Cutting tiles with an angle grinder: how to make a cut without chipping?

When installing ceramic tiles, it is often necessary to trim it in a certain way. To solve this problem is a special equipment, which includes all the well-known angle grinder (angle grinder).

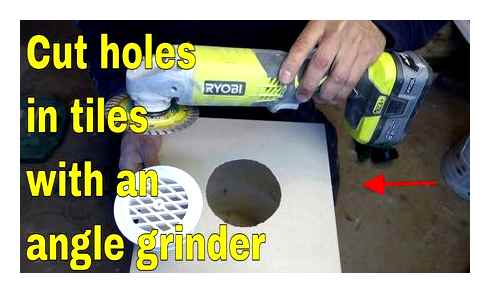

Cutting tiles with an angle grinder. the most popular way to perform this type of work. In order to cut a tile in a certain way, a tile cutter is used. The tool is represented by two types: manual and mechanical. But its price is quite high. It is mainly purchased by professional finishers for permanent use. For ordinary citizens, such a tool as an angle grinder is more popular. It is considered a multifunctional tool and helps to solve many household tasks. It can be found in almost any home. If the owner of the room himself is engaged in the installation of tiles, it is advisable to use this tool. Unlike any tile cutter, the angle grinder allows you to make even round-shaped holes, in the absence of a special drill bit (crown).

Discs for cutting ceramic tiles

There are also special kinds of cutting blades for working with different kinds of material. The following types of cutting discs are used for cutting tiles with an angle grinder without education:

- Stone discs are characterized by an affordable price, but at the same time by a fast wear and tear. Because of the considerable width of the cut will also turn out wide. For these reasons they are rarely used;

- Steel discs have a longer service life, and they are less thick. Diamond-coated discs are the most expensive. They are designed for the hardest ceramic and other kinds of tiles. This tool is divided into several types, which are determined by the way the diamond chips are sprayed and their purpose (dry cutters, for wet cutting, combined). Accordingly their cost will be different. The optimal disc width for this kind of work is not more than 2 mm (to get the most even cut line), the thickness of the edge of the disc should be thicker than the thickness of the tile.

Safety rules when working with an angle grinder

To avoid injury when working with an angle grinder, the following rules must be observed:

- Use personal protective equipment. gloves, overalls, safety shoes, goggles and a respirator;

- The grinder may only be operated with the steel guard installed on the tool;

- the grinder’s power cable should be at least 2 m long in order to reduce the risk of damage by the rotating disc during operation;

- make cutting in the direction “from yourself”, holding the tool with both hands;

- the direction of rotation of the disc must coincide with the direction of translational motion of the angle grinder;

- cut material by plunging the grinder blade into the cutting line trimmer not more than one-third of the radius;

- each material must be treated with the appropriate disc, i.e. the metal cutting nozzle cannot cut ceramic tiles, and the stone cutting disc is not designed for grinding ceramics (you can grind with a steel “dry cutter”);

- when working with the angle grinder, both extremely low and extremely high RPM should be avoided;

- cutting with the grinder of material immersed in water in order to reduce the amount of dust generated is prohibited due to the risk of electric shock;

Dust is explosive, so cut or grind with an angle grinder in a well-ventilated area.

Discs for cutting ceramic with angle grinder

For cutting ceramic tiles with an angle grinder, stone or diamond-tipped steel discs (dry cutters) are used. Dry cutters, in turn, are divided into solid and segmented. The more intensive the diamond coating on a dry cutter, the more effective and durable is the disc.

Stone discs

Stone discs are many times cheaper than dry-cutting discs, but they wear out in the course of work and must be replaced with new ones. They are also thicker than a dry cutter and the cutting line with a stone cutting head is wider, so more dust is generated.

While cutting with a stone grinding nozzle is necessary to control the condition of its cutting edge. if the edge is chipped or burr is formed, the disc must be immediately replaced, because such damage is fraught with the destruction of the nozzle and causing injury.

