What and how to saw plywood and chipboard without splitting

Chips and fiber breaks occur because the structure of the material being sawed is not uniform. Usually they are observed on the back or on the face of plywood or chipboard. This is especially true of laminated plywood, the protective surface of which differs significantly from the inner structure of the sheet. Let us tell you how and what you can saw chipboard and plywood without splitting at home.

A perfectly even cut is obtained when cutting materials on laser or milling machines. But sometimes it becomes necessary to saw panels manually. The following tools may be needed in such cases:

To get a cut without chips and ripped out fibers, you should use a saw blade with small teeth and their small camber. There are only two requirements for the selection of circular saw blades. First, they must also have small teeth. Secondly, the cutting edge should touch the surface of the plywood panel or board Woodchip board at almost right angles.

To get a clean cut, you can use blades designed to work with metal. The fine teeth result in a neat cut, although the sawing process slows down. Because of the great thickness of metal saws, they are not suitable for sawing small shapes. The minimum bending radius that is possible with them is 60-80 cm.

Answer@: What is the best way to saw plywood??

The best option-electrol jigsaw, if the plywood is thick, if thin, and a little need to saw off, you can, and hand, and to avoid chipping correctly pick up a saw, they are sold in almost all hardware stores, are numbered and there is a destination for each material. I cut plywood with a saw designed for laminate. Good luck with your construction projects.

The jigsaw, small chips will be, it is necessary to grind with a sandpaper. you know what I mean electric jigsaw.?

on a format cutter or at least a circular saw, but with a proprietary blade for cutting Laminated chipboard. Better contact the company, which deals with furniture, you on the formatting machine will saw, though you first need to see their sawing, and then formatters are different and adjust them in different ways can, and blunt saws can also saw) Well, if it does not fit, then the jigsaw, but pre-scotch in place of the saw to glue on both sides, but it is already nonsense get, though who knows what cut you actually need.

The jigsaw will give chippings in any case You want without chippings? or with a high-speed circular saw or a circular saw

Jigsaw-just need to pick up a saw try on the scraps, as well as when sawing put on a constant mode and lead the jigsaw without pressing and not hurrying.

A circular saw will be smoother than a jigsaw will not be perfect, and chips will be in any case

angle grinder with a disk from a circular saw. a week ago. without any chipping at all. 8000 rpm. but it’s dangerous.

I sawed 4 sheets of plywood today with a hand-held circular saw evenly turned out.

If you do not have a power tool, you can saw off with a wide metal hacksaw blade.

How to saw plywood without chips and burrs

Often beginners have trouble cutting plywood. Namely, when sawing plywood across the fibers, the top layer of veneer chipped. It is especially unpleasant if the sawing is done on an already scorched painting. These chips appear for various reasons. In most cases, they are almost impossible to fix. In this article we will consider the main reasons of splinters and a couple of tips on how to avoid them in finished portraits.

Chipping occurs because the saw with its teeth pointing upward rips off the top layer of veneer. Because there is space between the jigsaw tines and the saw blade, the breaks occur in this space.

Disengage the pendulum motion on the jigsaw.

On a number of modern electric jigsaws there is a setting that helps speed up wood sawing. Sawing speed increases significantly. But the quality of the cut suffers, and splinters appear on the surface.

How to saw plywood without chipping with a circular saw?

It is recommended to make the cut on a flat floor. A sheet of plywood is placed on wooden blocks of equal thickness, placed perpendicular to the cutting line. Full support from below ensures that the corner of the sheet will not break off at the end of the cut. A metal or wooden guide rail is installed on top, which is rigidly fixed with clamps.

In order to accurately and without splinters to cut laminated plywood, you need:

- Setting minimum cutting depth. On the opposite side of the sheet the teeth should protrude 2-3 mm. With this cutting depth setting the blade does not cut through, but rather gently cuts through the wood.

- Choosing the right circular saw. For a gentler cut, a blade with a minimum size and a high number of teeth (e.g. 40) is chosen.

- Low feed rate of the cutting blade when moving without stopping. In this case, the teeth do not chop, but gently cut the wood without chipping. In order to cut laminated plywood correctly, it is also recommended to set the disk rotation speed to maximum. One disadvantage of this method: the carpenter risks overheating the blade.

