How to cut round glass for a watch

In this article, we asked the master to answer the question: “How to cut a round glass for a watch?”, And also give useful recommendations for our readers. What came of it.

How to cut a circle out of glass

In some cases, it becomes necessary to cut out glass of an unusual shape, for example, round. Unlike straight cuts, which are made with a glass cutter along a ruler, figured products are much more difficult to make. There are several methods for this, depending on the thickness of the glass and the size of the circle.

But first, the glass must be cleaned, since it will be difficult to cut when dirty, moistened or with traces of grease, cut to an insufficiently deep depth, and when breaking, it may split not along the cut line of the mowing line. Therefore, at home, wipe the glass sheet on both sides with a rag, and, if necessary, rinse with a soda solution. If the material was in the cold, then before cutting it must be kept in a warm room until it dries, and then wipe it well with a rag or newspaper.

Perhaps the most difficult thing is to draw the circle exactly. This can be done using a special tool (radius glass cutter), which consists of a square bar, a fixed suction cup on one side and a moving glass cutter with a ball-shaped handle on the other. The suction cup should be fixed in the center, and the glass cutter should be fixed on the outer radius.

The angle of sharpening of the roller tool is 100 degrees, the resource of 350 m on glass is 5-1 mm. The lubrication function can increase the resource up to 6000 m, for materials 1-10 mm, the sharpening angle becomes 135 degrees, and for 10-20 mm glass. 150 degrees. The liquid that wets the cutting line must be filled into a transparent handle, as a rule, the tool head is fixed in such models. The mileage of diamond models is up to 10 km, they are suitable for material up to 10 mm thick. Synthetic diamonds are designed for glasses up to 5 mm. Most often, diamond or oil modifications are used in circular glass cutters.

A diamond glass cutter can easily cope with curved sections, the problem is only subsequent chipping. With your fingers, you need to press on the inside until a continuous crack appears along the entire contour, then turn the glass over and repeat the pressing procedure. To maintain the integrity of the inner circle, it is advisable to make cuts from the circle to the edge of the glass at the four corners. Next, gently break off the outer segments. If necessary, the edge can be abraded, but always under running water. In this case, the workpiece will be in the same plane with the abrasive so that the glass does not work in bending. Fine burrs can be removed by hand with a sharpening stone, or wear protective gloves to avoid accidental cuts. As a rule, you can manually remove no more than 2 mm, for more serious processing it is better to use a sharpener.

Hold the diamond glass cutter in your hand near the base like a pen or pencil. cut the line without effort, the cut should be slightly noticeable. The roller glass cutter needs to be pressed a little harder, but the presence of oil lubrication will greatly simplify the process. The slots in the holders allow you to do without pliers when breaking off straight pieces; for curly cuts, it is advisable to use pliers. In the same way, you can make round coffee table tops. To create an ellipse, the arcs of semicircles are outlined with a tool on both sides of the workpiece, after which they are carefully connected with straight fishing lines.

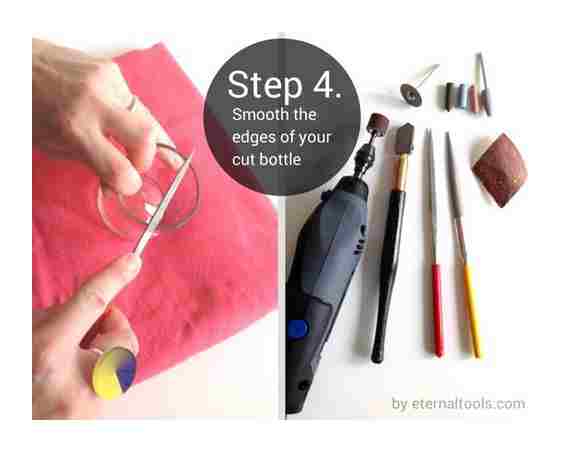

If your glass is very thin, then a circle can be cut out of it with ordinary scissors. First, you need to make a stencil on the glass with a waterproof marker. Then the glass must be placed in water, take scissors and cut a circle using a stencil, biting off small pieces of excess glass with pincers, while gradually approaching the shape of a circle. This method produces a slightly uneven circle, but if an urgent situation arises and a glass circle is needed, you can use this method. But remember that this method can only be used with a glass thickness of 2-3 mm, otherwise it will not work.

