Cutting tiles with a manual tile cutter

How a manual tile cutter works

- The tile is inserted into the tile cutter, and the markings on it are aligned with a special mark.

- The handle is lowered and held away from you. It must be driven at the same speed and even pressure so that the roller cuts the glaze to the same depth. It will be enough to run the roller once. If you drive several times, the breakage may turn out to be of poor quality.

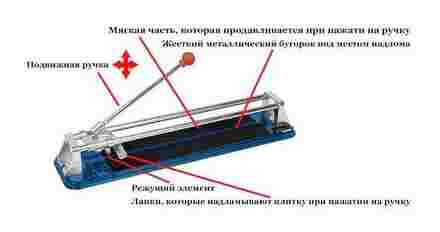

- Next to the roller there are special paws that lower and break the tiles into 2 parts, after a sharp push on the lever. In this case, all tile cutters have a metal tubercle on their platform, and soft pads along the edges. When you press on the edges of the tile with your paws, maximum stress will be created at the notch, if correctly aligned with the backing, and it will evenly break off.

It is difficult to explain this in words, so it is easier to watch a video that shows how to cut tiles correctly with a tile cutter:

High-quality tile cutters allow you to cut even tiles with a thickness of 10 mm without problems. It doesn’t matter at what angle you cut it: at least 45 degrees, at least 30.

We make a drink at 45 degrees

Ceramic pencil skirting is best for protecting the sharp outer corners of tiles

If you are using a professional electric tile cutter, the tilting platform there makes it easy to make a 45-degree angle on the tile bevel, but not everyone has such a tool. It is easy to make such an angle on your own using the same grinder “by eye”. The disc is drawn along the incision line, while it should be slightly tilted inward.

Undercut tiles at 45 degrees

Electric tile cutter

If you have a large amount of work, then the fastest and highest quality cut comes from an electric tile cutter. They use a diamond wheel and supply water to the cutting site to cool and remove dust. The cheapest types of amateur class can be found on sale for 3-4 thousand rubles.

How to cut tiles without a tile cutter

If you only need to cut a few tiles, it doesn’t have to be spent on a tile cutter. You can use the tools at hand:

- Glass cutter.

- Drill. It should preferably be with a victorious tip, as it will scratch the tile better.

- Nail.

- Construction knife.

Attach a metal ruler to the notch and draw once with a glass cutter or drill. A deep scratch should remain on the enamel. If you use a knife, but you will need to carry out several times.

Place the tile with the cut at the corner and press down on its edges with a sharp motion. The cut will not turn out perfectly even, unlike the tile cutter, but you will not have to spend additional money.

To make cutting ceramic tiles easier, many craftsmen soak them in water for about 1 hour.

How to choose the right disc by tile

For cutting, metal discs are used with diamond dusting along its edges. But they are different: for concrete, brick, stone. Tiled discs do not have any holes, the soldering on them is uniform and smooth. Discs for concrete have slots on the solder, and will chip when vibrated. If you cut ceramic tiles with them, then these chips can fly into the face.

How to cut a tile with the letter “G”

Since the tile cutter can only cut the tiles straight, many have difficulty with L-shaped cutouts. The easiest option is to divide this tile into 2 rectangular elements, but then you get an extra ugly seam that will catch your eye.

But this can be avoided if the short side is cut with a grinder, and then the long side with a tile cutter.

Step-by-step instructions on how to make L-shaped cuts on tiles

The second method: by any method available to you, a cut is made on the glaze, and the excess is gradually broken off with pliers. Irregularities are treated with sandpaper. This option will even allow you to get a rounded incision for abutting the risers.

How to cut porcelain stoneware

It is believed that porcelain stoneware is the hardest material from which floor tiles are made. You can trim it in the same way as a regular tile.

Sometimes simple floor tiles are more difficult to cut than porcelain stoneware. There is a hardened tile, on which, after cutting with a tile cutter, the notch on the glaze is almost invisible. And even the diamond disc on the grinder does not take it. the incision turns out to be torn, like after a tractor. In such cases, you need to use a grinder, and file a 2-3 mm groove on the back side to mark the place of the break.

Helpful advice

So now you know how to cut your floor tiles correctly at home using a dedicated tool. Working with a tile cutter is relatively easy. But the risk should be carried out as carefully as possible. Only one precise cut is allowed on the material. The carriage cannot move longitudinally a second time. In any case, the new risk will not coincide with the first one and the material will be spoiled.

