How to cut hardened glass at home. How to cut paved glass

Glass products have been very popular at all times: frescoes, dishes and many other things created from scraps of this material have always struck people with their grace and smoothness of lines. Looking at this splendor, it seems that in order to create it you need to be a real professional who has vast experience with glass and a lot of necessary tools, and for a simple “mortal” do not master this complex science. In fact, not everything is as sad as it seems at first glance, and everyone can get knowledge of how to cut glass at home.

The most ordinary sheet is called the hardened glass (the manufacturing temperature and the hardening temperature during the production of ordinary glass coincide and are approximately 660 O C), which is cooled very quickly, using blowing (cold air) on both sides of the finished sheet. Hardening (process) is due to very fast cooling. The glass hardened in this way has high mechanical strength, resistance to high temperatures and increased safety (in case of destruction, the glass breaks up into a large number of small and non.resistant pieces that will cause special harm to a person).

Tempered glass is used as a showcase.

The inhabitants of the former USSR are familiar with such glass. it was called “Stalinist”. This is due to the fact that with such cooling, in the crystal lattice of such glass, the residual compression voltage appears. Due to its three positive qualities, such glasses are widely used in the construction sector, in the production of dishes, they are used as windows of supermarkets, in various social institutions (schools, universities, hospitals, etc.D.), in the manufacture of cars and other machines.

The main drawback of such material is its vulnerability with mechanical shots to the ends. Even with a weak blow to the sheet edge, the glass is broken into a bunch of small fragments, and the whole sheet becomes unusable. However, even such a drawback found its application in everyday life. it is used if you need to create the effect of “broken glass” (in the design of furniture or dishes).

Most often you can find tables or cabinets with “broken glass”.

This effect is achieved through the use of 3 sheets at once: the upper. whole, the middle. broken, lower. whole.

Manufacturers of such leaf glasses do not recommend (and some even prohibit) cut such glass at home, since there is a high probability of leaf damage. And how then there is a cutting of hardened glass in domestic conditions?

Nuances when cutting at home

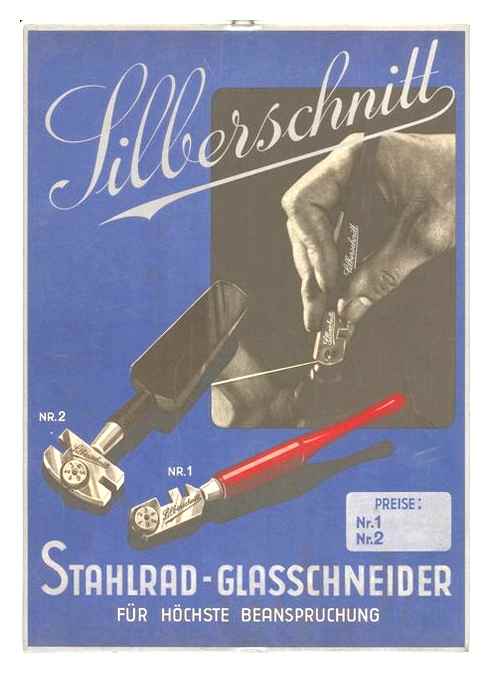

When considering the question of how to cut fisted glass at home, you need to pay attention to the choice of a more suitable tool. The following glass cutters were distributed:

- Diamonds today are used extremely often. Due to the use of durable and solid material, the tool can last for a long period. From time to time, it is necessary to sharpen the cutting edge when using a special sharpener stone.

- Roller. Cutting hardened glass at home is often carried out when using such a tool, since it is ideal for the work under consideration. There may be 6 videos that are often made from cobalt and tungsten. Due to the combination of a large number of rollers from durable and wear.resistant material, the task of cutting is significantly simplified.

- Oil is similar to the option with rollers, but at the same time the design has a special oil storage container. When performing work, lubricants are added to the cutting zone, due to which the cutting process is greatly simplified. That is why such a version of execution is used more often than others.

Before direct work, you need to check the degree of sharpening of the cutting edge. When using a worn tool, the processing quality is significantly reduced, there is a possibility that the created fishing line for the cutting trimmer will have insufficient depth.

