DIY drill

The best suited for this operation are small hand drills, the likeness of which you can make yourself. To do this, two laces and a handle are tied on top to a rigid axis, which can be a steel or wooden rod, and a sharpened nail from below. In the middle of the rod, you need to fix a heavy flywheel, which will act as an inertial battery. In order to put this drill into action, the laces are manually wound on the rod, and then, having set the nail in the right place, they press the handle. The rod rotates and the nail drills, the pressure on the handle is stopped when the laces are completely untwisted. The flywheel rotates by inertia and again winds them onto the rod, and then stops and you need to press the handle again. Viscous wood species may not succumb to such a drill, as the drill will get stuck and slow down the rotation..

- How to drill a hole in wood without a drill

- How to choose a drill

- How to drill granite

The easiest way to get these holes is to use an awl with a diameter of 1 to 3 mm. It is easy to make an awl from a thick needle or even from a trim of piano wire, the length of which is about 5 cm. The needle or wire is first driven into a piece of hardwood half the length, and a handle is subsequently made from this tree. The end of the wire remaining outside is sharpened on 3 or 4 edges. A well-made awl acts in this case like a drill, piercing the wood, it is rotated and it cuts and twists the wood fibers, and does not just push them apart..

How to drill without a drill

When renovating an apartment, fixing shelves, lamps, carpets, paintings and other objects on the wall is not an easy task, especially if the walls are made of reinforced concrete blocks or panels. The main difficulty in this is to punch a hole for a nail or screw..

Earlier, 20 years ago, various bolts and drills were used for this. It was a difficult and long process. Today, all this work can be done with special power tools. The depth of the hole depends on its purpose. A hole 5-7 cm deep is required for attaching heavy objects. For lighter objects – 5 cm.

But what if you need to make a hole, and the electricity has not yet been supplied? The old way is fine here. The hole can be punched with a special bolt. The technology is simple. Place the bolt at the point of the future hole and start hitting it with a hammer. After each blow, the bolt must be turned around its axis. During operation, the bolt must be periodically removed from the hole and cleaned. Long, but effective.

You can punch a hole with a metal dowel. With strong and sharp blows we hammer the dowel into the wall by 2-3 mm, then loosen it with pliers and remove it from the hole. We repeat these steps until a hole of up to 2 cm is obtained. It is difficult to make a deeper hole in this way. And one more way. This is when a hole is made with a drill inserted into a hand brace. In the absence of a brace, the drill can be used as a punch. In this case, you need to hit the drill sharply, but not too hard..

DIY screw drill

For the construction of a screw drill, a rotation mechanism from a children’s top is well suited. Instead of a cartridge, a compass pencil holder works well. When lowering the engine with the same thread by hand, the screw axis of the drill begins to rotate. With this mechanism of action, the drill head must necessarily rotate on the axis freely.

If the top is not at hand, the screw of this action can be bent by yourself. To do this, you need a strip of steel, one end of which must be fixed in a vice fixed on a machine or on a table, and the other end must be fixed in a manual vice. When the hand vise rotates, the strip will evenly twist into a screw, onto which a wooden slider with a pre-drilled hole is then mounted. In order for the engine not to have any difficulties when passing the helical surface of the strip, the strip is heated and, passing through it with the engine in this state, a thread is made on the strip. For making a hat, a small wooden ball is suitable, in which a hole is made in diameter slightly larger than the diameter of the screw.

HOW TO PRE DRILL WOOD without a drill bit

While traveling in Laos, I need to drill some holes in the wood of the double door in order to install the locker. The wood is pretty hard and I don’t have an electric drill (and I can’t find one).

I only have two small screwdrivers (- and), a small hammer, but I can find screws, nails and other basic tools. The wood is solid (so much that I can’t even get it to fit into the small screw), the screwdrivers are not very good quality and the screws are even worse.

Any recommendation for locking the door from the inside would be interesting if this is not possible.

Answers

Make a bow drill:

Take a piece of wood large enough to hold in your hand. Clean out a small hole in the woods. The non-pointed end of the drill fits into this hole. This is called “hand holding”.

You are going to use this wood block to push the drill towards the door.

Make a bow with sturdy wood and sturdy thread. Wrap the cord around the drill bit, maybe a couple of times to get a good grip on it..

Drill through the wood by pushing down on the handle and sliding the bow.

You can find more detailed instructions on how to make a fire ignition archery here:

http://www.wildwoodsurvival.com/survival/fire/bowdrill/pmoc/basicbowdrill.html

The traditional answer for drilling large holes would be a bracket and a bit.

How to properly drill metal

The first thing to start with is the selection of drills. They are distinguished by a sharp edge designed for easy penetration of the drill into the metal. Conventional metal drills are good for not too hard metals like copper or aluminum, but for something harder (for example, for stainless steel), you need to take products from titanium carbide or chrome vanadium alloy.

