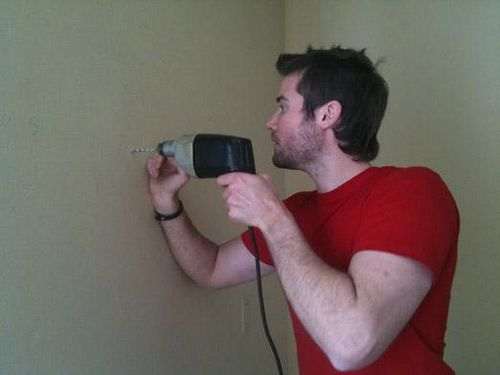

How to properly drill holes in concrete Drilling in concrete has its own characteristics and nuances, without knowing which it will be problematic to drill the correct hole.

Recommendations for drilling concrete at home

For drilling holes in concrete walls, drills with victorious tips are used. Holes with a diameter of up to 13 mm are drilled with a drill, and to obtain wider holes it is more advisable to use a hammer drill, since this tool, from the point of view of mechanics and design, is significantly superior to a drill with an impact function, as a result of which the speed of drilling concrete with a hammer drill is significantly higher. In addition, the drill chuck allows for quick drill changes, which shortens the work time. If the drill is not available and the hammer drill is not helpful, it is easier to drill concrete with an asymmetrically sharpened carbide drill.

However, they outline and begin to drill holes with a drill with a conventional sharpening. Of course, in the process of drilling concrete, dust is indispensable, so you can put a can with a hole made in it in the middle on the drill, as a result of which all the dust will collect in it. It is because of the dust that the depth of the hole for the plastic dowel is made 1 cm longer than its length. This allows the plug to be fully inserted into the hole. When drilling, due to strong friction, the drill heats up, and its cutting properties decrease, therefore, to facilitate work, the drill is periodically moistened with water or oil. While drilling holes in concrete, it is difficult to keep the drill horizontal. Therefore, it is easier to use a drill with an equipped level, and if the drill is without a level, then a small building level can be attached to the tool body with tape or electrical tape.

In the case when the existing drill does not allow to drill a through hole in the wall along the length, proceed as follows: a blind hole is drilled from the inside of the wall and a magnet is placed in it, and then, from the outside, using a compass, the exact location of the magnet is found and drilled in this place. If there is a reinforcement in the place of drilling, then it is drilled with a drill for metal, and then work continues with a carbide drill for concrete. Concrete is a heterogeneous material (cement, crushed stone, sand, steel reinforcement), of a certain grade, corresponding to GOST, and the drill can float on a hard pebble, which makes it difficult to get the right holes, which is why certain skills are needed. It should be remembered that before drilling concrete, check this place for the absence of communications.

How to drill a concrete wall a possible way out of the situation

Sooner or later, most people living in houses with concrete walls need to hang a cabinet, lamp, shelf or painting. At this point, the pressing question arises of how to drill a concrete wall. It is no secret that every home craftsman at least once in his life has encountered this problem, but not everyone knows how to solve it. Many courageously torture the drill and their own strength, but without achieving the desired result, throw everything until the next attempt to make a hole in the wall. But the drill eventually breaks, and the shelves remain standing somewhere in the corner of the room or gathering dust in the closet. But the options, nevertheless, are, they just need to be known and be able to use them.

What do the professionals advise?

Concrete structures are strong enough and difficult to drill. In addition, drills quite often come across crushed stone, which is part of the concrete mixture, from which wall and ceiling slabs are formed.

Holes in concrete have to be made quite often, especially in the process:

- Finishing works;

- Furniture installation;

- Air conditioner suspension;

- Additional electrical wiring device;

- Installation of plumbing.

There are two ways to solve the problem of holes in a concrete wall:

- An impact drill, or better with a perforator, with a victorious drill;

- Diamond drilling.

What will help a home craftsman?

In domestic conditions, when it is necessary to make 2-3 holes in concrete, you can do with an ordinary drill, without the impact function. To do this, it is necessary, as the victorious drill is immersed in the body of the wall, from time to time to break the concrete with a strong metal pin (punch) that matches the size of the hole diameter. It is used when the drill starts to get stuck in the wall. At this moment, a steel punch is inserted into the hole and they begin to hit it with a hammer or a sledgehammer, trying to crush too dense areas and punch the hole deeper. In this case, the pin is slightly turned. Then the hammerless drill can again come into operation.

All of the above steps are repeated one after another until the hole increases to the required depth. This method is quite laborious and tedious, but quite acceptable for a pair of holes.

Alternatively, when drilling a hole in concrete, you can use universal diamond-coated drills. They are highly effective when working with metal, gravel and concrete. They can be installed only on a conventional electric drill, or on a tool with the vibration function disabled.

Safety precautions for making holes in concrete

The structural frame of a building made of reinforced concrete is a durable heterogeneous material. Inside it is metal reinforcement, gravel or crushed stone of various fractions. Therefore, drilling a hole without complying with safety standards means exposing yourself and those around you to the risk of injury. Experts recommend compliance with the following requirements when drilling / drilling reinforced concrete structures:

- Use of protective clothing in combination with goggles / mask, petal respirator, helmet;

- Installation of fences: during through drilling, when the worker does not see the opposite side of the wall, there may be a risk of pieces collapsing on passers-by or his colleagues;

- The use of reliable scaffolding: without them, work at a height of more than one and a half meters is prohibited, since the stability of the operator is not ensured, when using ladders, it is necessary to strengthen them with stops.

To drill a hole in concrete, it is necessary to change the speed of the drill, hammer drill, special diamond machine smoothly, use only a two-handed tool. The presence of plaster dramatically increases the risk of destruction of internal communications. Therefore, before you drill a hole in the supporting structure of a building, you must make sure that they are not present.

Drilling with a hammer drill in percussion mode is allowed only when a drill or drill is used as a working body. If a crown is immersed in the concrete, a non-impact rotation is applied. The tool is able to drill a hole, qualitatively cut internal reinforcement, stones.

Unlike a conventional drill, which destroys crushed stone inclusions by impact, it is not able to drill through reinforcement. To drill a solid wall, you need to study the location of the seams. It is in them that the internal wiring of the power cable, gas, sewer pipes is often hidden.

DIY technology for making holes in concrete

In the process of construction, finishing of buildings, there is a need to manufacture blind or through holes of different diameters. Blind holes are created for fasteners, their diameter is limited to 2-16 mm. In this case, compliance with the declared diameter is an important factor. Otherwise, plastic dowels for self-tapping screws and nails in the broken holes will loosen over time, reducing the strength of fixing wall cabinets, curtains, pipelines, decorative elements.

For drilling blind holes of large diameter or through penetration of reinforced concrete walls, crowns are used to enter communications. They represent a cylinder, one side of which is attached with a shank to the chuck of a drill, perforator, the second has victory or diamond bits welded to it. A victory drill is installed in the middle of the structure to provide direction.

Drilling with a drill or drill leads to the destruction of the entire volume of concrete at the point of contact of the tool with the structural material. If there is reinforcement inside the reinforced concrete structure, it is impossible to pass it with a drill, the hole is moved to the side.

Drilling holes in concrete with a crown differs from the previous method:

- Concrete collapses only along the perimeter of the hole;

- A concrete cylinder remains inside the crown.

Therefore, after reaching the required depth of the blind hole, the inner concrete cylinder remains connected to the wall by the rear end. To remove it from the hole, destructive methods are used: a chisel with a hammer or a perforator. During through drilling, concrete cylinders are removed from the tool by light blows of a mallet on the body

Drilling holes in concrete is done with the following tools:

- Spiral impact drill is more often used for blind holes, the diameter of the carbide tip inserts is always larger than the spiral body of the tool, the shank is round, not intended for working in concrete with a hammer drill with SDS chucks;

- A spiral drill instead of a pobedit one uses a zirconium or tungsten tip (spraying), a shank with grooves is suitable only for SDS chucks (Max, modifications), dust-free, low-noise drilling is ensured;

- Diamond core bit large diameter tool exclusively for high speed rotary drilling.

Impact drill bits are marked with the caliber, not the diameter. This is the distance between the protruding edges of the solder / insert. Holes are drilled with this tool in the following modes:

- 800-1200 turns for diameters within 4 mm;

- 300-500 turns for diameters 5-13 mm.

Even the presence of a red marking on the tip of this instrument does not guarantee that the tip material will match the metal declared by the manufacturer. Cheap substandard at the first use adds up to an incomprehensible configuration, becomes unsuitable for work.

Zirconium, tungsten burs are suitable for the following operating modes:

- 60-100 revolutions with a diameter of 42-76 mm;

- 150-400 turns for diameters 4-60 mm.

The length of the drill can reach 1 m, a small amount of dust when working with this tool allows you not to take furniture out of the room. The destroyed concrete flows out of the hole in a trickle along spiral channels, collects on a lined film, paper.