Precautions and safety precautions

Before cutting off the mirror, it must be understood that this type of activity poses a potential threat to the performer.

Many design projects require non-standard mirrors in the interior.

Therefore, in order to protect yourself from unforeseen production injuries, it is important to adhere to the following safety measures:

- Mandatory put on protective glasses and gloves. Eye protection is required, since small fragments that can accidentally get to the mucous membrane will subsequently inflict irreparable damage to the body of vision.

- Prepare a special box in which production scraps will be folded. It is imperative to do this in order to prevent small parts of the glass from getting into clothes or not cut about them.

- The surface on which all manipulations will be carried out should be exclusively even and large in area. Also, all improvised tools and materials should be nearby.

- After glass or mirror was cut at home, it is necessary to wipe the working surface and the floor around it with a damp cloth. This manipulation should also be performed with all precautions. Otherwise, you can drive small fragments under the skin, from which it will subsequently get rid of it is quite problematic.

Before cutting the mirror with glass cutter, read the requirements of safety precautions.

Cutting with scissors in water

They resort to this method when a small piece of glass must be given in a form different from a rectangular. It is not suitable for working with sheets thicker than 4 mm and fan.

Put the container and fill it with water. The liquid will play the role of lubrication and create external pressure, preventing cracking. The scissors should be strong, tailoring is well suited. The glass is held with a hand and immersed in the water, the deeper the better. Then they break off with scissors a small piece from the edge of the sheet, then another one, etc. D., until they get the desired shape. When cutting complex figures on either side of the glass, a pre.prepared template made of dense cardboard is glued.

Cutting with scissors in water

They resort to this method when a small piece of glass must be given in a form different from a rectangular. It is not suitable for working with sheets thicker than 4 mm and fan.

Put the container and fill it with water. The liquid will play the role of lubrication and create external pressure, preventing cracking. The scissors should be strong, tailoring is well suited. The glass is held with a hand and immersed in the water, the deeper the better. Then they break off with scissors a small piece from the edge of the sheet, then another one, etc. D., until they get the desired shape. When cutting complex figures on either side of the glass, a pre.prepared template made of dense cardboard is glued.

Victive drill

The presence of a winning drill with a non.extended tip can really help out when it is necessary to cut off the glass without glass cutter. The plus of the method is that other tools do not need work. A flat large table is cleaned of crumbs and other garbage. The cover of the soft fabric, such as woolen cloth. Then put glass, apply a guide ruler and cut off the desired part with one movement of the drill towards themselves. It is worth making sure that the cutting tool concerns the material with the most acute side of the tip. Compared to glass cutter, pressing on the drill must be stronger. At the end, the edge of the sheet is chopped so that the groove created on the surface goes parallel to the countertop at a distance of 3-5 mm. The master, holding the glass with one hand, the second with a sharp movement down breaks off the cut off part. If he does not have enough strength, then he tapps a hammer along the cut line from below, after which he repeats the attempt.

When cutting corrugated glass, the side with a rough surface rotates to the table, and the master works with smooth. Also refers to mirrors and glasses with a pattern.

How to cut off: instruction

First prepare the surface of the glass. It should be well washed, rid of fat and dried. If stains or stains remain on the surface, the cutting tool can slip, which will lead to a crooked chip. As a working surface, it is better to choose a table or piece of wood-mounted plate. On it you can lay a cut of dense fabric (tablecloth, sheet) or linoleum.

After preparing the surface and materials, markings should be carried out. If you need straight edges, it is better to draw them on a thick ruler, for smooth lines you can use patterns. So that the thing does not slip, you can fix it with pieces of islands from the inside. Then, with the help of a file, a corner grinder or other cutting tool, a even clear fishing line for a trimmer is carried out.

When the cut is ready, you should break the glass. A small object is placed under it (match, nail, pencil) and easily pressed with both sides. You can also split the mirror on the edge of the table, or knock on it with a small hammer from below.

Important! If the glass does not go out, you do not need to use gross strength and crush very much. It is better to make a second incision at a distance of 2 cm from the first.