Medium-sized glass discs can be cut with tubular drills (or a piece of liquid abrasive pipe). The maximum size of the workpiece should not exceed 30 cm in diameter. Abrasive must be periodically added under a regular pipe. It is necessary to drill through, breaking off a few millimeters (even microns) will not work exactly. the inner part will burst. Glass rings can be made using a circular glass cutter (in the first step) and a tubular drill (in the second step).

If you don’t have a glass cutter and tubular drill, you can use a diamond saw. This tool is a smooth diamond-coated strip where the teeth of a conventional saw are. To work with such a saw, a stencil of the desired circle should be cut out of thick cardboard or plywood. Then it must be glued to the glass. When the preparatory work is completed, you can start sawing with a diamond saw. During this process, periodically moisten the glass with water, therefore it is best to carry out the process of cutting round glass in the bathroom. When working with this tool, you need to be patient and cut glass with great care.

There are several non-standard glass cutting methods. For example, hydrofluoric acid can corrode the glass, leaving the paraffin-coated part intact. When heated by plasma, glass wool will be projected from the glass disc. A diamond engraver in an engraving machine can also cut a glass blank of any configuration according to a template.

As you can see, a high-quality glass blank of any thickness of the desired diameter at home is easiest to obtain with a special tool. In the field, the task can be completed with a minimum set, but in this case, the circle will turn out to be imperfect, additional processing of the edge of the workpiece will be required.

For example, in the evening, young football players knocked out the glass for you with a ball. You fill the gap with glass from some interior room, but it is slightly larger in size. What to do? Glass cutters are clearly no longer working, running around neighbors in search is not a fact that you will find. So that we have to remember the folk methods of dealing with fragile material.

How to cut glass without a glass cutter? Several methods have been invented to solve this problem. Each of them gives quite high quality results. We hope that our tips will come in handy if the necessary tool is missing or lost among other things.

The method is not universal and is suitable only for thin glasses with a thickness of no more than 3 mm. But almost the simplest. In addition, it allows you to cut not only in a straight line, but also figuratively, if you need glass of a certain shape (for example, an insert in a door). Another drawback. you won’t be able to cut too large a piece.

First of all, take a shard of the same glass and try to trim on it. If the glass cracks during operation, it means that it is tempered, and this method is not suitable in this case. If everything is in order, then let’s proceed.

The desired contour is marked on the glass with a marker. Or a fishing line is drawn if you just need to cut off the excess. Some craftsmen advise cutting out the template from cardboard and sticking it on glass. In our opinion, this is not a good idea. Firstly, the paper will get soaked, and its rags will interfere with work. Secondly, there may be problems with the glue: the water-soluble one will not hold the template, and the waterproof one will then have to be removed from the surface with something. unnecessary trouble.

Water is poured into a wide basin. The edge of the glass to be cut is lowered into it. The deeper the piece is immersed, the easier the process will go. the water pressure helps it.

Strong scissors like tailors are taken, plunged under the surface, and pruning begins. The sensation is more difficult than when cutting paper or fabric. Rather, they resemble working with cardboard. At the same time, crumbs are also formed, so it is better to cut with protective glasses in case of a rebound, if you did not immerse the glass deep enough in water.

Gloves also do not hurt, and they will, perhaps, be even more useful than glasses, since you will not notice the fragments in the water, but they cut hard.

Many do not believe that scissors cut glass, and they are very surprised to try that this is really possible.

In cases where the glass is thick or so large that it does not fit in the basin, it is suggested to find it in a soldering iron. Some have used a woodburner for similar purposes. And those who are especially poor for a tool. even a red-hot nail. Although it will take a very long time to bother with cutting glass, since you need to constantly heat it up.

- Glass is laid on a flat surface.

- The cutting line is outlined. Here, by the way, curly cut is also available.

- At the very beginning of the line, a neat, not too deep file is made on the edge of the glass with a file or file. You can tear off the edge of the angle grinder (only extremely, carefully, at the lowest speeds!) Or even scratch it with a nail.

- The soldering iron turns on. When heated, inserted into the incision.

- The soldering iron is slowly, without much pressure, is drawn along the drawn contour. If the line is straight, and you are not sure that you can draw it straight at such a low speed, attach a metal ruler and move the soldering iron along it.

- A thin crack appears behind the tool along the traced mowing line. To separate two pieces of glass, a thick mitten is put on (a kitchen oven mitt is suitable at home) and the unnecessary cut is neatly broken off. If you have a curly cut, it is better to lead the soldering iron as slowly as possible so that a fraction of a millimeter remains to break off, and the openwork is not damaged when separating the pieces.

