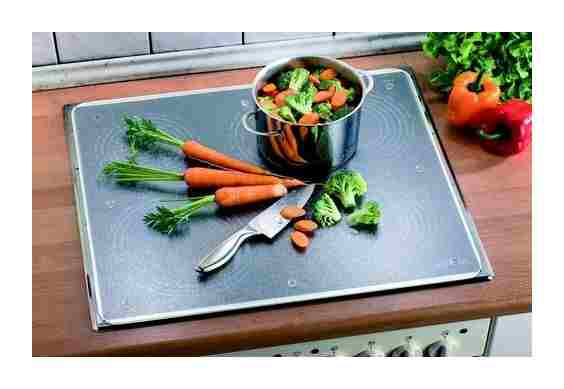

How to care for your glass ceramic hob every day

This method is the only one that is officially allowed to be used by all manufacturers of glass-ceramic plates for daily cleaning.

- After cooking (or during cooking), while the stove is still hot, carefully remove any burnt liquids and food debris with a scraper.

- When the stove has cooled down (!), Treat the dirty areas with soapy water (for example, dishwashing liquid) and rub them with a not too hard sponge. You can also wash the stove with a wet sponge and laundry soap.

- Remove stubborn dirt with a special paste or cream for glass ceramics.

- Wipe the stove clean and dry, removing the rest of the product itself.

- A soapy solution or a frothy cap from it can be left on the stove for 20-40 minutes. The main thing is that the liquid does not leak out of the stove.

- The main tool for cleaning the glass ceramic hob is the glass scraper. How to use it? Place the scraper at an acute angle to the surface of the stove and simply slide it back and forth.

How and what to clean a glass-ceramic hob. 7 ways

- How to care for your glass ceramic hob every day

- How to clean a glass ceramic hob with baking soda

- How to clean your glass ceramic hob with 9% vinegar

- How to clean a glass ceramic hob with toothpaste

- Cleaning the plate with a glass cleaner

- Removing tough stains with a melamine sponge

- How to restore the shine of glass ceramics and protect it from future contamination

- Tips for choosing a glass ceramic cleaner

- Tips for caring for your glass ceramic hob

All manufacturers recommend cleaning the glass-ceramic hob only with soap solutions or special products for glass-ceramics (in the form of creams, pastes or sprays). The latter are good in that they not only clean the surface of the slab, but also leave a dirt-repellent film on it, give shine.

But what to do if a special cleaner is not at hand or it simply cannot clean stubborn dirt? In this case, you will be helped by the funds from your first aid kit or kitchen cabinet, as well as our advice on choosing more effective means for glass ceramics.

If you have a gas stove, see the material: How to clean a gas stove in 8 steps

How to clean your glass ceramic hob with 9% vinegar

Vinegar is an excellent cleaner for removing lime and grease stains from glass ceramic hobs. Yes, it is no more effective than dishwashing liquid or ordinary glass ceramic cleaning spray, but it is always at hand and is inexpensive.

- When the stove cools down, spray or moisten the dirt with 9% table vinegar, wipe the stove with a damp cloth to remove the dirt.

- Wipe the stove clean and dry.

How to clean a glass ceramic hob with baking soda

We want to warn you right away: all manufacturers prohibit the use of soda for washing glass-ceramics because of its abrasive properties (micro-scratches remain on the surface, due to which the gloss is somewhat lost). However, as practice shows, soda does not bring significant harm, and most users use it to wash glass ceramics regularly. If your stove is very dirty and you have nothing at hand, you can try this cleaning method.

Due to its alkaline properties, it copes well with old carbon deposits, dirt and grease

- Sprinkle baking soda all over the stove.

- Prepare a solution of hot water and dishwashing liquid in a small bowl.

- Soak a towel well in soapy water and completely cover the stove with it as shown in the photo.

- Leave the towel on for 15-30 minutes to loosen dirt.

- Rub the surface of the stove with the same towel, using the rest of the baking soda as a rubbish against soot and dirt.