- Laying of adhesive tape on the kerf. It is recommended to use masking tape that does not leave marks on the surface of the sheet. When work is complete the band is removed at a 90 o’clock angle with the saw blade pointing in the direction of the cut.

If laminated plywood is to be processed, it is recommended that the circular saw blade is also sealed with tape. This avoids scratching the front side of the sheet.

Both an electric jigsaw and a circular saw are suitable for cutting this material. The first option is indispensable in the case of a shaped cutting path.

To saw thick plywood without chipping with an electric jigsaw, it is recommended to use either of the two types of blades:

An ordinary circular saw is also good for a straight cut of a plywood sheet. It is enough to install a blade with a fine tooth (for example, 40), to adjust the depth of cut in the range of 12-13 mm and lay the sheet on flat wooden bars. It is recommended to make the cut along the guide, with a low feed rate of the tool and without interruptions.

If the front surface of the sheet is laminated, the place of the cut should be preliminarily covered with masking tape.

Everyone who doubts which saw is better to cut plywood, we recommend to address to the specialized firm with laser cutting and professional equipment for sawing.

To saw from the rough side

The fact that standard saws have their teeth facing away from the jigsaw (as opposed to back-toothed saws). These files “eat up” the wood as they move from bottom to top. When the tooth catches on the top layer of veneer, it often splits and creates a chip. The underside is often left with a very good edge. From this the craftsmen drew the simple conclusion that for a clean saw it is enough to turn the plywood upside down and saw from the “wrong” side. The method gives the best result, so feel free to take it.

It is a special liner for a certain brand of jigsaw. It is simply inserted between the legs of the jigsaw and is not fixed in any way. The liner adjoins the file so it does not let the top layer fluff up (that is why chips occur) and therefore the saw is very smooth. Masters advise to use saws of the same manufacturer as the jigsaw. so the quality of the cut will be better with the use of the insert.

Pads are sold in sets of three to five. They are not eternal. you have to change them periodically.

It costs about 400 for a Bosch jigsaw, for example.

If you can not find the insert on your jigsaw, or do not want to buy it, there is a little handyhack from the masters. glue an ordinary scotch tape in the place where you will saw. The scotch needs to be well ironed with your fingernail. Then saw right on top of the tape. Then remove it. The result is similar to the liner.

You can also make a sole like this yourself. Here is an example of how our customer made a backing for his jigsaw from a thin sheet of tin.

But it’s more convenient to make such a platform out of Plexiglas sheet. And glue it to the bottom of the jigsaw with double-sided tape.

You get a clean cut with a homemade jigsaw insert as well.

Using painter’s tape

Before sawing, you can glue masking tape on the plywood, then the cut will be cleaner. It is better to use masking tape, not ordinary tape. It leaves no sticky residue on the plywood and is easy to remove. Before cutting, make sure that the tape is well adhered.

This method is not so bad. But I personally don’t like this method.

First, the tape often comes off when sawing and chips appear in these places.

Secondly if you want to saw off plywood that already has a burnout picture made on the pyroprinter machine there is a risk that the fine details of the picture will remain on the painter’s tape.

What to cut plywood with? Choosing a tool and saw blade for a jigsaw

For the home craftsman it can be quite difficult to get a quality, splinter-free cut of plywood. It not only requires a certain skill, but also the “right” tool.

Choose a tool

At home, you can cut plywood with both hand and power tools.

Power tool for cutting plywood:

Less common, but still can be used to cut plywood with power tools such as angle grinders or band saws.

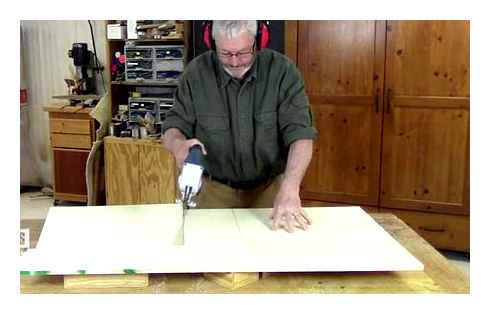

How To Make Straight Cuts with a Circular Saw and a Straight Edge or a Kreg Rip Cut

| Fig. 1.а. Cutting plywood with a circular saw | Rice. 1.б. Cutting plywood with an electric jigsaw |

All pictures are taken from public sources and are provided as examples, illustrations. And they are not the copyright of our company. If you found your pictures here and want to delete them, write to us.

