How to fix polycarbonate-a step-by-step master class of fastening to a metal and wooden frame of a canopy, greenhouses, fence

The monolithic model has a continuous structure, as in the usual glass, but due to the polymer base, it is much stronger and lighter than glass, and has an additional opposite of physical influence, due to the property of bending.

These elements are used as a complete change of glass in municipal and residential buildings in trade, entertaining and scientific institutions. In the future, the narrative will be discussed how to fix polycarbonate, the characteristics of raw materials and the details of actions with it.

It is not difficult to fix this material, for manipulations, accessible tools are used, and the fasteners can be captured in a short time.

Polycarbonate structure

The material is inherent in the cellular structure, the plates consist of 2-3 sheets, interconnected by bulkheads. These bulkheads are ribs of stiffness and endow the plates with a large fortress.

Thermal insulation properties are detected by the number of layers in the stove, there are 2-4 of them. 90% of the light passes through the material, the material bends, much stronger than glass, has a large parameter of resistance to violations.

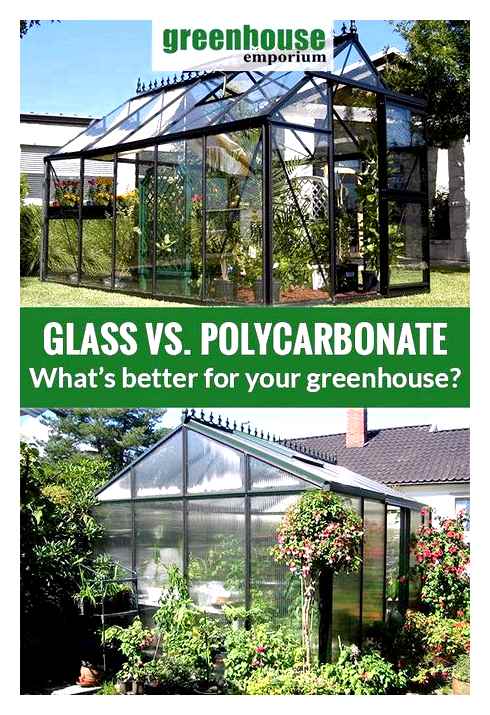

Perfect for the formation of arched structures and is very often used to cover greenhouses. A separate sheet has a film cover that protects it from destruction by an ultraviolet spectrum.

On the front side there is an additional selective coating that transmits only the necessary spectrum of light. Such plastic is designed for greenhouses.

What is cut polycarbonate

A feature of polycarbonate is the fact that in order to cut it at home, you can use any construction tool.

- stationery or construction knife;

- electric jigsaw;

- corner grinding machine (corner grinder);

- a circular saw;

- hacksaw designed to work on metal.

If we consider industrial equipment, then you can use a milling machine that has a numerical software control and a special laser of several types.

It is worth considering the fact that there are a number of building tools that in no case cut polycarbonate. This is due to the fact that there is a high probability of damaging the sheet, as a result of which the quality will suffer greatly.

Many experts recommend refraining from use:

- Hacksaw designed to work on wood. as you know, such a model has quite large teeth, so that the material is not cut, but torn during operation. Ultimately, the slice will have a large number of cracks, zabrin and burrs.

- Building scissors or metal scissors. this option is perfect for thin monolithic polycarbonate. Cellular polymer material will be deformed from two sides.

Before cutting polycarbonate, you need to choose the right tool.

How to cut monolithic polycarbonate

If necessary, you can carry out the process of cutting monolithic polycarbonate at home. For these purposes, a disk saw that has small teeth is perfect. In order to not only cut the polymer material, but also achieve the best result, many experts recommend giving preference to teeth that are equipped with special hard inserts. Thanks to this approach, you can prevent an undesirable process of heating the material. If it is planned to cut a sheet, the thickness of which reaches up to 2 mm, then in this case it is recommended to simultaneously cut from 10 polycarbonate sheets. As practice shows, cutting several sheets at the same time is much easier and more convenient than one.

It is important to understand that if you cut a single polycarbonate sheet of small thickness, then the material can be covered with cracks during operation. In this case, it is best to use a guillotine cut, but this method has a significant drawback. the edges of the cut will be rough. If necessary, you can use a strip saw up to 2 cm wide.