How to cut floor tiles at home correctly

After the tool has been inspected, you can proceed to the actual cutting itself. In order not to be mistaken with the dimensions, the tiles must first be marked. You can use for this either an ordinary simple pencil, or a thin marker. In order to draw a straight line, you should use a wooden plank or a regular school ruler.

Of course, the material should not move during cutting in any case. Some tile cutters have special clamps. If they are not there, the tiles or porcelain stoneware will have to be held as tightly as possible with your hand. It is necessary to set the cut material exactly along the marking line.

During operation, the handle of the tool should be moved as smoothly as possible. Cutting in this case is carried out by the method “on oneself”, carefully controlling the force of pressure. If the incision is not deep enough, it will not be possible to break the tile exactly in the future. Pressing the tool handle too hard is also not allowed. Otherwise, ugly cracks may appear on the tiles.

After the risk has been made, the material must be placed on a firm, level surface. Next, you should carefully lift the edge of the tile farthest from the notch and do not press too hard on it. As a result, the material should break at exactly the risk.

How to cut with a grinder

When using this tool, the work is done on the “from oneself” method. Tiles, porcelain stoneware or artificial stone are preliminarily placed on the table so that the line of risks extends beyond its surface. You should work as smoothly as possible. You do not need to press on the tiles around. As soon as the cut piece falls to the floor, turn off the grinder.

What is the tool

First, let’s figure out how to cut floor tiles at home using this particular equipment. The tile cutter is actually very easy to use. There are many models of such tools. But in most cases, a tile cutter consists of:

a metal base on which all other elements are attached;

tubular guides designed to move the actual cutting roller;

a handle with which you can move the carriage;

the cutting element itself.

How to cut floor tiles at home: methods, tools, tips

Types of flooring such as tile, porcelain stoneware or artificial stone have many advantages. All these types of coatings not only look beautiful, but are also not afraid of moisture, are easy to clean and serve for a long time. It is also not too difficult to mount such materials. However, working with tiles has one peculiarity. during installation it almost always has to be cut. This procedure must be performed, for example, when fitting to size or, if necessary, pairing with various communications or surfaces.

There are several ways to cut tiles. All of them are relatively simple and do not require any special skills. Further in the article in all details and consider how to cut floor tiles at home.

Preparatory work

The tile cutter tool is very simple. However, when performing work using it, a certain order of actions should be followed. Before starting to cut tiles, you must:

carefully inspect the tool for defects (especially guides);

check how smoothly the carriage moves;

check the condition of the cutting roller (must rotate freely).

Gloves should be put on hands before starting work, and safety glasses should be on eyes.

Using wire cutters

It is very difficult to work with this tool on tiles. Therefore, nippers are usually used only when you need to make a curly cut. Application of this simple tool. a good answer to the question of how to cut floor tiles in a semicircle. In this case, the markup is performed using patterns, compasses, protractor, square, etc.

Cutting with pliers is performed by gently breaking off the tiles, gradually approaching the figure drawn with a pencil or marker. And they do it immediately along the entire length of the line. If you start to move the pliers directly to the markings on one side, the tiles can crack very easily.

Working with tile clippers is thus very difficult. In addition, the cutting line itself on the tile is not very neat. Its edges come out “bitten”. Therefore, when using such a tool at the final stage, the ends of the cut figure must be aligned with a file.

Basic ways

Most often, when facing the floor, porcelain stoneware or tile is adjusted in size using tools such as:

Of course, the best answer to the question of how to cut tiles is to use a tile cutter. In the production of finishing ceramics, professional mechanized versions of this equipment are used. At home, it is worth using, of course, a simple household tile cutter. Such models do not differ in special performance, but at the same time they are inexpensive. Almost any home craftsman can afford such simple equipment.

We cut the tiles correctly

Using tiles for wall decoration, a situation will surely arise when you need to cut off part of the slab so that it fits into the remaining space. over, a similar procedure will be required regardless of which type of tile you choose. Cutting is required most often in cases where unique patterns on the walls are created or various decorative objects are formed using tiles.

If you have already prepared all the attributes you need for work, you can consider how the tile should be cut correctly. The grinder is an excellent assistant in the matter under consideration, since with its help you can create not only straight cuts, but also curly cuts. Next, we will look at how to cut tiles in various ways.