- Thoroughly wash and wipe the glass ceramic clean and dry. Use 9% vinegar if desired to remove baking soda residue faster.

- Instead of one large towel, you can use two small.

- The towel should be wet enough to dissolve the baking soda and wet the surface, but not so wet that it will form puddles and drain off the stove.

- This method of cleaning can be used immediately after the method (see below). this will make cleaning even more efficient.

- Particularly stubborn dirt can be removed with a soda paste (soda water in a 1: 1 ratio). In this video you can see how to clean a glass ceramic hob with soda paste.

Cleaning the plate with a glass cleaner

An ammonia-based glass cleaner removes grease and dirt well from the glass-ceramic hob, and also restores its shine.

- Spray glass cleaner on the stove and wipe with a cloth or moderately hard sponge.

- Wipe the stove with a damp microfiber cloth.

How to clean a glass ceramic hob with toothpaste

Whitening toothpastes contain fine and delicate abrasive particles that can remove burn marks, dirt and grease. Simply apply the paste to dirty areas, scrub with a sponge and rinse thoroughly to remove any remaining toothpaste.

Removing tough stains with a melamine sponge

The melamine sponge is easy and quick to clean glass ceramics, but it must be used with care. Before using it with contraindications and properties of the product.

What are the qualities of such glass??

- increased flexural strength

- increased resistance to impulses and impacts

- increased resistance to temperature changes

- safe, when broken glass ceramics or tempered glass breaks up into small fragments with blunt edges, which prevents cuts and damage

How did you manage to achieve such quality indicators??

Ordinary glass heats up to high temperatures around 600 degrees Celsius. After that, it is sharply cooled by a stream of air. As a result, tension is redistributed inside the glass.

Dear guest, stay!

Already many people earn just talking on our forum!

For example, like this. Or like this.

You can start chatting on the forum now. Just log in through or register, it will take one minute.

But if you’re just passing us, you can still:

Cutting heat resistant glass

How to cut tempered glass at home?

Yes, I have not forgotten. Thank you all for your participation in this problem, the current… something doesn’t work out. I have already ditched 11 glasses from old Soviet stoves. Tried nichrome wire and input and in the air. it bursts. It almost happened the last time with a diamond disc on a 7000 rpm motor. in water. I cut off one side, and immediately crumbled to the other. In short, gimor

Or like in a glass factory. First, warm up to yellow, and then with a stream of water.

The only thing is that then how will you cool it?

Added on Aug 19 2005

I wonder what has electronics to do with it ?

And on the Soviet one-layer was, internal.

Added on Aug 19 2005

mastak, the second side fell, most likely that you began to hurry.

patience is enough for one side, and then, although this is an assumption, you know better, you drive.

in the Great Soviet Encyclopedia it is written, perch, fish up to 2 kg, but

10 kg is not uncommon.

red-hot different things happen, even 30-40 years ago they made shelves of auto glass, here is one still alive.

Today, there are others who are hot, you need to look for technologies.

How to cut glass with a glass cutter?

Since glass is one of the most common building materials, it is often used for a wide variety of household needs. For example, to replace an accidentally broken window, as a decorative insert in an interior door or to decorate a greenhouse. And then inevitably there is a need to cut out a piece of the required size from a large canvas. For this, a glass cutter is usually used. And at first glance it seems that it is not so difficult. However, the masters who first faced the question of how to cut glass with a glass cutter should keep in mind that this business has its own subtleties and nuances.

How to properly cut glass with a glass cutter: general recommendations

Working with glass requires care and accuracy. It is imperative to take care of your own protection. wear thick gloves and large glasses so as not to suffer from fragments and glass dust. Cutting glass is more convenient on the table, it should be covered with a cloth or newspaper.