Advice! For monolithic polycarbonate, the thickness of which exceeds 6 mm, it is recommended to use an electric tool.

How to cut cellular polycarbonate

If it is planned to cut cellular polycarbonate at home, it should be understood that this type of building material has a porous structure, as a result of which the process of work can be very specific. If the thickness of the material does not exceed 1 cm, then in this case you can do only with a clerical or construction knife with a retractable blade. When cutting cellular polycarbonate along the ribs of stiffness, it will be necessary to perform work in several stages.

The starting cutting should be carried out on the outer surface, after which a sheet of cellular polycarbonate is turned over and performed a similar action, only on the other side of the building material. Когда возникла необходимость резать поликарбонатный лист поперек ребер жесткости, то алгоритм действий будет включать уже 3 этапа. Thus, as in the previous version, the product is cut on both sides, after which they carefully cut the internal partition.

When a polymer product in thickness exceeds 1 cm, you will need to use a hacksaw for metal or wood, while the teeth must be divorced. In the presence of an electric tool, for example, an angular grinder or a jigsaw, it is possible to give preference to them, but at the same time the revolutions of the selected tool should be at the minimum level.

Preparation and marking of sheets

Before starting to cut polycarbonate on a greenhouse or any other structure, it is necessary to pre.carry out preparatory work and make the corresponding markup on the material.

First of all, it is necessary to completely clear the place where it is planned to cut the polymer material. All garbage and extra objects must be removed. This is necessary not because of considerations of purity, but so that during operation nothing distracts from the process. After the surface is prepared, it is necessary to put a sheet of plywood on it or a wood.fiber slab. Only after this, the place for cutting can be considered as even as possible.

A sheet of polycarbonate should be put on the workplace. In the event that the material has a laminated surface, a mirror or special coating, then this side should look up. Until that moment, until the material is cut, the protective film should remain in place.

Preliminary marking should initially be applied to a blank sheet of paper as a scheme in compliance with scale. After that, you will need to transfer all the marking from the paper sheet to polycarbonate. For measurements at home, it is best to use roulette or metal ruler. Black marker is used to apply markup. If it is planned to work with a large polycarbonate, then many experts recommend putting a board on a polymer material, 10 cm wide and move only along it. This approach will eliminate damage to polycarbonate.

In the place where it is planned to cut the sheet, it is required to put wooden boards about 4 cm high on the right and left side of the cut line 10 cm wide. The ends of the boards must look out on both sides of the polymer material.

Movement must be carried out on the board in the same way as at the time of application of the appropriate marking. This is the only way to not damage the material, carrying out all the work at home.

Attention! If the sheet lies on top of garbage and other objects, then dents may appear. So cut polycarbonate at home, it is unlikely that it will work.

Cut polycarbonate into the ends of the greenhouse by steps

If the polycarbonate sheets are simply placed on the frame in the length of the greenhouse entirely and attached, then for the ends where the doors are (or the deaf “wall” with the window), it is necessary to cut out the details of the corresponding form. In this article, we will give useful tips from professionals on how to correctly cut polycarbonate and how to accurately cut the end elements. Therefore, you can perform high.quality installation of a polycarbonate greenhouse with your own hands.

Since modern greenhouses have different forms and features of frames, you need to familiarize yourself with the instructions for your product or request it from the manufacturer. In it you will find a diagram of cutting polycarbonate for the ends. it will vary for greenhouses of arched, drip, gable. Next, you can transfer the drawing to the sheets of polycarbonate and cut the necessary elements of the specified sizes.

Prepare a convenient place for cutting. clear the site by removing sharp and solid items that can damage plastic. For reliability, you can cover the place of cutting cardboard or any other dense and even material.

Without removing the protective film, lay out the sheet (or several at once).

Use the drawing from the instructions or draw up a diagram on paper yourself, checking with dimensions and configuration of the frame of the greenhouse.

Using a long ruler and marker, transfer the drawing to polycarbonate. Remember that you can’t walk on plastic in order to avoid deformation, if necessary. do it only by lingering a wide board under your feet or knees.