A few words about circular saws

Some of the advantages of the circular saws are, for example, the ability to cut several sheets of plywood, chipboard or fiberboard (stack) at once. And also that electric circular saws allow cutting both thicker and thinner sheets of plywood.

The disadvantages of the circular tool, on the other hand, are the difficulty in obtaining geometrically difficult cuts and details in plywood. This way of sawing is suitable mainly for cutting in straight lines.

The plywood jigsaw. perfect for the do-it-yourselfer

However, more “piecework” or even small figurative work is more often required in home conditions. For which an ordinary hand or electric jigsaw is quite suitable. The latter, of course, significantly speeds up and facilitates the process of cutting plywood sheets.

Hand tools for cutting plywood:

If we talk about hand tools, then for straight and long cuts can be used special hacksaws for plywood and chipboard. Such as these:

Hacksaws and saws of this kind are usually made of spring steel with a t.н. reverse tines. And they can be additionally equipped with what the manufacturers call a “kick tooth”. made of a material harder than the basic saw blade.

Spring steel is a medium or high-carbon steel with the ability to easily return to its original shape (despite significant bending and twisting). This is due to the high yield strength of this type of low-alloy steel.

If you plan to cut from plywood quite small and geometric complex parts, shaped workpieces. then from the hand tool you will, of course, need a jigsaw. It is something like this:

Hand tool or electric tool?

We would like to note, however, that sawing plywood with a hand-held tool may in some cases not be a very pleasant procedure. The layered structure of plywood with differently oriented wood fibers in these layers makes the process quite complex. You will not saw much.

Therefore, choosing what to cut plywood at home, we recommend opting for a modern electric tool. of which the most universal tool for working with plywood, as it seems to us, is an electric jigsaw.

What saw for a jigsaw to saw plywood?

However, often the most important is not exactly what tool you decide to use of the available to you. And how well you choose the cutting edge for your tool.

Choice of jigsaws by material type

Deciding what saw for a jigsaw to choose for plywood, first of all, pay attention to the purpose of the saws by the type of material that is planned to cut.

- It is clear that as the plywood is made of wood the saws for plywood are mostly the same as for wood.

- For laminated plywood, many craftsmen also recommend saw blades for laminate to avoid chipping on the front side and to make the cut neat. It has a special “reverse tooth”. it is directed to the other side comparing to other saws. that just to avoid chipping on the face side of both laminate and plywood not to spoil the appearance. (The reverse tooth saw may be marked with the letter ” R”. reverse).

- Some people prefer to use universal saws that work equally well with wood and metal. Sometimes such universal saws include also combined ones: teeth on one half of the saw blade are small, and on the other half. large.

By the way, most manufacturers of equipment for power tools adhere to the standard labeling, which also contains information about the purpose of the saw blade depending on the cutting material. First of all the steel grade from which it is made is taken into account. And it is the letter designation of this brand that can be found on the so-called saw’s neck (at the border of the shank and the cutting blade itself):

- CV. chrome vanadium steel (for wood and wood-based panels),

- HCS. high carbon steel (for wood and wood-based panels and plastics),

- HSS. high-speed steel (for ferrous and non-ferrous metals),

- HM. tungsten carbide hard alloy (for ceramics, fiberglass, etc.).)

- BM (or BIM, or Bi-Metal). highly flexible combination of HSS and HCS (professional saws for wood and metal).

What to cut plywood with. Tools for sawing plywood at home.

Plywood. sheet material. Sheets are glued veneers with the fibers of each subsequent layer oriented perpendicularly to each other. It is this gluing technique that gives plywood sheets stiffness and strength. Depending on the type of plywood and its moisture resistance, its veneer is glued with different adhesives. Plywood is available in 1525x1525mm, 1220x2440mm, 1250x2500mm, 1500x3000mm and 1525x3050mm formats. At the factories saw plywood with professional machines and equipment, but in the home there are certain difficulties when choosing a tool for sawing plywood sheets. In this article we will tell you how to saw plywood and how to get a perfectly straight edge of the plate.

Tools for sawing plywood:

Hacksaw / Wood saw 2. Manual jigsaw 3. Electric jigsaw 4. Manual electric saw 5. angle grinder / angle grinder 6. Circular saw.

Sawing plywood with a hacksaw.

You can buy a universal wood hacksaw at construction stores (fig.1). It is good for sawing plywood, but it doesn’t always cut straight. But still, we advise you to buy a special plywood saw (Fig.2), due to small and frequent teeth it allows to get a perfectly flat edge of the sheet. Small serrations are also available with a laminate and plastic saw, it is also a good solution for cutting plywood.

Disadvantages of using it:. Sawing plywood with a hacksaw will take a lot of time and effort due to different directions of grain of veneer sheet materialNo hacksaw can make only straight cuts, curved details and strongly curved elements cannot be sawed When sawing it is necessary to observe the technology of cutting: it is recommended to place sheets of plywood on two supports to avoid failure of hacksaw and damage of sawn fragments.

Cut thin plywood without saw and chippings

Sawing plywood with a hand jigsaw.

For sawing plywood into small shaped elements, as well as for sawing inside the sheet a hand jigsaw is used. The advantage of the hand jigsaw is the formation of complex areas, where the wood saw does not cope, the disadvantages include the labor intensity, as well as cutting thin sheets of plywood. for sawing sheets of thickness over 8mm hand jigsaw is not used.

Sawing plywood with an electric jigsaw.

Electric jigsaw allows you to qualitatively and quickly saw a plywood sheet. When choosing a cutter it is necessary to take into account size and pitch of teeth, which will determine the quality of the edge of the sawn sheet. The smaller and more frequent the teeth of the electric jigsaw head, the better will be the cut, and you will get less chips in the sheet. The best cutting result is obtained when using a special saw for plywood. Alternatively, you can use a metal saw, it also has a fine and frequent teeth, but when sawing they can be clogged. Particular attention must be paid to the direction of the teeth; depending on the direction, one side of the saw will be free of chips.

Cutting plywood with an electric hand saw.

In the range of handheld electric saws there are saber saws (Fig.3) and a circular saw (fig.4) (circular saw). A saber hand saw is more suitable for rough work, with its help it is not possible to get a smooth and accurate saw.

For even cutting of plywood sheet use circular saws, they can easily saw your sheet without splintering to specific dimensions. You can saw a large volume of plywood with a circular saw without any difficulty, the disadvantages are straight cuts of plywood, and it is impossible to saw the curved elements with it. The advantage is ease of use, cutting speed and adjustable cutting depth. For cutting plywood with a circular saw you should choose small disks with fine teeth, also pay attention to the teeth pitch: for cutting thicker sheets you should buy a disk with maximum pitch.

Sawing plywood angle grinder

angle grinder is very rarely used when cutting plywood, but in home conditions, when there is nothing but an angle grinder, you can use it to cut plywood to your size. It takes a little effort to hold an angle grinder when sawing. For cutting plywood on the angle grinder set disk from a circular saw, but still, if you do not use a cover, this method of cutting is the most dangerous, be careful.

Sawing plywood with a circular saw

Circular machine is a device for sawing plywood, which is a cutting disk mounted on a tabletop. The advantages of cutting plywood is fast and easy sawing. It is not necessary to hold the tool like in case of electric hand saw, it is only necessary to fix the plywood sheet on the table surface. When choosing a disk you need to consider the number of teeth: the more teeth on the disk, the cleaner and more accurate the cut of plywood will be. The disadvantages include the fact that the machine takes a lot of space, unlike hand tools, to work on it you need a separate room or garage.

Tips

To cut a plywood sheet correctly, you need to use the right tool and follow some rules:

- Before the cut it is necessary to make all measurements and check yourself in order to avoid unfortunate mistakes;

- keep an eye on the power cord during operation;

- Before using the tool it is necessary to adjust the depth of cut to the desired value;

- the saw blade must be suitable for cutting plywood;

- Use of the saw must be accompanied by the use of protective gloves and goggles;

- blunt saw blades are more dangerous than sharpened ones;

- while cutting plywood it is necessary to observe safety not to bring your hands close to the blade;

- Do not put your hands close to the blade;. Unlearn how to work with power tools.