Dry cutters

Ceramic tiles can be cut with the dry cutter without water cooling, but one continuous cut should not last more than 1-1,5 minutes, after which the disc is allowed to cool down by rotating it idly. When buying a dry cutter prefer a tool with a solid diamond coating.

If during cutting a solid glowing spark-line appeared on the cutting edge of a dry cutter. the phenomenon of metal “licking”. the temperature at the tile cutting point rises sharply in such a situation, which can lead to material damage. In this case the rotating dry cutter can make several cuts on any abrasive surface (concrete, plaster) and the disc will be back in working order.

Segmented dry cutters

This type of angle grinder bits is a steel disc with evenly spaced slots from the cutting edge to the center and dividing the disc into equal segments. Segmented nozzle can cut tiles made of porcelain tiles and natural stone. Slots between the segments of the disk serve to increase the life of the nozzle by improving the air cooling of the tool while cutting hard facing material, but increase the formation of chips.

Solid dry cutters

This type of dry cutter can not only cut ceramic tile, but also work the lateral surface of the cut edge. The lack of tool detonation during work due to the solid shape of the disc increases the cutting speed, allows you to cut a fragment evenly and reduces the number of chips.

How to cut porcelain tiles at home: the methods and necessary tools

If you have time and desire, many people prefer to do the repair themselves, because it helps to significantly save money and gain personal experience. When it comes to tiling the room with porcelain tiles, many people overestimate their capabilities relying on previous experience with regular tiles. As for the laying technique itself, the process is identical, but cutting porcelain tiles requires a little different skill and knowledge of the peculiarities of the material from the master. In this article we will explain in detail how to cut porcelain tiles at home even without any experience, what materials are required and give some useful tips.

First you need to choose a cutting method based on the characteristics of the material, the size of the room, aesthetic requirements and personal experience. For example, if the area of the room is large, then the use of a mechanical tile cutter or electric jigsaw is not justified, these tools are suitable for finishing apartment rooms. The use of an angle grinder is also not always suitable, as it results in a large amount of dust, noise and the quality of the cut leaves much to be desired.

We are often asked if it is possible to cut porcelain tiles with a hand cutter? You can try it, of course, but the result most likely will not please you. The tool is not designed for this material and you will only ruin the tile. Below we will look at each method in detail.

Cutting with a mechanical handheld tile cutter

The use of a mechanical tile cutter is ideal for work with small volumes of cladding, bathroom, toilet, kitchen or hallways in apartments or private homes. Advantages of the device include:

- There is no dust and noise at work;

- They do not need electricity;

- Mobile and easy to maintain;

- Relatively safe and suitable for both experienced craftsmen and beginners.

For your information. Disadvantages include the ability to make only a straight cut. Inexperienced users can get uneven cuts. No chamfering and the cutting wheel wears out quickly when working with porcelain stoneware.

Important! Before you cut porcelain tiles with a mechanical tile cutter, make sure the device is in working order, stands on a level surface, all elements are securely fixed and have no backlash. If the tool is not an expensive one, you need to lubricate the slide’s guides before working. The more expensive models have bearings on the guide rail to ensure smooth running.

Then perform the work according to the step-by-step list:

- Make the markings on the tile with a pencil or marker, which can be wiped off after the cut;

- Lay the material on the bed of the appliance so that the trimmer line of the cut corresponds to the markings on the bed. If there is no marking, roll the cutting wheel effortlessly along the intended line and make sure that it does not move away from the intended cut;

- Next, with light pressure on the handle, make the cut in the direction away from yourself;

- Then press the special feet on the tile to split it.

Important! Do not make the cut twice, or put too much pressure on the pen, as this can cause chips. When pressing the tile to break it, make sure that the cutting wheel is outside the material and does not catch on the porcelain tile when pressing it. For clarity we suggest to watch video material where a specialist shows the process of cutting on the machine.

Cutting porcelain tile with an angle grinder

Using an angle grinder for cutting porcelain tile is not the best solution. From the obvious disadvantages of this tool can be noted noise, a lot of dust, uneven cut with a lot of chips especially on glossy porcelain tiles, the increased danger of the tool. Of course, in the hands of an experienced technician angle grinder does a good job, but if you have little experience and the work is carried out in the apartment, it is better to buy a mechanical tile cutter.

