World of concrete

In the process of repairing an apartment or a private house, the question often arises: how to cut concrete? This is necessary when the owners plan to lay new wiring, make an opening for the door, and in many other cases.

Currently, there are several options for dealing with concrete:

- cutting in circles;

- waterjet;

- oxygen-spear.

But most often this is done with an angle grinder equipped with a diamond blade. The advantages of this method are:

- very even cut;

- relatively low noise;

- speed;

- universality.

What you need to know about concrete

In order to properly cut concrete, you need to know what type of concrete you are dealing with in a particular case. In particular, the choice of the most suitable diamond wheels depends on this.

Many structures inside have metal reinforcement, which gives them proper strength and at the same time significantly complicates the task for anyone who wants to make a stub in it. The problem in most cases arises if the depth is required over 10 centimeters. For such work, it is necessary to purchase a special diamond turbo-disk. the usual one will not cope with the task.

Fresh concrete is quite malleable, while the old one is quite solid. In the first case, you can limit yourself to buying the cheapest circle, and in the second you have to fork out a quality one.

The presence of basalt or quartz-containing gravel in the crushed stone ensures maximum hardness. In such a wall, the circle becomes very dull very quickly. In order for the work to go faster, it is necessary to take those cutting elements in which diamonds are fixed in a soft binder metal. This will allow you to quickly open their protective shell and provide maximum returns at the same costs.

The crushed stone fraction, among other things, affects the speed of the tool. the larger it is, the slower the circle rotates.

Based on the foregoing, it should be concluded. before starting work, it is important to carefully understand what type of concrete you have to deal with. A careful study of its properties will allow you to choose the most suitable circle.

Tile cutting

Sometimes it becomes necessary to shorten a standard concrete slab at home without a power tool.

Here you have to work manually. For this:

Video: How to Cut Fittings in Concrete

- mark the line with a pencil on both sides;

- crack concrete with a scarpel and a hammer;

- a chisel and a hacksaw will help to cope with the fittings.

With this method, on the one hand, the edge is uneven. This butt is laid against the wall, and subsequently it is covered with a baseboard.

Shallow cuts

To lay pipes or wiring in the walls, it is necessary to make shrabs in them. It is best to use an angle grinder. If there is not much work, then take the usual circle on concrete. In other cases, it will be cheaper to purchase a diamond disk of the required diameter (from 105 millimeters to 125).

- turbocircle;

- wave, also called "silent";

- segmented.

The latter variety has some disadvantages, but they are offset by low cost.

Wavy-edged turbo discs are used in situations where particularly difficult work is to be done, for example, cutting steel reinforced concrete. But they cost about one and a half times more expensive than segmented ones.

However, for wiring there is enough cut depth from 10 to 15 millimeters. So close to the surface of the rod, usually not stacked, because it will be enough the cheapest disk. If your angle grinder is not very powerful, do not overload it. Let the tool cool.

To do without dust, ask someone while you cut concrete to spray water into the stub. This will not only make the air cleaner, but also cool the diamond wheel and, accordingly, extend its life.

This method will not work if the angle grinder used does not have water protection or it is not possible to reliably isolate the power source from it. Here you have to work "dry." In order to provide cooling of the circle under such conditions, it is periodically removed from the wall and allowed to rotate freely for some time. The harder the concrete, the longer the cutting tool needs to rest.

The strobe is cut according to a pre-applied marking (width 1.5-2 cm). Angle grinder make two lines at the edges of it. The concrete left between them is then knocked out with a puncher or a chisel with a hammer.

Deep cuts

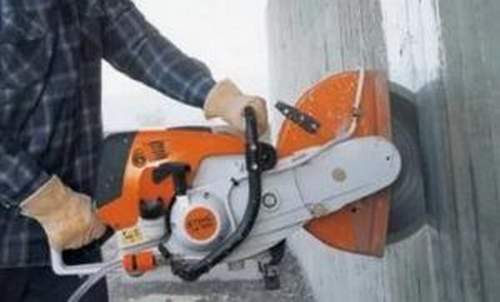

In those situations where you need to arrange an opening in a concrete wall, the depth of the cut is usually more than 10 centimeters. Here the angle grinder will no longer help. It is more advisable to use circular saws specifically designed for such work. They are hydraulic or electric.

Large diameter discs are installed on them. from 350 millimeters to 400. They are able to penetrate concrete to a depth of 160 mm. Of course, few people have an instrument of this type on the farm, because it costs a lot, and in addition to everyday life, the need for it arises infrequently. Therefore, it is easiest to rent it for the duration of the work. Now in any city in Russia there are rental points for construction tools.

Safety precautions

Concrete dust is extremely harmful to humans, therefore it is necessary to work with an angle grinder by wearing a respirator. It will be needed both with the dry cutting method and with the wet one. In both cases, the smallest fragments of cement mortar fly around the room and enter the lungs. In turn, this leads to the development of diseases such as cancer or silicosis.

In addition, “canned” glasses are used to protect the eyes, and special headphones will save the noise generated by the power tool.

And finally, do not forget about gloves. the angle grinder is a very dangerous device. Losing vigilance even for a second can result in very serious injuries.