Why blunt tools get blunt

Every chainsaw has a certain durability period. This is the time from when a new tool is used until it becomes inoperable.

Destruction or wear of wood cutting tools occurs due to the set of forces that occur during the cutting process. One of the key ones is the friction force. Dulling of the saw chain occurs due to prolonged use, due to improper use of the chainsaw

The size of the wear can be defined as a weight measured in milligrams. Wear is a parameter that shows the change in shape and size characteristics of a cutting blade. A change in geometric parameters that occurs during cutting and there is no linear wear is called dulling.

There are parameters on the basis of which the decision about the possibility of further operation of the tool is made. In particular, when examining the teeth of a saw chain, look at the edges of the front and rear surfaces, the height of the blade, the area of wear. If they are not in a satisfactory condition, it is time to resharpen the chainsaw.

Signs that the saw has lost its sharpness include the following:

What is needed to sharpen the saw?

To start sharpening the chain, it is necessary to make some preparations:

- When sharpening, the chain must be tensioned tighter than usual in order to maintain the correct sharpening angle;

- First, find the shortest cutting tooth; make a mark on it, according to its size, all the other teeth of the saw will be sharpened;

- It is best to clamp the blade in a vise or a scraper. fixing the position at work;

- The marked tooth in the sharpening area and then engage the chain brake;

- To sharpen the chain you need: a flat file, a round file, a holder, a template, a filing hook.

Instructions for sharpening chains

Absolutely all chainsaw owners sooner or later face the need to sharpen the chain. This problem can be solved in two ways, either by taking the chain to a professional sharpening shop or by sharpening it yourself. With the first variant everything is clear, but if for some reasons the appeal to the grinding center is impossible (for example, the chain got blunt during the works at the country house, and to the nearest repair shop is a hundred kilometers away), it is necessary to cope independently. How to sharpen a chainsaw chain correctly, we will tell in the article.

How to Sharpen a Chainsaw by hand with a file

How to sharpen a chainsaw chain

Chainsaw chain sharpening is a procedure regularly encountered by gardeners and professional woodcutters. In this article, the master plumber will tell you how to restore the damaged teeth of the saw headset, and quickly return it to its previous working condition.

To understand how to properly sharpen a chain, you need to understand the basic principles of its design and operation. You can not just sharpen the chain by eye, you need to know the basic characteristics of the chain and its components.

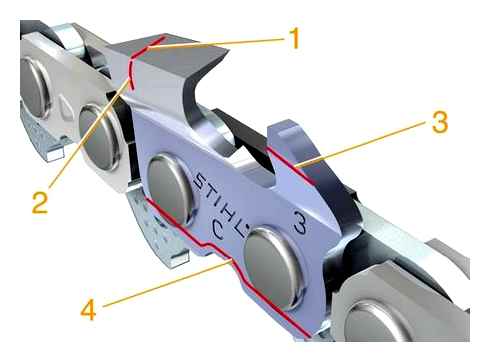

Chainsaw chain consists of three types of links made of high-alloy steel:

- The cutting links are the basic elements of the chain. A distinction is made between right-handed and left-handed, which are arranged alternately, with their cutting edges above the plane of the bar. Tooth design includes cut depth limiters.

- Driving (shanks). serve to transmit torque from the gasoline motor to the chain through the drive sprocket. This feature extends the life of the sprocket and gives the chain a more stable hold on the bar.

- connecting pieces. they connect the shanks and cutters of the chain.

One of the main elements of the chain is the cutting tooth, which plunges into the wood and removes the chips. The tooth depth limiter determines the thickness of the wood chip and limits the depth of penetration into the wood.

Recommended settings relative to the limiter are 0.025″ (0.65 mm) or 0.030″ (0.75 mm), depending on the type of chain.

The long life of any chainsaw depends on proper care and use, including the chainring. Good performance of the latter influences the performance of the device and the parameters of productivity. Untimely sharpening can cause some problems with the saw itself. The most common is:

- Crooked cuts;

- High loads on the saw, resulting in increased wear of the device parts, and hence a reduction in the service life of the entire device;

- Increased fuel consumption.

If the cut produces fine, dusty chips and the saw plunges into the cut with great force, it is a blunted target.

There are other signs of a dull chain:

- The speed of the tool has decreased;

- Uneven and sharp sawdust is produced;

- It is necessary to put a lot of effort to cut the wood;

- The chain is stretched or has become slack.

A chainsaw chain can quickly become blunt for the following reasons:

- If you work with the saw too often;

- When the operator presses hard on the saw while sawing;

- If the chain is made of poor quality metal or if the steel is not properly heat-treated;

- When cutting wet or resinous wood frequently;

- When sawing hardwood trees such as: oak, birch Karelian, cherry, acacia, elm, ash and others;

- If the chain encounters obstacles such as sand or stones;

- If the chain is not properly sharpened, or has insufficient tension during operation.

The design of all chain saws is similar, so the chain removal algorithm will be the same:

- First put on oven gloves, cotton gloves, to prevent cuts by the cutters.

- Remove the protective cover from the chain saw and place it on a flat surface on its side.

- Unscrew the fixing nuts that hold the body and guide bar with a socket wrench of the required diameter, remove the top cover of the body.

