How to cut tiles without a tile cutter

In the production of various construction works by yourself there is often a need to cut ceramic tiles at home. It is not necessary to have a professional tool for this. a tile trimmer. We should say at once: We are not talking about constant work and large volumes, but about small batches or even piecemeal products. In such cases, buying an expensive tool makes no sense, it is quite possible to do with improvised means.

- Cut in a straight line. A distinction must be made as to where the cut is made. If there is less than 2 cm to the edge from the cutting line, such a cut can be considered a shaped cut;

- Round holes in tiles of various diameters;

- Shaped cutouts;

- Mosaic elements. If there are requirements for precise geometric shapes, this type also refers to shaped cuts. Otherwise, it is actually crushing the tile into pieces. Products are placed in a bag and with the help of a heavy tool (hammer, sledgehammer) are crushed to the desired proportions. Non-ceramic tiles may be an exception.

Ways to cut a tile without a tile cutter

For all its hardness, ceramic or glazed tiles are fragile. when cutting at the edges may appear irregularities, and the tile often breaks. How to cut the material yourself, quickly and qualitatively, so that the tile does not lose its appeal?

You can cut ceramic tiles without using a tile cutter in different ways. It is recommended to begin the preparation for work by soaking the material in water for 40 minutes. The next important point that should not be neglected is the application of markings. Before you start cutting, it is necessary to make a test cut on a tile fragment. This will help control the force of the pressure and not to damage the material.

angle grinder and jigsaw

Using an angle grinder (angle grinder). angle grinder on ceramic tile can make a straight cut. During the work it is recommended to use protective equipment: goggles to protect the eyes from dust, respirator. respiratory organs, headphones. hearing organs, gloves. hands. You must also monitor the condition of the equipment. change discs when they wear out, to prevent injury to the operator and tool breakage.

First it is recommended to mark the material with a pointed tool (nail or drill bit) by scratching the tile. The material is placed on the work surface. table or floor. To avoid damaging it, under the tiles should be placed fragments of plywood, cardboard, thick cloth, the material should be fixed with a clamp.

The pieces, the length of which does not exceed 2 cm, are considered small. the material is cut to its full thickness all at once. When making a straight cut, it is recommended that the recess on the outer edge of the tile should not exceed 3 mm in one go. This reduces the likelihood of damage to the material.

To make curvilinear cuts with large radii of curvature use a jigsaw with a saw for ceramics, natural or artificial stone. For the convenience of the jigsaw it is necessary to use the “precisely cut” mode.

Focusing: Glass cutters and other tools

For cutting thin (3 mm thickness) ceramic tiles without using a tile cutter, tools that have a sharpened cutting edge. glass cutters, drills, knives and other devices are also used.

To apply the markings with these tools use a ruler, the scratch is applied to the top layer of the tile. It is recommended to perform the cut on yourself, without interrupting. Control the force of the tool so as not to damage it and the material. After making the cut you should break the tile on the edge of the table.

Pliers

Pliers are used to perform a curved cut of the ceramic tile. At the beginning of work, it is recommended to make a marking on the outer side of the material with a marker. Then from the edge of the tile you need to start biting off small fragments of the material, squeezing the cutters. If necessary, you should make the edges of the tile smoother with a file and sandpaper.

Tweezers with a cutter

First you need to draw a marking on the outside of the material with a marker and ruler. The side of the pliers, which is located on the cutting part of the tool, spend on the front side of the material, while it is recommended to control the force of the pressure on the material so as not to damage the tile. Start cutting from the far edge along the line of the marking, pointing towards yourself. If necessary, the operation is repeated. Then turn the tool over so that it grips the material along the cutting line. The final step is pressing the tongs; if necessary, the edges of the material can be smoothed with an emery board and sandpaper.

Splitting ceramic tiles

The final stage of the work on cutting ceramic tiles is splitting the material. There are several types of tile splitting by the breaking point: on the edge of the table, on a solid rod, between the clamp.

When splitting ceramic tiles using a stiff bar, you can split the material into larger and smaller pieces. A rod with a diameter of 8. 15 mm (drills, nails, pencils and other devices) is used, the length is 2/3 of the breaking length. The ceramic tile is placed on the rod, aligned at the breaking point. The final step. pressing on the material.

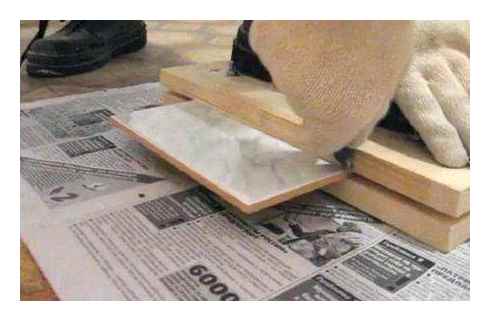

When using the method of splitting the material between the clamps, the ceramic tile is fixed between two pieces of plywood, bars and other improvised materials. Tile is placed on a break trimmer fishing line, clamped. The final step is to press on the free edge.

Thus, it is possible to cut tiles without using a tile cutter in different ways. For convenience, it is recommended to soak the tile in water for 40 minutes in preparation for work. When working, it is also recommended to mark the material and control the pressure so as not to damage it.

