What do the numbers on the chainsaw mean??

For example, the marking of the saw chain on the packaging may be as follows: 63PM50. This means that 6 is the chain pitch 6 = 3/8 “P; 3. chain groove 3 = 1.3mm; PM. type of cutting tooth PM. Picco Micro; 50. the number of driving links (depending on the length of the tire). If your saw chain is dull, sharpening it is easy.

How to find out the wear of a chainsaw tire?

A good tire should provide adequate chain tension. To check it, release the chain brake and pull the chain by hand in the direction of its movement. If the chain does not move, then the attachment is too tight. It must be slightly released, and then again check the free play of the chain.

How to count the links on a chainsaw?

So, to know the number of links in your chain, you just need to count them. For convenience, fold the chain with links to each other, count the bottom side and multiply by two. This will help you stay on track. May 28, 2018.

What do the numbers on the tire of a chainsaw mean??

The main symbols for marking tires for chainsaws are numbers indicating the length of the bar (cm), the chain pitch (1/4, 3/4, 3/8, 0.325, 0.404), and the number of links. For example, the tire is 40×3 / 8×56, where 40 is the length of the bar (400 (mm)), 3/8 is the chain pitch (9.52 (mm)) and 56 is the number of teeth.

What are chains for chainsaws?

What are chains for chainsaws. types and features

- Longitudinal. the use of such sawing elements during operation increases the performance of the chainsaw;

- Transverse. the use of chains of this type allows you to smooth out the “aggressiveness” of the saw, which significantly reduces vibration on its handle and the load on the tool motor.

How to determine the chain pitch by an asterisk?

To find out the chain pitch, you need to subtract the diameter of the roller from the distance along the outer sides of the roller. In this case, the chain pitch is 26.035 mm. 10.16 mm = 15.875 mm.

What is the chain pitch on the STIHL 180?

Chain (16 “; 1.3 mm; 55 links; 3/8”) for saws STIHL-180, 210, 230, 250 Rezer PS-9-1,3-55.

How to choose a chain for a chainsaw in the shape of a cutting tooth

The choice of chain for a chainsaw should take into account the shape of the cutting tooth. When viewed along the tooth, the cutting edges form a similarity to the number 7. The rounded tooth is called Chipper, with an acute angle. Chisel.

Chisel teeth are characterized by high productivity and cutting speed, because their configuration reduces the contact area of the tooth with the wood during operation. A serious drawback of the “chisel” tooth is that it quickly becomes blunt on wood contaminated with grains of sand. Resharpening such a tooth requires very precise adherence to all standard angles and parameters.

The Chipper tines have a larger cutting area with the wood and therefore lower cutting speed. But this drawback compensates for the undemanding quality of regrinding. The rounded corner of the “chipper” will tolerate sharpening errors more easily and shows itself well in working with contaminated wood.

How to choose a chain for a chainsaw according to the thickness of the shank

The shank is the part of the chain link that fits into the guide bar. Its thickness must strictly correspond to the groove of the tire so that the chain moves as smoothly as possible, the cut is smooth and there is no excessive tire wear.

How to choose a chain for a saw with a gasoline engine step by step

Chain pitch is measured in inches. It is indicated on the product and affects the quality of the cut. The higher the saw power, the more you pick up the step. For non-professional instruments up to 2500 W, standard 0.325 ” pitch.

The chain pitch must match the pitch on the drive sprocket of the engine and tire. If you change it together with the tire, replace the engine sprocket with a collapsible one and install the drive ring on it with the desired pitch.

How to choose a chain for a chainsaw in length

Its total length is determined by the number of links that make it up (it is also equal to the number of shanks). The chain for one bar may not fit on a bar of the same length on another saw. Therefore, see what length the manufacturer recommends in the instructions for the saw.

