Drywall prices

Structural structure of drywall.

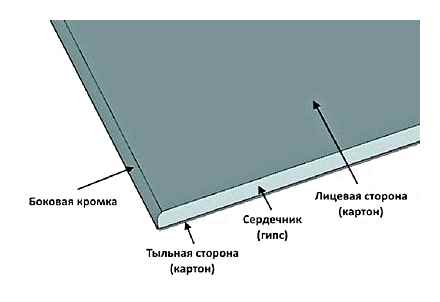

The structural structure of the sheet of this material is a three-layer “sandwich”. The outer layers are made of thick cardboard, and the core is made of a compressed gypsum mixture. The long sides of drywall usually have rounded or trapezoidal edges and are also protected by cardboard. The edge is not provided on the end sides.

Cardboard is produced in several types. this is an ordinary (GKL) material of gray color, moisture-resistant (GKLV) has green shades of the front side, fire-resistant (GKLO). pink or light purple, and moisture-resistant (GKLVO). a dark green shade. In addition, an innovative drywall is now on sale for soundproofing walls. It is made in blue.

How to cut drywall / Sheetrock

Most often, there are standard sheet sizes of 2500 × 1200 mm, that is, having an area of 3 m2. Other options are available, but they are less common: 2000 × 1200 mm (2.4 m²) and 3000 × 1200 mm (3.6 m²). The thickness of the sheets can be 12.5 mm (for walls), as well as 9.5 mm and 6 mm, which are usually used to create ceiling structures.

The table below shows the main standard dimensions of drywall with an indication of the approximate weight of the sheets. This is in order to be able to evaluate. the sheets are very cumbersome and rather heavy. That is, you should work with them carefully: they may not withstand the load on a fracture if handled carelessly. they break.

| GKL | 2000 × 1200 × 6 | 2.4 | 12 |

| 2000 × 1200 × 9.5 | 2.4 | eighteen | |

| 2000 × 1200 × 12.5 | 2.4 | 23 | |

| 2500 × 1200 × 6 | 3.0 | fifteen | |

| 2500 × 1200 × 9.5 | 3.0 | 23 | |

| 2500 × 1200 × 12.5 | 3.0 | 29 | |

| 3000 × 1200 × 6 | 3.6 | eighteen | |

| 3000 × 1200 × 9.5 | 3.6 | 27 | |

| 3000 × 1200 × 12.5 | 3.6 | 35 | |

| GKLV | 2000 × 1200 × 12.5 | 2.4 | 24 |

| 2500 × 1200 × 12.5 | 3.0 | thirty | |

| 3000 × 1200 × 12.5 | 3.6 | 35 | |

| GKLO | 2000 × 1200 × 12.5 | 2.4 | 26 |

| 2500 × 1200 × 12.5 | 3.0 | 31 | |

| 3000 × 1200 × 12.5 | 3.6 | 37 | |

| GKLVO | 2000 × 1200 × 12.5 | 2.4 | 27 |

| 2500 × 1200 × 12.5 | 3.0 | 32 | |

| 3000 × 1200 × 12.5 | 3.6 | 38 |

However, whatever drywall is used for construction or finishing work, it is cut in the same way.

How to properly cut drywall

There are some helpful tips to make your job easier:

- Drywall is a flexible material. In order not to break it during work, you need to put the sheet on a stable flat surface.

- When cutting a large sheet, it should be done gradually.

- The workplace should be free of moisture, otherwise the material will get wet and become unusable.

- Which side to cut the drywall from is not so important. However, it is best to cut on the surface that will attach it to the wall.

- When cutting a profile, don’t worry about jagged edges. They will subsequently be covered with a drywall sheet.

- When working with the material, it should be understood that it can crumble strongly and create dust. Be sure to protect your eyes and respiratory system.

What is drywall cut with? How to properly cut drywall

Today drywall is widely used in construction and renovation. You can work with this material yourself. However, you should first find out what the drywall is cut with so that there are no difficulties during the repair process. Below are the main ways to work and the tools you will need are listed.

