How to cut plexiglass

Cutting plexiglass at home is an event that an ordinary person is extremely rare. Despite this, the time from the time the question arises. how to cut plexiglass? But those people who like to craft with their own hands and use this unique material in their works, very often face such a task. to quickly cut acrylic into the necessary elements. In production conditions, some methods of cutting this material are used, at home it is more convenient and more practical to use other methods. Below, consider which methods are used not in production.

If you need to cut a orgepget sheet into certain elements, you can use one of the listed methods:

The first method is a metal hacksaw

Surely almost every home master in a box with tools has such a hacksaw. Working with her is quite simple, your actions should be exactly the same as when cutting metal or wood. In advance on the material sheet, it is necessary to mark the cutting lines, after which you can proceed. In the process, control the evenness of the hacksaw and do not be too zealous so that the material does not begin to melt, otherwise you will get an uneven and melted slice.

After you drink the necessary elements, pay attention to the cut. It turns out rough. Additional grinding will be required. You can use a file or sandpaper.

Second method. cutter

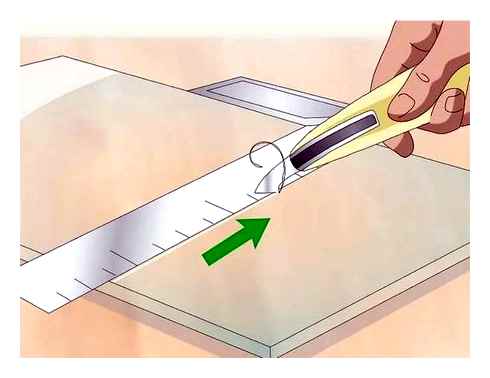

If the thickness of the material is not large, even an ordinary stationery knife will suit you. So, before cutting the necessary elements, you will need to prepare. In order for a fishing line for a cutting cutter to be even, such as you need, prepare a ruler. It is better if it is metal, if there is no one, any other is suitable. Place the ruler along the intended cut line, after which, with neat, but confident movements, take a cutter along the ruler. It can be several movements. The sheet in thickness must be cut by 50%. Now with a neat, but accurate movement break the sheet. The cutting line for the trimmer of the cut is also not perfectly flat, you will need additional grinding.

The cutter can be made if necessary. Some home craftsmen use a regular piece of glass, having previously secured the place where they hold on.

Tools for cutting plexiglass at home

Than cutting plexiglass at home, as it is not very difficult to bend, but you should remember the several rules that will not only show you how to behave correctly with a sheet of organic glass, but significantly speed up the task and choose the right tool.

At home, plexiglass can be cut using the following tools:

- manual saw for metal;

- a circular saw;

- cutter;

- milling machine;

- ordinary stationery knife (provided that the thickness of the orgagla leaf is no more than 2 mm).

Plexiglass is a material that is characterized by reduced electrical conductivity. In other words, during cutting any of the above tools there is a danger of obtaining a burn, because it heats up very quickly. At home, it is recommended to work with thin sheets that can be cut as soon as possible.

Just in case, stock up on cold water for instant cooling, especially if you use a circular saw or a milling machine. Put the orgpesla leaf on the desktop, using the steel line, find the place that you will cut, carry out the tool along the ruler. In the case when you need to cut curls from the sheet, you can use a thread of nichrome.

Remember that after cutting a plexiglass at home, the edges at the joints become very sharp. Therefore, after the completion of the cutting procedure, it is necessary to polish and polish the sheet.

The need to saw organic glass does not arise very often when it comes to home use, but sometimes you still have to think about what tools may be required in this situation.

If you decide to independently make any of the plexiglass, then you will need to master the skills of working with this material. Acryl is most common 8 mm thick. It is worth noting that cutting or cutting off organic glass is not at all difficult, because this material is very excellent for all processing methods. Below, consider how you can cut plexiglass at home using available tools.

This is the best device than you can cut plexiglass. Adjust the speed with which the spiral enters the plexiglass. It will be easy to get used to work soon.

Then there will be no problems than cut orchins. The wood burning device is also suitable for these purposes.