Take two boards that have a length larger than that of polycarbonate sheets. They should be a thickness of 4 cm and up to 15 cm wide. the devices will serve as supports to support plastic during cutting.

Next, using a suitable tool, make cuts along the marking lines and remove the chips from the sheets. Now the details are ready, and they can be attached.

Useful tips for the disclosure of polycarbonate

The process of cutting polycarbonate for ends is quite simple in steps, but when they are performed, you may face some difficulties. To do everything right and prevent damage to polycarbonate, read the basic rules of cutting.

- It is better to cut a stack of sheets than only one. it helps to avoid cracks.

- Not suitable for cutting polycarbonate: a hacksaw on wood, saw with large teeth, construction scissors and scissors for cutting solid plastic.

- Suitable for cutting polycarbonate: mounting or stationery knife, electric jigsaw, metal hacksaw, grinding angular grinder, circular saw, laser.

- It will be more accurate to cut polycarbonate, working together. the second person must hold sheets.

- Small irregularities of the cut are most convenient to fix with a knife.

- For greater durability and tightness, you can glue the sealing tape (at the top) and an oral tape with a end profile (below). So moisture will not destroy the honeycomb from the inside.

- Cut the canvas along the line along empty cells.

- Remove the protective film only at the end of the installation. It is a mistake to leave it. later the glue under the sun is deformed, and polycarbonate will lose in translucent, its appearance will deteriorate.

Some manufacturers provide a polycarbonate cutting service for independent installation by the buyer. This greatly facilitates installation work, excludes the errors of cutting. And the most reliable is to order installation from the manufacturer, since it is he who best owns the technology for installing his greenhouse. Contact us and we will offer the most acceptable option for you.

Choosing tools and cutting rules

Consider how and what is better to cut cellular polycarbonate and monolithic translucent polymer.

It is important that the tool does not spoil the material. for example, scissors for cutting plastic or construction scissors cannot be used, they compress cellular polycarbonate, deforming the edges of the cut.

A sawing tool with large teeth is also contraindicated, including a hacksaw on wood. it tears the material, the cut is uneven, with burrs and zazubsi.

- knife (mounting or stationery);

- corner grinding machine (corner grinder);

- circular saw;

- hacksaw for metal;

- electric jigsaw;

- laser.

The cutting method is selected based on the tool at the disposal, thickness and structure of the material.

Using a knife

For cutting polycarbonate, a stationery knife is used, in which the blade consists of broketing out segments. A construction knife is also suitable, it is more convenient to use thanks to an ergonomic handle. You can use a shoe knife.

For monolithic polycarbonate, this tool is not suitable, since the material is too hard and the work will require a lot of time and effort. It is convenient to cut cellular sheets of small thickness with a knife. no more than 6-8 mm.

Before cutting the panel, check the sharpness of the blade on unnecessary scraps. If necessary, sharpen the boot knife or remove the dull elements of the drawer blade. Use the rule or metal ruler for cutting in a straight line. The knife blade should be located at an angle to the surface. the thicker the material, the more the angle should be closer to the straight.

First, an incision is performed at the end, then, without removing the blades from the serif, they slowly lead it along the marking line. Irregularities and random extra fragments are removed after the element is cut out of the stove. If polycarbonate material is not cut from one entry, repeat the process according to the same scheme. It is impossible to disinfect, break the sheet, otherwise its edges will be strongly deformed.

If you need to cut the sheets of large area, it is better to choose a tool that will provide higher performance. In this case, the knife will be required in any case to remove the burrs and cut off the irregularities, adjusting the glazing element exactly to the specified dimensions.

Cutting corner grinding

To cut polycarbonate with an angle grinding machine, use circles designed to cut metal. Cut the panel with a corner grinding, without afraid to melt the edges of the polymer material, will help:

- the use of a cutting circle for working with aluminum (it is less heated during friction);

- The use of corner grinder with a speed regulator (work should be carried out at low speeds, this also reduces the risk of burrs).

It is convenient to cut a monolithic polycarbonate and cellular panels, including along a curved trajectory. When working, be sure to use protective glasses that protect your eyes from flying chips.