How to cut a glass bottle

There is a separate way to cut the bottle.

To apply it, you have to prepare some materials:

- A bottle that needs to be cut;

- Natural twine made of wool, cotton or flax;

- Combustible liquid (kerosene, gasoline or alcohol);

- Matches or lighter;

- Cold water container (bottle, glass).

At first, a fishing line for a trimmer is drawn on the glass, which determines the necessary sizes and the shape of the future item. Then the twine is thoroughly impregnated with combustible liquid, laid on the bottle over the marking and set on fire. When the fire completely goes out, you can start pouring water from the vessel with a thin stream along the marked line. The glass should crack on its own, it remains only to break your hands slightly, and then fade with sandpaper.

If the crack on the glass has not appeared, you have to repeat the whole process again. You can lay out the twine figure, then in the end you get pieces of glass of bizarre shape. In the same way, you can make holes in the bottle.

All these methods allow you to successfully cope with glass cutting even a person without special preparation. No need to be afraid to experiment, this work is not as difficult as it seems at first glance. The main thing is to believe in yourself and use ingenuity.

How hardened glass is cut

The difference when processing ordinary and hardened glass only in the fragility of the last. The methodology with a corner grinder and a diamond disk is suitable, but you need to work extremely carefully. A method with a soldering iron can also be useful (depending on the thickness of the material), and it will definitely not be a Focus with water and scissors.

How To Cut Glass, Without A Glass Cutter? Here Is How

There are several options. either drill with a drill with a winning nozzle, organizing a surface of plasticine with a campaura and turpentine, or the thermal method. To do this, apply moist sand of a small fraction to the glass, and with the help of a sharpened bar they make a funnel in it, where they dripped with molten solder or lead. After a couple of minutes, sand and solder are removed.

Maybe someone considers a list of incomplete methods-we have a lot of Kulibins, and there are many more options for solving the problem. But the plus of the described methods, and fatty, is that they work.

How to cut glass without glass cutter

Some staglores advise cutting glass with a woolen thread, which is placed or wrapped in the alleged place of cutting glass, then it is moistened with kerosene, and then set fire to it. After the thread burns, the glass is dipped in cold water, where it breaks up into the desired halves.

You can try to cut the glass with a corner grinder, putting on a fine.grained circle, but you need to do this very carefully, adhering to all precautions.

Correctly cut glass without glass cutter:

In order to cut off glass without glass cutter, you can take a nail or any sharp object. Just this option will take you much more time.

There are still ladies’ files with diamond coating, but they are suitable only at once.

After you spend one of these items on the glass, you need to lightly knock from below at the place of cut.

They say that you can cut the glass with scissors under water.

And you can also stick some rope, wet it with kerosene, set fire and lower it into cold water-the excess falls off.

True, not one of the ways I myself tried.

Cool methods, especially with scissors!. 4 years ago

My husband cut the glass with a corner grinder, it turns out, but it is necessary very carefully and on a flat surface.

HOW To CUT Glass WITHOUT a Glass Cutter!

Yes, I cut a soldering iron.Well, just need to be careful.

If the glass is thin, then it can easily be cut with ordinary scissors, having previously released it into the water. Dvochka is cut like clockwork, I personally tried. But the troechka is already hard to give in, but carefully cuts carefully. If the glass is overhemed, then, unfortunately, it will not be able to cut it with anything, even glass cutter.

How to cut glass without glass cutter? 3 practical ways

Life can sometimes puzzle with a completely unexpected problem. For example. how to cut glass without glass cutter, if it suddenly did not be at hand, and work needs to be done urgently? Not everyone has it in the list of necessary tools. I don’t want to buy it for one.time work. once in a life to cut a new mirror, and then the tool will be lying for years without use.

For example, in the evening, young football players knocked out your glass with a ball. You lock the slot with glass from any interior, but it is slightly larger in size. What to do? Glass cutters are clearly not working, running around the neighbors in the search is not a fact that you will find. So that you have to recall folk methods of combating fragile material.

How to cut glass without glass cutter? Several ways have been invented to solve this problem. Each of them gives quite high.quality results. We hope that our tips will be useful if the necessary tool is absent or lost among other things.