A straight cut is as simple as possible:

- First, you need to fix the tile on the plane so that it does not slide and ride on it.

- The part of the tile that needs to be cut must remain in weight. The surface line will be the guideline for the notch line;

- It is necessary to take the grinder so that you can see the cutting line. If you hide it from yourself, you will not be able to make an even cut.

- You need to direct and move the blade towards you, not away from yourself. This is the mistake many beginners make. Hold the tool firmly and level so that it does not move in different directions, otherwise the cut will be ugly. Holding the grinder crooked, you can ruin the disc, as it can fly off because of this.

A round hole is made as follows:

- Initially, you need to use a marker to draw the required hole. Draw on the glossy side of the tile.

- Then you need to determine the center of the circle. This can be done using straight lines drawn crosswise.

- Gently saw the tiles from the inside in a circle with a grinder until we go deep.

- It is necessary to turn the grinder so that the blade gradually fits into the outlined circle.

- When the cut is deep enough, you need to cut the drawn cross along the drawn lines, after which you carefully take out the resulting 4 sectors of the circle.

You need to cut the tiles only on the front side, since this is the only way to get a cut without various defects. Therefore, all possible damage will be concentrated on the back of the tile, which will be hidden with tile adhesive.

It is best to measure and mark the tiles to be cut from the start.

To cut at a 45 degree angle, follow the instructions below:

- It is important to note that cutting the tiles obliquely is more difficult than making a straight cut. However, this is much easier than creating curly elements. You need to start by doing.

- The grinder must be turned so that the disc is located at the angle you need, while you must carefully drive the blade, removing excess, so that at the end an even angular cut is obtained.

- Perfectness can be achieved by using ordinary sandpaper, which is best fixed on a block.

Required tools and materials

Cutting ceramic tiles is a laborious process that requires maximum concentration. The difficulty is largely due to the fact that the tiles are made of durable material. Dust-free tiles can be cut and sawed down with a tile cutter, but such a tool is not cheap. This is almost impossible with conventional cutters and saws, and the cut will most likely be uneven and unattractive. An ordinary grinder is best suited, the cutting wheel of which allows you to neatly cut the tiles even at home.

Despite the fact that this process is relatively difficult, if you get the hang of it, it does not take much time and does not require much effort. This task can be handled by an ordinary homeowner who has not dealt with such work and can even cut off a “hog” without the help of a tile cutter.

You can cut tiles using the following tools:

- special tile cutter;

- diamond tools;

- Bulgarian.

For cutting ceramic tiles, those that have a diamond coating are suitable. Their use minimizes the formation of cracks and chips. It is forbidden to use discs used for metal work, as they will only damage the tile. Even if you manage to cut with such a circle, it will be uneven and of poor quality. This is due to the sliding of the disc on the tile, due to which the presence of small cracks is inevitable. At the same time, when it comes to home surface finishing, you can ignore these damages, since they will surely disappear during subsequent processing.

In no case should you neglect safety measures, since the risk of harm is quite high.

Be sure to carry the following attributes with you:

- glasses;

- mask;

- thick gloves.

Please note that the selected grinder or grinder must have a speed regulator, since many modern inexpensive tools are devoid of this function. Such models operate at the highest speed, which is why it is impossible to cut tiles with their help.

How to cut tiles with a grinder?

When making repairs, many homeowners need to cut ceramic tiles, which can be done using a grinder. This tool allows you to do this work at a high level, with minimal risk of chips or cracks. In this article we will tell you how to cut ceramic tiles using a grinder.

Important nuances

The grinder must be set at a low speed so that you can control and adjust its actions. When you have the ability to secure the tool, be sure to do so, as this will simplify your work. Having secured the grinder, you will only need to move the tile along the desired trajectory.

If there is no possibility of securing, then the floor is the best place to work. Be sure to put bars or lumber under the slab. It is important to note that a low speed should also be set due to the fact that this will exclude the discarding of the blade or disc upon contact with the surface.

Turning on the maximum speed will surely simplify the cutting process, but this increases the risk of damage to the tiles, which can simply fly to pieces. The easiest way to cut is the straight line, since even a beginner can handle this job. When it comes to rounding, then it will take more effort. If you have not previously encountered such work, then we recommend that you first try your skills on defective material.