When using it, it is especially important to comply with all fire safety measures, since it involves the use of open fire.

- The glass is again placed on a flat surface. This time, care should be taken that it is not flammable.

- Cutting line is drawn on the glass.

- From a thin cord with a diameter of 1-2 mm. a piece is cut to the width of the glass. Only twine made from natural materials is suitable. cotton, linen, synthetics are not suitable.

- The rope is impregnated with something combustible. kerosene, campfire, gasoline, lighter refill. and laid straight along the mowing line.

- The cord is ignited so that it ignites along its entire length.

- When the fire is almost extinguished, the cut line is spilled with cold water. Glass cracks exactly at the place of burning.

- If the crack has not reached the end, you can go in two ways: wipe the surface and repeat the trick with the twine, or put the glass on the edge and lightly tap the mowing line with a wooden or rubber pad with a hammer.

Sometimes even craftsmen use this method to create original vases, candlesticks, glasses and ashtrays from empty bottles and glass jars. A glass cutter for creating such masterpieces is of little use, since it is very inconvenient for them to saw a curved surface.

Glass containers in the right place are tied with a combustible cord, especially since the temperature difference is created in the case of a bottle is very simple: it is immersed in a bucket of water.

Often, roughness and small fragments remain at the glass cutting site. To eliminate them, a fine sandpaper is taken, and the incision is sanded until smooth. This stage is especially important if you have built an elegant glass from a beautiful bottle: without such treatment, there is a great risk of injuring your lips or swallowing a piece of glass that is invisible to the eye.

So it is quite possible to do without special tools, using one of the folk notions of how to cut glass without a glass cutter.

In our life, situations arise when a circle needs to be cut out of ordinary glass.

If you take a glass cutter and a ruler and try to cut such glass, then you will not succeed, because such a task must be approached with all responsibility and seriousness. There are several ways to cut round glass. The choice of method depends on the thickness and dimensions of the glass.

To cut round glass, you need to prepare the necessary tools and items. These include:

Glass cutter;

Drill;

Protective glasses;

Ticks;

Diamond blade;

Abrasive;

Rope and suction cup;

Thick cardboard;

Scissors;

Tubular drill;

Capacity with water;

Scissors.

Now let’s look at the easiest way to cut round glass. To do this, you need to take a glass cutter and tools in order to cut an even circle. First, mark the center of the circle on the glass, then attach the suction cup to the place where the center was marked. We will tie a rope to the installed suction cup, and a glass cutter should be tied to the rope. The length of the rope from the suction cup to the cutter should be equal to the radius of the circle that you plan to cut. After all the preparations are completed, you can draw a circle on the glass with a glass cutter. Now draw “rays” from the resulting circle on the rest of the glass with a glass cutter. And after that, with ticks, break off the extra pieces that are between the previously held “rays”.

If it becomes necessary to cut a circle with a diameter of less than 30 centimeters, then for this you need to use a tubular drill. A tubular drill is a tube made of metal that has a fastener for fixing it in the drill chuck. The edges of the tubular drill must be smooth, because glass is cut with an abrasive and water. Before you start cutting a circle out of glass, you need to apply an abrasive with water to the edges of the circle, and when cutting a circle from glass, the abrasive with water should always be under the tubular drill so that the glass does not overheat and crack. If done correctly, the result will be an even circle.

If it becomes necessary to cut round glass, but there is no glass cutter or tubular glass, then you can use a diamond saw. A diamond saw is a smooth diamond-coated strip where the teeth of a regular saw are.

In order to work with a diamond saw, it is necessary to cut a stencil of the circle to be cut out of thick cardboard or plywood. After that, the cut out stencil must be glued to the glass. When these preparatory work is done, you can start sawing with a diamond saw. During the sawing process, the glass from which the circle is cut must be constantly moistened with water, so the process of cutting the round glass must take place in the bathroom. If you decide to cut a circle out of glass using a diamond saw, then you need to be patient and cut the glass with great care.

If you have thin glass available, you can cut a circle out of it with ordinary scissors. To do this, you need to make a stencil on the glass using a waterproof marker. After that, you need to place the glass in water, take scissors and cut out a circle using a stencil, biting off small pieces of excess glass with pliers, while gradually approaching the shape of a circle. With this method of cutting a circle from glass, the circle will turn out to be uneven, but if an urgent situation arises and a glass circle is needed, then you can use these methods of cutting a circle from glass. This method is used when only scissors can be found from the tools. If the glass is 2-3 mm thick, then a circle can be cut out of it with scissors. And if the glass is thicker, then you need to apply the methods described above.