The method is not universal and is suitable only for thin glasses, with a thickness of not more than 3 mm. But almost the easiest. In addition, it allows you to cut not only in a straight line, but also figuratively, if you needed glass of a certain shape (for example, the doorbell insert). Another drawback. you will not be able to cut too big a piece.

First of all, take a fragment of the same glass and try to trim on it. If the glass cracks in the process, it means that it is hot, and this method is not suitable in this case. If everything is in order, then we start.

The desired contour is planned on the glass with a marker. Or a fishing line for a trimmer is carried out if you just need to cut off the excess. Some masters advise cutting out a cardboard template and stick it on the glass. In our opinion. not the best idea. Firstly, the paper will soak, and its rags will interfere with work. Secondly, problems with glue may arise: the water-soluble will not hold the template, and then the waterproof will have to be removed from the surface-unnecessary troubles.

Water is poured into a wide basin. The edge of the glass to be pruning is lowered into it. The deeper the piece is immersed, the easier the process will go. the water pressure helps it.

Strong scissors like tailoring are taken, plunged under the surface, and trimming begins. Sensations are more difficult than when paper or fabric is cut. Rather, they resemble work with cardboard. At the same time, crumbs are also formed, so it is better to cut in protective glasses in case of rebound if you are not deeply loaded into the water.

Gloves will not hurt either. And perhaps they will be even more useful than glasses, since you will not notice fragments in water, and they cut it strongly.

Many do not believe that scissors cut glass, and are very surprised to try that this is really possible.

In cases where the glass is thick or so large that it is not placed in the basin, it is proposed to be found in a soldering iron. Some used wood burner for similar purposes. And especially poor on the tool. even a hot nail. Although it will have to be busy with him with cutting glass for a very long time, since it is necessary to constantly heat it.

- Glass is laid on a flat surface.

- A fishing line for a trimmer cut. Here, by the way, a figured cut is also available.

- At the very beginning of the line, on the edge of the glass, neat, not too deeply tiled with a file or a file, is made. You can tear the edges of the corner grinder (only extremely, carefully, at the lowest speeds!) or even scratch it with a nail.

- The soldering iron is turned on. When heated, inserted into the incision.

- The soldering iron slowly, without much pressure, is carried out along the drawn circuit. If the fishing line is straight for the trimmer, and you are not sure that at such a low speed you can draw it evenly, attach a metal ruler and move the soldering iron along it.

- A thin crack appears behind the instrument along the drawn line. To divide two pieces of glass, a thick mitten is put on (a kitchen-bag is suitable at home) and an unnecessary wrapping is carefully broken off. If you have a curly cut, it is better to lead the soldering iron as slowly as possible, so that there is a fraction of a millimeter remained, and the openwork was not damaged when separating pieces.

How to cut glass without glass cutter

Some staglores advise cutting glass with a woolen thread, which is placed or wrapped in the alleged place of cutting glass, then it is moistened with kerosene, and then set fire to it. After the thread burns, the glass is dipped in cold water, where it breaks up into the desired halves.

You can try to cut the glass with a corner grinder, putting on a fine.grained circle, but you need to do this very carefully, adhering to all precautions.

Correctly cut glass without glass cutter:

In order to cut off glass without glass cutter, you can take a nail or any sharp object. Just this option will take you much more time.

There are still ladies’ files with diamond coating, but they are suitable only at once.

After you spend one of these items on the glass, you need to lightly knock from below at the place of cut.

They say that you can cut the glass with scissors under water.

And you can also stick some rope, wet it with kerosene, set fire and lower it into cold water-the excess falls off.

True, not one of the ways I myself tried.

Cool methods, especially with scissors!. 4 years ago

My husband cut the glass with a corner grinder, it turns out, but it is necessary very carefully and on a flat surface.

Yes, I cut a soldering iron.Well, just need to be careful.

If the glass is thin, then it can easily be cut with ordinary scissors, having previously released it into the water. Dvochka is cut like clockwork, I personally tried. But the troechka is already hard to give in, but carefully cuts carefully. If the glass is overhemed, then, unfortunately, it will not be able to cut it with anything, even glass cutter.