Mounting support

This gypsum plasterboard tool is a lever arm mounted on a pedestal and equipped with a metal slide to hold the material. In the process of wall cladding, as well as the creation of niches and partitions, such a device ensures the vertical position of the sheet, which is attached to the profile. At the same time, the integrity of the lower edge of the mounted gypsum board is preserved.

Edging

The job doesn’t end with cutting drywall. Sharp and uneven edges need to be smoothed out. You can handle nicks and chips with sandpaper.

It is recommended to level it with gentle movements until a smooth surface is achieved. At the end of the preparatory stage, fascination is performed. Two-thirds of the thickness of the drywall sheet must be cut off at each end. Next, a chamfer is cut off at an angle of 45 degrees with a plane. If there is no suitable tool, you can use a regular knife.

After sanding the edges, place the drywall in the desired position. However, at this stage, numerous cracks appear that require a putty. Once the material is completely dry, the drywall surface is primed for additional reinforcement. Then they start painting or glue the wallpaper.

Successful examples and options

The lightest is standard drywall cutting. Following our instructions, it will not be difficult to deal with it.

Shape cutting will require more skill from you.

Having studied these methods of cutting drywall, you can easily independently complete this construction process alone, without resorting to the help of professionals, which will save money, as well as gain useful experience in carrying out construction work.

How to cut drywall quickly and evenly, see the next video.

How to remove gypsum dust?

When cutting drywall, very fine dust is formed, which is then difficult to remove. On smooth surfaces, it leaves white stains even after you wash the floor for the 3rd time, and clogs very tightly and reliably on porous or corrugated surfaces.

The easiest way is to prevent contamination. Use a jigsaw or other power tool to connect the vacuum cleaner to it. As a rule, there is a special round connector on the back of the case.

Cover the floor with newspaper or oilcloth. If they are moistened, the dust will settle and retain better, but if moisture gets on the drywall, it can ruin it.

Give preference to cutting with a clerical knife or circular cutters: practically no dust is formed when the gypsum layer is broken

Vacuum up the bulk of the plaster before cleaning the floor.

To clean a porous or matte finish. porcelain stoneware, textured linoleum. prepare a mixture of vegetable oil and water. The ratio is 1: 100, that is, 100 ml of oil per 10-liter bucket. Having washed the floor with such a solution, you will draw in the floor particles from the pores and recesses: they will all collect in an oil film on the surface. You can finally clean the floor with a vinegar solution.

A glossy floor, for example a tiled floor, will relieve white stains with a warm light pink solution of potassium permanganate.

In a straight mowing line

The most used method. Allows you to cut pieces of sheets to cover the remaining empty sections of the wall after the basic plasterboard finish. A cutting knife is usually used for cutting. The electric jigsaw is ideal for cutting thick arched sheets or cutting multiple plates at the same time.

- Take measurements on the wall.

- Measure the distance on the drywall sheet.

- With a ruler attached, draw the line to be cut with a pencil.

- Pressing the ruler firmly, carefully cut the sheet along the line mark, deepening the blade by a maximum of 5 mm.

- Move the plate lying on a horizontal substrate so that the cutting line is about 15 mm beyond the edge of the table. Tap your fist on the bottom protruding surface of the sheet until the gypsum core breaks.

- If the plate is installed vertically, pull the edges of the plate, trying to fold it in half. Tap on the front side that has no notch.

- Flip the drywall, cut along the mowing line of the break.

- Align the edge of the sheet with a plane.

Mounting knife

Optimal tool for cutting drywall longitudinally into large pieces. There are several types of assembly knives, all of them are suitable for cutting plates. An exception is a clerical knife. It is too thin and unreliable for cutting drywall sheets and any sandwich panels.

Useful tips for cutting drywall

In order not to have to redo the work, when cutting drywall, consider the following recommendations:

- Do not bend the plasterboard on two supports. Otherwise, it may crack.

- Do not press the knife blade hard into drywall. Otherwise, the edge of the sheet will turn out to be uneven, with defects. Also, with such work, the blade becomes dull faster.

- Work with a plane also without strong pressure on the material. Drywall edges are brittle and likely to crumble.

- It is convenient to cut a large plate on the floor. To break the cut drywall, place a stable support under it along the mowing line for cutting.

- Do not use an angle grinder, it is irrational to cut drywall with it. And there will be a lot of noise and gypsum dust.