How to Cut Plexiglass Without Chipping

Now you know in detail how to cut plexiglass. There are many modern technologies to use various methods with maximum efficiency.

Read how to cut the inner corner on the knock

When you understand how to see Plexiglas in your case, remember that it also bends well. We hope you will find this article useful.

How to cut acrylic sheet diy

One of the grandiose steps on the path to absolute leadership in the market was the purchase of special raw materials for.

produces sheets from plexiglass and occupies a leading position in the modern market.

Plexiglass. This is a universal synthetic material, which due to high wear resistance, strength and attractive appearance.

Polycarbonate visors. Modern and practical element of the protection of the porch and front door. For improvement.

Cellular polycarbonate is well known to a wide range of people, it is very popular, especially among those who.

Matte plexiglass. This type of organic glass made of synthetic acrylic resin has the following technical characteristics.

In the suburban zone there is always a need for additional buildings for household needs and relaxation. Majority.

Polygal. Best polycarbonate for greenhouses and greenhouses. High.quality polycarbonate for greenhouses makes it.

- Polycarbonate for greenhouses

- Is polystyrene harmful to human health?

- Polycarbonate windows

- Monolithic polycarbonate: types, characteristics, processing features

- With your own hands grinding methods

- Quickly remove polycarbonate film

- How and how to glue plexiglass. The most reliable ways

- How to make a plexiglass transparent?

- Which side to put polycarbonate in the sun on. Useful tips

- Plexiglass

- Gluing polystyrene: a piece of polystyrene, wood, metal

- Make your drops from greenhouse polycarbonate: photo, video, instructions

- Polystyrene or polyurethane. What’s better?

- Make your greenhouse from polycarbonate

- Polycarbonate drill: Make yourself: photo, video, instruction

- Make the greenhouses yourself from polycarbonate inside

- How to prepare a polycarbonate greenhouse for spring

- Make yourself a polycarbonate greenhouse loaf in 1 day

- Organization system from plexiglass: Instructions, photos, videos

- How to plant in a polycarbonate greenhouse: tips for gardeners

Thanks for your application! Our manager will contact you soon.

Here grandmothers have become modern. Ours, for example, called early in the morning and said: “I want a gazebo in the garden with a transparent roof, right under the scattered apple tree and a new greenhouse”. No, good, what is the habit of waking good people neither light nor dawn? She gets up with roosters, so she wakes us up! I understood this on a touch phone and wakes up, boring, you see, she also came up with something.

We will build a gazebo ourselves, but what kind of roof to make, and not a glass, in fact, to put. At least why not. “Organ! Orgagdoglo light, transparent, durable, ideal for arbors and greenhouses. And you can cut it yourself if it does not fit. You know how to cut plexiglass and how to do it right? Let’s look at this question in more detail.

Kryzaovka for work on metal

One of the most affordable options is to use a hacksaw. A good alternative than to cut plexiglass at home.

In its firmness, plexiglass can be compared with beech. So you can imagine how difficult and long you will have to cut the material. In addition, you will need to ensure that the glass does not heat up. Therefore, you will have to work very slowly.

It is convenient to make the markings with a marker, it leaves a bright and noticeable trace. The cutting line for the cutting of the cut is well applied with a knife, a nail.

At the same time, a hacksaw is an option on how to cut a plexiglass at home only if you have to cut it in a straight line. Fortable cuts will not be possible to perform well.

Good to know. When the canvas gets stuck during operation, pour a little water. So it will be possible to cool the fishing line for the cutting trimmer.

Cutting plexiglass at home

Cutting plexiglass at home is not difficult, as it is a malleable and easy to work material. Despite the external resemblance to ordinary glass, the operational characteristics of the organic glass are different, and it is processed by various methods: turning, strict, sawing, etc. Cut the plexiglass is permissible using a large number of devices.

Organization processing is carried out using the following tools:

Nichrome thread

Cutting by melting is carried out using nichrome wire. A voltage of up to 24 V is supplied through the reduction transformer to the wire, as a result of which it is severe heated. The nichrome thread is made by curved and curly cuts that have good surface quality and do not require further grinding.