Those who do not know how to cut glass with a glass cutter should heed the following recommendations from professionals:

- the sheet of material must be first cleaned and marked;

- the glass cutter must be positioned perpendicular to the glass surface;

- you need to lead it along the mowing line smoothly. from the far end towards you;

- the degree of pressure should be sufficient, but not excessive. the glass should crackle slightly when cutting;

- the pressure must be uniform along the entire length of the cut.

Before starting work, you should also choose a tool, because glass cutters are different: roller and diamond.

How to properly cut glass with a roller glass cutter?

This glass cutter has a metal roller with a diameter of just over 6 mm. This tool can be used to cut thin glass. no more than 4 mm thick. When working with a roller glass cutter, you should lightly press on it so that a clearly visible white strip remains behind.

Lakeland Induction Hob Protector Liner

Where glass ceramics or tempered glass is used?

In construction requiring the use of safety glass: schools, kindergartens, sports facilities, office buildings.

In the design of commercial and residential objects: stairs, glazing of terraces and loggias, glass doors, railings, glass partitions.

In architecture: double-glazed windows, ceiling glazing, facade glazing.

In fences where high heat loads are possible: glass located at a distance of less than 30 cm from heat sources.

In everyday life, stoves with a glass-ceramic hob, dishes made of impact-resistant tempered glass.

Also, our specialists carry out professional glass cutting.

Fire protection glass marking

Most of the information regarding the characteristics of fire protection glass can be found from its labeling. The letters of the Latin alphabet are used for designation:

- E. resistant to destruction;

- I. has a high resistance to heating up to a critical temperature;

- W. retains heat, does not let heat into the adjacent room.

The manufacturer guarantees the preservation of the declared characteristics for a certain period of time. The time in minutes is indicated after the lettering. For a better understanding, you can consider examples:

- EIW 60. the product retains resistance to destruction, resistance to heat and retains heat for 60 minutes.

- EI 60. resistant to destruction, prevents heating for 60 minutes.

- EI 30. resistant to destruction, prevents heating for 30 minutes.

The characteristics and test methods of fire-resistant fire-resistant glasses are regulated by GOST-33000-2014.

Varieties

The very concept of “refractory glass” includes a wide range of materials that differ in production technology and purpose. A distinction is made between glass that protects against high temperatures and glass that does not interfere with heat exchange, but protects the room from combustion products and prevents the spread of fire. The first is used in fire-fighting systems, the second in heating systems, for the manufacture of hobs, dishes.

There are three main types of fireproof glass:

- reinforced;

- hardened;

- compositional.

Reinforced fire-resistant glass withstands the stresses associated with temperature changes due to the presence of a metal mesh inside. Such a solution allows to provide the product with a sufficiently high heat resistance, but noticeably limits the scope of its application due to its low transparency. These materials are widely used in fire protection systems.

Tempered glass production technology includes the procedure of repeated heating and cooling of the material (tempering). Both single-layer glass and multi-layer glass units are on sale. In double-glazed windows, the space between the sheets is filled with a special transparent multicomponent gel. These solutions are quite affordable in terms of price, while they have good consumer characteristics.

Composite heat-resistant glass should be noted separately. In a general sense, this is not glass, but glass ceramics. The material has a practically zero coefficient of thermal expansion, which allows products from it to withstand extremely high temperatures.

Refractory Glass Properties and Applications

Glass is one of the most demanded materials in construction. As the main part of the window, it lets in sunlight while maintaining a comfortable indoor environment. It is used for glazing facades, decorative elements, dishes and even furniture are created from it.

In addition to classic window glass, the industry offers materials that are similar in appearance, but with much higher characteristics. One of the striking examples of such products is fireproof glass.

Material disadvantages

It is worth remembering that most types of refractory glass are fragile. When working with this material, shock loads and excessive pressure on its surface should not be allowed.

Fire resistant glass is difficult to process. Many types of glass do not cut at all, or are used for cutting by laser, hydraulic devices. Cutting it at home is extremely difficult. It is better to measure several times in order to once again make sure that the dimensions are correct, than trying to fit the sheet to your needs.

