Can I drill with an electric screwdriver?

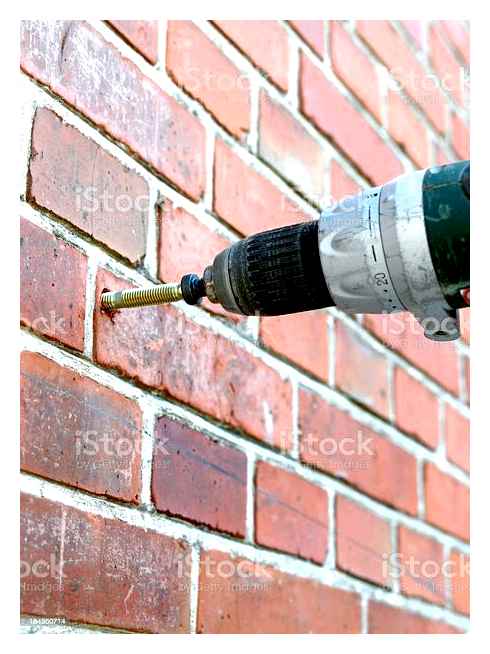

An electric screwdriver is not always a multi-tool. It often performs certain tasks. But sometimes we have to deal not only with wood and simple fasteners. There are brick, concrete and metal at work. In this article we will discuss whether or not a concrete or masonry wall can be drilled with an electric screwdriver.

| Location | Model | ||

| 1. | Metabo PowerMaxx BS 2014 Basic 2.0Ah x2 Case 34 Nm | Prices | Overview |

| 2. | Zubr ZSSh-300-2 300 W 35 N-m | Prices | Overview |

| 3. | Makita DF333DWYE4 Li-Ion 1.5 Ah 12 V x2 case 30 N-m | Prices | Overview |

| 4. | DeWALT DCD791D2 70 Nm | Prices | Overview |

| 5. | Interskol DSh-10/320E2 320 W 35 N-m | Prices | Overview |

| 6. | Bosch GSR 120-LI Li-Ion 2.0 Ah 12 V x2 case 30 N-m | Prices | Overview |

| 7. | Interskol DS-10/260E2 1012200000 260 W 25 N-m | Prices | Overview |

| 8. | Metabo PowerMaxx BS 2014 2.0Ah x2 bag 34 N-m | Prices | Overview |

| 9. | Makita DF333DWYE 30 N-m | Prices | Overview |

| 10. | Sturm! ID2145P 450W 45N-m | Prices | Review |

Choice of cutting tools

The names of its sides are written on the brick. it helps to navigate in masonry Source bel-dom-stroy.ru

Several types of bricks are used in construction today:

- Private is a ceramic product made from fired clay and is red in color.

- Silicate. made from quartz sand with small additions of lime.

- Hypercompressed. made from sifted dolomite, shell rock and/or marble.

In addition, bricks made of the same materials can be construction, facing and fire brick (chamotte is added). Be that as it may, in any case, it is a mineral product, in friction against which metal is very quickly abraded, as it is nothing but an abrasive. This means that the requirements to the cutting device are based primarily on this factor.

Choice of drills

Tool for making holes in various hard materials: concrete, brick, stone Source.ua

Pobedite drill bits are most commonly used to force a hole into a brick wall. This is necessary because steel (even tool steel) tends to wear down under intense friction against mineral abrasive formations (composite or natural). But that said, the word “victor” is not the correct name for the carbide that is used for the cutting part of the drill bit. it is a general term for alloys BK10, T15K6, etc.д., accepted in the USSR and remained to this day. In general, for pobedite use 90% WC (tungsten carbide) and 10% Co (cobalt) with small additions of C (carbon). for each grade, the percentage composition varies.

Continuing with the question of how to drill a brick wall, it should be noted that the process and tool requirements are virtually the same as drilling concrete, since in either case we are dealing with minerals. It means that the drill bit in an electric drill or peorator must rotate in percussion mode, that is, the hole is made more by frequent sharp blows, and the rotation works on the function of the mineral crumbs formed in the process. For the drill such drills are manufactured with a diameter of up to 10 mm, but for the peorator drill bit may have a shank (either corresponding to the diameter of the cutter, or narrowed) to be able to fasten it in the chuck.

Note: there are also diamond-coated drills for drilling without impact, but they are used very rarely.