Perhaps you have your opinion on the topic “How to cut a round glass for a watch”? Write about it in the comments.

How to cut round glass

For example, in the evening, young football players knocked out the glass for you with a ball. You fill the gap with glass from some interior room, but it is slightly larger in size. What to do? Glass cutters are clearly no longer working, running around neighbors in search is not a fact that you will find. So that we have to remember the folk methods of dealing with fragile material.

How to cut glass without a glass cutter? Several methods have been invented to solve this problem. Each of them gives quite high quality results. We hope that our tips will come in handy if the necessary tool is missing or lost among other things.

Water and scissors

The method is not universal and is suitable only for thin glasses with a thickness of no more than 3 mm. But almost the simplest. In addition, it allows you to cut not only in a straight line, but also figuratively, if you need glass of a certain shape (for example, an insert in a door). Another drawback. you won’t be able to cut too large a piece.

First of all, take a shard of the same glass and try to trim on it. If the glass cracks during operation, it means that it is tempered, and this method is not suitable in this case. If everything is in order, then let’s proceed.

The desired contour is marked on the glass with a marker. Or a fishing line is drawn if you just need to cut off the excess. Some craftsmen advise cutting out the template from cardboard and sticking it on glass. In our opinion, this is not a good idea. Firstly, the paper will get soaked, and its rags will interfere with work. Secondly, there may be problems with the glue: the water-soluble one will not hold the template, and the waterproof one will then have to be removed from the surface with something. unnecessary trouble.

Water is poured into a wide basin. The edge of the glass to be cut is lowered into it. The deeper the piece is immersed, the easier the process will go. the water pressure helps it.

Strong scissors like tailors are taken, plunged under the surface, and pruning begins. The sensation is more difficult than when cutting paper or fabric. Rather, they resemble working with cardboard. At the same time, crumbs are also formed, so it is better to cut with protective glasses in case of a rebound, if you did not immerse the glass deep enough in water.

Gloves also do not hurt, and they will, perhaps, be even more useful than glasses, since you will not notice the fragments in the water, but they cut hard.

Many do not believe that scissors cut glass, and they are very surprised to try that this is really possible.

TUTORIAL FOR GLASS HOLE

Thermal method

In cases where the glass is thick or so large that it does not fit in the basin, it is suggested to find it in a soldering iron. Some have used a woodburner for similar purposes. And those who are especially poor for a tool. even a red-hot nail. Although it will take a very long time to bother with cutting glass, since you need to constantly heat it up.

- Glass is laid on a flat surface.

- The cutting line is outlined. Here, by the way, curly cut is also available.

- At the very beginning of the line, a neat, not too deep file is made on the edge of the glass with a file or file. You can tear off the edge of the angle grinder (only extremely, carefully, at the lowest speeds!) Or even scratch it with a nail.

- The soldering iron turns on. When heated, inserted into the incision.

- The soldering iron is slowly, without much pressure, is drawn along the drawn contour. If the line is straight, and you are not sure that you can draw it straight at such a low speed, attach a metal ruler and move the soldering iron along it.

- A thin crack appears behind the tool along the traced mowing line. To separate two pieces of glass, a thick mitten is put on (a kitchen oven mitt is suitable at home) and the unnecessary cut is neatly broken off. If you have a curly cut, it is better to lead the soldering iron as slowly as possible so that a fraction of a millimeter remains to break off, and the openwork is not damaged when separating the pieces.

Thermal method No. 2

When using it, it is especially important to comply with all fire safety measures, since it involves the use of open fire.

- The glass is again placed on a flat surface. This time, care should be taken that it is not flammable.

- Cutting line is drawn on the glass.

- From a thin cord with a diameter of 1-2 mm. a piece is cut to the width of the glass. Only twine made from natural materials is suitable. cotton, linen, synthetics are not suitable.

- The rope is impregnated with something combustible. kerosene, campfire, gasoline, lighter refill. and laid straight along the mowing line.

- The cord is ignited so that it ignites along its entire length.

- When the fire is almost extinguished, the cut line is spilled with cold water. Glass cracks exactly at the place of burning.