- If you cannot squeeze out the cut piece by tapping your fist, use a mallet. Do not knock it too hard so as not to damage the edges of the drywall.

Cutting a round hole

Small circles are usually cut out after the drywall is secured to the wall. It is more convenient to use a drill. Pen and core drills are suitable for work. In this case, you do not need to mark the circle, you just need to make a central point mark for drilling along the guide.

You can also cut a circle with a narrow hacksaw. In this case, the markings are made with a compass. Then a hole is drilled under the hacksaw blade, carefully cut along the mowing line. With this method of operation, the hole is usually defective. It has to be processed with a file or sandpaper.

Drywall cutting methods

In order for the cutting of drywall to be even, without defects, when performing work in any way, you must follow the sequence of actions and a number of rules. There are 5 options for cutting sheets.

How to cut drywall. the necessary tools and cutting methods

Gypsum plasterboard is a material widely used in construction, with which walls are aligned, arches and two-level ceilings are created. It is easy to use, inexpensive. this is the reason for its popularity. Even someone who has never done finishing work before can understand how to cut drywall. The main thing is to follow the step-by-step instructions and choose the right tool.

- 1 The structure of drywall

- 2 Drywall Cutting Tools

- 2.1 Mounting knife

- 2.2 Hacksaw

- 2.3 Jigsaw

- 2.4 Planer

- 2.5 Needle roller

Aligning the drywall cut

The edges of the mounted plasterboard sheets are usually putty using a corner or mesh for reinforcement. Additional surface treatment is not required.

It happens that the cut has convex defects, due to which accurate installation becomes impossible. Either the corner is not used for the putty. In these cases, alignment is required with one of the following tools, selected for convenience for a particular job:

- Rasp.

- Sandpaper.

- Rough planer.

- File.

- Mounting knife.

Jigsaw

The advantage of working with an electric jigsaw is versatility, the ability to create lines and holes of any shape. It is convenient to operate the tool, cutting does not take much time, and the cuts of the plates are almost free from defects. The only drawback of the work is the scattering gypsum dust.

Cut to specified geometry

Figured cutting of drywall is used in the situation of creating unique shapes for a specific structural element. This procedure is more complicated, and you cannot do without basic experience and a sufficient arsenal of tools.

When curly cutting, the material is also marked first. If you need to draw a circle, but there is no compass at hand, then they arm themselves with a needle and thread and a tied pencil.

For curly cutting of HA in different situations, we will apply one of the methods described below.

Option one. Describes the process when a hacksaw is selected as the tool. Manipulating a hacksaw is akin to working with a serrated knife and a handle. Using a drywall hacksaw, you can cut out fragments with any non-trivial shapes (for example, butterflies or flowers).

Option two. An electric drill with a cylindrical nozzle allows you to create even circles of small diameter in drywall. The circle is not marked here, but limited to a mark in the desired area.

Option three. For cutting GVL with an electric jigsaw, a clear marking of the contour of the required shape is performed. Priority in the choice of a jigsaw is given when the diameter of the circle to be made must be greater than the diameter of the crown of the electric drill, and the rounded mowing lines of forms are not limited to a circle.

Option four. The most primitive, when the choice of tool comes down to a knife and a hammer. Drywall is cut along the outlined border. At the same time, they try to press on the blade as hard as possible.

Then the HA is placed on a flat surface with a depression. over, the detachable part of the element must fall into this hole. It is less effective to support the sheet against the wall. Then hit with a hammer in the middle of the fragment to be separated. The part to be removed should break. A layer of cardboard is cut from the bottom, leveling the ends as necessary. The GC masters strongly discourage people with no experience from using this technique. Since you have to spend a lot of drywall sheets for stuffing your hand and working out the pressure.

Introducing the toolbox

The obligatory list of tools for sawing gypsum fiber with your own hands includes three groups of objects

Devices for applying markings on a sheet of gypsum board. a simple pencil, tape measure, long ruler.

Cutting and sawing devices themselves.

- Knife. You can cut the gypsum fiber board with a clerical knife, as well as with a specialized construction knife with a double-sided replaceable blade (suitable for denser materials).

