Cutting thin glass

If you have a thin glass, then the circle can be cut out of it with ordinary scissors. To do this, you need to make a stencil on the glass, using a waterproof marker. After that, you need to put the glass in water, take scissors and according to the stencil need to cut a circle, biting off small pieces of excess glass with pliers, while gradually approaching the shape of the circle. This method of cutting a circle out of glass is uneven, but if an urgent situation arises and the glass circle is needed, you can use this method of cutting a circle out of glass. This method is used when the only tools you can find are scissors. If the glass is 2-3 mm thick, you can cut a circle from it with scissors. And if the glass is thicker, you need to use the methods described above.

How to cut round glass

Life can sometimes puzzle you with a completely unexpected problem. For example. how to cut glass without a glass cutter, if you suddenly do not have it handy, and the work must be done urgently? It is not on everyone’s list of necessary tools. You do not want to buy it for disposable work. once in a lifetime to cut a new mirror, and then the tool will lie idle for years without use.

For example, in the evening young soccer players knocked you with a ball glass. You are fixing a hole with glass from some interior room, but it is slightly larger in size. What to do? Glass cutters clearly do not work anymore, running around the neighbors in search. not the fact that you will find. So we have to remember folk methods of dealing with the fragile material.

How to cut glass without a cutter? Several methods have been devised to solve this problem. Each of them gives quite good results. We hope that our tips will be useful if the necessary tool is missing or lost among other things.

The method is not universal and is only good for thin glass, no more than 3 mm thick. But it is almost the easiest. Also allows you to cut not only straight but also shaped, if you need a specific shape of glass (e.g. a door insert). Another disadvantage. you can’t cut too big a piece.

First of all, take a piece of the same glass and try to cut it. If the glass cracks in the process, it means it is tempered, and this method is not suitable in this case. If everything is all right, then let’s begin.

Use a marker on the glass to outline the contour you want. Or you can use a fishing line if you just want to cut off the unwanted material. Some masters advise to cut a template from cardboard and glue it to the glass. In our opinion. not a good idea. First, the paper gets wet, and its rags will interfere with the work. Secondly, there can be problems with glue: water-soluble will not hold the pattern, and water-resistant will have to be removed from the surface. extra trouble.

Water is poured into a wide basin. Place the edge of the glass to be trimmed in it. The deeper the piece is immersed, the easier the process will go. it is helped by water pressure.

Take sturdy scissors like tailor’s scissors, plunge under the surface, and begin trimming. It’s more difficult to feel than when you cut paper or cloth. It’s more like working with cardboard. This also produces crumbs, so it is better to cut with safety glasses in case of rebound if you do not dip deep enough in the water.

Gloves won’t hurt either, and will be, probably, even more useful than glasses, because you won’t notice splinters in water, but they cut strongly.

Many do not believe that the scissors can cut glass, and are very surprised when they try it, that it is really possible.

In cases when the glass is thick or so big that it does not fit in the basin, it is suggested to find a soldering iron. Some people use a wood burner for the same purpose. And if you’re especially poor on tools, you might even use a red-hot nail. Though you have to spend a lot of time with it, because you have to heat it all the time.

- The glass is placed on a flat surface.

- The line of the cut is outlined. Here, by the way, a shaped cut is also available.

- At the very beginning of the line, a neat not too deep notch or file is made on the edge of the glass. It is possible to tear an edge with the angle grinder (but very carefully, on the lowest revolutions)!) or even scratch it with a nail.

- The soldering iron is switched on. When it heats up, it is inserted into the notch.

- The soldering iron is drawn slowly, without much pressure, along the outline. If the line is straight and you are not sure if you can hold it straight at such a low speed, put a metal ruler on it and move the soldering iron along it.

- Behind the tool appears a thin crack along the outlined mowing line. To separate two pieces of glass, put on a thick glove (a kitchen oven mitt will do at home) and carefully break off the unwanted piece. If you have a shaped cut, it is better to lead the soldering iron as slowly as possible, so that the chips remain a fraction of a millimeter, and the tracery is not damaged when separating the pieces.

When using it, it is especially important to observe all fire safety measures, because it involves the use of an open flame.

- Again the glass is placed on a flat surface. This time you should make sure that it is not easily flammable.