Choice of core cutters

For the installation of undercuts or drilling holes for the installation of heating and plumbing pipes, the diameter of drills is not enough and for this purpose, core drill bits are used, as in the top photo. These cutters can be tipped with diamond or tungsten carbide inserts, which are also important factors. Since it is possible to make a hole in a brick wall, taking into account its further processing, for example, for the passage of a heating pipe, in most cases, use pobedite bits, which, when entering the mineral wall, leave not quite even and clearly outlined circle. Such a small detail does not matter at all if further facing of the surface is foreseen. Pobedite milling cutters vary in diameter from 35 mm to 120 mm. If the wall is too thick, an extension.

Segmented or solid diamond drill bit for concrete is used without impact Source metal-archive.ru

Diamond core cutter can be segmented or solid, and its diameter varies between 35 mm and 162 mm. This increase in capacity by 42 mm is explained by the fact that this cutter is used in a drill or peorator without impact torque, that is, it is used specifically for drilling bricks and the hole is formed solely by friction of the diamond segment on the mineral wall. These cutters are usually used for drilling decorative (facing) bricks. the hole is perfectly flat, without tearing circles.

Drilling Through Brickwork For Wires

Choosing a power tool

It is impossible to answer exactly how to drill a brick wall, because the diameter and depth of holes vary. Consequently, not only different cutting tools are used for this purpose, but also different power tools, which provide rotation.

Drills and torches

To make a hole in a brick wall, it is enough to use an electric impact drill, as in the top photo. Of course, it does not have to be exactly Makita, because it is the best brand in Europe and Asia, therefore, its cost is quite high, though quite justified (who worked with such a tool. he understands that). You can apply any domestic drill that has a percussion mode, but if you use a diamond drill bit or diamond drill bit, then the rotation mode is sufficient. But it should be mentioned that such a drill as Makita or, for example, Bosch, are designed for long-term operation not only with drills, but also with drill bits, and the gear retains its integrity for years.

High-tech tool that operates in modes: drilling / drilling with impact / impact without rotation Source 4people.com.ua

Do You Drill into the Brick or the Mortar?

The quality of the torch, just as in a drill, is determined by the manufacturer and in the photo above you see the leader among such machines, it is a Makita. First of all, such a tool is very convenient for drilling holes in a brick wall, as it is the lightest compared to competing models. Of course, a Makita may be of different power and thus have different dimensions, hence weight, but in any case such a peorator is the leader on the Eurasian continent. Drill bits for universal peorators have a shank with a diameter of 10 mm with a 40 mm plunge in the chuck.

For home use Makita is usually used up to 2 kg, but peoratori other manufacturers can reach up to 4 kg. in any case, for such tools is used SDS chuck for a drill up to 26 mm. Heavy professional peorators weighing 5 kg and more use an SDS max chuck. Such chuck is designed for drill or core cutter shank with the same diameter of 18 mm regardless of the diameter of the cutting part. Such shanks are lowered into the chuck by 90 mm and have 5 holding slots: 3 open guiding slots and 2 holding slots of closed type. With a high degree of probability we can say that the drilling in the brick with such a peorator in the home may be needed once or twice in a lifetime, so, heavy tools are more needed for professionals.

Diamond drilling technology is widely used in preparing holes and cavities for the installation of engineering systems, and communications Source myprofnastil.ru

How to drill a hole of any diameter in plaster

A drill and an electric screwdriver are the most popular tools for carrying out any repair and assembly work around the house. It is ideal to combine both tools in one. It saves not only space in the apartment, but also money and time for choosing the right model. Buy drills for an electric screwdriver and have a drill at your disposal without the extra cost.

- Drills for electric screwdriver

- Drill bit for quick-action chuck

- Electric screwdriver bits with hexagonal shank

- Electric screwdriver bits with hexagonal shank

- Installation of equipment

- Cutting a hole in a plasterboard wall or brick

- What tools are required?

- What is the difference between a wood screw and a metal screw??

- SCREWDRIVER APPEARANCE

- APPLICATION

- DIFFERENCES

- How to use the tool?

- DRILL AND HAMMER ICONS

- Screw with ripped edges

- Method No1. Screwing out

- Method no2. Sawing through

- Way #3. Extractors

- How to properly screw a self-tapping screw into concrete

- Rules of operation and maintenance of window hardware

Zubr ZSSh-300-2 300 W 35 N-m

max. idle speed. 1400 rpm;

additional modes of operation. drilling.

Drilling Technology

There are three ways to drill a hole in a brick wall: manual, electromechanical and automatic.