Glass products have always been very popular. The beautiful dishes, stained glasses, frescoes and much more are made from it (see. a photo). To make all of the above material, it is necessary to cut into different slices in size. How to do it at home? Everything is very simple. Glass can be cut in several ways. using glass cutter or without glass cutter using ordinary scissors.

Before considering how to cut the glass, it is necessary to determine what types of it are, because further actions will depend on this. For example, cutting ordinary material should not cause almost any difficulties. It can be carried out both using glass cutter and with scissors. But cutting hardened glass at home is not recommended, because it will lose all its properties. It is best to cut it before hardening, and then entrust this process to professionals.

The corrugated glass is most often used for glazing doors or to create interesting interior elements. As well as ordinary material, it can be cut at home with the only difference that the incision must be done on the smooth side. It’s good if the roller glass cutter is at hand for processing such glass. You can cope with organic material without glass cutter, using a cutter, ordinary saw or other tools for cutting. With a glass, the thickness of which is no more than 2 millimeters to cope with a perfectly and stationery knife.

First of all, before the harsh it is necessary to take care of your own safety, protecting the face and hands from fragments. After that, you need to prepare the material with your own hands. It’s enough to wipe the new glass, using a crumpled newspaper for this, for example, for this. With old material you need to work a little longer. First, it must be thoroughly washed with clean water, and also treated with a means of washing glasses, then degrease, for example, with alcohol or gasoline and dry well (see. video).

The method of cutting the material using glass cutter is quite simple. The main thing is to choose the right tool. For example, you can choose a diamond device, such as, for example, in a photo, which has been the most popular for a long time, or glass cutter with a slightly beveled cutting edge. The latter can cut the material up to 10 kilometers, after which it must be sharpened in a special bar. The roller instrument can consist of 1-6 rollers that are made of cobalt-wolframa alloy. Oil windshields work almost in the same way as the roller, with the only difference being that its holder is built.in a tank with butter, which allows you to cut even rough material.

So, after choosing the tool, the glass is placed on a flat horizontal surface. It makes a corresponding markup on it, to create which you can use the usual ruler. After that, making the same efforts along the entire necessary length, a flat fishing line for a trimmer is made (see. video). This must be done the first time, since repeated manipulations will lead to cracking of the material.

You can cut the material with your own hands and using ordinary scissors. To do this, prepare the scissors themselves, as well as a vessel with hot water. Marking on the surface is done in advance. Further, the spicy side of the scissors is carried out according to the marking, creating a small crack, after which the glass is simply broken with his hands. Of course, this method of cutting will not be as ideal as the previous one, but can help out in an unforeseen situation.

How to choose glass cutter and cut glass at home without chips and cracks

Steaches processing

Cutting refractory glasses is a rather complicated process that requires a special tool. There are several ways to perform this procedure at home:

- Using a winning cut with a turpentine.

- An alternative option is to use a thin diamond circle. To optimize the process, you must water the thread with water to remove dust and cool the working organ. At the same time, this must be done very carefully, without unnecessary loads.

Cutting hardened glass is absolutely excluded and is not performed by any tools. Although some home craftsmen manage to do this, but it rarely happens without damage.

If you need to cut off heat.resistant glass, it is advisable to entrust this to specialists who already have certain skills in solving such problems.

How do refractory glass make us look at

Personally, I have already encountered several times the need to cut such glass. And I did not see anything unusual or insurmountable here. Cut it in the same way as usual- with a diamond glass cutter. Of course, the hardness of the refractory glass is much higher than that of a simple one, but good glass cutter easily copes with it and with it. If you wish, you can make slots on both sides, and can do it well along the cut line.

It is impossible to cut hardened glass in the usual sense. After hardening, the material changes its properties. Kallen glass is more known to an ordinary consumer called “safe”. Its cutting in the traditional sense will lead to the fact that the material will simply collapse on many small fragments. However, despite the existing restrictions, with a great desire, such material is quite successfully cutting. The work boils down to the fact that the glass is first anneal, and after that it is cut. Then, if desired, the glass can be repaired again to make it very durable and safe again.