Pets are used to cut with melting a screwdriver with a straight slot. The metal part of the screwdriver is heated by an electric soldering iron, while the end is pressed to the surface of the plexiglass. Then, holding the tool over the edge of the handle, a sheated screwdriver with a heated blade of a cutting line for a cutting trimmer. To carry out straight lines, it is more convenient to use a metal ruler or the smooth side of the hacksaw. Sequestol easily breaks along the drawn strip. details on

Circular saw or milling cutter

Circular saw or milling cutter is also a good option for working with organic glass. In this case, the milling cutter for the cutting of the plexiglass should be no thicker than 1 mm. It should be borne in mind that during cutting a saw or a milling cutter, the processed material is greatly warmed up, as a result of which it melts and foams at the site of the saw. In order not to spoil the workpiece, you need to provide cooling. To do this, use water poured into a bottle. The vessel is fixed in any way near the cutting tool, and the water is supplied to the working area using a thin hose.

The circular saw should work at high speeds. Some tools have a special mode for processing plexiglass. When working that do not require high quality cut, you can use the saw. The milling cutter is suitable for the production of thinner and clean cuts. When using a water cooling system, a smooth and smooth surface is obtained, and the cut will be transparent and neat.

Rezak

Plexigilass of small thickness is perfectly cut using a construction cutter. For this purpose, a homemade tool made of a hacksaw canvas, and even a stationery knife is suitable for this purpose.

The cut can only be made by a straight section. To do this, the line (preferably metallic) is pressed to the sheet of the material along the alleged cut, then several times with pressure is carried out with a cutting tool on the surface of the plexiglass along the ruler. Когда разрез достигнет середины слоя плексигласа, его можно легко переломить. The place of fault will be uneven and rough, so additional grinding will be required.

Scabble for metal

The easiest way is the cutting of organic glass with your own hands is carried out by a knife.haired metal. The cut lines must be previously drawn with a pencil or felt.tip pen. In the process of work, the hacksaw must be kept evenly, trying not to tilt it to the side. It is advisable to fix the workpiece hard. The surface of the cut will not be even. All irregularities and burrs are removed by a file and sandpaper.

How to cut a plexiglass

Wikihow works on the principle of wiki, which means that many of our articles are written by several authors. When creating this article on its editing and improvement, authors-volunteers worked.

Number of views of this article: 23 730.

Acrylic glass (polymethyl methacrylate) is a solid transparent plastic, better known as a plexiglass. Plexiglas, or organic glass, is mainly used instead of glass due to its strength, it is not as fragile as ordinary glass. You can buy Plexiglas in sheets and cut it with ordinary wood tools. The second part describes how to cut small and large sheets of organic glass.

Use this method to cut small pieces of plexiglass. (A sheet with which you can easily cope without outside help).

- Leave as much paper as possible on the glass until you complete your project. When you are ready to remove the packaging, just pick up one angle of protective packaging and remove it.

Put the sheet (still covered with protective packaging) on a flat even surface. If you do not have a workplace, you can put goats for a file of firewood. Use as a large number of work surfaces as possible to support the weight of the plexiglass.

Take the measure to measure the piece you want to cut off. Do not use fabric or metal measuring tape. For this material, the measure is best suited.

- Install the measure on the line you marched.

- Draw a glass cutter or knife from five to ten times along the line. The deeper the incision will be, the easier pieces of plexiglass will be disconnected. There are several ways to cut off the plexiglass:

- Use the glass cutter.

- Cut the sharp end of the paper knife or its dull side.

- Cut the plexiglass on both sides to make it easier to break off. Technically, you do not “cut” the plexiglass, you just make deep cuts to make it easier to break off.

Place a cut off a piece on the edge of your workplace. If only one part is cut off, place it so as to clearly see the fishing line for the trimmer of the cut that you noted.

Press on the cut part. Press strongly enough to break off the cut part. It is easier to do this if you place the bars of the tree along a piece of the plexiglass and press on it. This pressure will be more than enough.