- Hacksaw. Better if it is a tool for processing metal than wood.

- Jigsaw. Ideal for cutting rounded elements. Least of all, high-quality saws for metal with a fine notch leave chips at the ends of drywall.

- Electric drill. Needed for making holes. For gaps of large d, you will need round crowns (which cut into the core of the door snap locks) and feather drills.

Edging attachments:

- roughing plane;

- chamfering planer.

This list clearly shows how the home craftsmen cut drywall. Of course, it is far from complete. The arsenal of experienced craftsmen may include professional equipment, for example, a special cutter for GVL. However, for those who are working with the material for the first time, this set is quite enough. To better understand how to properly cut drywall, you need to clearly understand the structure of this material.

Standard cut

Cutting the sheet in a straight line is the easiest way to cut. It boils down to the following:

GVL is placed on a hard and flat surface. Then mark the future mowing line of the cut.

Whichever knife is chosen, they should be cut strictly, placing a ruler on the side. An uneven cut is guaranteed if you decide to handle without a ruler. Cutting begins from the back (there is a thicker cardboard layer). The front part of the Civil Code is somewhat different, as it is intended for finishing work. When cutting, they try to deepen the knife as much as possible into the plaster content.

At the end of the process, the GK is turned over and bent in the direction of the solid (without the mowing line of the cut) side. Plaster not hit by the knife will break in the desired direction. The cardboard is cut from the opposite side along the formed mowing line of the fold.

It is not particularly important which side to start cutting drywall from. However, on a flat, dense surface, this is much easier to do than when holding the GL in weight.

Before you cut drywall with improvised devices, you should familiarize yourself with two more types of simple cutting, feasible for independent implementation.

Double-sided cutting. often, cutting in the form of any rectangle is performed in this way. With a hacksaw, one of the sides is sawed, the other is simply cut with a blade. After that, the material is cracked, and the cardboard is cut from the opposite side (as in a simple cut). The finished cut is polished to perfection using an edging planer.

Cutting on uneven mowing lines. To cut material along uneven lines, you must first prepare a drawing.

The structure and purpose of drywall

Plasterboard sheets are a layer-by-layer combination of two types of materials. gypsum (inner content) and sheets of thick cardboard glued to it on both sides. It is clear that if the cardboard layers are damaged, it is not difficult to cut the rest.

Therefore, in order to be able to quickly cut a sheet of gypsum plasterboard, it is not enough to know the best way to cut drywall. It is important to know the basic principle of this action: after the continuous even cutting of drywall is carried out, the second step immediately follows. breaking the sheet.

Sawing drywall, like any solid porous material, is not difficult. It also lends itself well to drilling.

The functions of the material make it possible to differentiate it into varieties: moisture-resistant, fire-resistant, standard, increased strength (for example, gypsum board or gypsum board made using Knauf technology), acoustic gypsum board, etc.

Despite the large assortment of GK, panels of any of its varieties lend themselves well to dividing into parts by means of the available material at hand.

Choice of methods for cutting HA

What method of cutting drywall to resort to will become clear after studying the options available for these purposes.

Drywall cutting

Newbies in the construction business do not know how and how to cut drywall in the best way. After all, any work, whether it is the creation of a ceiling structure, partitions or a complex decorative element, requires knowledge of the rules for cutting gypsum board and strict adherence to them in practice. Different tools are used for these purposes. It all depends on the chosen cutting method. So, how to cut drywall at home, the recommendations below will tell you.

The nuances of making circles

Circles in the ceiling structure are made primarily for the installation of luminaires. The easiest way is to cut a circle of a given diameter in the gypsum fiber with a blade. And gently knock out the middle part with a hammer. However, it will be easier to carry out what was conceived would be a drill with special equipment. a cylindrical nozzle. The same one that is used when cutting into the door of the lock mechanism with a latch.

Cutting after installation of gypsum board

Of course, it is more convenient to cut material that has not yet been fixed. But in practice, there are situations when cutting off the excess is required after mounting the sheets to the frame. Such trimming is due to the fact that the sheathed surfaces meet window slopes or corners on their way.

The sheet is fixed on the wall, leaving a small margin of size. Already on the wall, remove excess centimeters.