Having turned on the power tool, you should wait until it gains the necessary speed of rotation. Cut the leaf material by moving the corner grinder from yourself along the line of cutting. Cutting the panel along the jumpers, keep the tool so that the blade goes in a straight line without touching the ribs of stiffness.

At the end of the work, check the evenness of the sections, remove the chips and dust that fall into the cells using a blower or vacuum cleaner.

The use of circular saw

The circular saw should be equipped with a working disc with small cloves. use wheels designed to work with plastic or metal. To cut a monolithic or cellular panel, act on the same principle as when working with a corner grinder. First, let the tool pick up the tools, then cut the pancreas raised using two boards, moving the tool from yourself. Press the supporting plate of the tool to the sheet. this will help more precisely cut the material along the drawn contour.

Using metal hacksaw

A hacksaw equipped with a canvas with small frequent cloves will help cut off a straight line of polycarbonate, cut a sheet along or across. Elements of complex outlines with this tool cannot be cut out.

When planning the cutting of polycarbonate at home using a hacksaw, pay attention to the following moment: so that the cutting line for the cutting trimmer is as flat as possible, it is necessary to firmly fix the panel. It is recommended to use clamps and boards. The canvas of the hacksaw is located at an angle of about 30 degrees. Drink the panel in the direction of yourself.

Using a hacksaw, you can cut a polycarbonate for a greenhouse with a pitched roof, since the tool cuts the material only in a straight line. Electrolobsik will help to cut semicircular end elements of arched structures.

The use of a knife habits for metal is permissible with a small cut length. For a long cut, use a knife on wood, but with small teeth.

Cutting with an electrician

The most suitable tool for cutting polycarbonate on elements of complex shapes is an electric jigsaw. The tool equipped with a thin saw is safer and convenient in operation compared to the angular grinding and circular saw, while the speed and complexity of cutting significantly differs for the better with a knife. Electrician is allowed to cut a monolithic and cellular polycarbonate.

When choosing a file, pay attention to the shape of the cloves. Divorced teeth are designed for wood, they will tear polycarbonate, making the edges of the cut to defective. To make cuts with even edges without burrs and cracks, use a file with small straight or wave.shaped cloves.

Cutting an electric jigsaw

This tool allows you to combine three positive qualities that the corner grinder and the construction knife are provided, namely the cutting speed, safety and ease of involvement. Using an electric jigsaw, you can easily draw not only straight lines, but also cut out other more complex figures from different varieties of material. It can be used for a sawing polycarbonate with a thickness of 3 mm. If the sheets are too thin, then in this case, with its help, it is better to cut several pieces at the same time, after laying a cardboard of the corresponding size under them.

However, before cutting polycarbonate, it is necessary to choose a suitable file that plays one of the key roles. When choosing it, it is required to take into account a number of the following tips and recommendations:

- To cut cellular polycarbonate, it is better to give preference to a file with the presence of straight teeth. This cutting element provides slight cringing of the material and helps to make the maximum spray.

- It is necessary to choose files with frequent and small teeth. Cellular polycarbonate should be cut with cutting elements with TPI labeling, which indicates the number of teeth per inch. In this case, this indicator should be from 9 to 13 or more.

- It is necessary to give preference to high.quality files, which are designed for cutting metal, plastic or organic glass, which will provide clean cut with a minimum amount of shortcomings.

The very process of cutting polycarbonate using an electric jigsaw is as follows:

- Initially, it is necessary to prepare the place in which work will be carried out, after which it is required to mark the sheet.

- Then you need to install a pre.prepared saw in the tool. It is recommended to use a new and sharp cutting element that has no defects yet. In this case, the file must be securely fixed and adjusted. With incorrect fixation during the work of the jigsaw, it will begin to vibrate and will cause the appearance of various shortcomings on the surface of the material.

- The tool connected to the outlet or carrying should be brought to the end of the polycarbonate sheet along the sawing lane. For greater comfort, it is advisable to make a cutting in the indicated place using a knife with a sharp blade. In this case, before the end of the cut, the protective film should also remain on the material.

- Next, press the supporting tile of the tool to polycarbonate. In this case, it is not necessary to apply a very great effort, since otherwise the sheet along the cut of the cut is bending. It is recommended that there are clamps or people who would help to exclude vibration and shift of the material during work.