- Pick up a piece of organic glass on the table or machine.

- With the help of a motopile, burn glass angles. This method is suitable if your penigns sheet is at least 5 cm thick. Place the plexiglass so that you have enough protrusion to provide a sufficient gap for the saw blade.

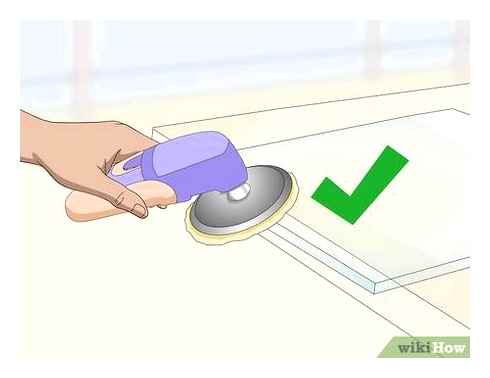

- Take a drill with a buffer for thicker pieces of plexiglass. Cover the grinding lining with a polishing mixture before starting to polish the surface of the glass.

Use high.speed metal blades. Buy blades intended for cutting plexiglass. Use a carbide blade if you cut more than one sheet of plexiglass at a time or a thick piece.

- In a bottle, mix together a couple of drops of an emulsion of water to get a spray.

- Spray the blade with this solution. There is no need to apply this solution abundantly, and in most cases it will not be useful at all.

Work with a saw at the right speed. The ideal speed when cutting a plexiglass is 3450 revolutions per minute. The speed of the material should be about 10 cm per second. Keep the correct and constant speed so as not to break the plexiglass or so as not to jam the blade.

Pour sharp corners. Use an electric saw or a polishing drill to smooth out the corners.

Electric

For cutting polymethyl methacrylate, an electric jigsaw is used with special files for organic glass. Jergery for plexiglass have a special marking. the letters of the Latin alphabet MP.S.

For slicing plexiglass at home, an electrician with mp marking saws are often used.S

During the cut, the canvas must be controlled by the speed of the tool. The more revolutions, the higher the speed of the electrician. With a high cutting rate, the synthetic polymer begins to melt. The cut place becomes white and sealed. such material is unsuitable for operation.

The feed speed and the number of speeds of the files are selected experimentally. Before cutting the working canvas, it is recommended to practice unnecessary fragments of polymethyl methacrylate.

The electric jigsaw is used to create a straight and curved cut line.

Cutting Plexiglass with a three.toothed disk

How to cut plexiglass in large volumes? Technical improvement of manual tools does not stand still. For more efficient use of corner grinder, the industry has released a three.toothed saw on wood.The three.toothed saw disk in its technical characteristics, along with wood, is also mentioned organic glass. He copes excellently with sharp acrylic for rectilinear cuts. The material does not heat up, does not melting and does not stick to the saw disc. This disk over the teeth thick from 5 to 10 mm.

How to work with a corner grinding grinder with a three.toothed saw disk, see this

In addition to corner grinders, people’s craftsmen use an electrician with special saws for plexiglass.

Cutting with an electrician

The use of an electric jigsaw is quite justified, but it should have a speed adjustment. For cutting, special files for organic glass are used.

If you do not have to buy them or you need to cut it already, then use wood files. The main rule exists here: the teeth should be small, and the cutting speed is small. At high speeds, the cut begins to melt and becomes white. For some products, such white seams are not suitable.

Tip: in order to remove the burrs, and make it cut with a clean flame of a gas burner. In extreme cases, you can adapt the lighter.

Electrician allows you to do curvaline cuts. For this purpose, you need to choose narrow saw canvases.

Tip: When buying files for organic glass, pay attention to the marking. It should have Latin letters MP.S.

Cutting mp files.S curvoline details

During cutting, pay attention to the speed of the tool. The higher the speed, the more the feed rate can be. The speed and turning speed are selected experimentally so that acrylic does not melt. During cutting, it is necessary to use a protective mask on the whole face from fragments flying at high speed.