Step by step instructions when working with an angle grinder is as follows:

- Lay the porcelain tile on a flat surface, it is advisable to put under it foam plastic or a piece of board not to damage the surface of the floor;

- Using a spirit marker, pencil or chalk (depending on the type of surface), apply a line to trim the notch;

- Secure the tile with a clamp or your foot, wearing special safety shoes beforehand;

- Turn on the angle grinder and make the cut away from you to a depth of 2-4mm;

Important! You should only make the cut once. Do not cut the tile all the way through, this will cause the cutting wheel to overheat and damage it. If the angle grinder has a speed regulator, it is recommended to set the range of 6 to 8 thousand. RPM when using a 100-120 mm disc.

- After finishing cutting, lay the porcelain tile on a flat and hard surface, under the line for the trimmer cut on both sides can put nails, two screws or any other object that will serve as a fulcrum and lift the tile by a few millimeters.

- Press down sharply on the opposite planes of the cut and the tile will break along the line of the cut, as shown in the video below.

Most likely the edges of the break will be uneven and you can use the same angle grinder or sandpaper with a coarse grain. The angle grinder may only be used for cuts which will later be hidden or are located in inconspicuous places. On our site you can read in detail how to choose a disc for cutting ceramic granite and tiles with an angle grinder.

Safety guidelines for cutting

Safety rules when working with cutting tools are very simple, and their observance is a must, because your health and even life depends on it. When using non-electric tools, the basic set of protective equipment is gloves and glasses. Gloves will help avoid cuts from sharp edges of the material, and goggles will prevent splinters and dust from getting into your eyes.

When working with electric tools, angle grinder or tile cutter, special attention must be paid to safety:

- It is strictly forbidden to change or clean the cutting disk if the machine or angle grinder is plugged in. The machine must be completely disconnected from the electrical supply.

- Do not submerge the cutting disk in porcelain tile by more than one third when cutting with an angle grinder. When working with a tile cutter, it is allowed to immerse the wheel no more than half of it.

- The angle grinder must have a protective cover and the cut of the tile must be made in the direction from yourself.

- Use protective clothing made of thick material and do not leave any exposed areas of the body. When the cutting wheel is heated, spray particles can bounce off and leave burns on the body.

- It is important to use thick cloth gloves. Experience has shown that knitted gloves are not suitable and can cause injuries. Often with improper tool handling, a disc or locknut will catch on the glove strands and can twist.

- There should be no dangling straps or clasps on clothing, and if you have long hair, it should be hidden in a headpiece.

Since power tools create noise and often a lot of dust, goggles, headphones and a respirator are indispensable.

Cutting a rectangular hole

By means of a marker and ruler on the outside of the tile should be marked the boundaries of the cut, then exactly at the corners of it, without crossing the limits of the contour, you must use a carbide drill hole diameter of 5-7 mm. Next, an angle grinder to make through cuts between the holes made throughout the rectangular contour, performing the removal of cut pieces of tile. When you are finished, the corners and cuts should be finished with a file or coarse-grained emery paper.

In this case, the angle grinder should not be held in a straight position, but at an angle. To make such a cut is a little more difficult than the usual one, but it is much easier to cut a hole of round or other shapes. The work is carried out as follows:

- First of all the tiles should be sawn in the same way as for the straight cut. In doing so, the wheel of the tool must be positioned at the required angle and, applying it slowly and accurately, it is required to remove all excess until a perfect angular cut is obtained.

- After the end to give a perfect look, you can use ordinary sandpaper, which for convenience should be fixed on a block of wood.

Note! To properly cut the tile with an angle grinder without chipping, it is recommended to perform its cutting only from the front side. In this case, the outer coating of glaze will be significantly less damaged, and all the defects formed during the work will remain on the back edge, which will be fully hidden during further gluing.