Leave your opinion and wishes to the article “How to choose a chain for a chainsaw: types, sizes, nuances”

How to properly tension the chain on a chainsaw

Regularly tightening the chain on the chainsaw is necessary not only for efficiency, but also for the safety of the worker. Most devices (especially the STIHL brand) have a special device on the side, as in the photo, to help bring the links to their normal position.

Chain selection

A Husqvarna chainsaw‘s performance and service life depend not only on the ability to tension the links, but also on whether it is suitable for a particular brand of machine. This detail differs according to several criteria:

- step;

- thickness;

- cutting depth;

- the length of the chain and the number of its teeth.

The pitch value is the main parameter for the chain, on the basis of which this part is selected. Its meaning is determined by the gap between the tails. Common options: 0.325, 0.375, 0.404 inches. You can find out which type is needed for a particular saw by reading the instructions. The smaller the step, the less power should be in the mechanism to which it should be pulled.

A large step affects the “aggressiveness” of the tool, that is, the cutting links penetrate the wood more strongly, and therefore the worker is required to hold the Druzhba chainsaw more tightly. The 0.325 chain is very common among household and semi-professional mechanisms. It can be pulled on Druzhba chainsaws with a power equal to 3 hp. This chain is best for sawing small trees and construction work.

The designation of the number 0.375 is rare, since the marking for the convenience of buyers has been replaced with the value 3/8, because 75 and 25 are easy to confuse if the purchase is made by a non-professional. The power of a Goodluck chainsaw, for example, should be 4 hp. Otherwise, the instrument may deteriorate.

Links with a pitch of 0.404 can only be pulled on professional mechanisms with a power of more than 5 hp.

How to tension the chain on a chainsaw

The first thing a newly-made owner of a chainsaw has to learn after studying safety precautions for working with a powerful tool is setting it up. The next thing to do after reading the instructions is to test the work, and if the saw does not work correctly, then the likely reason for this is incorrect chain tension. Therefore, the question immediately arises. how to pull a chain on a chainsaw?

Usually, manufacturers indicate in the instructions for the chainsaw how to do this, but if for some reason it got lost, or the device got without it, for example, by inheritance, then the text below will help you find the right answer.

Chain tension

Chain tension adjustment is carried out:

- when installing the chain on a chainsaw after sharpening;

- when the tension is released during the operation of the chainsaw;

- when replacing a worn out or broken chain with a new one.

The chain is tensioned with a special screw. Most often, for convenience, it is placed on the side surface. The tension force is adjusted empirically. The normal position of the chain is determined by the bar, while the lower part of the chain cannot have a gap, since it should not sag.

The degree of tension is determined manually. with a hand wearing a protective glove, the chain is scrolled. With the normal arrangement of the chain in the tire, the movement of the cutting tool should be carried out freely, without much effort.

Note: when adjusting the chain tension, the brake must be in a free state. unlocked.

Advice: when using the saw in winter conditions, the tension must be carried out on a heated saw. the metal elements expand from the temperature rise and the chain can sag. At the end of the work, the tension should be loosened. during cooling, an excessive load may occur from the contraction of the metal during the cooling process.

Chainsaw adjustment

Chainsaw is a hand tool designed for working with wood material. It is equipped with a gasoline internal combustion engine. It is a complex constructive device. During operation, the factory settings are violated, therefore, periodically it is required to carry out such a procedure as adjusting the chainsaw.

The principle of the chainsaw

The main internal combustion engine is started by means of a starter. The engine speed is controlled via the carburetor, which in turn is controlled by the accelerator. Upon reaching a certain number of revolutions, the automatic clutch begins to transfer torque to the chain.

To obtain more power and speed, more fuel is supplied through the carburetor via the accelerator. This is important during the sawing process, as the power of the cutting tool will be directed towards the wood.

Professional chain design features

According to the geometric shape of the cutting teeth, they are distinguished for the most commonly used type of profile:

- Chipper, or sickle. Provides high cutting speeds. It is easier to sharpen and does not require very strict sharpening angles. The profile has the ability to self-cleaning from sawdust and perfectly copes with cutting dirty and damp materials. The increased contact area of the teeth with the material additionally loads the engine. For cutting with such a profile, it is good to have a power reserve. The disadvantage is the occurrence of overloads when sawing hardwood or knots.