- At the next stage, you need to turn on the tool and wait for the moment when it gains suitable speed. As soon as the jigsaw reaches them, you can proceed to cut into polycarbonate in the intended strip. The tool should be carefully and slowly forward, making its supporting plate to the plane of the material.

note! In curved areas, it is necessary to observe the maximum caution, having previously prepared in cutting parts of a rounded shape on future surpluses and remnants, due to which it will be easier to carry out work.

- At the end of the cutting, you need to turn off and disconnect the tool from the mains.

- Then the cells of the material must be cleaned of chips by means of a vacuum cleaner or a jet of compressed air.

- Next, it is required to cut excess and remove the shortcomings from the edges of the sawed polycarbonate. After that, they should be covered with construction tape, which will protect the cells from the penetration of dust and garbage.

Important! With the simultaneous cut of only one thin sheet, there is a high probability of cracking it.

Sawing polycarbonate by means of hacksaw

In some cases, this tool is also used when cutting polycarbonate sheets on square and rectangular parts. The process itself is very much like the one that happens during the use of a construction knife, so if there is a need for its use, then you should first consider the phased instructions described earlier.

In addition, when using a hacksaw, 2 nuances must be taken into account:

- During the saw, the tool must be kept at an angle of about 30 °.

- Before carrying out work, polycarbonate should be fixed as reliably as possible. If possible, it is desirable to consolidate the sheet in the vice of the workbench.

Without the experience of carrying out such work before involving a hacksaw, it is necessary to thoroughly practice, since otherwise there is a high probability that the material will crack along the cutting line and will be unsuitable for further use. In this situation, it is important to carry out competent fixation of polycarbonate in order to avoid excessive vibration and stress.

note! Close.cut out complex forms will not have a aesthetic look. For them it is necessary to use one of the previously indicated tools.

Polycarbonate cutting an electric jigsaw

To cut monolithic polycarbonate of large thickness, they often use an eclectic jigsaw. Due to a powerful drive, cutting is achieved without the application of human efforts. Thin products, as well as cell panels, are best placed in a pack and cut several elements at once. It is not recommended to cut single thin sheets, in order to avoid cracking at the site.

The use of electrolobesics significantly reduces the complexity and increases the efficiency of construction. Rationally resort to such a method of sawing polycarbonate paintings when performing large.scale work.

Features of cutting a plastic canvas using an electrolobian:

Using corner grinder for cutting polycarbonate

Corner grinder is a high.performance tool for cutting materials. Efficiency is achieved due to huge revolutions of the cutting circle during work. However, there are some subtleties that should be taken into account when working.

Correctly cut polycarbonate with an angle grinding machine in compliance with the following recommendations:

Cutting process

Polycarbonate also differs in that it is very convenient and easy to work with it. Even a beginner at home can cope with this material. We offer some tips that will help correctly and without loss to cope with the harsh:

- When performing straight small sections of the canvas 4-6 mm thick, an acute construction knife is suitable. The cut along even long lines is better to perform a corner grinder. Rounded parts are cut by an electrician.

- When working with power tools, be sure to use personal protective equipment. Put on glasses that protect your eyes from fine dust. Rubber gloves will protect against accidental shock.

- If necessary, apply marking on large sheets of polycarbonate, pave long boards on top that go beyond the sheet. You can move around them like a bridge without causing damage in the form of dents.

- After the end of the work, remove the protective film, blow the electric pump with all the processed seams on the received details to get rid of dust, and close them with special protective profiles. Do not remove the film from polycarbonate sheets during cutting

A construction knife

To trim cellular polycarbonate up to 6 mm thick at home, you can use a construction knife. The only and main condition is that the tool should be sharp, high quality and have enough spare blades.

- Put the knife tip at the starting point, and by clicking on it, make a cut. Along the marking line, perform a small incision slowly and as accurately as possible.

- According to the cut, the knife is carried out again, gently introducing the material inside, and cutting it. In this case, the blade should be strictly perpendicular to the plane of the sheet.

Work requires special attention without haste and fuss.

Corner grinders are convenient to saw large polycarbonate sheets in length. We recommend using cutting circles for metal (better for working with aluminum). On the desktop, install several wooden supports along the edges, put the sheet on them.