If the details of a complex curved shape, then for cutting organic glass it is permissible to use a nichrome spiral.

How to cut a circle

If, without thinking of grabbing this business, then it is unlikely that something from this will come out.

After all, a very peculiar material was organized:

- It heats up quickly and contributes to the breakdown of the tool;

- If it is rude to handle it, then it can crack;

- In order not to break the strings of the jigsaw, you need not to influence the force;

All these properties indicate that cutting a circle from this plexiglass is not so easy. Before starting the cutting process, it is necessary to process the material.

These processing methods are for plexiglass, whose thickness is about four millimeters, but not more. There are also ready.made knives for acrylic. They will help a person in marks and in difficult areas will help to solve various problems.

Such a device can be sawed up to one centimeter of plastic. Also, this method will save a very large amount of time and will make cutting in sufficiently large quantities.

With the help of an electric jigsaw, you can also produce a large amount of work, only in this case it will be more convenient. You can use wood files. Just do not need to develop high speed, otherwise the device may fail.

Additionally: Miracle Lobzik for artistic sawing

But you need to remember that if the teeth are large, then such files will not go. Very small teeth are needed, and the speed of cutting should be the smallest.

In order to cut a circle, you need to draw the shape of a circle on a fake. Then start cut in the right form.

You should choose an interesting cutting option and proceed to the process.

Laser

The most convenient method of sawing acrylic is a laser. However, this method cannot be applied at home, it is used exclusively in industrial production.

A thin laser allows you to make accurate incisions and cut even the smallest details of the future structure or product. If necessary, you can contact a specialized workshop or an enterprise that is engaged in the production of organic glass and products from it. It is recommended to make drawings in advance and mark on the polymethyl methacrylate canvas.

The laser allows you to carefully chop and plexiglass even small parts, is used only in industrial production

Cutting organic glass at home is a fairly simple operation that can be performed using improvised tools. In order to decide how and how to cut the plexiglass, you need to pay attention to the thickness of the sheets, the presence of curved elements in details, as well as a set of tools that are available in a home master. The most universal is the method using a milling cutter and a nichrome thread, and the simplest method is cutting using a hacksaw.

In our online store you can buy colored plexiglass and other varieties of organic glass at a favorable price!

How to cut plexiglass at home

The need to saw organic glass does not arise very often when it comes to home use, but sometimes you still have to think about what tools may be required in this situation.

If you decide to independently make any of the plexiglass, then you will need to master the skills of working with this material. Acryl is most common 8 mm thick. It is worth noting that cutting or cutting off organic glass is not at all difficult, because this material is very excellent for all processing methods. Below, consider how you can cut plexiglass at home using available tools.

The methods of sawing plexiglass

If you decide to engage in the manufacture of some products from acrylic or maybe you need to repair the product that has a product, then it is quite possible for you to drink it to remove the deformed element. The following methods are available at home:

- Use a scum for metal. An plexiglass with a thickness of 8 mm can easily be cut with this tool, but be prepared for the fact that the place of the cut will turn out to be inaccurate, you will need additional grinding with a file or a file.

- You can use the cutter. The method looks as follows: on an element of organic glass, which needs to be cut off, a line made of metal is pressed, then draw a couple of times with a cutter. The thickness is cut into half and carefully pierce it.

- Circular saw is also suitable, it can easily cope with an organic glass of 8 mm or thicker. Some masters use metal mills, the thickness of which is from 0.5-1 mm. In the process of working with milling cutters, they are relatively fast, this leads to the release of smoke, while the surface acquires roughness, and due to high temperature it can be foamed. To avoid such a result, the saw must be cooled in the process. To do this, you can install a container with water on one side of the cutter and serve it on a plastic hose from there. When organizing such cooling, you can achieve a neat and transparent cut.

- If necessary, cut an 8 millimeter or other sheet of plexiglass is not on a flat line, you can use a nichrome thread.This will need to build a small cutting tool. The nichrome thread will need to be heated well, for this it is connected to a 24V transformer or less. When the thread is heated, it can be cut by acrylic according to the pre.prescribed trajectory.