- Chisel, or “seven”. The cutting edge is straight, in the profile it looks like a stylized number 7. The cut is more accurate, but they are more difficult to sharpen, it is required to maintain the corners with high accuracy. If the sharpening angles of several one or links are violated, all the advantages of the profile instantly disappear. It is better to sharpen such chains on automatic machines that provide high stability of parameters.

Chisel profiles are used in both household and professional models of chainsaws.

Types of materials

Conventional chains are made from chromium and nickel alloyed tool steel. Such models do well with soft woods.

When working in hard rock, wet or frozen timber, it is best to choose chains with carbide cutting surfaces. They are also recommended for work on foam concrete and aerated concrete. They are significantly more expensive than conventional ones; for their dressing and sharpening, specialized equipment with corundum grinding discs is required. It will not be possible to sharpen such a chain manually.

How does the need to sharpen a chain appear?

If the working teeth have lost their sharpness or are unevenly worn in height. working with such a chainsaw turns from pleasure into torment.

Characteristic signs of the need for chain sharpening are:

- decreased productivity;

- increased noise and vibration when cutting;

- frequent kickbacks when driving the saw into an existing cut;

- formation of fine shavings in comparison with ordinary shavings;

- the smell of a smoldering tree.

When these signs appear, stop work and sharpen the chain. This can be done in two ways.

The manual method of sharpening does not require complete removal of the chain from the bar. it is enough to loosen it. A special mandrel is installed on the link to be sharpened, which sets the sharpening angles of the working surfaces of the teeth. With the help of a round and flat file moving along the guides, the tooth is sharpened. Next, the mandrel is loosened and rearranged to the next link, repeating the operation.

Attention: sharpening can only be carried out with a suspended engine. If a saw with an electric drive is used, it must be unplugged from the mains.

The accuracy of sharpening in this way strongly depends on the qualifications and accumulated experience of the employee. Its advantage lies in the low cost of the sharpening set and the possibility of dressing the teeth right at the workplace.

The second method requires expensive equipment, comparable in cost to the chainsaw itself. Such a machine will pay off if you have to sharpen a large number of chains every day. The undoubted advantages of the method are

How to Measure a Chainsaw Chain

- high productivity of mechanized or automated installations;

- stability of sharpening angles from link to link;

- the ability to set the sharpening height according to the most sharpened tooth.

The latter feature allows you to automatically align the height of the teeth. This significantly increases the life of the chain, since the load is evenly distributed among all the links.

Another way to save both time and money is to send the chain to a service center for sharpening. It is convenient if there is a spare chain.

Shank parameters

Another important parameter for choosing a chain is the thickness of the tail. The most commonly used thicknesses are from 1.1 to 2.6 mm.

Thin chains and matching bars are popular in low-power household chainsaws. They provide good cutting accuracy and surface quality. For many short grain woods, the surface does not even need a finishing.

powerful machines are designed for shanks of 1.3-2 mm. They provide a reasonable balance between performance and accuracy. Such tools usually have a large resource.

The 2.6 mm width is already more common in professional models with a high cutting speed. Chainsaws used for felling and cutting trunks in felling areas have a width of up to 4 mm.

Length

The length is indicated in inches or the number of links. Knowing the step, you can calculate the first parameter from the second. Both characteristics are usually indicated on packages from leading manufacturers.

The length of the chain must strictly correspond to the overhang of the headset. Some craftsmen manage to pick up the length by throwing out several links. This practice is highly discouraged by experts. in a home workshop, it is difficult to achieve factory quality of fastening the rollers. Such a homemade product can break at any time, leading to the scattering of parts, damage to equipment and even injuries of people working nearby.