Corner grinder is perfect for sawing sheets of polycarbonate of large length

- Before you start cutting, try the work of the tool on a small unnecessary pruning of polycarbonate. Such a “rehearsal” will be especially needed for beginners.

- Do not forget about personal protective equipment.

- Turn on the machine, putting on a minimum rotation speed, and combine the cut.out circle with the place of cutting on the edge of the sheet.

- Slowly and confidently start moving the circle forward along the intended line. During cutting, do not be distracted and constantly control the combination of the cutting line with marking.

- Having completed the cut, turn off the corner grinder. Peel the edges of the cellular polycarbonate with sandpaper, then blow out a vacuum cleaner for cleaning from dust. Remove the protective film by sealed the ends with tape.

Electric

The jigsaw will cope perfectly, cutting both straight lines and other complex configurations. The main task is to choose the right file for cutting:

- For cutting cellular polycarbonate, it is better to purchase a file with straight teeth. It is capable of crushing the material less and makes the cut as even as possible.

- Choose files with frequent and small teeth. For cutting cellular polycarbonate, files with TR marking (from 9 or more teeth per 1 inch) are suitable).

- Give preference to the canvas that is high.quality and is suitable for work with metal.plastic.

Swap of polycarbonate sheets using an electrician requires experience, you should practice on small sheets of the material

The basic rules when working with an electrician are as follows (we advise you to practice the remains of the material before work):

- The desktop is ready to work, the corresponding canvas is inserted and securely fixed in the jigsaw. For convenience, make a small notch on the polycarbonate canvas with a knife.

- Turn on the tool, wait for it when it picks up, and bring the blade to the notch, slowly directing the machine forward. By clicking on the tool, make sure that the polycarbonate sheet does not bend.

- When working with large sheets of material, it is better to use the services of an assistant. He will hold polycarbonate, not allowing the sheet to vibrate. Work with long canvases can be divided into two stages: first go around to the middle, and then repeat the movement towards the opposite side.

- After finishing work with an electrician, do all the actions that are described above when working with a corner grinder.

If you have already gained some experience with this electrical appliance, you can cut several thin sheets at once on one pattern. Just put a cardboard of the corresponding size under them and cut all layers at the same time.

Beginners should thoroughly practice before starting work with a hacksaw for cutting polycarbonate. Without experience, sheets, as a rule, crack along the cut line and lead to large losses of the material. It is important to correctly and correctly fix the sheet without allowing excessive voltage and vibration.

Drinking polycarbonate sheets with a hacksaw is a very difficult task, as it has a number of nuances

The laser refers to professional tools and only a highly qualified specialist can work with it. Laser cutting is usually used on an industrial scale, since the purchase of equipment is quite costly.

Once again we want to remind you that when working with power tools, be sure to follow all safety rules. The health and life of the employee sometimes depend on this, sometimes.

How to cut polycarbonate correctly

Let’s step by step look at how to cut a polycarbonate sheet correctly:

- We clear the site for a sheet (s) of polycarbonate. We remove stones and extraneous objects that can leave traces on the panels. Ideally, it is better to pierce the site with sheets of a wood-fiber slab, a wood-cutting plate, or a mustache can.

- We make the necessary marking on the panel with a marker with the use of I sank or any even object. If necessary, we move along the panels with a wide board (moving along it) so as not to make dents on the surface of the plastic.

- Before cutting polycarbonate, we put under the panels on both sides of the marker marking of the board, at least 40x100x2200. On top of the panel, we put another board on top of the bottoms of the boards from above (at least 20x100x2200), in order to move along it during cutting. If you need to cut it on a flat line, then we use a corner grinder. If a rounded or curly cutting is required, use an electrician, and for a slight fitting sheets we use a stationery knife.

- With an even cut along the entire sheet, that is, along the honeycomb, the use of a marker is not required. As a rule, you can safely make a cut along the honeycombs themselves with a corner grinder, an electrician or knife, since the honeycombs themselves in this case will serve as a guide for the cut. This must be done so that it would not be stomping over the sheets of polycarbonate once again.

- Of course, after the sawing, you need to remove the chips and dust by purging with compressed air.