When there is simply no other option besides cutting, a small angle grinder with a diamond wheel will come to the rescue of the craftsman.

It is necessary to work with extreme caution, do not allow excessive pressure, constantly moisten the cutting place with oil. Cutting glass with refractory qualities will be a long and messy procedure, besides, no one will guarantee a positive result.

Fireproof glass in ovens and fireplaces

Fireplaces and open stoves are increasingly being installed in country houses and even in apartments. An open fire decorates a room, but it can also cause a fire. You can’t do without refractory glass. It is an excellent fire protection material. Transparent doors are created from it that do not let the flame into the room, but not only, modern design solutions allow you not to be limited to small glasses, you can easily create a unique transparent fireplace.

Regardless of the size of the door or the scope of the project, installing fireproof glass in the metal frame of a stove or fireplace requires careful attention to detail. There are a number of recommendations that must be followed in the process. When determining the linear dimensions of structural elements, it is necessary to take into account the difference in thermal expansion of materials. There must be a gap between the frame and the glass, in which the refractory cord is placed. When installing the glass, it is necessary to ensure uniform pressure on it from all sides. In no case should you seal the joints, this can cause cracks.

Scope of application

Heat-resistant glass grades are widely used in enterprises, the production process of which is associated with high temperatures. The use of transparent material with good heat–resistant characteristics makes it possible to ensure the continuous operation of units and assemblies, while guaranteeing the safety of the operating personnel. Installing fireproof glass in doors and partitions separating production facilities significantly reduces the likelihood of a fire occurring and spreading.

This material is indispensable in everyday life, where there is a high temperature, and it is impractical to use metal. A prime example is glass fireplace doors. This comfortable, beautiful and functional fireplace will perfectly complement the interior of a residential building, it will also create an atmosphere of warmth and comfort. The fireproof glass door is beautiful and practical. It will not become an obstacle to heat radiation, while protecting the room from smoke and soot.

Fireproof glass can be found in the kitchen, among other things: kitchen backsplash, transparent oven doors and microwave ovens. These solutions allow you to control the cooking process without having to open the door. Separately, you can recall the hobs of gas stoves, they allow you to evenly distribute the heating, thereby contributing to energy savings.

High temperature resistant glass is also used for making glassware. Transparent kitchen utensils are great for both open fire and oven cooking. over, transparent dishes can be used in the microwave. An additional plus. the glass surface is easy to clean.

Manufacturing features

The production of refractory glass is a complex technological process that includes constant control at every stage. The production technology varies, it depends on the type and purpose of the material.

Borosilicates are used for the manufacture of inexpensive, but sufficiently high-quality types of refractory glass. Quartz glass is more expensive. The components are mixed, melted, rolled. The obtained sheet material goes through a cycle of specific production processes, consisting of chemical treatment, hardening, followed by high-temperature polishing. All this is designed to provide the proper level of heat resistance and give the glass an attractive look.

Fireproof glasses undergo mandatory temperature tests, according to the results of which a certificate for products is issued.

Main characteristics

There are several indicators that determine the properties of fire resistant glass. They help to determine whether the material is suitable for use for certain purposes, whether it complies with fire regulations.

Thermal expansion coefficient. This is a value that characterizes the degree of change in the linear dimensions of a substance when its temperature changes.

Heat resistance. This value determines the maximum temperature at which the material retains its properties. Regular tempered refractory glass used in everyday life is guaranteed to cope with temperatures of 500-550 degrees. Short-term heating up to 760 (for single-layer) and 1000 (for multi-layer glasses) degrees is allowed.

Material thickness. The industry offers fireproof glass in various thicknesses. For household needs, a material with a thickness of 4-5 mm is used.

The service life of refractory glass directly depends on the operating conditions. To ensure the maximum service life of borosilicate glass used in fireplace doors, it is advisable not to raise the flame temperature above 500-550 degrees, in this mode it will last several thousand hours. With an increase in temperature, this indicator decreases markedly.