It is important to make sure that the HA is securely fixed to the frame. The incision is made on the side that is in contact with the wall. The cutting movements are repeated several times, following the markings. At the same time, they try to “squeeze out” unnecessary parts of the material. The sheet is cut from the other side.

Having studied these methods, beginners will understand how to cut drywall with a minimum set of tools at home. If you need to cut large quantities of HA, these options will not work. The best solution would be to turn to professionals.

How to properly cut drywall

Anyone who has worked with drywall at least once understands perfectly well that this building material must be cut to the required size. Under ideal conditions, most drywall sheets are installed in one piece. If the walls are aligned in a large room, then you will have to cut the gypsum board a little, and this can be done under the ruler. However, in small rooms, you will have to constantly cut the sheets so that they lie perfectly flat.

Everyone who has started repairs using this material has to think about how to cut drywall. Fortunately, if you just need to cut the material to the desired size, but what if you need to create non-standard shapes, such as arcs, triangles, ovals, etc.? Let’s consider all these nuances in more detail.

How and how to cut drywall at home video

Have you started renovating your house? It is not always possible to find well-qualified workers who will do “the right thing”, and as the saying goes: “If you want to do something, do it yourself! especially since it will cost several times cheaper than hiring workers in whose professionalism there are doubts.

This will be discussed in this article, or rather, what kind of drywall happens, how and how to cut it at home, with your own hands, and of course, step-by-step instructions.

Which tool to choose

How to cut drywall at home? To answer this question, you need to understand what kind of work needs to be done. If you want to make a hole for the outlet, then this is one situation, if the sheet is simply trimmed to the size of the wall, then this is a different situation. A completely different approach is required in cases where curly shapes are given to the edge of the sheet.

Regardless of the tool chosen, it is always necessary to pre-mark. Only after marking and checking its correctness can you start cutting drywall.

The most common tools used for cutting are:

Stationery or kitchen knives are really amateur tools. It makes sense to use them only when there is nothing else at hand. As the saying goes, if there is no pencil, then the markings can be done with a nail. So here, if a construction knife was not at hand, then you will have to take any other. However, thick sheets can be difficult to cut with such tools.

Everyone determines the entire list of necessary tools for themselves

How to cut drywall with a construction knife? First you need to make sure that the correct tool is selected. A construction knife must have a double-sided blade. It is clear that you can only work with a sharp blade. It is necessary to lay the sheet on a hill and make several cuts with such a knife along the intended mowing line. It is advisable to attach a metal ruler or profile along which the incision will be made. Then the sheet is cracked along the cut line of the cut. Cardboard on the reverse side of the sheet is easily cut when the gypsum board is already broken.

A hacksaw for metal is good because it has a thin blade. As a result, the edges of the sheets will be practically notch-free due to thin cutting (the structure of the saw teeth and its thickness accompany this). When working with a saw, drywall should be as if on weight, because you need a place on both sides.

The jigsaw is good when you need to cut shapes of varying complexity.

Next, let’s take a closer look at how to cut drywall at home using various tools.

Required tools

Of course, it is easier and faster to work with professional devices, but the article is devoted to how to cut drywall at home and with your own hands, so we will use the standard set of tools of any man.

Let’s talk about how to process drywall quickly and without delay. First of all, in order to cut dry gypsum plaster, we need: a ruler (profile), tape measure and a regular pencil. In order to cut the canvas, we will use a clerical knife. You need a hacksaw to create curved lines.

This is followed by the processing of drywall, it needs a skin. Drywall step by step instructions for self-taught masters. Below is a step-by-step instruction on cutting plasterboard with a stationery knife (standard).

- In order to make an accurate calculation of drywall, on the seamy side of the sheet (the one that looks at the wall), using a tape measure, mark the desired distance and draw a straight, even fishing line with a pencil and a ruler. To simplify the subsequent work, use a pencil, it will not be visible under the layers of plaster and putty, unlike a felt-tip pen or a pen.

- How to cut drywall correctly? We place the gypsum board on a flat surface, you can on an old table. With a clerical knife, carefully along a ruler we make an incision in the paper layer on the seamy side, we do the same on the front side. Then we press harder and cut along the previously incised track from the back. If you want to show imagination and be creatively realized, you can make the stripes not straight, but curved, using a compass or outlining a saucer or mug.