Professionals make blind holes for large-diameter socket boxes in a few seconds. A home craftsman who does not have regular practice of working with such a tool most often runs the risk of damaging the crown at the slightest distortion. Operating modes when using crowns are 2,000-3,000 revolutions for any diameter. The advantage of the crown is the high-quality cutting of reinforcement of any diameter, granite, basalt crushed stone inside the concrete at high cutting speeds.

The following modifications belong to the category of professional, highly specialized instrument:

- Segmented tubular drill is difficult to work, it is used by specialists in areas with a high probability of the presence of thick reinforcement;

- A core drill with a centralizer is a carbide modification, inside which a drill is located in the center, which facilitates the setting of the direction, reduces the sensitivity to pressure, distortions of the working body; these options are not suitable for cutting reinforcement.

The latest modifications of the crowns are operated at 600-1200 revolutions; when in contact with the reinforcement, the teeth crumble instantly. Therefore, before drilling, the walls are carefully examined with a special tool for the presence of an armored belt.

Power tool selection

To create small-diameter holes in small quantities, a percussion drill, a perforator with a power of 350 W. Professionals engaged in the distribution of communications in panel houses, brick cottages on a concrete foundation, use professional punchers or diamond machines.

When passing through reinforcement, granite crushed stone, the clamping force will not be enough, the tool is guaranteed to start scrolling in the chuck, wearing out the shank and cams.

Therefore, for large holes, an SDS chuck with a diameter of 10-18 mm is required. Slotting when creating holes with a crown is completely excluded, the punch must have such a function.

Puncher

Drilling holes in concrete is done with a hammer drill or hammer drill, the tool allows you to drill channels up to 500 mm deep. The disadvantages of using the equipment are the increased noise during operation and the risk of wall destruction due to vibration loads.

Preparation for work

Before starting work, the drill is installed in the tool. The centralized electrical supply is cut off in the room. Extension cords are used to supply current, which are connected to the junction box. The operator wears goggles and a mask to protect the eyes and respiratory system from dust.

Surface preparation

The surface of the wall is marked, crosses are applied in the place of the intended holes with a soft pencil. Some users use a core that makes holes. If drilling is carried out in a residential area, then a plastic wrap is laid on the floor. The collected concrete chips are disposed of together with household waste.

Hole drilling features

Concrete is a dissimilar mass, which consists of cement and sand with rubble kneading into it. To increase the strength of the material, metal rods are added to it.

When drilling concrete, it is common for a carbide drill bit attached to an electric drill to hit metal or a stone. When the tool hits the stone, the drill must be pulled out of the hole, and the stone must be crushed using a hand punch with a hammer. Drilling can then be continued.

Before you can drill a hole in concrete, you need to choose the right tool. It depends on the:

- Varieties of concrete;

- Diameter of the required hole;

- Drilling depths.

To drill holes in concrete, the following devices and tools can be used:

- Electric drill or hammer drill;

- Crown;

- Boer;

- Drill;

- Punch.

A few practical tips

For various types of artificial stone such as concrete, there are recommendations for drilling holes in it.

- If a perforator is used as the main equipment for drilling concrete, it should be borne in mind that this is only suitable for concrete with increased density. For cellular structures such as aerated concrete, it is better to use an electric drill with the hammer function turned off. Otherwise, there is a risk of cracks in the material;

- In order to prevent the breakage of an expensive tool during the drilling of the material, it is necessary to strictly observe the basic rule; the longitudinal axis of the equipment must be strictly perpendicular to the concrete surface;

- When drilling holes, a punch is an indispensable tool. It is an elongated, high-hardness metal trihedron with a pointed end on one side and a handle on the other to help hold the tool in hand.

The need for a punch is as follows:

- When preparing the solution, a gravel or crushed stone aggregate is used. When drilling holes, the tool often rests against such fractions, slips, and does not move further. In this case, you should insert a punch into the channel made in the wall and beat it well with a hammer to crush the pebble, and then resume drilling.

- When applying significant efforts, which are necessary to split such an obstacle using the hammer effect, there is a great risk of ruining the tip of the tool or diamond dusting.

- The cost of the punch is significantly lower than the drill. And when it is dull, you can easily give the working part of the part its previous shape using an ordinary file.

Drilling holes in concrete from preparation to finishing

Quite often, it is necessary to make, during construction work and their completion, drilling holes in concrete. And doing it yourself is a convenient and useful skill. This will allow you to easily hang shelves on the wall, hang your favorite paintings, fix lamps and perform many other operations.

Drilling holes in concrete is not too difficult, but the correct selection of tools and adherence to several rules will save time and effort when performing work. This will be discussed in the article.