- If the crack has not reached the end, you can go in two ways: wipe the surface and repeat the trick with twine, or put the glass on the edge and lightly tap on the mowing line with a wooden or rubber pad.

Sometimes even craftsmen use this method to create original vases, candlesticks, glasses and ashtrays from empty bottles and glass jars. A glass cutter for creating such masterpieces is of little use, since it is very inconvenient for them to saw a curved surface.

Glass containers in the right place are tied with a combustible cord, especially since the temperature difference is created in the case of a bottle is very simple: it is immersed in a bucket of water.

Often, roughness and small fragments remain at the glass cutting site. To eliminate them, a fine sandpaper is taken, and the incision is sanded until smooth. This stage is especially important if you have built an elegant glass from a beautiful bottle: without such treatment, there is a great risk of injuring your lips or swallowing a piece of glass that is invisible to the eye.

So it is quite possible to do without special tools, using one of the folk notions of how to cut glass without a glass cutter.

How to cut round glass?

Now let’s look at the easiest way to cut round glass. To do this, you need to take a glass cutter and tools in order to cut an even circle. First, mark the center of the circle on the glass, then attach the suction cup to the place where the center was marked. We will tie a rope to the installed suction cup, and a glass cutter should be tied to the rope. The length of the rope from the suction cup to the cutter should be equal to the radius of the circle that you plan to cut. After all the preparations are completed, you can draw a circle on the glass with a glass cutter. Now draw “rays” from the resulting circle on the rest of the glass with a glass cutter. And after that, with ticks, break off the extra pieces that are between the previously held “rays”.

How to cut round glass less than 30 centimeters in diameter?

If it becomes necessary to cut a circle with a diameter of less than 30 centimeters, then for this you need to use a tubular drill. A tubular drill is a tube made of metal that has a fastener for fixing it in the drill chuck. The edges of the tubular drill must be smooth, because glass is cut with an abrasive and water. Before you start cutting a circle out of glass, you need to apply an abrasive with water to the edges of the circle, and when cutting a circle from glass, the abrasive with water should always be under the tubular drill so that the glass does not overheat and crack. If done correctly, the result will be an even circle.

How to cut round glass?

In our life, situations arise when a circle must be cut out of ordinary glass. If you take a glass cutter and a ruler and try to cut such glass, then you will not succeed, because such a task must be approached with all responsibility and seriousness. There are several ways to cut round glass. The choice of method depends on the thickness and dimensions of the glass.

To cut round glass, you need to prepare the necessary tools and items. These include:

Glass cutter;

Drill;

Protective glasses;

Ticks;

Diamond blade;

Abrasive;

Rope and suction cup;

Thick cardboard;

Scissors;

Tubular drill;

Capacity with water;

Scissors.

Cutting glass with a diamond saw

If it becomes necessary to cut round glass, but there is no glass cutter or tubular glass, then you can use a diamond saw. A diamond saw is a smooth diamond-coated strip where the teeth of a regular saw are.

In order to work with a diamond saw, it is necessary to cut a stencil of the circle to be cut out of thick cardboard or plywood. After that, the cut out stencil must be glued to the glass. When these preparatory work is done, you can start sawing with a diamond saw. During the sawing process, the glass from which the circle is cut must be constantly moistened with water, so the process of cutting the round glass must take place in the bathroom. If you decide to cut a circle out of glass using a diamond saw, then you need to be patient and cut the glass with great care.

Cutting thin glass

If you have thin glass available, you can cut a circle out of it with ordinary scissors. To do this, you need to make a stencil on the glass using a waterproof marker. After that, you need to place the glass in water, take scissors and cut out a circle using a stencil, biting off small pieces of excess glass with pliers, while gradually approaching the shape of a circle. With this method of cutting a circle from glass, the circle will turn out to be uneven, but if an urgent situation arises and a glass circle is needed, then you can use these methods of cutting a circle from glass. This method is used when only scissors can be found from the tools. If the glass is 2-3 mm thick, then a circle can be cut out of it with scissors. And if the glass is thicker, then you need to apply the methods described above.

Cut a circle out of glass, cutting by a pro

Cutting glass with a diamond saw

If it becomes necessary to cut round glass, but there is no glass cutter or tubular glass, then you can use a diamond saw. A diamond saw is a smooth diamond-coated strip where the teeth of a regular saw are.