- Another method to cut an organic glass with a thickness of 8 mm or with other parameters, to use a slotted screwdriver. Having attached her end to the place of the cut, the blade is heated with a soldier for 25W. Code temperature reaches the melting of the material, with a sharp movement it is necessary to draw a straight line for a trimmer along the guide ruler. Then it remains to just break off the part, it will be very simple to do.

As can be seen from the information given, the cutting of an organic glass at home is a completely simple task. Home craftsmen use these methods, as well as adapt and come up with more convenient and accessible methods. So you can use a jigsaw, and if the thickness of the material is less than 2 mm, even an ordinary stationery knife will cope with cutting.

Regardless of the chosen cutting method or cutting, to obtain a neat cut place, it is recommended to polish, and then polish it.

Industrial cutting of plexiglass

The most popular tool, if it is necessary to cut or cutting a leaf of plexiglass, is a laser machine. When using it, you can achieve the accuracy and purity of the work performed. Productivity also increases significantly, the costs of human labor are reduced.

Laser cutting is carried out on the in.line lines. If there is a need to carry out non.standard orders, a machine with the possibility of management is used. Such equipment is enough to reconfigure to the necessary parameters to complete a specific order.

Milling cutting is carried out on a machine in which the fastening of the working tool is performed by vertical. The material sheet is fixed on a special machine. The operator enters the work parameters to the program, this is:

In order to inflict engraving to the surface of the plexiglass, you can also use the same equipment. The operator makes appropriate changes to the program.

In addition to the laser beam in production, disk and tape saws are used. The former allow you to perform rectilinear cuts, and the latter allow you to perform curved cuts. In order to obtain neat surfaces at the site of the cut, it is recommended to use the cutter. Disk saws are more often used for rectilinear cuts with a clear cutting line.

High.speed equipment is used to perform really high.quality cutting. The speed of rotation can reach 4 thousand. rpm. This method is better not to use with casting plexiglass, otherwise it can simply get better due to high temperature at the processing site.

Working with an outflow of the house

If necessary, you can process and cut plexiglass at home. Working with this material is quite simple. In order for you to succeed, you just need to remember some features of acrylic, which will help you achieve a good result when cutting.

You can choose one of the proposed tools that will be most convenient for you to work. So you may need:

- Hacksaw. Suitable is the one that is used to work with metal;

- A circular saw;

- Cutter. You can purchase this tool or make it with your own hands;

- Jigsaw;

- Filament.

It should be borne in mind that the plexiglass has a low electrical conductivity indicator. That is why at home, using improvised tools, it is necessary to act carefully. Cut acrylic better with a sharp movement. Therefore, it is necessary to prepare everything in advance, outline the fishing line for the trimmer of the cut. There must certainly be water next to the workplace. It will be required to cool the cut. After cutting, you will need to process the cut, remove the existing roughness.

Consider the process of cutting plexiglass at home when using the listed tools.

- A fairly simple and inexpensive way. this is cutting with a hacksaw for metal. The outline is not smooth. Additionally process it when using sandpaper or a file is suitable.

- Cutter. To carry out cutting, you will also need a ruler, better metal. Place it along the planned cut line.Next, using the cutter, draw a fishing line for a trimmer along the intended line with pressure. Do it 2-3 times. The thickness of the canvas must be cut by 50%. Then just break the plexiglass along the cutting line. The edge will also turn out rough, it will require its processing.

- At home, you can use a thin cutter. It is used as an electric drill nozzle. Be prepared for the fact that smoke will stand out in the process, and acrylic will quickly heat up. To avoid heating and melting the material at the process of processing, use cooling with water. Additional processing in this case does not need.

- To obtain curly circuits, you can use the voltage thread from the tungsten. To build such a tool, you will need a transformer that lowers a voltage of 220V by 24V. Next, attach the thread between the two insulators, the voltage is supplied to it. When everything is ready and the thread is heated, cut out the required figure. The heated thread will melt the material.

If you are planning to process an plexiglass with your own hands using the tools available in your house or building such, you can independently cut it into the required elements.