- A line of cuttings is drawn on the glass.

- From a thin cord with a diameter of 1-2 mm. Cut a piece to the width of the glass. Only natural materials like cotton and linen are suitable, synthetics are not suitable.

- The cord is soaked in something combustible. kerosene, campfire starter, gasoline, lighter fuel. and laid flat along the cut fishing line.

- The fishing line is lit so that it catches fire along its entire length.

- When the fire is almost out, the cutting line is poured with cold water. Glass cracks exactly where it burns.

- If the crack has not reached the end, you can go two ways: wipe the surface and repeat Focus with a string or put the glass on the edge and lightly knock on the mowing line with a wooden or rubber mallet.

Sometimes even masters use this method to create original vases, candlesticks, glasses and ashtrays from empty bottles and glass jars. Glass cutters are not very useful for creation of such masterpieces as it is very inconvenient to saw curved surface.

Glassware in the right place is tied with flammable cord, the more so that the temperature difference is created in the case of the bottle is very simple: it is immersed in a bucket of water.

Roughness and small splinters often remain in the place where the glass is cut. To eliminate them, a fine sandpaper is taken, and the cut is sanded to smoothness. This stage is especially important if you have constructed an elegant glass from a beautiful bottle: without such processing there is a great risk to hurt your lips or swallow an invisible to the eye glass breakage.

So it is quite possible to do without special tools, using one of the folk tricks, how to cut glass without glass cutter.

How to cut round glass?

Glass is an interesting building material that has found its application in many areas of the modern world. Essentially, it consists of quartz sand, dolomite and limestone, to which various components and impurities are added in order to obtain interesting properties. Note that it is the nature of these additives and the result at the end that contribute to the variety of pricing policy with respect to this material.

In order to use glass in construction, it goes without saying that it must be created according to certain technologies. Most often, glass is made by the float method, in the application of which the glass comes out in the form of a sheet from the furnace, after which it is fired. However, despite this special method of production, construction glass comes in several varieties, which also have a separate production technology. Therefore, separately note that the construction glass is: sheet. used for finishing doors, windows and partitions, laminated. double glass construction, attached to each other by a polymer tape, tempered. the most durable type of construction glass, which is now actively used to design store windows, doors and corridor openings, reinforced. rather interesting glass products, consisting of several glass layers, between which there is a layer of polymer film; эne.

How to cut round glass?

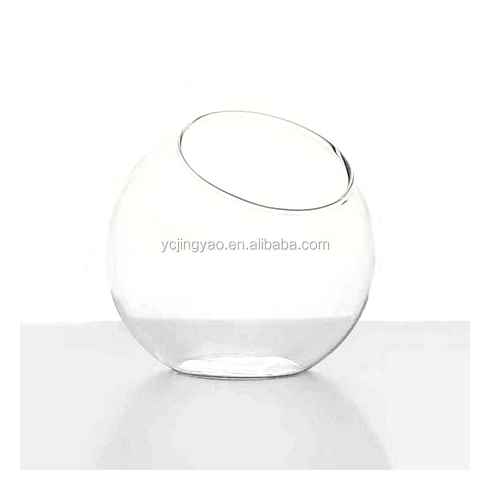

Considering the peculiarities of the glass materials mentioned above, it should be noted that cutting glass is a particularly difficult process that requires care, precision and, of course, professional tools. Nevertheless, if the question becomes relevant: “How to cut round glass?”, especially in home conditions, your attention is offered three possible variations of its solution, which with ease can be performed and independently. So, types of cutting round glass:

Cutting on the template. a rather complicated process that requires some knowledge in this area. The glass cutter and the glass template will be needed to make it. The starting material for the template can be any handy material (cardboard or plywood). Diameter of the template, as a rule, should be slightly smaller than that of glass with the mandatory reference to the thickness of the working tool. The main nuance of this process is the need for forceful pressure on the material, so as not to disrupt the production process;

Cutting with a caliper and a glass cutter. this is especially important if you need to cut a lot of glass. However, in order to carry it out, it is necessary to slightly modify the glass cutter itself for a comfortable cutting of the material, according to the previously determined round shape. On the handle of the tool itself, it is necessary to make a small hole for free entry into the sponge, after which the resulting structure is secured with a wire. It is necessary to put a piece of rubber under the base of the second jaw, which will contribute to a more reliable way of cutting during the work. Using pressure, the first cut is made, after which the remaining circular cuts can be made.