How to turn an angle grinder into a tile cutter

Not always when performing sawn tile is comfortable to hold the angle grinder on weight and perform all work only by hand. To simplify this task, you can turn the tool into a device that will leave both hands free. It resembles an electric tile cutter, and the transformation of the angle grinder itself is as follows:

- The first thing to do is to choose a suitable place for placing the machine. The base of the tile cutter can be made of sheet metal, in which it is necessary to make a cut to deepen the circle. This band will be used for all future work, as well as it will allow more convenient orientation in the process of sawing.

- The next step is to perform the fixation of the angle grinder. To fix the device in the desired position you need to resort to the use of special clamps. If necessary, they can be made by hand, but it should be borne in mind that in this case there is a possibility of tearing the fastening bolts in the process of making the cut.

Please note! This handmade electric tile cutter can be improved in the future with a container of water and a wet-cutting nozzle, which will get rid of dust and fully cool the cutting element during operation.

- After securing the tool, a test cut can be made. To do this, you need to lay the tile on the marks, and then you should turn on the angle grinder and slowly lower the circle. In this case, a tile must be cut on the outer side, filing the product away from you.

When properly performed work can be obtained cut into two parts ceramic tiles with smooth edges and the absence of chips, cracks and roughness. If necessary, bring the tile to an ideal condition, you can use fine sandpaper or file.

How to turn an angle grinder into a tile cutter

It is not always convenient to hold the angle grinder by weight and do all the work entirely by hand. In order to improve the cutting quality you need a helper. However, it will be much more rational to turn an ordinary grinder into an analogue of an electric tile cutter.

We have found out how to properly cut ceramic tiles with an angle grinder. The same principles of operation are retained for the tile cutter, but both hands are kept free. Let’s consider what you need to do to improve this tool.

First of all, choose a suitable location for the machine. The base of the future tile cutter can be made of sheet metal, in which a groove will be cut for deepening the disk. On this line and will be made all work, in addition, by such a mark will be much easier to navigate.

The most important step is to fix the angle grinder. In order to fix the tool in position you must use the special clamps. Their counterpart can also be made by yourself, but there is a risk that the fixing bolts will tear during the work.

For frequent use and convenience, the angle grinder can be fixed by making it a tile cutter

This version of a homemade electric tile cutter can be improved by adding a reservoir of water and an attachment for wet cutting. This will help to avoid dust and cool the tool.

After fixing the angle grinder, you can make a test cut. The principle of operation is as follows: the tile is laid on the marks, the angle grinder is turned on and the disk is slowly lowered. The tile will be sawed on the front side, and it is necessary to feed it from yourself.

If the work is done correctly, you will get a ceramic tile cut in two with neat edges, without chips, cracks and nicks. The final look of the tile can be given with fine sandpaper.

Cutting edge tiles

Paving tiles differ from other materials in their structure. The concrete is taken as the basis, and granite crushed stone is used as the filler. For cutting such workpieces with an angle grinder, it is recommended to buy combined or segmented diamond circles.

the working area should be set up outdoors only, because there is a lot of dust when cutting. If it settles on an already laid tile, you must immediately remove the dirt, as the dust digs into the material and changes its color.

It is recommended that you wear protective clothing, a respirator and goggles. For products of small thickness, the standard through-cutting technology is used, while thick tiles are first cut, then the excess part is broken off.

Safety precautions when working with the angle grinder

The angle grinder is a hazardous power tool, which can cause personal injury if operated incorrectly. When you cut while the disc is spinning, splinters of dust and other debris fly out from under it. Therefore, when cutting tiles with an angle grinder, protective equipment is used:

- A thick body suit, which should cover the body, legs and arms;

- Special glasses, better a mask to protect the whole face;

- gloves or mittens.

Before you start work, check that the angle grinder is in good condition:

Change grinding wheels only after disconnecting the tool from the power supply. After changing a part, check that it is securely fastened, free from defects and that the special key is disconnected. Only after these steps can the angle grinder be reconnected to the power supply.

Safety Precautions

To ensure safety when cutting tiles, you must comply with the following requirements:

- use a protective cover;

- Hold the angle grinder firmly and do not turn it vertically;

- use proper PPE. protective clothing, goggles, respirator, gloves, etc.д.;

- Work outdoors or in a well-ventilated room.