You can protect tiles from chips by using a special grinder or sandpaper. This work is not difficult, but it will significantly improve the quality of the cut. Thus, you can get rid of existing defects.

If you decide to choose a grinder for this work, and not sandpaper, then you need to work at the minimum speed.

Be sure to follow these guidelines:

- you need to work in special clothes;

- safety glasses are required;

- it is recommended to use earplugs when working;

- all used devices must be in good condition;

- work can only be performed by adults who know the safety rules for using a cutting tool;

- when wet processing, make sure that the sander does not get into the water, as this can lead to an electric shock;

- you cannot process slices at maximum speed;

- you need to work in a room with good ventilation.

To maintain your health, it is extremely important to follow these recommendations.

Next, see a master class on cutting tiles with a grinder.

How to cut tiles with a manual tile cutter. Instructions for using the tile cutter

A popular and practical finishing material for bathrooms, toilets and kitchens is ceramic tiles, which always require precise marking and cutting to the required dimensions. If we talk about the industrial scale of construction, then most often professionals use a mechanized (electric) tile cutter, but the manual option is quite suitable for home conditions.

Preparatory work

A manual tile cutter is an elementary, but at the same time, cutting tool that requires certain preparation and sequence of actions to obtain an accurate result. Let’s talk about them in more detail.

Before cutting the tiles with a manual tile cutter, it is necessary to carry out preliminary preparations:

- Inspect the structure of the tile cutter for visible damage and irregularities in the guides.

- Check the smooth movement of the carriage with the cutting roller along the tubular guides. It is important that they are free of any contamination that could become a hindrance. If you just cleaned them, you can apply a small amount of machine oil to the surface to lubricate.

- Check the condition of the cutter wheel. It should rotate freely without unnecessary sounds like creaking or jamming. If the surface of the cutter wheel is damaged (for example, burrs or dents), then it should be replaced. Otherwise, irregularities or cracks will appear on the cut.

How To Cut Porcelain Tile-using a tile cutter

Before cutting the tiles with a tile cutter, you should also take care of your own safety. To prevent scratches, cuts and other troubles, it is worth using construction gloves. When cutting the tiles, never allow your fingers to get under the cutting roller. Also, the field of obtaining an incision, the tile must be broken along it, while small particles are formed that can get into the eyes. wear safety glasses.

Cutting tiles with a tile cutter: a general beginning

After preparing the tile cutter for use, you can start cutting the tiles. To do this, you need an accurate marking of the surface. So, for this you can use a regular construction pencil or, for example, a marker. We apply a marking line with it. Before cutting a floor tile with a tile cutter or wall tile, it must be firmly fixed in relation to the cutting roller. To do this, in some designs of tile cutters, special clamps are used, which allow you to ensure a completely fixed position of the tile. If there is no such grip, then the tile must be held with one hand, and the handle with the cutter roller carriage with the other.

Immediately before making a cut, it is necessary to apply a drop of machine oil to the surface of the cutting roller, which will significantly reduce the friction of the surfaces of the roller and the tile, which, in turn, will increase the quality of the cut obtained.

What is a manual tile cutter?

Tile cutter is the combined name of a group of tools designed to produce straight or curly cuts on ceramic or tile. In terms of construction, the manual tile cutter consists of the following elements:

- The base, which is the supporting part for all other elements;

- Tubular guides for precise movement of the cutting element;

- Cutting element, which is an axle-mounted metal roller with a pointed edge;

- A handle designed to move the carriage with a roller along the intended cut.

Many years of experience in construction work shows that using a manual tabletop tile cutter in a domestic environment is the best option both in terms of productivity and accuracy, as well as simplicity. Benefits of using a manual tile cutter:

- Ease of operation due to the elementary design of the device;

- The handle in the design plays the role of a lever that significantly reduces the force with which it is necessary to cut the tiles;

- Quite accurate (in comparison with a more elementary method with a glass cutter) cut.

However, the use of this version of the tile cutter imposes some restrictions on the processing of tiles. So, for example, you cannot get a cut at a distance of less than 5 millimeters from the edge of the tile. If you try to do this, then there is a high probability of breaking the edge. Also, in addition, you can read the article on how to use the tile cutter.

How to cut ceramic tiles with a tile cutter?

After the tile is precisely aligned with the marking line, lift the handle of the tile cutter so that the roller surface touches the face of the tile. Now you can move the handle towards you in a smooth motion. In this case, it is very important to control the pressure applied to the tile surface. With insufficient pressure, the notch will be small to successfully break the tile depth.