- Then the sheet must be broken, and the resulting corner and the uncut layer of the front part must be cut. Make sure that the paper does not come off, otherwise you will have difficulties in your work.

- Next, you should process the edges on each side of the drywall. Since after such a trimming with a knife, irregularities and pieces of cardboard with gypsum will remain. Sandpaper the cut, and in addition, you can use a damp cloth to get rid of dust and process the drywall joints. This completes the preparatory work with drywall.

- When the installation is carried out, check the evenness using the building level.

- The joints of the sheets are primed and, in order to avoid cracks in the putty and plaster, a reinforcing tape is glued. To fill the joints, dilute very little of the plaster putty solution. This will make it easier to work and there will be no unused material.

- The particular advantage of this method is its silence, purity and simplicity. After all, if you use mechanical prof. tools, debris scattered throughout the house cannot be avoided, as well as the noise from the device that will bore you and your neighbors. Using a construction or office knife, there will be no such debris and dust, and therefore there is little noise and a minimum of cleaning.

This cutting option is needed if working with drywall involves sheathing a doorway, windows or a built-in wardrobe. To begin with, we calculate the drywall, set aside points at a certain distance with a pencil, and draw.

When we have drawn the width and length, the short side can be cut with a hacksaw, but the long one is processed in the same way as indicated above. Do not forget to process the edges of the blade after the hacksaw, because it is rougher and the edge will “swish more than a knife! By following all the points, the process will not only become easier, but it will also be enjoyable. Shape cutting, making round holes and bending parts.

Figured cutting is performed using a hacksaw. Drywall 2500 x 1200 mm is great for shape cutting. You can draw a curly ornament and decorate with it a part of the plasterboard wall or create an unusual partition in the room, the detail will be unique and give individuality to your project.

Round holes are required for recessed spotlights as well as outlets. It is very convenient when there are spotlights in the ceiling or in the closet. Bending drywall is a long and painstaking process, for these needs 5 mm thick drywall is suitable. From the back side, the gypsum board is passed with a needle roller, and then moistened with water to soften the gypsum.

Then the part is carefully, slowly bent, fixed and left to dry completely. Wetting should be carried out evenly, and not bend immediately, but after a short period of time. It is also not worth pressing hard, otherwise the canvas may crack and crumble. This method is useful for finishing and leveling the opening, well, or in the case of creating semicircular arches or rounded corners on the ceiling.

If a not strong transition from straight to rounding is required, cuts are made across the canvas, then bent, giving the desired shape. It is possible that stripes appear in places of fold, but everything is perfectly overwritten with plaster. During installation, if a wall cladding is provided, do not lean the canvas tightly on the floor, otherwise subsidence is possible.

To prevent undesirable consequences, a piece of the same material should be placed under the sheet. Another practical tip: Before cladding, make sure the wall surface is dry from the rough finish and primer.

Otherwise, sewing up the wall with gypsum plaster, it is possible that unwanted moisture may appear, and subsequently fungus! Which can adversely affect human health. Depending on the type of wall, brick or concrete, dry gypsum plaster is mounted on the frame. The frame can be either iron or wooden.

It is possible to glue the sheet to the wall (frameless method) using specialized glue and mastic. In the frame method, there are advantages, in the formed space between the wall and the canvas, you can put insulation (for example, mineral wool), thereby increasing the heat capacity in the room, as well as further increasing the sound insulation.

In itself, this is a convenient and practical type of interior decoration. It evens out, insulates, hides communications (electrical wires, plumbing pipes), but also gives charm and modernity to your interior.

In general, there is plenty of flight for imagination! The main thing is not to rush and do everything with heart, adhering to our tips and step-by-step instructions. We hope this article helped you in your choice, and gave you enough useful advice on working with GCR.

How to cut drywall quickly and smoothly

Rules for working with a hand hacksaw

If you need to cut off a piece of drywall of a special shape, then it is rational to use a hacksaw, because you cannot achieve such an effect with a knife. It is necessary to create arcs, waves and other curly edges on a drywall sheet. These forms are especially relevant when creating a multi-level ceiling and interior partitions.