In addition, it is necessary to observe electrical safety precautions, not to use defective tools with damaged insulation of the body and wire. Before you cut tiles with an angle grinder, you should prepare the workplace, ensure appropriate conditions. lighting, ventilation, etc.д. If you follow these simple rules, you will avoid injuries and do the work without any damage.

Highly specialized devices

Of course, the methods of cutting that we discussed above are suitable for those who are not able to shell out a good sum to buy a machine for cutting porcelain stoneware. However, for professional tilers saving time on cutting porcelain tiles is very important, that’s why the machine is very handy. Although the machine can only make straight cuts, most cuts are straight. In addition, a good machine will allow you to cut porcelain stoneware at different angles.

In addition to the large allowable cutting thickness, the machine has a number of other advantages. First, it will be possible to use wet cutting of porcelain tiles. This way reduces the probability of overheating of cutting disk and the appearance of chips on porcelain stoneware. Secondly, the hands are freed from the burden of the weight of the power tool. The machine has a platform, on which the electric motor and cutting edge are rigidly fixed. Thirdly, the machine has devices for straight forward motion: either the tiles or the motor with the cutting tool. This avoids irregularities and significantly improves the quality of the cut. The only thing left to do is to control the speed of the feed on the guides while the cut is being made. But the main advantage is the absence of dust when cutting tiles, which is especially important when renovating apartments.

Depending on how often and how much master has to work with tiles, he can think about what type and size machine for cutting porcelain tiles he will need. For example, if the work is done in a confined space or infrequently, a machine with the motor positioned below the work table is more suitable. Such machines are smaller, lighter and much cheaper than overhead machines (for example, the Praktika 1860 is a mid-range model). But this option has a greater restriction on the depth of cut. Not every model is equipped with guides for straight tile feed and tile fixing devices, which requires some skill from the craftsman. Also, 45-degree angle cutting is not provided in many models.

opportunities and comfort when cutting porcelain tiles are provided by machines with the motor located above the work table. For the master who specializes in working with tiles, this option will be clearly preferred. Although these machines will have larger dimensions, they will provide safer and more comfortable working conditions, a much greater depth of cut (up to 100. 135 millimeters), some models allow you to cut not only at an angle of 45 degrees, but also in the intermediate values. Naturally, this type of machines will have more powerful motors and larger diameters of diamond cutting discs. Some of these machines will be stationary, meaning they will be very large in size and weight.

Depending on the manufacturer, equipment, size and abilities, overhead machines come in a wide range of prices. Here you can read a detailed review of tile cutters.

Block: 6/8 | Number of characters: 3053

Gourmets of quality and refinement

It’s no secret that there is a special category of customers who can be called gourmets of quality. They are willing to pay a lot of money to have the work done to perfection. Most likely, it will be difficult to convince such a customer that it is possible to make a high-quality cut of porcelain stoneware by hand. The water cut or waterjet cutting of porcelain stoneware can be helpful. It is the latest technology that allows cutting porcelain stoneware of the highest quality. At home, this operation is not performed, because it requires special equipment. The main disadvantage is the high cost of this work, which is unlikely to be affordable to an average customer.

The thickness during waterjet cutting can be up to several centimeters, and the product does not need additional grinding. A big advantage of this method is the possibility of high complexity of the cut, which is impossible using manual methods. over, the complexity is not only in terms of the pattern of the cut line, but also in terms of the width of the parts to be cut. Waterjet cutting of porcelain stoneware allows to cut a detail at sharp angles to the edge of the tile, to cut thin elements, cut holes and other complicated cuts. Thanks to this it is possible to create drawings, mosaics, panels and other images from porcelain tiles of different colors. As the cut is controlled by a computer, it is possible to fit the mating parts with perfect accuracy. Really, gourmets will get the desired result.

Block: 8/8 | Number of characters: 1533

Number of blocks: 15 | Total number of characters: 22586Number of used donors: 5Information on each donor: