Carburetor operating instructions

Gasoline supplied to this device must not contain mechanical impurities.

All parts are processed exclusively with gasoline. Do not use a solvent, as the elasticity of the washer and rubber parts is damaged.

Use compressed air to dry the parts. Cleaning small holes with a wire or needle is not recommended. Installation after repair or cleaning must be carried out evenly so that there are no bends and deformation of parts.

The float chamber must be tightly connected to the body. Check the air filter connection before use. There should be no gasoline leaks.

Prepare the carburetor before starting the engine. To do this, you need to make sure that no gasoline leaks from it. To do this, simply open the fuel cock. Close the air damper and turn the control lever until it stops. Open the throttle valve 1/8. 1/4 of the maximum stroke.

At low air temperature (below 5 ° C), squeeze the drowner until fuel appears from the hole.

During starting, slightly open the choke, and after warming up the engine, open it completely.

How the tiller carburetor is adjusted

What to look for during a motor failure? If a carburetor malfunction occurs, the first step is to check the fullness of the fuel tank and the oil level. If there is enough fuel and oil, then proceed to inspect the spark plug. To do this, unscrew it and check the spark with the ignition. Next, the flow of gasoline to the carburetor is tested. For this purpose, remove the hose from the fitting and monitor the flow of fuel. If no fuel appears, then most likely the filter mesh will need to be cleaned. For this, the fuel cock is unscrewed and all parts are rinsed with gasoline. The same is done with the carburetor jet.

Carburetor cleaning is done as follows. To clean the device, you must first remove it. To easily remove the carburetor, you need to carefully inspect the body of the device and unscrew all the parts on which it rests.

So, remove the carburetor and pour gasoline out of it. We carefully separate all parts of the device (jet, float) for further purging and cleaning. This manipulation is performed with a special cleaner.

If it is heavily soiled, you can use a compressor.

After cleaning, we thoroughly dry all the parts and feel free to start assembling. After assembly, adjust the carburetor for the tiller.

We install the cleaned device using a standard gasket and fasten it with nuts. Don’t forget about the air filter, speed regulator and gasoline hose.

Tuning the tiller carburetor consists in adjusting it. In order to independently adjust the carburetor, you need to do the following steps:

- Screws at low and full throttle must be tightened all the way.

- Unscrew the low and full throttle screws one and a half turns (set the throttle valve in such a position that a gap of the appropriate size is formed between the base and the air duct).

- Start the engine and wait until it warms up.

- With the engine running, set the control lever to minimum speed.

- Achieve smooth engine operation. To do this, you need to make the minimum idle speed using the throttle screw.

- Set idle speed to maximum with idle screw.

- Set idle speed to minimum with throttle screw.

- Repeat steps 6 and 7 until the engine starts to run continuously.

- Set the engine control lever to gas.

- If an interruption occurs, unscrew the screw that regulates the quality of the mixture, no more than 2.5 turns.

I would like to note that the adjustment of the carburetor on the Neva Tiller is done clearly according to the above instructions. The K-45 device installed on the Neva tiller is single-chamber and horizontal. The float chamber is located in the central part. Throttle body. flat.

The Neva Tiller uses the DM-1K engine, which is produced at the Krasny Oktyabr Neva plant. The manufacturer categorically does not use Chinese-made engines. This also applies to the production of a motor-cultivator.

Features of adjustment for different brands

As noted earlier, the tiller carburetor is configured in the same way, regardless of the brand: Neva, Cascade, Agros (or Argo, as it has been called since 2012), Lifan and others.

If, after carrying out all the manipulations described above, the carburetor continues to work incorrectly, it will need to be removed and inspected. The assembly may need repair, cleaning or flushing of parts.

After adjustment, be sure to check the spark plugs for contamination: clean them from carbon deposits or replace them if they are faulty, adjust SZ.

How to adjust the tiller carburetor with your own hands: device diagram, K-45, video

The tiller carburetor must be adjusted periodically in order for the mechanism to work properly. The carburetor may be a possible cause of a fluctuation in the operation of the tiller engine. For this, the device is disassembled, cleaned and adjusted (tuned). Regardless of the brand of carburetor and the device on which it is installed, the principle of regulation is the same for everyone. The difference can only be in the number of revolutions.