Cross and rip chain models

Most models are available for conventional cross-cutting of wood. The cutting direction is determined by the angle of sharpening of the cutting surface of the tooth. The cross chains come from the factory with an angle of 25-25 °. Such teeth will be best cut across the fibers, but they may well perform several longitudinal cuts, for example, when forming an angular attachment of crowns or sawing grooves for rafters.

How to choose a chain for a chainsaw

For more than 100 years, the chainsaw and its electrically powered counterpart have served builders and lumberjacks, woodwork manufacturers and sculptors. The efficiency of the device is determined not only by the engine power. It is equally important to choose the right saw chain, based on the characteristics of the upcoming operations. The chain must match the length and width of the chainsaw bar, match the drive sprocket, match the material being cut and the direction of cut. The chain must be selected according to a number of parameters indicated on its marking. Correct selection, sharpening, timely care of the main working body of the chainsaw will allow you to operate it for a long time and with the expected performance.

Design features

In wide and heavy chains of high quality professional equipment, each link has a pair of shanks. This provides reliable contact with the tire and sprockets and enables the tool to withstand heavy lateral loads. In a conventional chain, the proportion of cutting links is half.

To lighten household-class tools, they produce lightweight inexpensive models:

- checkpoints. a supporting link with a shank is installed immediately behind the cutting one, their share is reduced to 40%;

- semi-through: the support is inserted after every second cutting, their share is 35%.

A decrease in the number of active links leads to a proportional increase in the load on the rest. This inevitably leads to a reduction in their service life and an increase in the frequency of sharpening.

You can pick up such chains if you do not want to spend extra money, with a small amount of work and their episodic nature.

Chainsaw chain wear signs

Normal wear and tear on the cutting links of the chain is not the only reason to change the chain.

- Damage to the circuit elements, they say that such a headset can no longer be used. They are found by visual inspection.

- Deformation of rivets and connecting links, the appearance of cracks occurs due to the strong tension of the chain and leads to its weakening and the need to replace.

These signs indicate that the saw head is worn out and should be replaced. In this case, it is strictly forbidden to work with a faulty circuit. Since it can suddenly break off and severely injure.

How to know when it’s time to change your chainsaw chain

You have become the happy owner of such a wonderful tool as a chainsaw, and now you can saw anything at all. But the moment comes when you begin to notice that the instrument is somehow not working well. Cutting requires more effort and time, and its quality is questionable. This is the first sign that your chainsaw chain needs attention.

over, if you have never sharpened the chain, then this is the very moment when the time has come to master this wisdom. To do this, you need to acquire a special tool. On average, a new chain undergoes 3-4 such procedures, after which it must be accurately changed.

To properly sharpen the saw head, you need to have some skills. At the same time, there is an opinion that the profitability of these efforts is very insignificant. Since the resource of the sharpened chain is small, and the process itself is laborious and takes time.

What you need to know when choosing a chain

If you have determined that it is time to change the saw headset, you need to decide how to choose it correctly. The easiest way to do this is by referring to the operation manual, where there are recommendations in this regard. Fdfmoto has a large selection of chainsaw chains from various brands.

Another way is that you can pick up the same markings on the old chain.

In order not to make a mistake when buying, you need to know the following data:

All chains are sized based on the pitch, which is measured in inches. There are sizes 0.325. for household saws, 3/8 or 0.375. for semi-professional and professional, and 0.404. for professional tool.

Drive link thickness. This dimension is determined by the width of the chain groove in the tool bar. Their difference also depends on the class of the chainsaw, the more professional the tool, the higher this figure.

This knowledge is enough to navigate the offered assortment that the market offers.

Negative consequences of incorrect chain adjustment

Checking the condition and tension of the chain is included in the mandatory list of preparatory work.

How much it is possible to put the chain correctly depends on:

- the duration of its subsequent operation;

- safety of cutting operations of increased complexity;

- resource of the engine and chainsaw as a whole.

A dragged headset dramatically reduces work performance, initiates excessive loads on the power unit and transmission. There is also tire overheating and excessive fuel consumption.