If you press the handle too hard, ugly cracks may appear on the decorative layer of the tile. If you are cutting a tile for the first time, it is best to take a piece on which you can experiment, since it is likely that an even cut may not work.

Important: the cut must be made in one longitudinal movement of the carriage with the cutting roller, otherwise the repeated risks will not coincide with the first one, so the cut will turn out to be inaccurate or excessively rough.

How to cut tiles with a tile cutter?

The composition of the tile is practically the same as the ceramic one. Only the color of the base is different. it is lighter. However, this practically does not affect the tile cutting process, therefore it is produced similarly to ceramic tiles.

So, the incision is made. Now we put the tiles on a flat horizontal surface and raise one of the edges, which is as far as possible from the notch line. Now, carefully, but at the same time, press the tile sharply enough in the area of the notch marks so that the tile breaks exactly along it.

If the cut is not accurate enough, then its edges can be trimmed with a grinding stone or sandpaper. Gentle longitudinal movements can be used to achieve a smooth cut edge. It is necessary if the tile will be butt-joined with the other. If it is placed in a corner, it is not necessary to sand the edge.

The tile has been cut, now you can start laying it.

It is also worth seeing more clearly how to cut tiles with a manual tile cutter.

Hand tool for professionals and hobbyists

Tile cutters are deliberately divided into such groups. The amateur version is not very expensive, but does not withstand prolonged load. There is no additional functionality, or its quality leaves much to be desired. Such a tool is used for a single repair.

A professional-grade tool will cost you quite a lot, but the price difference will pay off with high-quality assembly and good components, accurate design calculations. Cutting is performed better, the operating period of the tool increases.

For convenient use, the set includes rulers, thrust elements, squares and other accessories. A tile cutter of this group is popular among decorators.

Cutting with a hand tile cutter: the benefits

Before cutting a tile with a tile cutter, many experts decide to do it with a hand tool, finding certain advantages in that:

- the instrument runs silently. The electric tile cutter makes a loud noise due to the motor running and the cut-off wheel coming into contact with the material. In mechanical tools, such parts are absent, and therefore the level of the emitted noise is negligible. This fact is especially relevant in homes where there are small children;

- no need to connect to the electrical network. A mechanical tool for trimming tiles works on the muscular force of the master, transmitted through a lever to the cutting edge, so that the model functions completely without electricity;

- reliability of the tool. A mechanical tile cutter consists of a minimum set of elements that can lose their functionality. This is explained by a simple construction. By choosing the right tool, you can use it for a long time;

- light weight. The average weight of the tile cutter varies between two and ten kilograms, which makes it possible to move the tool from one workplace to another;

- additional equipment items. Most tile cutters come with a “ballerina”, with which you can easily make a hole in the tile;

- some models have an additional function that allows you to cut glass.

You can learn how to work with a manual tile cutter from the video on the Internet.

What is the choice based on?

To determine which manual tile cutter is better to choose, it is recommended to imagine how often it is planned to use it, what working volumes will have to be mastered, what building materials will have to be cut.

When purchasing a tool for DIY repair work, pay attention to manual modifications. They stand acceptable, cut a tile one and a half centimeters thick, do not make noise during work.

How to Use a Manual Tile Cutter Beginners Guide

In the case when finishing work is coming in large volumes, and ideal cutting quality is required, especially when facing tiles from different materials, up to stone, are used, it is best to immediately purchase an electrically driven tile cutter. This type of tool is more productive, cuts thick tiles in one minute, making an even cut.

Manual tile cutter: how to properly cut tiles?

Manual tile cutters rating

We bring to your attention a list of models of manual tile cutters that differ in cost and technical characteristics, from which professional specialists and lovers of self-repairs make the final choice. Many craftsmen prefer the Sigma manual tile cutter, but there are other decent options.

Bison 33193 80

Mechanical type monorail tile cutter suitable for tiles and porcelain tiles that are five to sixteen millimeters thick, even when cutting at an angle. The cutting process is carried out thanks to the existing roller with a diameter of 2.2 cm and a 6 mm bore.

Tool weight 7 kg 400 g, approximate.

The tile cutter is made by a domestic manufacturer, special guides guarantee the rigidity of the entire structure, which is necessary for working with porcelain stoneware. The existing bearings provide a smooth and easy cutter stroke. Pouch included.