How to cut glass without a glass cutter

Before we proceed to a detailed description of the techniques of cutting glass, we want to remind you of safety. Always wear gloves and safety glasses to prevent cuts and small pieces of glass from getting into your eyes when working. Be careful not to put too much pressure on the glass.

Using a flaming thread

We soak the thread in flammable liquid and fix it on the glass by the mowing line of the cut. Light it, wait until it burns through, and place it immediately in cold water or pour it over the heated area. The main thing is that the glass cools down as quickly as possible and breaks from the temperature difference. A “click” sound indicates the success of the operation. If the glass is not cracked, you can try to repeat the operation.

A similar method quite evenly scrapes bottles, but does not always work with large glass sizes. It is also very flammable and requires a fire extinguisher on hand or a container of water, which is already a must.

Use the soldering iron

Having marked the line of the future cut on the glass, take a file and make a small groove with it at the very edge. Step back from it 1-2 mm, heat the place with a soldering iron, until a micro-crack is formed between it and the groove. Then we step back from the crack at the same distance, and gradually move to the finish point. It takes a long time to cut the glass this way, but you can get all kinds of shapes. To speed up the process slightly, you can periodically cool the glass by putting a damp cloth on it.

With scissors in water

An easy way to directionally chamfer glass. It makes it easy to cut out round shapes, but it is not perfect for making straight lines. For such cutting you will need usual scissors and a bowl of water, which will serve as a kind of grease. The maximum thickness of the glass should not exceed 4 mm.

The process of cutting with this method is very simple. We take a piece of glass to be cut, immerse it in water, and use scissors to cut off small pieces from the edges. The water will not crack the glass, allowing you to make a controlled cut. You can cut both oval and circular shapes in this way.

With a diamond disc

not the safest way to cut glass, requiring extra care and following all safety rules. Can easily chip the glass and run the splinter in any direction. Otherwise, the method is effective enough and can cope with the task. For cutting you will need a special tool (angle grinder, drill bit, or drill bit) with a diamond disk with a thickness of 0.1mm.

The process of cutting itself is quite simple, but it requires certain skills and a steady hand to guide the tool precisely along the mowing line. We lay a piece of glass on the flat place to be cut, then we take the glass cutter and guide the saw blade on the glass surface. The main thing is not to plunge deep into the glass, but only to touch lightly, so that a small groove is formed, like a wide fishing line from the glass cutter. Then just break the glass in the right place.

To reduce the risk of glass breakage and to minimize glass dust, you can hose down the cutting area periodically with water.

File

Another way how to cut glass at home without a glass cutter and expensive power tools. You will need a file and some experience in working with glass. Note that a file must have angles, so a round one will not do.

To cut glass it is sufficient to make several notches on its surface with the angle of the file. Apply a little more pressure than average to create a clean groove that resembles a glass cutter. When the place of the chip is marked, just break the glass on the edge of the table or put a match under the place of the cut.

This method requires some skill, and if you are cutting glass for the first time, we highly recommend practicing on small, unnecessary pieces before moving on to the main material.

Using a cupped drill

If you know what glass cutting is all about, here is another way to cut glass without using a glass cutter. If you have some experience, for this operation may be enough a single drill bit with a pobedite tip. The main thing is that the drill should be more or less new, with sharp angles on the head.

The process itself of cutting glass with a glass cutter is very similar to the conventional roller glass cutter. The differences are the higher pressure, but otherwise all operations are standard. We lay the glass on the flat surface, mark the cutting line, put the plank and guide the line down along it. Before cutting, turn the ending piece so that the sharpest corner makes contact with the glass. Once you have a clear line, break the glass along the beveled line of the cut.

The method of cutting glass with a pobedite bit, requires skill and practical experience in handling this material. The beginners have very little chance to make an accurate cut by this method, but with patience and straight hands, it is possible to get the required result.

Working place

The convenience and success of the work largely depends on the place where the glass will be positioned during cutting. Unsuitable working surface can lead to uneven chipping, cracks, scratches, and even injuries. There are a few simple rules that will help you protect the material and get a decent result.