Read also: The life of gas cylinders

The difference between hardened glass and usual.

What is this material?

The most ordinary sheet is called the hardened glass (the manufacturing temperature and the hardening temperature during the production of ordinary glass coincide and are approximately 660 O C), which is cooled very quickly, using blowing (cold air) on both sides of the finished sheet. Hardening (process) is due to very fast cooling. The glass hardened in this way has high mechanical strength, resistance to high temperatures and increased safety (in case of destruction, the glass breaks up into a large number of small and non.resistant pieces that will cause special harm to a person).

Tempered glass is used as a showcase.

The inhabitants of the former USSR are familiar with such glass. it was called “Stalinist”. This is due to the fact that with such cooling, in the crystal lattice of such glass, the residual compression voltage appears. Due to its three positive qualities, such glasses are widely used in the construction sector, in the production of dishes, they are used as windows of supermarkets, in various social institutions (schools, universities, hospitals, etc.D.), in the manufacture of cars and other machines.

The main drawback of such material is its vulnerability with mechanical shots to the ends. Even with a weak blow to the sheet edge, the glass is broken into a bunch of small fragments, and the whole sheet becomes unusable. However, even such a drawback has found its application in everyday life. it is used if you need to create the effect of “broken glass” (in the design of furniture or dishes).

Most often you can find tables or cabinets with “broken glass”. This effect is achieved through the use of 3 sheets at once: the upper. whole, the middle. broken, lower. whole.

Manufacturers of such leaf glasses do not recommend (and some even prohibit) cut such glass at home, since there is a high probability of leaf damage. And how then there is a cutting of hardened glass in domestic conditions?

Cutting different types of glasses

When cutting ordinary glass, there should be no problems. Various tools will help to cope with this task: from scissors to special glass cutters. But how to cut off a hot glass? This is exactly what will be discussed below. At home, you can also cut organic and corrugated glass.

Calcated products are in great demand, since they are inserted into the doors and various interior structures. This material is easy to cut (like ordinary glass), so you can use the above tools. It should be remembered that the cut should be performed on the smooth side.

How to cut hardened glass? In fact, such a product cannot be cut at home. Work is best entrusted to professionals who have a machine with a diamond circle. A special emulsion is necessarily supplied to it, which is responsible for cooling the surface. You can, of course, try to cut the glass with glass cutter or corner grinder, but even with a slight deviation from the flat line, it will begin to crumble.

Organic glass is made of synthetic resins and very similar to plastic. The simplest tools are suitable for cutting it: cutting, saw metal, stationery knife, etc.

Recommendations for sawing paving slabs and borders

Porcelain tiles are a demanded material that allows you to equip the paths in the yard or in the garden beautifully and tastefully. In addition to an attractive appearance, the material is durable, durable, wide range. On the sides of the tracks in most cases, a curb stone is laid, which in its characteristics is similar to the material of the sidewalk.

Often when laying paths, tiles and borders have to be cut to the desired size. For these purposes, various tools are used, one of which is an angular grinder. To effectively carry out sawing, it is recommended to use this power tool with a circle with a diameter of more than 230 mm and power value equal or exceeding 2 kW. All work is performed using a diamond disk.

The cutting of paving slabs and borders of the corner grinding machine is performed similarly by sawing brick.

- First, the marking is applied to the surface of the sawn materials by marker or chalk.

- Check the accuracy of the applied marking lines by applying tiles or borders to the installation site.

- When the size and shape coincides, the construction of building material is carried out without strong pressure on the power tool used.

If the cuts contain defects after cutting, then they are eliminated using suitable tools (for example, a hacksaw for metal, chisel, file). The circle of a working tool should rotate so that dust flies in the opposite from the working side. In this case, he must hold the working power tool with both hands, being behind or from the side of it.

The quality of the result and the number of cutting tiles depend on the accuracy of the initial marking.

The tile cut into fragments of the desired dimensions should be put off separately so that dust does not fall on it. For the convenience of subsequent styling, you can numb pieces. Still uncircumcised material should be covered from dust, because then it is quite problematic to remove it from the surface of the tile.