Montolit masterpiuma 63p3

Another mechanical monorail model, equipped with a pair of millimeter rulers and side stop elements. It is used for cutting tiles and mosaic glass. A roller with a diameter of 1.4 cm cuts material 2.2 cm deep, weighs within nine kilograms, and costs about twenty-five thousand rubles. Made by an Italian company, used by professional craftsmen.

Subtleties of the process: how to cut a tile

Tips: how to cut floor tiles

When cladding a bathroom or a bathroom, you may definitely need a curly cut for mounting tiles near the toilet, bath, sink, etc. Therefore, it will be interesting for the craftsmen to learn how to cut the floor tiles at home. For this purpose, it is possible to apply an original method. a drill with a nozzle. It allows you to make a rounding or a perfect hole for the floor.

As an attachment to cut, it is possible to take:

- Ballerina. A nozzle that is fixed in the center with the help of a foot.

- Crown. Round nozzles of different diameters with a straight or serrated edge.

- Tubular drill. Small diameter straight carbide tube.

- Traditional sharp drill.

To flatten the cut when using the drills, you need to use wire cutters. It is necessary to work slowly and very carefully, then the rounding of the tiles on the floor will turn out to be of high quality.

Glass cutter for ceramic tiles

If you need to cut just a few tiles, then it is irrational to buy a tile cutter.

It is possible to use the tools at hand for work:

- Glass cutter.

- Drill. You need to take a product with a victorious tip, since it is more effective.

- Nail.

- Construction knife.

It’s not hard to work. The ruler must be applied to the cut site and walked once with a glass cutter or drill. There should be a noticeable scratch on the glaze. If we are working with a knife, then it will be necessary to walk on the surface 2-3 times. Then the tile must be laid with a cut at a corner and sharply broken. The cut should be perfect, and you will not have to spend financial resources.

Cutting ceramic tiles with a tile cutter

To simplify the process of cutting the tiles and make the necessary fracture line, it is necessary to loosen the glaze layer. that is, cut it, and then break it.

There are 3 main techniques:

- Electric tile cutter or special tongs;

- Bulgarian;

- Other sharp tools at hand.

The instruction looks like this:

- The tile must be inserted into the device, and the markings on the tile must be combined with a special mark.

- The handle must be lowered and held away from you. It must be driven at the same speed. You must also press evenly so that the roller cuts the glaze to the same depth. The video must be run once. If you drive more often, the breakage will be of poor quality.

- Next to the roller there are special paws, which, as soon as they go down, immediately break the tile into 2 neat parts. This happens after you sharply press a special lever. At the same time, all devices are based on a metal tubercle, and along the edge there are special non-rigid pads. When you press the edges of the material with your paws, in the place where the cut is made, maximum stress is obtained, and the tile breaks evenly.

High-quality tile cutters make it possible to cut without problems even ceramic material, the thickness of which is 1 cm. And it does not matter at what angle the material is cut: it will be at least 45 degrees or even 30 degrees. And how to cut a tile with the letter “G”?

Since the tile cutter can only cut tiles straight, many find it difficult to cope with L-shaped cuts. The easiest way. we cut the tile into 2 rectangles, and the resulting ugly seam of the short side is cut with a grinder, and the long side. with a tile cutter.

Many will also be interested in how to cut porcelain stoneware? It is believed that porcelain stoneware tiles are more rigid. It is possible to cut it in the same way as ceramic. Sometimes standard floor tiles are more difficult to cut than porcelain stoneware. There is a hardened material on which, after working with the tile cutter, it is almost impossible to see the notch. And even the diamond disc of a grinder cannot cope with it. the notch turns out to be crooked. Here you need to use a grinder, and file a 3 mm groove on the back side, thereby marking the place of the break.

How to cut floor tiles at home: tile cutters and grinders

Tongs will cost the master about 400 rubles, and they can be used exclusively for small amounts of work with thin tiles at home.

Cutting is done like this:

- It is necessary to carry out the marking, taking into account all the gaps and seams, minus 5 mm.

- Then you need to attach a metal ruler to the marking and draw it once with a cutter. It is not necessary to press hard so that the result is a strip. It is recommended to lead from the far edge towards yourself.