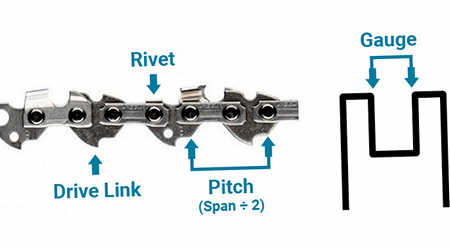

Technical Tips- Identifying Chain Pitch and Chain Gauge

A loose chain can fly off the bar or break. The formation of traumatic moments is partially or completely eliminated by emergency stop systems and catchers, which, with more or less success, unravel the chainsaw chain and determine its suitability for subsequent operation.

Installing a part with damaged or deformed links can lead to uneven wear of the guide groove of the tire and other undesirable consequences.

Loose tire

When the chain tension is reduced, the problem is often accompanied by a weakening of the tire itself. To check its condition, you need to inspect the place between the top plate on the headset casing and the inner surface on the case. When the fixing bolts are loosened, the bar begins to move, which can be seen by the characteristic vibration during sawing. For frequent use, it is recommended to tighten the screws regularly.

Figure 1. Loose tire

If you decide to tighten the tire yourself, then you need to find and lower the chain brake. Turn the tensioning screw until the chain fits snugly into the grooves. After that, pull back the chain in the direction of travel, if it is too tight, loosen the screw.

Important! Tire loosening is observed in both professional and household chainsaw models. If the tool is used intensively, check the tension before each start.

Step-by-step installation algorithm

Not all modern chainsaws are equipped with a setting wheel, which greatly simplifies the procedure for installing the saw blade. Systems with a setting wheel are generally a rarity among household chainsaws. Therefore, it is very important to know the technology and sequence of installing the chain on the chainsaw.

Key points to look out for:

- Prepare a level surface on which you will assemble the chain and bar. This will minimize the chance of damage to the chainsaw or loss of small parts. A tire is laid out on the prepared surface and a parallel chain next to it.

- Remove the sprocket protection, on modern chainsaws it is enough to unscrew the wing nut, on older models, you may need a spanner wrench of the appropriate size.

- At the base of the guide bar, turn the sprocket all the way to the right. Only in this position is the chain installed.

- Then the chain is sequentially placed, link by link, on the fixing groove on the guide rail. Install the chain from the top of the guide, gradually turn it so that the bar is always on top and the chain is on the bottom, this will allow it to always be taut and fit into the guide groove without problems. When doing this step, be sure to wear thick protective gloves, because your fingers will touch the cutting edge. Viewed from above, the cutter is always forward towards the end of the guide bar.

- Put both the tire and the chain on the drive sprocket.

- Secure the chain sprocket cover in place. Make sure all mounting pins line up with the holes. Incorrect installation with distortions or not completely can cause extraneous noise, rattling.

- Make sure that the guides “go” into the special mounting chute.

- After installation, check the fixation of the chain on the chainsaw and on the bar. Everything must be securely fastened without backlash.

An important point is the degree of tension on the chain after installation. Setting the correct tension is easy and takes less than three minutes. First you need to loosen the nuts on the protective cover. Using the freely rotating adjusting screw, catch the correct tension so that the chain does not pull more than 3-5 mm from the edge of the guide bar.

It remains only to tighten the nuts and check the tension. If correction is needed, adjust the tension again.

What is important to know: when the chain is in operation, due to the frictional forces, its metal heats up and expands, and the length increases. Therefore, it is important to regularly check the tension and correct it in time.

How to install the bar and chain on the chainsaw, see the following video, which presents a clear algorithm of actions:

How to untangle a chainsaw chain

When removing an old chain or putting a new chain on the guide bar of the chainsaw, it can become tangled. It can also happen with careless transportation. When the chain is tangled, it folds into rings.

Due to the lack of flexibility in the transverse direction, it is very difficult to untangle it with bare hands, because when you try to untangle one ring in another place, a new ring is formed.