In order to work with a diamond saw, it is necessary to cut a stencil of the circle to be cut out of thick cardboard or plywood. After that, the cut out stencil must be glued to the glass. When these preparatory work is done, you can start sawing with a diamond saw. During the sawing process, the glass from which the circle is cut must be constantly moistened with water, so the process of cutting the round glass must take place in the bathroom. If you decide to cut a circle out of glass using a diamond saw, then you need to be patient and cut the glass with great care.

Roller

The glass cutter roller has a built-in special roller, which is made of a very strong tungsten-cobalt alloy. The usual roller diameter is 6.6 mm, this roller diameter allows cutting glass with a thickness of up to 4 mm.

Organic glass

Plexiglas is a hard transparent plastic based on synthetic resins. To cut such glass, you do not need any special tools. At home, you can easily cut it with a metal saw, cutter and other tools. And if the thickness of the glass is not more than 2 mm, then the work can be done with an ordinary clerical knife.

Reinforced glass, application

The main application of reinforced glass is for doors with reinforced glass as a fire protection option or glazing for firewalls. We also produce double-glazed windows with reinforced glass. The scope of application is due to the property of reinforced glass to resist the spread of flame.

Diamond

The diamond glass cutter is equipped with a correspondingly small diamond, this diamond cuts the glass. The hardness of diamond is well known and therefore it has long been used for cutting glass.

Nowadays, as before, the diamond glass cutter is considered the best tool to cut glass.

Cutting technology

Glass markings. On opposite sides, mark the desired length with a marker, and draw a straight line with a ruler on the plane of the table.

Then the marked edges of the glass are aligned with the line on the table. The method is, of course, only suitable for transparent glasses.

The ruler or rail is laid parallel to the mowing line of the future cut so that it does not interfere with the tip of the diamond cutter or the roller of the glass cutter to move freely exactly along the intended mowing line.

To make sure that the roller is on the line, you can experimentally: by installing a ruler, apply a glass cutter and visually evaluate the accuracy of the coincidence of the cutting tip or wheel with the marked line.

It should be borne in mind that you should not put too much pressure on the glass cutter to cut the glass correctly. The most important thing is to guide the tool with the same pressure on the glass plane and constant speed. It is recommended to release the pressure at the edges of the glass. This will help avoid chipping and chipping in these areas.

Preparing glass for cutting

A lot depends on this stage, and the preparation process itself depends on what kind of glass you decide to use for cutting. New glass, bought specifically for this purpose, can be simply wiped off, and it is best to use an old newspaper for this (this will avoid streaks and settling of small villi). With used material, you will have to work with much more effort. First, it must be thoroughly rinsed using a special glass cleaner. Secondly, degrease with a cloth soaked in, for example, kerosene and finally dry indoors to avoid dust getting on the surface.

In addition, the preparation of the glass implies its cutting. As you know, you are unlikely to be able to achieve a completely waste-free production when working with glass, especially if you are planning to get a product of not quite the correct geometric shape. However, accurate calculation will reduce possible waste to a minimum. At this stage, a more rational solution would be to align the longer side of the glass with the longer side of the workpiece. Please note that the resulting scraps should not be thrown away, they can be used in the future to create new products.

Reinforced glass specifications

Reinforced glass, the technical characteristics of which have their own advantages and disadvantages, is made using a metal mesh. The mesh is made from chrome-plated or nickel-plated steel wire with a diameter of 4-19 mm, cells are square or hexagonal.

The mesh is imprinted inward 1.5 mm from the surface. The total sheet thickness is 5-6 mm, the maximum size is 1500×2000 mm. Glass can be flat or wavy, transparent or colored, matte or polished. The colored version is obtained by adding metal oxides to the still liquid mass. These are rich shades of golden yellow, green, mauve and blue spectra. The surface can be cast or patterned, while the pattern of the pattern follows the contours of the mesh.

As a rule, GOST can tell a lot about a product, reinforced sheet glass according to these documents should have a mesh size of 12.5 to 25 mm, bubbles from 3 to 6 mm in size and foreign inclusions are not allowed. The main advantage is that the debris is held in place by the mesh, and cracking in case of fire or impact does not cause the formation of a debris mass that can injure a person.

Fire and smoke cannot pass through the glass, and the spread of the fire stops. Falling stones or hitting it is also safe, the fragments remain in place. Triplex is made of two sheets of reinforced glass, bullet-resistant bulletproof glass is made of several sheets. It has only one drawback, it is a decrease in strength in comparison with the usual one by almost half.