- Tile-cutting tongs should be positioned with their paws along the fracture line close to the edges. The sponges are located on top of the glaze, and the straight part is on the bottom. The fracture line should be straight from the middle between the edges of the lip on top. Next, you do not need to sharply press the handles, the cutting will be done. Do not lift high, otherwise the tile will split.

Cutting methods are different, for example, you can use an electric tile cutter. An ideal solution if the volume of work is large. The highest quality cut is obtained from the electrical tool. Here a diamond wheel is used and water is supplied to the place of the notch, due to which cooling occurs and there is no dust. The most inexpensive devices cost about 4,000 rubles.

You can cut the tiles with a grinder. If the tile is curly, then you may need to cut a narrow strip of material 0.5–2 cm, and a standard tile cutter will not cope with this matter, because its legs are very wide.

Here it is necessary to draw a fracture line with a pencil and perform a wash down, using a grinder with a diamond disc. But if you do not wash down, then during cutting, a narrow strip will break off in pieces. Therefore, it is necessary to carefully, slowly, walk the grinder along the markings in order to make a cut of about 2 mm.

It is necessary to pass the disk along the line, and not directly along it, then the width of the strip will be as necessary, it will not decrease. Cutting is performed in the same way, after several times. Now you can work with the device faster, but you need to try to press the grinder to the opposite side, then chips will not form. It is better to cut by weight, so vibration can be avoided. When it becomes noticeable that a narrow strip is about to fall, it is necessary to put a soft matter, then it will remain intact.

How to cut tiles with a glass cutter

How to cut tiles with a mechanical (machine) tile cutter

The machine tile cutter easily “takes” even floor products of medium thickness (6 mm). Due to the large diameter of the cutting wheel, the groove is deeper and the cut breaks more easily. You can quickly cut pieces of the desired size with minimal scrap.

Advantage of a machine cut: the harder the tile structure, the easier it is to cut a narrow strip.

How to work with the machine tool:

- mark a segment on the front surface and place it on the plane of the tool so that the cutting wheel coincides with the marking;

- walk along the line by operating the lever;

- fix the tiles on both sides of the cut border;

- lift the opposite edge of the tile (ceramics) and press the cutter handle;

- she will split.

Life hack. How to cut porcelain stoneware or tiles that are constantly chipping

– Insert into the machine, make a cut;

– Mark the boundaries of the cut and line the back side (a level or ruler is for help);

– Cut along the marked border with a grinder, making a depression. From the inside, it will become thinner, and from the outside it is marked with a tile cutter;

– Cut on a lathe. There will be no chipping or chipping on the cut. You don’t even have to grind.

Watch a video review of the advantages of Makita GA9010 and Makita GA9020 grinders

How to cut tiles to get a perfect cut without chips

The best way to cut tiles: 4 proven ways

Let’s buy an expensive tile. rejoice! We start to work with a tile cutter. we get problems: it cuts poorly and gives chips. One of two things: either the video is dull, or you are doing something wrong.

How to cut tiles with a manual tile cutter or glass cutter

The handheld cutter for thin to medium hard ceramics and tiles is very easy to use:

- mark the tile surface and cut forcefully towards you. Keep the glass or tile cutter strictly at right angles. There should be a visible continuous strip on the front side;

- take your time push and break down that line like chocolate.

Soak a hot (hard) tile in water for half an hour or an hour. It will cut exactly along the intended cut and adhere well to the wall when laying.

There are two ways to break tiles.

- Align the notch with the edge of the table and press down on the overhang. Will break along the cut line.

- Place the already cut tiles on a glazing bead or nail. Press down on both sides of the cut edge. Will break where it’s supposed to.

Life hack. How to cut a tile that “does not fit” into the machine

Cut non-standard tiles (more than 60 cm) with a hand cutter or glass cutter. The ruler will be the same tile cut.

– Line up and mark the edges of the cut.

– Cut off this section (you get a barely noticeable track).

– Place the tile vertically on your knee, grab the top edges and break. There will be perfectly smooth edges of the halves.

How to cut a tile without chipping with an electric tile cutter

The feature of the water-cooled electric cutter is a powerful diamond blade and water supply to the cutting site. With no dust and no special effort on your part, the tool makes cuts with smooth edges, even for porcelain stoneware with a thickness of up to 60 mm. In a matter of minutes, you can cut a lot and the desired size without spoiling a single one. Just remember to wear safety glasses to protect your eyes from flying debris.