The tile apron in the kitchen Building yardTwo common methods for cutting tiles

Using an angle grinder for tile

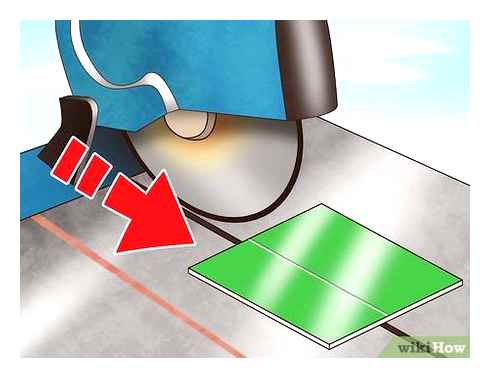

An angle grinder is often used to cut ceramic granite tiles. This method is considered an alternative, but it has its own advantages. First of all, it should be noted that the angle grinder allows you to cut much faster, which affects the productivity. The principle is similar to the action of an electric tile cutter, but in this case the cut is made with a dry disc. The disadvantage is that after cutting, the tiles create small chips on the edges. The number and size of chips largely depends on the accuracy and skill of the tiler. Therefore, before you cut tiles with an angle grinder, it is better to improve your skills with this tool on unnecessary scraps of material.

The tile must be secured to a flat surface. On its front side, a straight line for the trimmer is drawn. Angle grinder should be taken in the hand so that the cutting occurs in the direction towards yourself. Be sure to wear safety glasses and a mask in order to protect your eyes and respiratory system from ceramic dust. This method of cutting is quite dangerous and noisy. It generates a lot of dust during cutting. Without experience, you will get a lot of inaccuracies and mistakes. This should be kept in mind, all the important points are discussed in the video for the lesson.

Alternative tools, features

There are plenty of opportunities to cut tile without equipment using the following tools:

Cutting tools

Angle grinder. grinding machine, which with the use of special attachments with diamond coatings cuts tiles, other materials (even floor tiles, porcelain tiles).

Glass cutter. a tool that is the size of a ballpoint pen and does a great job with tile, but you need confidence and clarity in your work.

Drill. suitable for roundings, holes, using different attachments (drill bit, ballerina, crown).

Pliers. the edge of the tool cuts the top layer of tile, makes a line for the trimmer notch. Often used for shaped cuts.

In addition to these tools, use a saw with a spray, an electric jigsaw, even a nail.

Attention! In working with tiles, they use nozzles with diamond spraying. others do not cope, spoil the material.

Using an angle grinder for tile

For cutting karemogranite tiles, an angle grinder is often used. This method is considered an alternative, but it has its own advantages. First of all, it should be noted that the angle grinder allows you to cut much faster, which affects the productivity of labor. The principle is similar to the action of an electric tile cutter, but in this case the cutting takes place with a dry disc. The negative point is that after cutting, small chips appear on the edges of the tile. The number and size of chips largely depend on the accuracy and skill of the tiler. Therefore, before you cut the tile with an angular grinder, it is better to slightly improve your skills of possession of this tool on unnecessary scraps of material.

The tiles must be fixed on a flat surface. On its front side, a straight line for the trimmer is drawn. The angle grinder must be held in the hand so that the cut is in a forward direction. Be sure to wear safety glasses and a mask to protect your eyes and respiratory organs from ceramic dust. This cutting method is quite dangerous and noisy. A great deal of dust is generated during cutting. Without experience, you will get a lot of inaccuracies and mistakes. Keep this in mind, all important points are explained in the video for the lesson.

Ø 20-30mm

- Spear-head drill bits oriented for tile work. Drill well into normal tiles.

- Special drill bits that have a sharp-angled sharpening on one side. They can be used if you want to drill even hard floor fragments of ceramic flooring.

- Bits designed for stone and concrete with tungsten carbide tips. Do not differ in durability, but a few holes allow to perform.

Ø 31-50 mm

- Teeth. They can be corundum, diamond, carbide-tungsten. Have a rather high cost.

- Ballerina. Is a lance-shaped drill with the presence of a second cutter, which is set to work with the movement of the rod, fixed on the central leg. Although the durability of such an attachment is low, it is valued for the ability to cut a variety of hole diameters.

If you need to get a hole in the tile over 50 mm in diameter, use an angle grinder.

Methods of cutting tiles without a tile cutter

Depending on the type of cutting, there are several technologies for performing this task:

- Electromechanical. the process occurs with the use of a tool with a crown, drill, disk, stone or other device. In one case or another, everything is performed strictly under the ruler.

- Mechanical. cutting tiles without tile cutters, namely without the use of electric tools. Based on physical strength and the use of hand tools. These include: glass cutter, pliers, pliers, file.

- Hydromechanical. a method of cutting, in which the separation of tile into parts occurs by influencing the place with a powerful jet of water with an abrasive mixture. The thickness of the cut is narrow enough, and the quality of the cuts is high.

Angle grinder angle grinder

Consider how to cut tiles without a tile cutter using an angle grinder. This will require:

- A diamond wheel grinder of suitable grit size.