The device and adjustment of the carburetor K-45

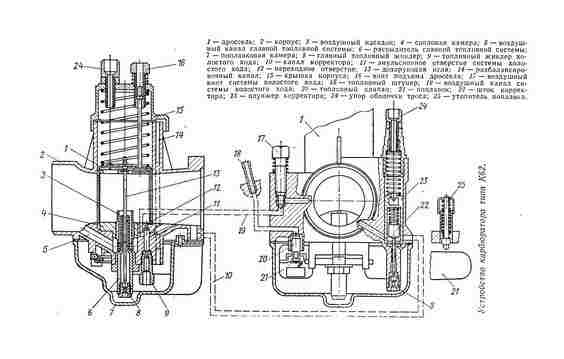

Tiller Neva of the MB-1 and MB-2 models is equipped with a DM-1K engine with a K-45 carburetor. There are also modifications of the model, such as K-45R, K-45U, K-45M.

For the correct configuration, we will briefly consider its device.

Carburetor. an engine unit that pours fuel, mixing it with air, and regulates its flow into the cylinders.

Consider the K-45 scheme. Here, the throttle lever 11 is located at the bottom of the damper, which regulates the amount of the mixture of gasoline and air. The regulator rod is attached to it. In the upper part of the throttle valve there is a stop screw 5. The main throttle lever 14 controls its position. In the closed position, it is held by a spring, and when the internal combustion engine is started, it opens to a certain angle. The degree of the angle is calculated so that there is no excessive enrichment in the fuel mixture of a cold tiller engine.

Adjustment of the K-45 allows the entire power system and the engine itself to work without interruption:

- prepare the carburetor for tuning and warm up the tiller motor;

- reduce the speed of rotation of the engine with screw 5;

- using screw 8 it is necessary to set the maximum idle speed of the engine;

- and finally change the rotation speed by turning the screw in the opposite direction 0.25 turns.

Repair of K-45: basic recommendations, video

In order to repair the carburetor with your own hands, we suggest that you familiarize yourself with the video of the repair of the tiller “Neva” MB-2.

Consider the main malfunctions of the K-45:

- If an excessive amount of air enters the internal combustion engine chamber. Try replacing the gasket between the head and the carburetor and tightening the fastening nuts on the joint tighter. If this does not help, the cause may be wear on the shaft on the damper or the hole where it is connected. Such a shaft must be replaced, and in the case of broken holes, the entire device is replaced.

- When too much fuel enters the float chamber. In this case, check and replace worn parts: float, jets, needle.

- If the carburetor is low on gas, check the filter and sump, fuel hoses, and gas tank. Contaminated elements must be rinsed or replaced, and if the inside of the tank is rusted, you will have to clean it with caustic soda.

- If there is an increase in fuel consumption, adjust the carburetor by referring to the operating instructions.

Replacing with another carburetor

In order for the tiller’s carburetor to work properly and without interruptions, it is necessary to constantly monitor the condition of the filters, adjust for the correct supply of fuel and air, and also use gasoline with an octane rating of at least 92. In case the breakdown of the K-45 could not be avoided :

- purchase an original node;

- dismantle the faulty mechanism, starting from the engine head;

- drain the remaining fuel from the faulty carburetor;

- clean the connection and replace the assembly.

Or contact the service for a replacement. If you want to put a different brand of carburetor on the unit, buy the necessary adapter.

How to handle the carburetor if the tiller has not been used for a long time

In this case, follow these steps:

- Separate the device from the engine.

- Remove dust using a soft brush and gasoline.

- Unscrew the float and the union.

- Flush the filter and all parts with clean fuel.

- Purge with compressed air.

- Check that all parts are dry.

- Assemble the device and install on the engine.

The carburetor does not require daily major cleaning or adjustment, but it is necessary to monitor its condition for flawless engine operation.

When a tiller motor malfunctions, the most common cause is contamination of the instrument. This is very often associated with the quality of gasoline.

The problem can be associated with both contamination of the carburetor and with the wire connecting the accelerator pedal to the carb. If, when the wire is disconnected while the engine is running, the speed indicators are normalized, then the wire will need to be changed.

What problems have you encountered in the operation of the tiller carburetor and have you managed to solve them yourself?

Tiller carburetor: adjustment, repair, maintenance

The carburetor is the element of the tiller that is necessary to control the flow of air and fuel.

Thus, the optimization of the motor operation is carried out at a stable load. Like any mechanism, the carburetor needs proper care.

Types and methods of carburetor adjustment

As you know, the tiller, like many other units of this type, is powered by an engine. Due to the fact that the engine cannot ignite without supplying oxygen, it becomes necessary to use a carburetor. Two types of carburetors are used for the tiller. One of them is rotary, the other is plunger. Naturally, each of the mentioned types has its own advantages and disadvantages, the choice depends on the tiller, his performance and the type of work performed.

There are times when there are abnormalities in the operation of the carburetor (the process is unstable). In such a situation, the carburetor needs adjustment. How do I adjust the carburetor on the tiller? It is quite possible to do it yourself, following a certain sequence of actions.

- First, you need to turn the screws (full and low throttle) until they stop. Then turn them one and a half turn.

- Turn on the engine, give it time to start and warm up.

- Do not shut off the engine and put the motor control lever in the lowest speed mode.

- Next, set the minimum number of revolutions when the device is running stably.

- Then run idle to maximum.

- Shift idle to minimum. Repeat this step, alternating with the previous one, until the engine runs smoothly.

- Move the control lever to the “throttle” position.

Following this instruction, you can independently adjust the tiller carburetor.

Carburetor care, replacement and repair

Sometimes, in order to bring the carburetor for a tiller into a stable, working condition, there is not enough adjustment, repair or replacement is necessary.

It so happens that the carburetor choke does not close completely. To eliminate this problem, you should check the operation of the drive. If jamming is found, remove it. over, given that the carburetor provides fuel and, therefore, drives the tiller itself, you should carefully monitor the condition of this part and properly care for it.

To avoid serious damage to the carburetor, you must constantly monitor its operation. In addition to adjusting the idle speed, you need to regularly clean the carburetor and replace worn parts. Since the carburetor interacts with the fuel mixture and air, the cause of its contamination can be either in the first or in the second source.

Tiller carburetor: device and adjustment

The carburetor for the tiller acts as a unit of the power supply system. Its task is to optimize the fuel to obtain the desired composition.

The carburetor requires constant load monitoring. For its proper operation, regular checks and proper operation are required. Much depends on the equipment of the unit and the quality of the fuel used.

Features of the tiller carburetor device

Tiller is a powerful mini power unit with additional equipment to perform various functions. It is often based on a gasoline engine, less often a diesel or electric one. A carburetor is used to ignite the fuel.

There are two main types of carburetors:

- Rotary. Differs in simplicity of structure, often found in engines of small sizes (12-15 cubic inches);

- Plunger. Multi-piece design is relevant for high power tillers.

Carburetion is performed using the following parts: piston, fuel tank, Venuri tube, fitting (acts as a connector), high and low speed needles.

The piston moves upward, creating a vacuum. The carburetor begins to absorb air that travels through the venturi. The created vacuum allows fuel to flow from the tank to the engine through the connecting fitting. The fuel then flows around the main needle and through the inlet into the venturi.

While pressing the throttle lever, the low speed needle opens access to gasoline, after which the fuel flow is controlled only by the main needle.

The demanded agricultural machinery “Neva”, “Agro”, “Ugra”, “Oka” is in demand due to its configuration. When it comes to the carburetor of the Tiller “Neva” K-45, it is a reliable device, distinguished by its quality and durability. KMB-5 is an older model of the carburetor in the Neva units. Before buying, it is worth clarifying this nuance in order to acquire a truly professional assistant. Powerful motors on MTZ (Belarus-09-N) and Neva MB-2 tillers are supported by reliable carburetors that can withstand heavy loads. On the “Kadvi” MB-1, “Cascade” technique and the “Pchelka” motor-cultivator, lightweight models of carburetors to optimize the functionality of the engine.

Tiller carburetor adjustment

A situation may arise in which the engine is unstable. In this case, it is necessary to adjust the carburetor on the tiller.

It is worth setting up in early spring (after a long downtime of the unit) or in late autumn (after heavy loads).

It is better to carry out all repair work in a free and well-lit space. To set up a carburetor with your own hands, it will take a minimum of time and effort. Procedure:

- the motor warms up for five minutes;

- the screws for the minimum and maximum gas are screwed in until they stop;

- adjust the screws by a maximum of 1.5 turns;

- set the gear lever to the minimum stroke;

- using the throttle control screw, achieve minimum rpm when the engine runs “without dips”;

- using the idle screw, adjust the idle speed to maximum until the engine runs continuously;

- the engine must be running during all operations. Only at the end it needs to be muted and turned on again for control.

If you check your actions with the instructions, you can avoid mistakes in the repair. After adjustment, the engine should run silently and without interruption.

Other malfunctions may occur. If the fuel does not enter the cylinder, you need to first check its amount in the gas tank. The next step is to check the flow of fuel to the carburetor. It is worth removing the hose from the inlet fitting. In most cases, cleaning the tiller carburetor will be required. the blockages are removed from the filter of the mechanical cleaner.

Tiller owners should familiarize themselves in detail with the specifics of the carburetor operation, as well as ways to eliminate breakdowns. The proposed video will help to deal with the problem that has arisen.

Tiller carburetor

The rated power and stable operation of a gasoline factory engine largely depend on the initial quality of the fuel filled into the tiller, namely, on the ratio of fuel and air in the internal combustion engine cylinder. The carburetor of the agricultural machine is responsible for enriching the fuel with intake air in the required proportion. Its good continuous operation guarantees high torque of the factory engine, its durability and low emission of exhaust gases.

Tillery brand Cascade

The complete set of most of the branded models produced by the Cascade brand includes carburetors of the KMB-5 brand.

To configure this fuel assembly, you must:

- Drain the remaining fuel from the factory float chamber;

- Open the union and let the air into the fuel unit;

- Adjust the position of the throttle flap in such a way that a neat 2 mm gap gradually forms between it and the air duct located under the flap;

- Tighten the bolts responsible for adjusting the fuel supply;

- Start slowly turning the screws one by one until the speed of the power unit decreases;

- Screw the screws back in slowly one by one.

As a result, the user will achieve the elimination of failures during engine operation and reduce the consumption of fuel consumed by him.

Tiller carburetor device

Knowledge of exactly how the carburetor works for a tiller. will help to independently eliminate any of its malfunctions, as well as to clean and timely adjust the standard fuel unit.

Structurally, the mechanism consists of:

- a float that is connected to a built-in needle locking steel valve;

- float metal chamber with chrome-plated internal cavities;

- an additional chamber required for mixing fuel with air;

- a fuel distribution structure equipped with a diffuser;

- adjustable throttle valve;

- fuel and standard air pipes made of technical rubber.

Depending on the manufacturer and purpose of the tillers, their carburetors can be equipped with additional elements. But regardless of this, fuel holsters work on the same principle.

One of the most important elements of the mechanism is the float, the main function of which is initially to adjust the amount of fuel required for the tiller to work properly. The fuel itself is in the float chamber, and as soon as its volume decreases, the float opens the built-in needle valve. Through it, the missing volume of the refueled fuel enters the chamber, after which the float rises and slowly closes the valve.

The carburetor on the tiller is equipped with an outlet channel, which is located in the float chamber. For normal operation of the fuel unit, the amount of fuel in the standard float chamber must be continuously kept at a level that is several millimeters below the location of the outlet channel.

The atomizer initially plays the role of a kind of fuel distributor, which falls from a chrome float into a steel mixing chamber. The latter is needed directly to enrich the fuel with air. Pre-cleaned air flows into it through the built-in inlet pipe.

tiller MTZ-09

It is necessary to adjust the carburetor of the Belarus brand tiller in the case when its engine does not pick up or does not maintain the required speed. It is necessary to adjust the fuel unit before the start of the season.

The procedure should be as follows:

- First, you will need to completely screw in the bolts that regulate the flow of low and full throttle. Immediately after this, the metal screws must be unscrewed 1.5 turns;

- Next, the power unit adjustment lever will need to be moved to the minimum nominal position. It is important to make sure that the motor does not stall;

- At the end, it remains to set the adjusting screw to the factory position, in which a sufficient amount of air will enter the fuel unit.

The standard idle adjustment screw is initially required by the operator to adjust and set the maximum generated engine speed while the engine is idling. Manipulation of this bolt allows the operator to set the built-in throttle valve directly to the position in which the gasoline power unit will operate as steadily as possible, consuming the amount of fuel specified by the manufacturer.

Tilleri Neva MB-1 and Neva MB-2

Most often, K-45 carburetors or their modifications are provided in the factory design of the MB-1 and MB-2 models of the Neva brand. The order of their setting will be the same.

For factory fuel units of the K-45R type, the adjustment should be performed as follows:

- First, you need to screw in the factory screws to the end, intended for self-adjusting the intensity of the maximum and minimum gas supply;

- Next, you need to unscrew each of these steel screws in turn;

- Next, the operator will need to start and completely warm up the power unit of the used tiller;

- After that, it will be necessary to correct the operation of a completely serviceable engine at the lowest possible idle speed;

- Repeat the previous 2 steps if necessary. This must be done until the action of the power unit at the lowest possible idle speed becomes as stable as possible;

- If, after several repetitions, the result is not achieved, then the screw for adjusting and setting full throttle will need to be unscrewed and screwed back. This procedure will need to be repeated until the motor resumes its work.

If numerous manipulations with the adjustment and full throttle screw did not bring the desired result, then you will need to remove and inspect the carburetor. If necessary, it must be repaired or thoroughly cleaned.

Tilleri Agro

To set up a standard fuel unit in the design of models of this brand, you need:

- Fully screw in the screws initially responsible for adjusting the engine operation in idle and full throttle. Immediately after that, each of the screws must be unscrewed 1.5 turns;

- Start the power unit and wait 10 minutes for it to fully warm up;

- Adjust the continuous operation of the built-in engine of the existing tiller directly at the minimum permissible idle speed. The operator must begin to turn the self-adjusting screw of the standard throttle position alternately in different directions directly until the operation of the internal combustion engine is as quiet and stable as possible;

- Adjust the amount of fuel and intake air that are supplied to the carburetor float chamber and engine cylinder. Tightening the screw gradually will enrich the fuel with intake air in the factory metal float chamber. Twisting it slowly, on the other hand, will increase the amount of air that is fed directly into the cylinder. details about setting up the carburetor Tiller Agro will tell you the video.

It is necessary to adjust the Tiller Agro carburetor when extraneous sounds from the engine side appear, as well as when the volume of fuel consumed and the generated exhaust gases increase. Timely adjustment of the unit with your own hands will improve the quality of the fuel, which will lead to an increase in the power and efficiency of the power unit.

tillery bee

The need to urgently adjust the built-in carburetor of the Pchelka branded tiller will be prompted by problems with starting its engine, as well as a significant increase in the volume of fuel consumed by it. Before starting to adjust the fuel unit, you need to remove and clean the air filter of the agricultural unit, inspect and, if necessary, blow out the fuel supply channels, and also clean the spark plug.

When carrying out your own tuning of the carburetor of an existing tiller, you need to:

- Screw in the screws for self-adjusting the low flow and adjusting the generated full gas to the very end

- Set the standard gearshift lever to the minimum permissible position;

- Set the minimum generated speed of a standard working engine, at which it will function stably and without any extraneous sounds;

- Adjust the generated maximum permissible operating speed of the built-in internal combustion engine in idle mode using the built-in idle adjustment screw. As a result, the power unit of the existing tiller should start working as stably as possible;

- Switch off the engine and start it again to check the tuning results.

After the actions taken, the motor of the agricultural unit must demonstrate stable operation in any of the modes. If this does not happen, then you will need to inspect the carburetor and, if necessary, replace its faulty parts.

“Neva” MB-1, MB-2

Tillers manufactured by ZAO Krasny Oktyabr are classic models developed in 1984. Farmers appreciate them for their unpretentious and high-torque engine, which is easy to maintain. A well-thought-out power system allows you to regulate the quality of the fuel mixture while the power unit is running. Progress:

It is not difficult to make an adapter for a tiller with your own hands, if you collect everything you need for work, understand well.

- Warm up the internal combustion engine at high speeds.

- Unscrew the idle speed control screw (XX) until the engine starts to stall or stops.

- Screw the regulator back slowly. The procedure is stopped when the revolutions are stabilized, and the sound of detonation of the fuel in the cylinder becomes clear and smooth.

- To prevent the adjusting screw from unscrewing spontaneously, a little oil paint drips onto the edge of the thread.

Selkhozaparat Ufa enterprise. UMPO is designed to perform agrotechnical work on a farm. The popularity of the brand among users is due to the high quality of components and their assembly. In addition, the powerful engine allows you to process a large area of land in a short time. Setting the carburetor tiller “Agro” (“Agros”):

- Drain fuel from the gas tank or close the fuel supply valve to the remote control receiving chamber.

- Unscrew the glass of the float chamber. The part is fixed from the end with one bolt.

- Remove the container, opening access to the float.

- According to the data given in the ICE operation manual, the position of the locking mechanism is adjusted. If the latter does not provide proper tightness, perform an audit with replacement of damaged parts.

- Assemble the knot in reverse order.

“Cascade”

Low-power agricultural machinery is produced by the Perm Motors OJSC concern, which produces transmissions and gearboxes for helicopters. The high requirements for aircraft production contribute to the high-quality assembly of the “Cascade” vehicles. The adjustment stroke of the carburetors on the tiller depends on the model of the power unit installed on it. The first representatives of the “Cascade” series were equipped with DM68 engines, which were produced by the Kaluga Machine-Building Plant. In the future, domestic motors began to be replaced by Chinese (“Lifan”) or Japanese (“Honda”) counterparts.

Tillers of the “Cascade” brand are mainly equipped with engines with a remote control of the KMB-5 brand. Regulation stroke:

- Shut off the fuel supply from the gas tank.

- Fold back the pipe from the air filter to access the throttle valve.

- The adjusting screw sets the gap between the wall of the fuel channel and the valve of about 2 mm.

- Collect everything in reverse order.

- The engine is started, the idle speed is adjusted with the tuning screw. The speed must be stable, but as low as possible.

Setting up the power system

The carburetor for the tiller is a mechanism, the accuracy of the adjustment of which determines the performance of the technique. “Floating” rpm, torque dips, starting difficulties are signs that the remote control needs to be adjusted. If the device has low idle speed, and it periodically stalls, it is necessary to slightly increase the crankshaft speed. To do this, turn the adjusting screw clockwise under the throttle actuator. If it is necessary to reduce the speed, the regulator, on the contrary, is unscrewed.

The carburetor is one of the most important parts of a lawn mower, the function of which is to prepare fuel.

fine tuning of the remote control implies its complete disassembly and the establishment of the required level of flammable liquid in the float chamber. At the same time, the revision of the moving mechanisms is carried out, the internal surfaces are cleaned from oily deposits. The gasoline level is controlled by the position of the float in the primary chamber. If during operation there is dark smoke from the exhaust pipe, and there are traces of unburned fuel on the spark plugs, these are signs that the fluid level is too high. By bending the spring mechanism of the needle valve, set the correct position of the float.

Carburetor adjustment

During the operation of gasoline agricultural machinery, it is periodically necessary to adjust all of its components. It is necessary to adjust or clean the carburetor in the chiller when the engine starts to malfunction or is unstable. In the equipment of different manufacturers, the remote control is adjusted individually. The sequence of the procedure, as well as methods of adjustment, depend on the model of the dispensing mechanism.

“MTZ-09”

Minsk Tractor Works produces several models for work in difficult conditions. However, all of them are based on the experience of production and operation of the very first design, accepted for manufacture in 1978. “MTZ-05”. The line of heavy equipment is represented by a lineup based on MTZ-09. Remote control adjustment:

- Warm up the engine to operating temperature.

- Screw in the low and maximum throttle screws completely. Then weaken them by 1.5-2 turns, rotating in the opposite direction.

- Transfer the accelerator lever to XX mode.

- Regulate the idle speed of the engine with the idle screw.

- The maximum crankshaft speed is set by the maximum power regulator.

- After obtaining a satisfactory result, tighten all screws.

Roto-Tiller project Pt. 3: Carb rebuild and part suppliers

Service

In order for agricultural machinery to work properly, it needs to be periodically audited. Maintenance of the fuel unit is reduced to cleaning the carburetor of the tiller, checking the contamination of the air filter and elements for fine cleaning of gasoline. Considering that the remote control provides fuel supply, and, therefore, drives the cultivator itself, you need to carefully monitor the state of this mechanism, properly care for it and carry out repairs in a timely manner.

Continuous monitoring of the remote control will prevent serious damage to sensitive components. In addition to adjusting the idle speed, they regularly clean both the outer surface and the inner cavities. During the audit, the condition of the moving parts and the calibration jets is checked. The former are subject to abrasion when interacting with each other, and the latter are clogged with dirt. If during disassembly deviations in geometric dimensions are found, the worn parts must be replaced.

The carburetor is an integral part of the chainsaw, the function of which is to mix the fuel mixture with.

Contamination of the nozzles occurs due to the ingress of foreign chemicals into the fuel system. Since the remote control interacts with gasoline and air, the cause of pollution can be in the first or in the second source. To reduce the intensity of sedimentation of dirt, additional filter elements are used, which are cleaned as they become dirty.

“Bee”

A lightweight cultivator with a weak motor is designed for simple agricultural work in the garden. Difficulty starting as well as reduced performance and increased fuel consumption are signs that fuel system adjustments need to be made. Before starting to set up the unit, you need to remove and clean the air filter of the agricultural unit, inspect and, if necessary, blow out the fuel supply channels, and clean the spark plug. Progress:

- Start, warm up the engine.

- Transfer the accelerator drive to the initial position.

- Gradually unscrew the idle speed adjustment screw. When there are interruptions or high vibration in the work, the part is turned in the opposite direction by 2 turns.

- Similarly, adjust the amount of fuel by rotating the gasoline feed screw.

- The device is muffled, then after a few minutes it is turned on again to make sure that the setting is correct.

Cleaning the carburetor

To adjust the level, the carburetor on the tiller is completely cleaned of dirt beforehand. Before starting work, drain the fuel from the gas tank. To do this, unscrew the drain plug or remove the supply hose. Gasoline is poured into a clean canister or plastic container. Before refilling, it is advisable to pass the flammable liquid through a filter. After emptying the fuel tank, dismantle the supply hose, dry it and blow it off with compressed air.

The remote control is attached directly to the cylinder head. To remove the dosing mechanism, dismantle the air filter with the supply pipe. Then the throttle actuator is disconnected, the fasteners are unscrewed, the carburetor is removed from the seat. Remote control cleaning:

- Dismantle the body of the filter-settling tank. At the bottom, unscrew the fixing bolt, take out the glass. Inside it, oily deposits are cleaned out, everything is thoroughly wiped and dried.

- A float chamber is made in the lower part of the body. In its center is the main fuel jet, which is unscrewed with a screwdriver. There is a small sleeve underneath, which is also removed. To remove the float with a closing needle, remove the support axle with pliers.

- The carburetor body (with previously removed plastic parts) and jets are placed in acetone or white spirit for a day. Polymer components are washed with clean gasoline, cleaned with a soft brush, then dried thoroughly.

- Soaked parts are cleaned of plaque with a rag, and the metering holes. with a thin needle or wire.

- The assembly is carried out in the reverse order.

Floating revs on a tiller

Tiller carburetor adjustment

The instability of the tiller engine speed indicates that the carburetor needs adjustment. The need to perform this procedure, as a rule, arises before the start of the growing season, when the equipment has not been used for a long time, or after it, when the tiller has been subjected to significant loads for a long period of time.

Before proceeding with the adjustment, it is necessary to warm up the engine. The work process itself looks like this:

- The screws regulating low and maximum throttle are screwed in completely, after which they are loosened by about one and a half turns.

- The engine starts and warms up for about 10 minutes.

- The lever that controls the operation of the power plant should be set to the minimum position, but the motor should not stop.

- The throttle throttle adjusting screw will help to adjust the minimum idle speed so that the engine is stable, without extraneous noise and stops.

- The rotation of the screws makes it possible to accurately set the amount of combustible mixture that enters the motor.

- Tightening the screw contributes to the enrichment of the mixture, while unscrewing it, on the contrary, increases the volume of air entering the engine;

Using the idle screw, adjust the maximum idle speed. Proceed in the same way with minimum speed, using the throttle stop screw. The essence of such an adjustment is that the shutter screw allows you to adjust the angle to which it is closed;

The lever responsible for controlling the engine should be moved to the “throttle” position. If the tiller still cannot be said to be stable, the full throttle screw is adjusted until ideal travel is observed. However, the maximum permissible propeller speed is 2.5.

The accuracy of carburetor adjustment can also be determined by how the spark plug looks after a short period of time under load. If the working mixture is ideal, then there will be neither carbon deposits nor traces of fuel on the spark plug, which indicate that the combustible mixture is too lean, or, conversely, too rich. However, it should be noted that carbon deposits or traces of fuel on the spark plug can indicate not only incorrect adjustment, but also more serious problems of the tiller, including faulty ignition or cooling system.

Tiller valve clearance adjustment

Over time, with significant loads, the valve clearance of the tiller engine changes. This may be due to wear on the parts. Insufficient distance leads to the fact that the stages of gas distribution change significantly, as a result of which it is not possible to achieve a sufficient compression ratio, the power plant works intermittently and does not reach the declared power. In particularly serious situations, even deformation of the valves can be observed. If the gap is too large, significant mechanical noises are recorded, the gas distribution phases also change significantly, the valves open for too short a time, due to which the cylinder does not fill up properly, the power drops, and malfunctions occur. Clearance adjustment is necessary as soon as the engine operation becomes incorrect or occurs with significant noise. Ideally, the engine being adjusted should be cooled down.

So, first you need to get to the flywheel. It is on this part that the value of the top dead center is marked. The flywheel is hidden under the cover, and therefore will have to be removed. Before removing the casing, the oil bath of the air filter is removed. It is possible to facilitate the task in the process of removing the casing if you fix all the latches with rubber bands. All bolted connections are unscrewed with a key, after which the cover can be removed without problems.

On the flywheel, you can see marks that indicate TDC, as well as values of 5, 10 and 20 degrees. The 20 degree mark indicates the injection of the combustible mixture. The flywheel should be brought under the top dead center, focusing on the appropriate division. The valve cover is unscrewed and removed.

In the process of adjustment, you need to use the following tools:

- Screwdriver;

- Box key for 10;

- Blade 0.1 mm thick.

According to the technical data sheet, the valve clearance of the tiller engine is from 0.1 to 0.15 millimeters, and therefore it can be adjusted very precisely with the help of a blade. However, you need to pay attention to the fact that some blades are 0.8 mm thick, which is unacceptable. The exact value can be found with a micrometer or from the information on the manufacturer’s website. The adjustment is done as follows:

- Screwdriver;

- We loosen the nut, insert the blade and begin to tighten;

- You should focus on the blade, carefully tightening the nut;

- The adjustment is carried out until the valve free travel is eliminated. It should fit snugly enough.

- In the reverse order, we assemble the casing, put the oil bath in place.

If all manipulations are carried out without errors, then the engine will run smoothly and without unnecessary noise.

Carburetor care, replacement and repair

Sometimes, in order to bring the carburetor for a tiller into a stable, working condition, there is not enough adjustment, repair or replacement is necessary.

It so happens that the carburetor choke does not close completely. To eliminate this problem, you should check the operation of the drive. If jamming is found, remove it. over, given that the carburetor provides fuel and, therefore, drives the tiller itself, you should carefully monitor the condition of this part and properly care for it.

To avoid serious damage to the carburetor, you must constantly monitor its operation. In addition to adjusting the idle speed, you need to regularly clean the carburetor and replace worn parts. Since the carburetor interacts with the fuel mixture and air, the cause of its contamination can be either in the first or in the second source.

Types and methods of carburetor adjustment

As you know, the tiller, like many other units of this type, is powered by an engine. Due to the fact that the engine cannot ignite without supplying oxygen, it becomes necessary to use a carburetor. Two types of carburetors are used for the tiller. One of them is rotary, the other is plunger. Naturally, each of the mentioned types has its own advantages and disadvantages, the choice depends on the tiller, his performance and the type of work performed.

There are times when there are abnormalities in the operation of the carburetor (the process is unstable). In such a situation, the carburetor needs adjustment. How do I adjust the carburetor on the tiller? It is quite possible to do it yourself, following a certain sequence of actions.

- First, you need to turn the screws (full and low throttle) until they stop. Then turn them one and a half turn.

- Turn on the engine, give it time to start and warm up.

- Do not shut off the engine and put the motor control lever in the lowest speed mode.

- Next, set the minimum number of revolutions when the device is running stably.

- Then run idle to maximum.

- Shift idle to minimum. Repeat this step, alternating with the previous one, until the engine runs smoothly.

- Move the control lever to the “throttle” position.

Following this instruction, you can independently adjust the tiller carburetor.

Floating revs on a tiller

Tiller fuel system adjustment

If the fuel is not supplied to the cylinder, then, first of all, it is necessary to check if there is enough fuel in the tank. You also need to check whether it goes to the carburetor. For this, a hose is removed from the inlet of the device. If we are talking about a K45 type carburetor, press on its quench so that fuel starts to pour out through the drain hole.

If fuel does not enter the carburetor, then you need to turn off the fuel supply valve, completely disassemble it and remove accumulations of dirt from the mechanical filter. To achieve maximum cleanliness, all components must be treated with gasoline. The fuel cock is assembled and returned to its original location.

If fuel enters the carburetor, but is not supplied to the cylinders, it is necessary to check the correct operation of the fuel valve, as well as the presence of dirt on the jets.

To deal with the carburetor of a gasoline tiller of the KMB-5 type, you need to remove it from the engine and pour out the fuel from the float chamber. Through the fitting (see figure), with the help of which the gasoline is supplied, it is necessary to supply the air mixture, having previously installed the carburetor in the operating position. The passage of air should go unhindered, and when the carburetor is turned over, it should completely stop. These features indicate the full performance of the part.

Details in the figure: 1. fuel supply connection; 2. upper body; 3. throttle valve; 4. idle needle; 5. jet; 6. lower body; 7. air damper; 8. screw fixing the tie; 9. maximum gas needle; 10. spraying element; 11. float; 12. fuel supply valve.

The fuel level inside the float chamber can be adjusted using the float tab. Ideally, it should range from 3 to 3.5 centimeters.

To purge the nozzles, it is necessary to unscrew the screws responsible for full and low gas.

Cleaning the carburetor parts begins by loosening the screws holding the upper housing. The lower body is removed, the fuel supply valve is flushed with gasoline, and the dirt from the nozzles is blown out by a pump. It is necessary to check if the float is intact. It is absolutely impossible to use rags in the cleaning process.

After completing the cleaning, the housings are connected. It is necessary to check that the spray tube is clearly inserted into the hole located on the upper body. Open the throttle valve and check how well the assembly is done. The screws that secure the upper case are tightly tightened. After the assembly process is completely completed, the carburetor should be adjusted. This will significantly improve the performance of the tiller with attachments, since for correct operation, perfect adjustment of all its parts is required.

If the carburetor DM 1.08.100 is installed on the tiller’s engine, then the method for adjusting it will be as follows:

- Screw in screw 10 (Fig. 3) at idle until it stops and unscrew it half a turn.

- Then you need to tighten the full throttle screw 9, unscrew it completely by 2 turns.

- Unscrew screw 4 (Fig. 4) of the minimum engine speed right up to the stop of the lever against the bore of the carburetor body and tighten it 2 turns.

- Start the tiller engine, then adjust stable operation at maximum speed after warming up with screw 9.

Do not allow the engine control lever to be turned off, move it to the minimum throttle (rpm) position and by unscrewing screw 10 set stable idle rpm.

That’s basically it. The main points of adjusting the main parts of the tiller are considered. Regulate your tiller with pleasure!