However, before you get to work, you need to study the location of the electrical wiring, because accidentally hitting the fishing line for the trimmer wiring will not only damage it, but can also electrocute a person. Most often the wiring is vertical or diagonal to the sockets and switches. In case of doubt it is worth using a special device to detect hidden wires. Portable metal detector will help to detect aluminum wire or copper wire, located no deeper than 1 cm.

Portable metal detector will help find hidden utilities

Automatic process

Using professional, expensive equipment, diamond drilling is done. In this case, it is desirable to have special skills and qualifications. With such a tool, the drilling process is fast, accurate, almost noiseless, can be performed at different angles to a depth of up to 40 cm, and an even hole is formed, without chips or cracks. This method does not create a lot of dust and dirt, since the tool is equipped with an attachment to cool the drill and wash off the dust.

How to drill without dust: options, what is better

Construction work is always accompanied by dust and debris, but using some recommendations and tips, it can be significantly reduced:

- The torch leaves a little dust when it is working, so that it does not fly around the room at the same time use a construction vacuum cleaner. Some brands of tools have a built-in vacuum cleaner, which facilitates the task;

- Using a drill, it is best to make either a conductor on the end or a pile, or make an envelope under the hole so that debris falls into it.

What to drill holes in a brick wall: the choice of tools and nozzles

To make a hole in a brick wall is suitable peorator with a drill or impact drill, often use the latter. Its power should not be less than 600 watts, the minimum number of revolutions from 2500 per minute. It is best to use a drill with stepless power control and a function of rapid clamping.

The drill becomes identical to a rotary hammer drill when using the impact function. Increases speed and ease of operation. To make a hole in a brick wall, you need to use a dynamic impact method. Without it, the drill can not catch on the inside of the brick.

What to drill a bearing wall in a panel house with a peorator

In most panel houses the walls are made of concrete, in order to make a hole you need to use pobedite drills.

Special core bits can also be used. They have tips on the circumference. When using them, the impact function of the rotary tool should be disabled.

Specialists use diamond drilling, it requires powerful equipment and skills.

How to drill with a hammer drill properly under a pipe

Using an impact drill for reinforced concrete, you must use the “peorator” mode and pobeditovye drills. At the beginning the hole is made with a smaller volume, then with a larger one. The drill bit should be periodically cooled.

Important! Working with concrete, it is necessary not to hit the armature, otherwise the drill will break. With a special device you can check where it is located.

How to make a hole in a concrete wall with a drill

It is difficult to drill a concrete wall with an ordinary drill. It is necessary to insert the pilot drill bit and choose the lower rotational speed. A dowel is inserted in the desired location to help the tool pierce the surface. Further drilling should be alternated with strikes on the dowel.

If the drill does not have adjustable speed, it will not be possible to make a hole.

How to make a hole in a concrete wall in the apartment with a drill

For a small hole, you can use a hole punch. For small holes, you can use a hole puncher. It is most convenient to use a drill with a diameter of 8 mm. Sharpen the tip sharply. The drill is put in the right place, turn it while hitting it with a hammer. Periodically moisten the drill bit so that it will last longer.

Rules of the job: tips

When working with tools, it is necessary to comply with safety rules and general recommendations:

- 1) protect your respiratory system when you do this, dust is hazardous.

- 2) If you work outside, you must put the fence at 2.5 meters.

- 3) When working at heights higher than 1.5 meters, use a strong base. scaffolding or trestle.

- 4) While working the tool it is necessary to switch on the speed slowly and do not switch off when it is in the wall body.

- 5) When drilling through plaster, the layout of the utilities must be carefully examined so as not to hit anything.

- 6) It is strictly forbidden to drill through decorative surfaces.

- 7) choose the right drill bits for each surface.

- Wet the drill bit with water so that it does not overheat.

Tips from the experts

In order for you to be able to drill a concrete wall correctly, it is necessary to have the necessary equipment, perform all work carefully and adhere to the following recommendations:

- Without a torch, work can be done with an impact drill or an electric screwdriver;

- Do not buy cheap drill bits, as their bit tip falls off very quickly and fails;

- Instead of a puncher, you can use a pobedite tool, one you will break the rubble, and the other, inserted into an ordinary electric drill, drill;

- For working with concrete, the drill should have an SDS-plus chuck;

- Take into account the location of fittings, to determine where it is, you can use a metal detector, if the armature is bare, it must be painted to prevent rusting;

- Universal diamond drills can be used to work with concrete, but they must only be inserted into a regular drill, or the impact mode must be disabled.