It is necessary to put the chainsaw chain on a horizontal surface and spin the rings in different directions, while pulling the blade in such a direction that the diameter of the rings increases. Sooner or later the chain will unravel into its natural position.

There is another way. you can rivet one link of the chain and straighten it, then connect it into a ring and rivet the riveted links back.

Why did the chain fly off?

There are several reasons why the chain can fly off during operation. This may be due to improper tire operation or insufficient tire tension. The problem sometimes appears even with an insufficiently secured drive and driven sprocket. Determining the cause allows you to accurately select the required repair, tools.

Chain tension

The chain of the chainsaw together with the guide bar is subjected to the greatest stress during operation, unlike other parts of the chainsaw. Over time, it lengthens in size due to boring gaps in the connecting links. This process occurs with absolutely any type of chain, therefore, when using a chainsaw, it is necessary to periodically monitor the correct tension of the chain and its wear.

- the length of her life;

- safety of felling or timber breaking;

- internal combustion engine resource.

If the chain is overtightened, the efficiency of the sawing work decreases, and the motor and transmission are subjected to increased loads. The guide bar heats up a lot due to increased friction, the operating mode of the chainsaw goes into excessive consumption of the fuel mixture.

How to install a bar with a chain on a chainsaw?

Often, problems in the operation of a chainsaw arise when the tire is incorrectly installed. This can be determined by the characteristic rattling, vibration and low performance of the saw during operation. The tire is fastened to the body between the outer plate, fixing is carried out with a special bolt.

Popularly referred to as the “engine assembly”, this part consists of a drive sprocket and locking bolts. It is not difficult to install the tire together with the saw. you need to remove all protective covers, unscrew the fixing bolts by a third of the length and put the headset. Then tighten all the nuts tightly, turn the tensioner with a special lever.

How to tension: installing the chainsaw cutting element

We have analyzed the main reasons for the sagging chain. How to install a chain on a chainsaw is described in the paragraph above. Now you need to correctly tighten the chain, and check if it will overtighten.

Chainsaw device features

The main part of a gasoline saw is the engine. In most modern devices, the engine is single-cylinder. Air cooling, two-stroke piston system. Oil in these types of engines is added directly to gasoline, and all due to the fact that the fuel is constantly flushing the crankcase. The oil-to-gasoline ratio varies from 1:20 to 1:50 depending on the manufacturer of the chainsaw.

The air filter on gasoline saws plays an equally important role. It needs regular cleaning. If the filter is heavily contaminated, dust from it will fall directly into the piston system, which will lead to engine damage.

If the filter is clogged, the saw loses speed and the engine starts to overheat, which can lead to burning of the piston rings.

The starter on gasoline saws is a rope with a handle that you pull on to activate the motor. When you pull on the rope, the teeth catch the ratchet, the flywheel starts to spin.

Many people complain that they have to pull the rope for a long time to ignite the engine. It depends on whether the carburetor is correctly aligned. If the carburetor produces the correct oil-gasoline mixture, then there should be no problems.

The main working mechanism is a tire with a chain.

The chain consists of three types of teeth: leading, cutting and connecting. They are riveted together. Cutting teeth are located on two sides: right and left.

Chains are divided into two types: high profile and low profile. The first type includes chains, in which the teeth are located with a large gap, the second. with a smaller gap. Chains can also vary in shank thickness and link length. The chainsaw chain is attached to a bar that guides it in the correct direction. The end of the tire has a specific groove that holds the links and allows the chain to rotate. A driven sprocket is located at the front of the tire. The chain together with the bar is called a headset, since they are detachable parts of the chainsaw.

The gasoline saw has an automatic chain lubrication system. The tire supplies oil, which is then absorbed by the sawdust. If the saw is idling, the oil supply stops.

Poor drive sprocket

One potential chain slack on your device is a drive sprocket issue. Most often, everything happens due to the fact that the star is poorly fixed. Now we will tell you how to properly fasten the star and then put the chain on the chainsaw.

First you need to remove the protective cover of the engine. Next, remove the protective cover of the spark plug, pull out the air filter. Then you need to unscrew the candle with a special key. A special stopper is placed in its place, which fixes the piston in a certain position. With a special wrench (you can use a universal wrench for an angle grinder), turn the clutch disc clockwise until the piston reaches its highest position. If you look into the hole of the plug, the piston should remain at the bottom. A thick rope can be used as a stopper; it is better to fold it several times. Once locked, you can clamp the drive sprocket by rotating the clutch disc counterclockwise.

After clamping, you need to do everything in the reverse order, that is, assemble the chainsaw. A chain is put on the tire, it must hit the drive sprocket that holds it. The tire is placed in special mounting holes and bolted. Then the defense is put.

The chain is stretched

If your chain sags on a chainsaw, then this indicates a malfunction of some mechanism, one of the options is the wear of the chain itself.

Over time, the metal deforms and the chains become 0.5-1 cm longer. It is best to fix this problem by purchasing a new circuit, but there is a way to get the old one back to work. Experts say that it is very difficult and almost impossible, but we will tell you how it can be done at home.

For this we need:

- vice;

- file;

- electric welding machine (not needed in all cases);

- a hammer;

- pliers;

- beard.

A regular chainsaw chain is made of strong steel, so it is difficult to disconnect. You need to disconnect the chain on the inside of the rivet, which serves as a connecting mechanism.

To begin with, the chains need to be fixed in a vice, and then gradually grind off the protruding part. You need to grind with a file or file. It is not recommended to use an angle grinder, as there is a risk of damaging the lateral parts of the links. After sewing, the rivets are knocked out with a beard. A knocked-out rivet should not be thrown away. You may not be able to find a replacement for it. Manufacturers of gasoline saws do not produce individual parts for the chain, as they do not assume that consumers will be able to repair the chain themselves. Most likely, you will not be able to make a new rivet yourself, so you will have to install the old one.

In order to shorten the chain, you need to split it in two places. But remember that the number and spacing of the guide lugs on the inner side of the chain must match the drive sprocket.

After removing one or more of the links (depending on the degree of chain stretch), the chains can be connected. We connect to old rivets, while pressing them tightly on the sides.

Next, we need a welding machine. The rivet must be welded to the lateral parts of the link. After that, we grind off the excess that was formed during welding with a file. The chain can be considered serviceable again.

Installing the chain on a chainsaw, how to properly tension and check the tension

If you have a chainsaw at home, then you should know that it requires special care. It is necessary to periodically clean and sharpen the chains, clean the air filter, oil supply and tires. And, of course, you need to monitor the chain tension, since with a poor tension there is a risk not only to harm the saw, but also to your health if the chain flies off at high speeds.

How-To Properly Adjust The Chain Tension On Your Chainsaw. Video

Tension check

To check the chain tension, the saw brake must be disengaged. Then manually run the chain along the bus, if it runs smoothly and does not sag, then everything is fine. If the chain walks very tightly, then it needs to be slightly loosened, because there is a risk of rupture during work.

Why the chain flies, we find out the reasons

If you are wondering why the chain on your chainsaw flies, then there is some kind of malfunction in the mechanism. There are three main reasons for this problem: bar malfunction, chain stretch, and loose sprocket. Let’s take a closer look at each of the possible causes of breakdown.

Chain tension

There are two ways to stretch the chain: fast and frontal. It is best to stretch in the frontal way.

If you carry out a frontal tension, then you need to unscrew the nuts that hold the tire and lift it over the edge. With a special bolt on the right, you need to tighten the chain until an acceptable tension is obtained, and then raise the tire even higher and clamp it.

If using the quick tightening method, first lift the wing nut handle and loosen it. Then tighten the chain tensioning screw clockwise as far as it will go. Then retighten the wing nut and lower the handle.