Again, the whole process begins with the fact that the markings are made on the gypsum board. The order of the markup depends on the specific task. It is one thing to make a circle for the hole for the outlet, and quite another thing to make the “daisy on the ceiling.

Especially convenient to cut arcs with a hacksaw

When creating a pattern, pattern, or mowing line to cut, you need to consider the entry point for the hacksaw. Somehow she has to go through the drywall to cut it. After the hacksaw is inserted into the gypsum board, you just need to cut along the marked lines. It is desirable that they do not have strong bends, because such a turn is extremely difficult to repeat.

This pattern is understandable if you need to cut from edge to edge. But how to cut drywall if the shape is not in contact with the edges of the sheet? In this case, you need to punch a hole with a knife somewhere in the middle on the marked mowing line. The hacksaw will be inserted into this hole.

The composition and types of drywall

First, let’s take a look at the composition of drywall. First of all, a finishing material consisting of compressed gypsum located between two cardboard layers, due to which the properties of drywall are strength, and the core does not scatter into small fractions. Depending on the main filler and cladding, the following types of drywall can be distinguished: Plasterboard is ordinary. it is used in all rooms that are not associated with fire and water.

Waterproof. plasterboard walls in bathrooms, swimming pools and other areas with high humidity in the air. Fire resistant plasterboard finish. used in places subject to high temperature and fire (fireplaces, heating elements, stoves).

Plasterboard walls must have all the protective properties. Types of drywall also differ in the color of the facing (cardboard). Drywall color is usually gray, sometimes blue. Moisture-resistant is green and fire-resistant is red.

There is another type of dry gypsum plaster. moisture resistant gypsum plasterboard plus protection from open flame, few people are engaged in the production of such material, one of the few is Knauf drywall. The size of drywall is usually standard (length. from 2 to 4 m; width. from 60 cm to 120 cm, thickness. from 6 to 12.5 mm). But depending on the place of application, these values change.

How much should a plasterboard sheet weighing 1 m2? During installation, the priority is to find out how much a drywall sheet weighs, in order to choose suitable fasteners, profiles, etc. Drywall is standard, 1 m2 in size, depending on the thickness: 6.5; 9.5; 12.5 millimeters, has a weight of 5; 7.5; 9.5 kg.

The choice of drywall on the market is great, the question is: which drywall to choose? Which is good, which drywall is best? Should proceed from its immediate intended purpose and the type of premises.

So, we figured out the choice, now we turn to the question, but how to install drywall with your own hands? Here we will look at the best ways to cut drywall, how to build drywall walls yourself and some basic ways to cut it. Working with drywall is quite simple, it is not at all difficult to cut it.

But do not forget that “the sandwich is sandwiched with plaster, and after you evenly cut the cardboard, every millimeter is important, then gently break the material.

How to cut drywall with a knife

How to Cut Drywall EFFICIENTLY!

We use a construction knife

It is rational to use a knife in cases where you want to cut off an even piece of drywall or dissolve it in two. These are the situations that prevail in the repair process.

The procedure for cutting the gypsum board with a knife

The first step is to take measurements to determine which piece needs to be cut. By drawing the line through the place of the future cut, we will simplify the whole process for ourselves. Often, several sheets are marked up at once or one sheet in several places. Therefore, they take a pencil, the line from which will be clearly visible.

A ruler or profile is applied along the edge of the mowing line, which should fit snugly against the drywall. In this case, the building material should not sag. The edge of the knife is pressed into the line and, with pressing, is drawn along the ruler several times.

Now the sheet needs to be broken with a cut outward. For this, drywall is laid on the edge of the table so that the incision protrudes slightly beyond this edge. Usually they hold the sheet with one hand, and the cut part is broken with the other.

The fracture can be done with a precise blow with the palm of the hand on the back of the sheet. Someone taps with a hammer or knee.

The broken sheet is placed at an angle on the floor, after which a whole piece of cardboard is cut in order to separate the cut piece. The edges are processed with a planer in order to remove burrs and make a hollow for high-quality sealing of seams.

From the video below you can learn how to properly cut small drywall directly on the floor.