- A level, stable surface to do the job.

- A ruler or pre-marked trimmer line on the back of the tile.

- A backing pad under the tile to prevent the tile from wobbling and sliding while cutting.

- It is desirable to connect a vacuum cleaner, because a lot of dust will be formed in the process of work.

After the tile is lying stable, you can begin to cut. Start at the near edge and guide the stone so that it runs over the face coating. This way the chips will be formed only at the bottom, and the top will remain smooth. In the same way it is convenient to make cuts.

Electric jigsaw

Another handy tool for cutting tiles is an electric jigsaw. To use it, you need to buy special saws for stone. The peculiarity of using this tool is that it can be used to make curved cuts.

Applying the ruler to the surface of the tile and moving along it, a fairly even cut is achieved, and the end face remains with a slight roughness. To avoid chipping, guide the teeth of the saw into the glazed surface and guide the tool slowly.

To perform the work, use a sturdy table, securing the tile to it with a wooden clamp, and the surface must be perfectly flat.

A glass cutter or any pointed instrument

This is the most ancient and quite effective method, which is still used for cutting glass. With an experienced craftsman and a well sharpened instrument the flank is smooth, without bevels or twists. The glass cutter does not actually cut, but notches, creating cracks in the upper layers of the tile.

Once the strip is outlined, the tile should be placed on a hard surface along the cutting point and a sharp movement should be applied to the edge. If the facing is hard enough, the chipping is even, but if the ceramics is loose, the irregularities will have to be removed with a nail file.

Recommended for wall tile, not for floor tile. Porcelain stoneware is very difficult to break in this way.

Round Holes

To cut round holes in ceramic or porcelain stoneware, it is necessary to use specially designed bits. They are equipped with diamond segments or sputtering that is used to drill. The diameter of the hole can be anything from 30 to 80 mm using these fixtures.

If you need to drill more for the installation of electrical or plumbing components, it is better to use a ballerina drill. It is a drill on a bracket in the center and two cutters, with an adjustment of their position relative to the center. A circular saw and diamond bits are also used for this. The principle is the same.

Shaped breaking out

Breaking out shapes in ceramics is not an easy task. To do this, you must first make a lot of notches with fine spacing from the end to the shaped cut. The smaller it is, the more accurate is the bend on the ceramic. the cuts are made just a little short of the base line. After that, using pliers, each segment is carefully broken out and the unwanted ceramic is removed with small bites.

Depending on the diameter of the holes the tool and nozzles are selected. For making holes in tiles any tools with a rotating tip are best suited (drills, screwdrivers, rotary screwdrivers, hand hammers, etc.).д.).

Note! The tool’s power output is not important, it is the rotational speed that matters. A low rotational speed is preferable. Anything over 500 rpm only harms the cutting tool. Although the hole is made faster, but the cutter gets very hot and breaks down faster. High RPM also increases the risk of chipping around the edges of the hole.

Various nozzles for drilling holes in tile. Nozzles for small diameters (up to 15. 30 mm):

- Special drill bits with a single-sided pointed sharpening. The best option, but it is quite expensive. Lasts for a long time, drills almost any hard tile surface;

- Tile drill bits. Cheap drill bits, best for single-use work. When used on simple tile, they are enough for a few dozen holes;

- Carbide-tipped drills (concrete, stone, peorator and other). Not the best option, but if necessary, you can make a couple of holes with them too.

Ceramic tile cutting technology with a tile cutter

To make a straight cut with the tile cutter, you need to draw a line with a felt-tip pen on the material. Next, lay the tile on the special base of the tool and combine the indicated line with the wheel to apply the risk. When making many identical cuts, it is advisable to fix the frame with a screw in the specified position. Hold the tile with one hand and the lever with the wheel with the other hand.

The lever should be raised until the wheel makes contact with the tile surface, and then perform the movement of the handle towards yourself. Using a little force, make one pass on the wheel, applying the mark.

Note! If you carry out the cut repeatedly, the executed cut will turn out to be of poor quality.

Next, according to the made mark you need to divide the material into elements. To do this, place the wings at the beginning of the arm so that they are at the level of 1/3 of the bottom plate. Cover the wings of the tool with painter’s tape beforehand so that they do not damage the material. Hold the tile in the desired position by lightly pressing the lever with the thumb of one hand, strike the lever with the palm of the other hand.

Note! If the material does not splinter, hit harder. If the material still does not give in, start the process all over again with another tile.

After completion of the work, the cut edge may stand out. This is corrected by sanding it with sandpaper or a sanding stone. Make sure you have the right type of stone for the structure of your tile. There is no need to work on the edges when they are covered by adjacent tiles.

Particular attention should be paid to safety when working with the “angle grinder

If you need to make holes and semicircular cut lines at home, use a drill with special attachments, wire cutters with carbide holders.

To make holes in the tiles use a special attachment to the drill

How to cut tile without any cutting tools | DIY easy way to cut tile without any tool

The peculiarity of work with pliers is “biting off” fragments of ceramics on a pre-drawn contour. Remember that only small pieces should be separated. In any case, after such procedures it is important to make grinding.