Most importantly, make sure the work surface is level. There must not be any bumps or indentations on the table, floor or any other place where you cut the glass. If there is a void between the material and the surface, the fragile glass can simply crack under the pressure of the glass cutter.

The table, workbench, stool or any other structure should be stable so that the glass cutter will not jump off the mark when you run the mowing line. For better adhesion to the surface and to avoid cuts on the glass, it is better to put a piece of cloth between the glass and the working area. Lay a sheet, blanket, or any other soft cloth on the table slightly larger than the glass to be worked on.

Preparatory activities

In order for the cut to be of high quality, you must first prepare the material for the work. If the glass is new, you just need to wipe it down. Newspaper is best for this purpose, it wipes the surface dry and does not leave behind lint and streaks.

If the glass has previously been in use, then before you cut the material with the glass cutter, it will take a little more time to prepare it. First of all, such a surface will need to wash well, using special means for cleaning glass. Then you should carry out a thorough degreasing process. You could also use kerosene. To do this, use a rag soaked in kerosene to wipe the glass thoroughly and wait until it is completely dry.

At the same time in the phase of glass preparation also includes its cutting. There is no doubt that you will be able to achieve the final result without waste, especially if you need to cut the product irregular geometric shape. But if you do the calculation as correctly as possible, you can reduce the amount of waste by several times.

Also, make sure that the work surface is flat enough and without a slope, but also not too hard, preferably the work surface is made of plywood or fiberboard, and cover the top with oilcloth or a soft cloth.

How to cut glass

But the simplest types of glass work. e.g. glass cutting. are often carried out by non-professionals. In principle, you can always learn how to cut glass properly and safely.

- The basic tool for working with any kind of glass is a common glass cutter. The design of this tool is extremely simple: it consists of a convenient handle-holder and a cutting element made of hard alloys. Usually the cutting element is in the form of a wheel. Professional glass cutters are usually equipped with a cutting element made of industrial diamond. It is easy to work with this type of tool because it allows you to cut glass with very little pressure. You can also use a diamond glass cutter to draw curved lines on the glass in very complicated shapes, and these lines will be very precise and accurate.

- In the home, it is most common to cut glass in a straight line with a ruler. Cutting glass in a straight line with a scythe line is a fairly simple procedure that requires a glass cutter and a handy ruler (in extreme cases, you can use a regular rail instead of a long ruler). Press the glass as firmly as possible so that the ruler does not move during cutting. Professionals who work with glass frequently glue a strip of thin rubber onto the ruler. The glass cutter should be held straight and the cut should be made accurately and evenly. For a good cut, the tension on the cutter must be even, it is necessary to press the cutter with a single line at the same time and with the same force, holding the cutter at the same angle.

- To make cutting glass easier, you can lubricate the wheel of the glass cutter with kerosene. To do so, just run it over a sponge soaked in kerosene.

- After you’ve run the fishing line across the surface of the glass, you need to turn the crack you cut in the glass into a full-fledged break. When using the cutter as a percussive tool, make small but steady impacts on the opposite side of the pane. After this procedure is complete, place the glass on the edge of the table and break it in one swift downward motion. The glass should break along the intended scythe line.

- How to cut a circle out of glass

- How to cut the glass

- How to choose a glass cutter

- How to cut tiles with a glass cutter

- How to cut glass

- How to cut a glass edge

- How to cut plexiglass

- How to cut a hole in glass

- How to cut on a cutter

- How to make a hole in a glass bottle

- How to make a mirror out of glass

- How to make a glass table

- How to make a mirror out of glass

- How to make a curved mirror

- How to drill through thick glass

- How to cut business cards

- How to blow glass

- How to make a mirror at home

- How to replace broken glass

- How to make a mosaic out of broken glass

- How to make a hole in the glass

- How to cut a bottle with acetone

- How to cut a tabletop

Before you cut or shape cut glass, you should prepare for work. You must take care about the safety of the workplace, as well as the comfort and quality of cutting glass. To do this, you will need to:

- Prepare the workplace, which must take into account the peculiarities of the cutting work. All operations you will perform on a special table, which should have at least the same dimensions as the sheet. But it is better if it will be 50-100 mm larger than the dimensions of the glass. Arrange the table in such a way that on each side of the passage was not less than 1 meter. On one side, make a space with a length equal to the longest side of the table. You will need it for storing cut sheets, broken glass, and leftover material. The table must be as flat as possible, so we recommend putting a thick sheet of particle board with a thickness of 30mm on it anyway. In addition to this you can also cover it with a soft cloth. Make sure all aisles are clear of unnecessary things.

- The tools you will need for cutting glass or mirrors include the glass cutter, a template, and a measuring tool. Before working, make sure that the glass cutter is in good working order, to do this, draw a fishing line on a piece of glass with it.

- Plan out for yourself what you will be doing. You will need to measure the windows or other constructions you are going to glaze.

Glass. Cut “circles” from the sheet and rings from pipes, bottles, cans.

Unfinished edges can be hidden in the structural components of the monocle:

Option 2:

There’s another ingenuous method. cutting glass with scissors in water, and that’s what Bender used in his work The first googles, as they are. With enough experience you can cut very good circles.

Option 3:

Option 4:

Steamimpactor, in its “Dieselpunk Vision” vorklog project of Steamimpactor, cuts out “rounds” with a special drill bit: The crown is clamped in the drill chuck, the cutting line is immersed in water and at the lowest possible three hundred rpm, with uniform pressure on the crown, the prepared glass is turned into the desired googly round. After three minutes of leisurely drilling, I got two neat discs of the right diameter and color. The edges of the discs treated on a sheet of sandpaper with wetting, after which, got a completely “company” glass three millimeters thick! I must say, in the absence of a drilling machine, the successful use of drill bits with a similar diameter, in a hand-held power tool, is almost impossible. I would like to finish I would like to very original way of processing Plexiglas, let them not apply directly to the glass, but the way is very good, not straining can even do lenses: I saw it in Arin (a) in his work WatchMashine at the contest. Part 1

result:

Now for the tubes, bottles, jars and the like:

First about the marking, because this will depend on how smooth your rings will be and how long you will be “bothering” with finishing the planes. Wrap a wide strip of paper (with a straight edge) tightly around your workpiece, as shown on the photo and draw a line marker on the glass (along the edge of the paper): Now let’s start cutting. Tip: Wet the cutting area with plenty of water. The options everyone will choose their own from dipping the workpiece in water, to a thin trickle or periodic dipping. The better the wetting, the cleaner the seam and the fewer chipped edges.

Method 1:

With the help of a glass cutter and a gas burner, separates the bottom of the bottle in the master class Recycle! (alternative materials in goggle construction). we make a circular mark with the glass cutter. Accuracy is not so important, the main thing is to try to make the risk continuous Again, we do not need a perfectly smooth cut, our task is simply to separate the bottom of the bottle. For the next step, we need a propane torch, the flame of which we will evenly heat the fishing line left by the glass cutter, smoothly rotating the bottle around the axis The operation must be carried out with gloves and eyes protected with goggles! If the heating is correct the process is accompanied by cracking, and stops when we hear a muffled click, indicating that the bottle is split in two by the crack.

method 2:

Trou for his project in the “Time” contest cut the rings with a diamond-tipped cutting disc: But even with such a useful tool, I follow a few simple rules: a). Abundant wetting during cutting. б). To avoid chipping on the back of the workpiece, I cut the workpiece from both sides (of course if you can get to the place of cutting). And if you are lucky enough to have a tubular drill bit and a diamond drill bit, you can cut even “unconventional” shapes of holes in glass:

method 3:

How To Cut Round Glass|Aluminium ||#aluminiummaker

Valery (Wall-ery), on the site of our brothers (technari.ru), found his way of cutting the tube of a fluorescent lamp. Here is a link to his master class. And some pictures to make it clear what is going on: And what happened in the end:

Method 4:

Interesting way to cut the bulb bulbs practiced by yug74 for his stick Way worthy of attention, because the bulb is part of the base. and it is beautiful and practical:

Exotic, old-fashioned way. cut from a bottle “spiral”

I will not write anything, there is nothing to add:

Drilling holes:

Example 1:

Paul (2Dimensional) in “A set for the smoking gentleman.» сверлил отверстия алмазной коронкой диаметром 4 мм: