Repair circular saw with their own hands: how to disassemble the electric saw and diagnose

The circular saw is an indispensable tool for home construction and household chores. Even with proper care and attention to usage, a circular saw, like any machine, can fail. In order to repair the malfunction yourself, you need to know how the tool is built, and how to correctly diagnose the broken part.

Design of a circular electric saw

The circular saw is not fundamentally different from other electrical devices (household or construction tools).

The main difference between the saw and other tools is the presence of the saw blade, which receives the torque from the electric motor when the trigger is pressed.

Hand circular saw armature

The armature is the copper coil to conduct the current and the magnetic circuit in which the rotating shaft is mounted. On one side of the armature is the gear and on the other side is the collector with the blades. The magnetic wire is made up of insulated plates and grooves.

Rotor for circular saw

The rotor is a steel shaft on which is placed a core with a grooved, equidistant grooves, into which is placed the anchor winding.

Stator for circular saw

The stator is made of electrical steel, which has a high coefficient of magnetic permeability. This element is rigidly fixed in the body of the saw. It is shaped like a cylinder with grooves in which the stator windings are placed.

The electric motor for a circular saw

Most circular saws in wood are equipped with collector-type motors. It includes the above elements: armature, rotor, stator.

Circular saw shaft

The shaft is a metal rod that transmits the torque from the motor to the flange of the circular saw blade by means of bearings.

Teardown- Makita Circular Saw 5740NB

Interskol circular saw repair with your own hands

Repair of the tool begins with determining the cause of the failure. If you see smoke coming out of the tool while it is working, it indicates an engine failure. If the saw makes a noise or whistling noise, it is symptomatic of a mechanical problem.

It can happen that the tool simply does not turn on without any sign of a malfunction. In this case, first of all, you need to check the integrity of the wire that supplies electricity, and contact brushes. Since the brushes carry current to the moving elements, they are subject to abrasion and can wear down over time to the point where the saw does not work. It can happen that the contact between the brushes and the stator terminals is damaged or oxidized.

To repair the electric motor it is necessary to disassemble the tool. Do it one by one and remember the order in which you removed the parts. A wiring diagram for the electric chain saw can be prepared. This is necessary for proper reassembly at a later date. As a rule, motor failures are associated with problems of the manifold. To remove it is not so easy. This should be done in such a way as to protect the armature bearing. It is necessary to use a sharp tool. Insert it in the recess and gently tap it with a hammer until the shaft is released.

Then the armature must be removed and the soot removed. If it is very worn out, the part has to be completely replaced. After that, the contacts of the collector windings are cleaned, and if necessary, they are replaced.

To avoid damage to your tool, it is best to handle, transport and store it carefully. Most breakdowns are caused by a blunt saw blade or a lack of lubrication in the parts, which leads to overloading of all elements of the saw and failure of the equipment.

Main Malfunctions and Signs

Typical malfunctions of handheld circular saws include the following situations.

- The saw will not start. The power cord, power plug, start button, or electric brushes can be defective.

- The tool motor gets very hot. These symptoms may be caused by a short circuit (open circuit) in the armature or stator coils, or by the unit being operated too intensively.

- Unit gearbox is overheating. If the unit overheats due to bearing failure or lack of lubrication of the gears.

- Brushes are sparking. This is usually caused by excessive wear and tear.

- A burning ring can be seen around the motor manifold. If the unit exhibits a circular spark around the motor collector, the spark can be caused by a faulty armature winding or graphite dust clogging the space between the collector lamellae.

- The machine is not developing the required power. The power drop can be caused by voltage drop in the mains, malfunctioning motor windings, worn electric brushes, malfunctioning start button.

- A grinding or other noise is heard when the machine is running. These symptoms can be caused by broken gears or broken bearings.

- The engine hums, but the unit does not run. Check fuel filter Check fuel filter.

Troubleshooting on your own

If the engine cannot be started, take the following steps in sequence:

Locate air filter and spark plug.

- Check that there is gas in the tank.

- Change the fuel if it has been stored for over a month.

- Check the fuel filter. Disconnect the hose from the carburetor and watch the trickle. If gasoline is flowing freely, the fuel filter is not clogged. If flow rate is too low, clean the filler cap port or filter.

- Clean the air filter. The air filter can be removed for a test run.

- Check and clean the muffler for cinders.

- Check the function of the starting device. If necessary, repair the starter (replace the pulley, spring or rope).

- Disassemble and clean a clogged carburetor.

- Use a tester to test the high-voltage wire for a breakage.

- Measure the gap between the flywheel magnets and the ignition module (should be 0.2 mm).

- Unscrew the spark plug and examine it. Measure the gap between the electrodes with a dipstick (normally 0.5-0.6 mm). Determine the nature of the fault by the appearance of the electrodes. If the spark plug is dry, there is no working mixture coming in. The working part, flooded with gasoline, indicates a low-quality adjustment of the carburetor or the absence of spark. To check for spark, connect the high-voltage tip to the spark plug, place the skirt on the cylinder radiator, and pull the starter cord. If there is no discharge between the electrodes you need to replace the spark plug. Carbon deposits on electrodes indicate poor quality fuel mixture. Clean center and side electrodes with emery paper.

- No compression. The reason. failure of the piston group. Measure compression. First you need to unscrew the spark plug. Then put a pressure gauge in the cylinder bore and use the starter cord to move the piston. Cylinder pressure is used to judge the condition of the cylinder-piston group (CPG). It must be at least 8 atm. Low readings are caused by wear of the cylinder, piston, piston rings.

18V MAKITA SAW REPAIR DSS611Z TOOL RESTORATION

Troubleshooting Algorithm

The cause of saw failure or impaired performance can be:

- A clogged fuel tank cap intake;

- The carburetor air intake due to a broken gasket or loose threaded fasteners;

- Mechanical jamming of removable dust equipment and other minor defects.

Before disassembling, make sure you have an overhaul.

Most likely, you will not be able to reassemble a new chainsaw yourself after repairing it with original quality. Modern chainsaws are often designed with burner press fittings, which have minimal repairability.

Even a partial analysis of a chainsaw with a handy tool can lead to undesirable consequences. In most cases disassembly can be limited to removal of one unit or system.

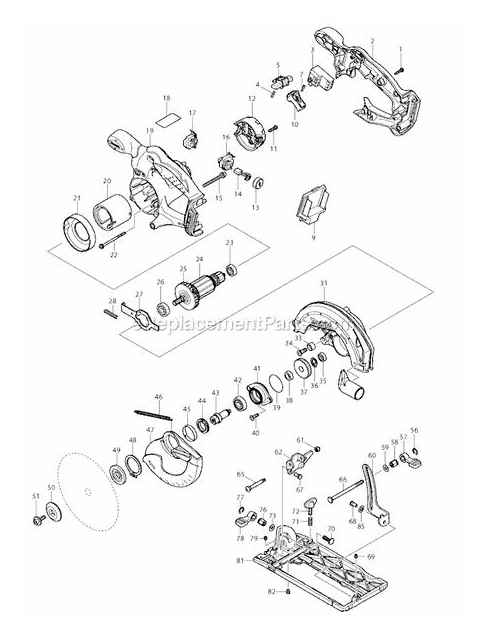

Design and operating principle of the circular saw

The circular saw differs from the sliding compound mitre saw in the lack of a frame with a turntable and in the placement of the handle. But in general, both models are similar in internal structure, operating principle and do not differ in design complexity. The following illustration shows the manual circular saw arrangement.

The main components of the machine are as follows.

- The upper protective cover, which has a hole for the emission of sawdust.

- The housing that houses the electric motor and the start button. Some electric saw models can be operated with rechargeable batteries. The housing also accommodates the battery pack.

- The lower (movable) guard, which automatically closes the cutting element after it leaves the workpiece.

- Saw blade. Mounted on the gearbox shaft with a nut or bolt.

- Parallel stop. Makes it possible to make a straight cut without any other tools.

- Base plate (sole plate) of the unit. It enables the tool to be positioned at different angles to the workpiece or guide bar.

- Depth regulator. With it, the outreach of the saw blade in relation to the base plate can be adjusted.

- Adjusting the angle of the base plate. Allows you to tilt the unit for cutting at an angle.

How this tool works is as follows. Voltage or battery power is supplied to the start button, which breaks the chain. Power is supplied to the electric motor by pressing the start button. The machine schematic diagram is shown below.

Electric motor starts and feeds rotary motion to saw blade through reduction gear. The unit is positioned with the base plate on the workpiece or guide rail and then makes longitudinal as well as crosscutting cuts.

Main problems and their causes

Circular saw is a very convenient and practical tool, which allows to implement a lot of ways of wood processing. With its help it is possible to cut planks along and across, without limitations on sizes and distances, to make laths, to remove in parts the excess material. Such a device is indispensable when working at height, in cramped and hard-to-reach places, where large-sized and stationary analogues are powerless.

Like any electrical appliances, these saws differ in quality and the permissible working intensity. Experts distinguish two main classes: industrial and household. Industrial circular saw is designed for use in conditions of prolonged intensive load, while the household saw is considered a low-quality tool, for which failure is commonplace.

Diagram of a circular saw tooth design.

It is the latter type of device that is most often encountered when working at home. Household saws are designed for occasional short-term use, but even this does not save them from frequent breakdowns. These power tools typically do not have power regulators, safety devices, or fuses. There is only a power button.

These tools are especially vulnerable to malfunctions and can break down at any time. The main reasons why this can happen:

- short circuit;

- Excessive strain on the motor;

- careless handling;

- high pressure;

- operation with a blunted circular saw blade;

- Not using the tool for its intended purpose.

Overview of the features of the 5704 RK circular saw

The circular saw “Makita 5704RK” will cost a little more. 7300 It is a professional tool that can be used for deep cuts. The equipment allows you to adjust the angle and depth of cut, which is guaranteed by the presence of a platform at the bottom. Smooth cutting results from the supplied parallel supports.

Sawdust is evacuated through a special outlet. The maximum diameter of the disk is 190 mm, while the minimum value is 170 mm. Such “Makita” wood circular saws are safe in use, after all they have a pendulum mechanism, which excludes the contact of the working disc with the workpiece, the contact is possible only during operation.

