.

How to cut drywall correctly

Its essence lies in the fact that this letter is reduced to certain sizes. This task is very easy and accessible. To do this, mark the desired dimensions with a pencil on both sides and put a ruler or profile and cut the top layer of drywall with a knife.

You do not need to cut the cardboard along the mowing line drawn with a pencil, it is better to attach a ruler and do it along it. Use the knife to cut 2-3 times to make the cut deeper. And only then the cut will turn out to be even and neat, it is possible that the cardboard can break in the right place for you.

Then put the letter on the cardboard edge, and approach it from the side where it is not cut and lightly knock on it. After a couple of blows, the drywall will break in the right place, clearly in size. The matter is small. Cut off the cardboard (paper on the other side), which is still holding the two halves together. Everything, the work is done, you can think that you have coped with this work.

Such a cut is needed if there are any obstacles during the construction of the structure, for example, you need to cut a letter under a window, door, etc. To do this, at home, you need to cut a square or rectangle on one side. It will not be difficult for you to do this.

On the one hand I cut it with a hacksaw, on the other. Let’s cut the cardboard as described above. And everything is ready. It remains only to process the edge with a plane.

How to cut round holes

Almost always, these types of holes are used for cutouts for an outlet, chandeliers in the ceiling, lamps, and more. There are two options for doing this. The first is to take a special nozzle with which holes are made for the lock in the door. Such a nozzle is pushed onto a drill, and after that a hole is cut.

With the second option, you will not need a drill, but just a hammer and a cut out circle of the desired size. You need to attach this circle and gently hit with a hammer. Of course, the effect will be worse than with the nozzle, but it can also be quite amiss.

This type of cut is usually used in toilets or shower rooms, since there are a large number of pipes and other plumbing units. The biggest problem is calculating the dimensions of the cutouts. First, it is advisable to check the contour several times on which the cutout will be applied.

If it is more than necessary, then there will be many problems with fastening the letter to the frame. If not suitable in size, then it will take your time to fit.

Next, you need to make a plan of your actions. Take a few more looks at your resulting drawing. Usually, in many cases, all curvature flaws are a hybrid of straight lines and a semicircle. For straight and semicircular you have your own tools. In those areas where you definitely intended to make a cut, use a hacksaw, and all uneven bends and roundness are cut out thanks to the knife.

That’s all, now you know how to cut drywall at home. There is really nothing complicated about it. Everyone knows that only with practice can experience come.

Advantages of GVL

To answer our question, you need to figure out what this material is. Gypsum-fiber sheets, like drywall, are made from gypsum plaster. But that’s where the similarities end. The main features of GVL are:

- Reinforcement with loose cellulose.

- Complete material homogeneity.

- Lack of top cover.

- Incombustibility.

- High density.

Many manufacturers are engaged in the release of this building material, but the GVL manufactured by the Knauf company under the name Superlist is the most popular. If we continue to compare gypsum fiber with drywall of the same company, we can see that they ideally complement each other. And the use of THESE materials in finishing work will simultaneously only benefit the repair.

Despite the fact that any box can be made from gypsum plasterboard, and the walls will be strong and non-flammable, nevertheless this material cannot be bent like drywall. This means that it will not work for the installation of complex structures with rounded shapes.

But on the floor, in dry screeds with expanded clay (KNAUF-SUPERPOL technology), gypsum fiber sheets are unmatched. Using them in the construction of a subfloor will give guaranteed positive results. Floor elements glued from two sheets of GVLV with a total thickness of 20 mm have the following useful properties:

- They DO NOT break.

- DO NOT pass the cold.

- Creates a perfectly flat surface.

- Moisture resistant gypsum fiber boards withstand humidity up to 70%.

Tools needed to work with GVL

Many who independently prepared for installation and installed drywall mistakenly believe that they work in a similar way with gypsum plasterboard. But here an unpleasant surprise awaits them. Gypsum-fiber sheets, with all their strength properties, when you take them for a break, turn out to be brittle and easily break. By the way, that’s why it is impossible to bend them like drywall.

Tools that cut gypsum fiber sheets at home:

- Sharp construction knife with a thickness of 12 mm. Blades will have to be changed frequently as they dull quickly.

- A special hacksaw for gypsum board, which can dust this material almost without dust.

- Use an angle grinder or circular saw only in a well-ventilated area and provided that the end justifies the means. This is the fastest way and also very dusty. If you decide to choose this tool, you will have to stock up on respiratory and eye protection.

- A jigsaw with a built-in vacuum cleaner is ideal if you install a saw on wood with a 4 mm tooth pitch. But there will still be a lot of dust, so you should work in protective goggles and a respirator.

What makes GVL dusty: how to cut sheets at home

When finishing work, gypsum-fiber writing, or GVL is often used. This material was created much later than drywall, so He did not gain such wide popularity as GKL. However, thanks to the special composition, these boards have outstanding strength and fire-fighting characteristics with indicators much higher than that of drywall. Therefore, GVL is indispensable for the installation of bulk floors, rough finishing of walls and ceilings, as well as for the construction of all kinds of boxes. The only question that arises when working with these building materials. How to cut GVL from “Knauf”.

Gypsum fiber cutting process

With any method of cutting, remember to be careful and careful when handling gypsum fiber boards. If it is decided to use cutters or a special hacksaw for work, then you need to proceed as follows:

- On the sheet of GVL we make the necessary markup.

- We apply a flat bar to the mowing line. You can also use the rule.

- We carry out the knife as many times as necessary so that the depth of the cut is at least 2/3 of the sheet thickness.

- We put the rail under the fishing line cut.

- With a sharp upward movement, gently break.

Before cutting it, it is better to additionally look at how to properly cut the sheet.

But the seam is most convenient to do with a boot knife-cutter or a chisel. For large volumes, you can use cutters. A groove cutter of 3-4 mm will allow you to perform the necessary work in 2-3 passes.