So in this article we figured out how to cut polycarbonate, and most importantly, how to cut polycarbonate sheets correctly.

In conclusion, I want to remind you of another important thing, as you know, “we mark it seven times, we cut off once”. So, do not forget this wisdom, because polycarbonate sheets are not cheap pleasure, and their spoilage will become a good penny.

Yes, I almost forgot, when cutting a corner grinder or an electrician, be sure to put on the goggles. They will undoubtedly protect you from dust and microparticles. Well, that’s all. Good luck in a difficult, but necessary business!

The choice of tools

In the household, there will certainly be funds to perform the cutting of cells of cell plastic, without seeking help to specialists. They use the latest laser or milling devices.

Accuracy may be required to make small elements for decoration.

It is customary to close the edges with profiles to conceal minor defects.

The cut of the monolithic sheet is most often polished. This should not be forgotten in order to avoid entering the empty spaces of sheets of foreign particles and insects that are not able to independently get out of narrow channels and die in them.

This not only destroys them, but also makes the design less attractive. In most cases, to cut a carbonate, use: a well.cooked knife, a hacksaw, an electric jigsaw, a corner grinder with an abrasive circle or saw.

Sheets should be straight, do not exceed 4-6 mm. This is the best option, if necessary, only to adjust the edges.

Cutting out figured details will take more strength. Work should be done without haste.

The knife should not be used in the presence of more than 2 layers.

- The sheet is laid on a solid base.

- They are convinced that the knife is sharp, if necessary, the blades are changing.

- To the place where the cut will be made, the rail of metal or ruler is applied.

- When cutting a sufficiently length of the canvas, it is covered with a dense sheet or put a board for support.

- The work is performed from the distant edge.

It must be taken into account that with an increase in the thickness of the material, the blade is tilted from a large angle.

angle grinder

In order for the sections to be extremely even, a circle of 125 is installed on the corner grinder, designed to work with metal.

To exclude unevenness, in the absence of experience with this tool, it is better to practice first.

Perfectly cuts with significant rounding. Put massive boards so that there is space.

With a cut into the honeycombs, shavings can get to the walls. Before putting on the only end profile, they should be removed with a vacuum cleaner.

You can get rid of garbage with the pressure of water, but then wait for its evaporation from the channels before the start of installation work.

Circulation saw

Manual or stationary, it is also used for cutting.

The difference from the corner grinder is that the cut is carried out in the direction not to itself, but forward.

It is better to cut bulky canvases for manual use with a manual use tool, and small parts with the possibility of installing the desired sizes.

Kryazuvka for metal

For cutting, even a primitive manual saw is suitable.

Beginners need to be careful in order to prevent cracks on the cut stripes.

To cope with the task and exclude vibration, a strong fixing of the sheets will be required.

Although with a hacksaw you can also get a high-quality cut, it should still be considered as a spare look due to complexity and inconvenience in work.

So that the edge does not deform and does not crack, the rush here is absolutely inappropriate.

The tool is held at an angle of 30-45 ° to the surface.

Professional methods

There are more advanced methods of cutting polymer plastic.

Laser

This type of cutting of cellular polycarbonate is not used so often due to the lack of such technical equipment and the necessary skills in most people.

But qualified masters will perfectly cope with this type of activity.

The laser installation is equipped with software, which greatly accelerates the cutting process in a straight line and to give plastic the most complex shapes

Milling

This path also provides accuracy and speed of cutting.

The base built into the cutting table for plastic will not cause excessive cash costs, but guarantees an excellent result.

Using an electrician

It is also considered an inexpensive option for cutting continuous polycarbonate sheets.

Files with the most small teeth are installed on the traditional tool in advance. If you miss this moment, then the material will simply be torn.

Electrician is not complicated in circulation, allows you to cut, create intricate models for the best decor or perform even rounding.

The information received will help to equip a greenhouse with your own hands, make a visor above the porch or decorate at your own free will.

The given methods do not require special knowledge, and there is a tool in every house.

As any business, the cutting of polycarbonate should be treated responsibly and seriously. Consolidate everything you need in advance and, if necessary, consult a specialist. Then to do all work at home will not be difficult!