Separately, we should talk about optimal speeds. A common mistake of novice wizards is to use too many revolutions. In fact, medium speeds are used for hard metals: for example, a centimeter-thick brass will be optimally drilled at a speed of 2000-2500 revolutions.

There are a few more points to highlight. So:

- If a thin iron plate is to be drilled, it must be fastened between two pieces of wood. This is done so that the sheet of metal does not break off..

- Use lubricating oil from time to time to cool the drill and make drilling easier.

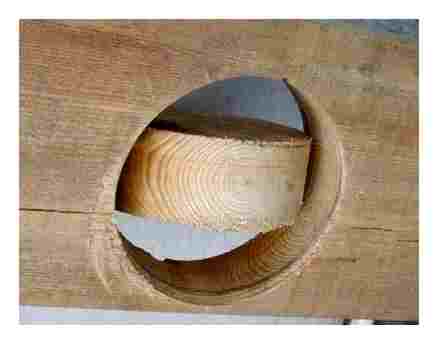

- If you want to make a hole in the pipe, then it must be securely fastened. To prevent the pipe from flattening under the influence of a drill, a piece of hard wood should be placed inside.

If you are guided by these simple rules, then even a beginner will be able to perform well drilling.

At what speed should you drill

One of the important parameters when drilling is the number of revolutions per minute. The speed at which you need to drill depends on the type of material and the type of drill. There is a general rule of thumb: the harder the material and the thicker the cascade, the lower the rpm should be. As for the specific numbers, they can be seen in the table below..

| drill diameter, mm | soft wood | solid wood | plastic (acrylic) | copper | aluminum | steel | Notes (edit) |

| 1.5-4.8 | 3000 | 3000 | 2500 | 3000 | 3000 | 3000 | When drilling metal thicker than 3 cm, lubricate the drill with oil. |

| 6.4-9.5 | 3000 | 1500 | 2000 | 120 | 2500 | 1000 | |

| 11.1-15.9 | 1500 | 750 | 1500 | 750 | 1500 | 600 | |

| 17.4-25.4 | 750 | 500 | – | 400 | 1000 | 350 |

This table is for conventional twist drills. For specific options (Frostner drill, etc.), the drilling speeds of various materials are slightly different from the above..

How To Drill Clean Holes In Wood | Two Minute Tuesday

How to carefully drill wood

Wood is one of the easiest materials to use with a drill. However, there are some subtleties here too..

- The drilling speed directly depends on the type of wood. Loose, not too hard types of wood will be within the power of even a low-power apparatus. Of course, the estimated hole diameter also plays a role – the larger it is, the more powerful a drill is needed..

- In order to make large holes, special drill bits must be used. Their diameter can exceed 120 mm. As for the depth, on average the crowns are suitable for materials with a thickness of up to 20-22 mm, but there are also special models that can cope with thicknesses of more than 60 mm..

- If you need to make a blind, and not a through hole, then Forstner drills, which are produced with a diameter of 1 to 5 cm, are perfect for this..

Separately, it is worth talking about drilling a bar. While it is convenient to hold it in place for further drilling, the thicker material poses a challenge. Drilling a bar for further fixing in the holes of the dowels. For a standard timber 18 cm thick, it would be best to take a drill with a diameter of 25 mm and a length of 36 cm. You will need to drill slowly at low speeds. In terms of power, a 1300-1500 W drill is perfect. If the bar is not very long, then two holes on each side are enough. If the length of the dowel bar is large enough, then it will be necessary to make an additional hole in the center. After the holes are made, dowels can be driven into them with a hammer or small sledgehammer..

General drilling principles

As already mentioned, drilling is the most common occupation for a repairman, and therefore it is important to immediately learn a few basic rules associated with this occupation..

- Using the right tools. There are a variety of drills, each designed for a specific type of material. Therefore, you should not try to drill concrete with a wood drill and vice versa. It is also important to consider the conditions in which the tool will be used. For example, industrial drills cannot be used for repairs indoors (this is simply unsafe). It is also important to take into account the resistance to moisture: for outdoor work, a tool of class IP34 will be needed if the climate in the area is humid and IP32 if you have to work in good weather. Indoors, you can use IPX2 /

- Competent markup. Before starting any work, it is important to accurately and accurately mark the drilling sites with a marker. You can still stick paper tape under the marker so that the drill does not slide over the material.

- Selection of the required drilling speed. Here everything depends equally on both the material and the diameter of the blade. If we are talking about very thin drills (with a diameter of less than 3 mm), then here it is necessary to work at low speeds, less than four hundred per minute. For the rest of the drills, there is the following rule: the thinner the drill, the faster the drilling speed is required..

In addition, it is important to ensure that the handle is securely attached to the shaft of the hand drill. The drill must also not be skewed..

Drilling cast iron – how to do it correctly

Cast iron is a fairly hard material, so drilling it is very, very difficult. In addition, cast iron products are fragile, so it is important not to crush them. Like other materials, cast iron has its own subtleties in matters of drilling..

- No rush. This is perhaps the most important rule when working with cast iron. Everything should be done slowly, with extreme care and attention..

- The drill must be of a very hard and durable alloy and must be perfectly sharpened. In order for the cast iron not to crumble, you need to take drills with an angle of 114-119 degrees.

- It is unacceptable for the drill to overheat. Sometimes they don’t pay attention to the fact that the tool has overheated. And this can lead to poor-quality work performance or even breakdown..

How to drill correctly and evenly

In the field of repair, the ability to drill correctly is one of the basic ones. In addition to the general rules, it is important to take into account all the nuances when working with a specific material: concrete, tiles, metal, etc. All issues related to drilling will be covered in this article..

How to work with tiles with a drill

Often, people who do not have rich experience in the field of repair are afraid to drill such a fragile material as tiles. However, this can become an urgent need, because you need to attach a variety of cabinets and shelves in the kitchen, bathroom or toilet to something. Alas, in many respects the state of the tile after drilling is determined not by the master who takes up the drill, but by the one who laid the tile. A competent tiler lays the tiles so that voids do not form between the tile and the wall. In this case, careful drilling will in no way harm the tile. If there are “air pockets” between the wall and the tile, then, most likely, the tile will crack.

In order to properly drill the tile, you need to take a drill, masking tape, perforator (or a powerful drill with concrete drills). Next, you will need to do the following:

- The drilling location is marked with a piece of masking tape and a marker. Scotch tape here so that the nail does not slide on the surface of the tile.

- Drilling is performed strictly perpendicular to the material. The number of revolutions should increase gradually: from the minimum possible to 150-200 revolutions per minute. This avoids damage to both the material and the tool..

- It is important to ensure that the drill does not overheat. If smoke starts to go, then the drill needs to be urgently cooled.

When the holes are made, you can insert dowels into them. This is done with a hammer..

How to drill holes in a concrete wall

Construction, decoration of premises, repair, installation of equipment – this is an incomplete list of works, in the production of which you cannot do without drilling holes in the walls. Holes are needed for laying communications, power and telephone lines, heating and sewerage pipes. And even if you just need to hang a mirror in the hallway, you have to drill. After all, you can’t drive a nail into a concrete wall.

The eyes are afraid. hands do | | How to “drill” a hole in concrete WITHOUT a PUNCHER

The eyes are afraid. hands do | | How to drill a hole in concrete WITHOUT a PUNCHER My drill with no drill

There are such crowns for drills. But they have a coating of a different nature – from a cabrid-tungsten alloy. It is convenient to use them, since it is quite within her power to drill a hole in the concrete wall with a drill and at the same time make a hole in the tile. Such crowns are used only with powerful drills..

Drills are another tool than drilling a concrete wall. Their diameter is varied. In the overwhelming majority of cases, when installing hidden electrical wiring, you cannot do without such a dirty and noisy procedure as chasing. Experienced craftsmen advise to make a selection based on the diameter of the dowels.

We drill concrete with a perforator

So how to drill a hole in a concrete slab using a hammer drill? The procedure is simple:

- the drill switches to impact mode, after which drilling begins; the tool must be held strictly at right angles;

- after a while, the drill is moistened with water, this will help to avoid overheating;

- after it is possible to drill the reinforced concrete wall, the drill must be removed without turning off the device itself;

- to clean the resulting hole from dust, a drill is run into it several times.

Can’t drill through the wall? Is the hammer drill hitting something hard? So, you need to try to make a hole in another place..

How to make a hole in a concrete wall in an apartment with a drill

For a small hole, you can use a punch. It will be made, most conveniently, from a drill, diameter 8 mm. The end is sharpened sharply. The drill is placed in the right place, rotated, while hitting it with a hammer. Moisten the drill periodically so that it works longer.

Is it possible to drill a hole in a concrete carrier or brick wall of a panel house with a conventional drill, puncher or screwdriver without dust, how to do it

When making repairs in an apartment or house, the question of drilling a wall always arises. Different tools can be used depending on the purpose of the hole and the material from which the surface is made..

There are nuances when working with each tool, especially when drilling a wall. How to make the right hole correctly, and what recommendations to follow?

Is it possible to do without a drill and punch

Make a hole without a drill and hammer drill, but not in a concrete wall. This will require a bolt or punch..

With the working end, the tool is applied to the place where the hole will be. On the opposite side of it, you need to hit hard, rotating the tool after each turn..

DIY Drill Holder

Circular saw from a drill The entire machine (without an electric drill) consists of a base, on a work table, four racks they have not two holders: a drive (electric drill) is not a free end of the saw blade shaft. For the base, furniture (faced) chipboard with dimensions of 300 × 250 mm and a thickness of thirty mm was used. For the table (working plate), a rigid duralumin plastane with a thickness of four mm was selected not […]

During the performance of these works, it is necessary to adhere to the developed technologies and safety rules, then you can not only make a hole yourself without the involvement of expensive specialists, but also avoid injuries.