The upper part of the saw has an outlet for the vacuum cleaner hose, where the sawdust will be evacuated during work. Not to mention the versatility of the design. The operator can set the desired cutting angle with a scale with a slider. Operation of the equipment is very simple, because the design has a handle, which is made taking into account the laws of ergonomics, it allows the specialist to accurately guide the tool.

How to repair circular saws: how to do it and how not to let the machine go to this state?

The causes of failure can be very different. Manufacturers recommend that you first conduct a thorough inspection of the tool and try to visually determine the fault. If this has no effect, it is necessary to proceed with disassembly. The device of the circular saw is quite complex, the main task is to get to the manifold, because the main problems arise with it.

The collector needs to be removed, but this is not straightforward. This must be done in such a way as to protect the armature bearing and to separate the motor armature from this bearing accurately. For this purpose it is necessary to use a sharpened tool, which is inserted into a special recess in the middle of the shaft of the engine. Inserting it into the recess, hit the tool with a hammer until the shaft moves.

The armature is removed and cleaned of carbon deposits, and replaced if necessary. Next, the collector winding contacts are cleaned.

It is also necessary to check their inductance with an ohmmeter, and if any faults are found, the contacts are replaced. It is often the high friction between the jaw and the holder that causes the tool to jam.

If this is the cause of the damage, the jaws must be set absolutely perpendicular to the holders.

These faults are not difficult to fix and can be corrected by the user. It is, however, necessary to remember that it is strictly forbidden to open the tools under warranty, otherwise the warranty will be cancelled. That is why saws under warranty should be taken to specialised dealerships.

In many ways, the quality and reliability of a circular saw depends on knowing how to sharpen the blade. A badly sharpened circular saw blade increases the load on the tool and reduces its service life.

Warning signs of disc wear are: higher cutting forces, burnt cut edges, thick coating of the blade guard.

Sharpening of circular saws starts from the back surface right on the machine.

Before starting, mark the tooth where the sharpening will begin. When sharpening the first tooth, memorize the number of strokes, because the other teeth should be sharpened in exactly the same amount. If the disk will be removed from the machine, it is clamped in a vise with wooden planks.

As you sharpen the disk, rotate it. After the work is done, place the disk on the machine and make a test cut of the unwanted material. If there is a lot of noise and uneven feed, the teeth should be checked for height. If there are any protruding teeth, they should be filed down to the general level.

It should be noted that improper use of a circular saw greatly affects its service life and leads to the need for repairs soon. Even knowing how to sharpen a circular saw will not keep it safe if used improperly. Let’s consider how to use the circular saw, so that its repair had to be done as rarely as possible:

- It is necessary to use only those discs that are suitable for this model of saw;

- All discs should be sharp, as dull ones will cause the engine to overheat;

- You should always check that the blade is mounted correctly and that the clamp is tightened securely;

- Never allow the motor to overheat.

These simple rules are the best way to prevent damage to your power tool. Remember that adhering to the rules of operation is far less expensive than necessary repairs in the event of a circular saw breakdown. Important! When working with a circular saw, the safety rules must be carefully adhered to.

Armature and stator faults

These faults are the most common. During operation, a strong spark suddenly appears in the brush area. There may be smoke and a smell of burning. Such damage is sometimes very difficult to diagnose. Let’s start with the simplest and most expensive case.

Diagram for checking a circular saw’s functionality.

After opening the motor, you find traces of burning on both the rotor and the stator. Everything is clear here. Both need to be replaced. It is an expensive alternative, but it is not prone to error. Worse is the case when the stator is burnt and the armature is as good as new. At first sight it seems simple. you need to change the stator. Not necessarily. The rotor may also be faulty, but it is “open”. over, it could be the cause of a more serious breakdown. To determine if the stator is faulty in this case is quite simple.

- Disconnect the stator terminals from the brushes. Put the tester’s feeler gauge in its place, and it should show little resistance.

- Rotate the motor shaft slowly, if at any point the resistance increases, then the armature is defective.

And the last, the hardest case, when visually everything is fine. Even if you apply the method described above, it does not guarantee that the rotor is in good condition. But if it shows a breakage, you can try to change it. And in general, in such a case, it is better to contact a master. You can’t do without special equipment.

Very often a circular saw is bought with a specific purpose. A person does not even think about whether it is suitable for this purpose. The fact is that there are professional circular saws which are designed for long-term work, and there are those that can work for only 3 hours a day, and even then with interruptions.

Of course, if you work with such a saw all day long without interruption, it will definitely burn out. After all, no manufacturer makes any secret of the intended mode of operation of this particular saw. Nobody is usually interested in that. Besides, many people who bought the saw in a store and noticed that its disk has pobedite tips decide that it doesn’t need to be sharpened. The result. the smoke from the engine. Even such a disk blunts over time. The efficiency of the saw goes down drastically, but you expect the same performance from it as before. That’s why it doesn’t hold up.

Therefore, before you actively operate the circular saw, read the manual and consult with experts. The same applies to the work of chainsaws, other tools. Maybe after that the repair will not be needed. Good luck!