- Now slide the bar all the way down to the sprocket, loosen the chain, and remove the working parts from the mounting bolts.

- Disconnect the chain from the bar.

Sharpening angles and chainsaw tooth configuration

The chain saw chain teeth have the following characteristics:

- Sharpening angle for longitudinal sawing should be between 6° and 12°, and between 25° and 30°. if the cross-cutting sawing prevails.

- Chain profile height: professional models have a high profile of 0.762 mm, while residential saws have a high profile of 0.625 mm.

- The shape of the chain teeth can be rounded, semi-hollow, chiseled and with carbide plates.

- Thickness of drive links. this parameter is the same for the majority of home chain saws, and has the value of 1.27 mm. There are 1.1 mm thick shanks on low-powered saws that are only suitable for cutting limbs. Thicker shanks (1,5 mm, 1,6 mm, 2 mm) are used in semi-professional and professional saws.

- Tooth pitch is the distance between the chain links. Has a value that depends on the power and torque of the tool motor. the higher these parameters, the larger the pitch: 1/4″ (6.35 mm), 0.325″ (8.25 mm), 3/8″ (9.53 mm), 0.404″ (10.26 mm), 3/4″ (19.05 mm).

The pitch is determined by dividing the distance between the three rivets by two.

A chain saw chain sharpened with your own hands in good time not only extends the operating time of the device, but also saves time and effort for woodworking. Signs of a sharp chain is the formation of uniformly sized sawdust in a regular geometric shape.

- Clean chainsaw chain;

- Check the chainsaw chain for damage and, if necessary, replace damaged components;

- Increase chain tension to prevent the cutting teeth from moving during sharpening;

- secure the chainsaw;

- Find the shortest tooth (for orientation) on both sides;

- Sharpen all cutting teeth on one side, then move to the other side;

- Check the sharpening result: sharpening angle, side and top edges;

- Check the height of the depth stop (reduce the height with a flat file if necessary);

- Remove metal dust;

- Lubricate the chain;

- Adjust chain tension.

Any chain saw chain sharpening tool, such as any sharpener, will do for the right level of sharpness. Such are the file, angle grinder, and machine tool.How to sharpen a chainsaw chain with a file

This method is valued for its ability to perform the work in any, even field conditions, simplicity of procedure and lack of need for expensive tools. To correctly sharpen a chainsaw chain with a file only a round sharpening tool can help.

To determine the dimensions of a file you need to know the dimensions of the saw itself, especially the tooth pitch.

To process the depth limiter of the guide tooth a flat file can be used.

Depending on the type of chain or tooth and the manufacturer’s recommendation, the position of the file to be held horizontally against the guide bar is 90° or with a 10° slope.

While sharpening, make sure not to damage other chain components. The file will only mill in the forward direction, so you can’t move it back and forth, damaging the tooth and the file itself.

In the story. Sharpening the chain of a chainsaw by hand, without removing it from the bar, with a circular file

In the story. Chainsaw chain sharpening with a file

Has a small disadvantage of this method. In particular, it takes a lot of time to. But you don’t need to buy expensive equipment or special tools.

How to sharpen chain with a chain saw angle grinder

The method of grinding the saw chain with the angle grinder, the least popular because of its non-safety. sharpened tooth can be very different from the one using a file, t.к. during dressing with the angle grinder, it is quite difficult to control the sharpening angle.

The big disadvantage can be considered a possibility of cutting the disc angle grinder lug fastening chain link, which will subsequently lead to a break, when carrying out work.

Only a special disk for working with metal is suitable. It must be at least 2.5 mm in diameter. It is advisable to use a used disc with rounded edges.

Before you start sharpening, you need to insert a wedge of wood between the chain and the bottom of the bar to prevent the headset from moving.

In the story. How to sharpen a chainsaw chain with an angle grinder

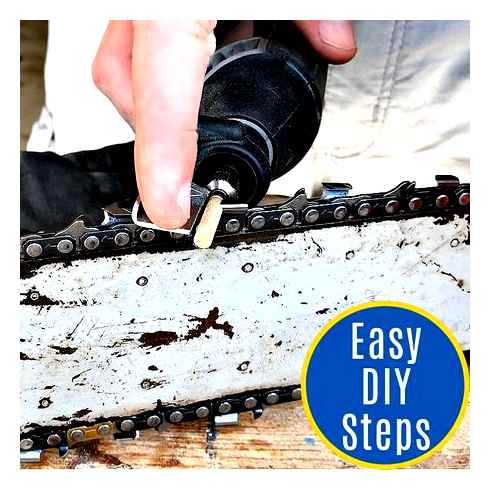

Sharpening a chainsaw chain with an electric screwdriver

To sharpen the chain yourself with a drill or an electric screwdriver, you will need a circular file. To select it, you need to specify the value of the rounding diameter of the cutting tooth of the chain.Most domestic chain saws can be sharpened with a file with a 4.8 mm cross sectional area.

In addition to the sharpening tool, you will need any bearing, which will be convenient to hold with the fingers on the outer rim.Prepare the tool:

- First remove the file shank with an angle grinder.

- Insert the file into the chuck and secure it.

- Use plastic, cork or a small piece of wood to make a sleeve of such a diameter that it fits snugly into the bearing.

- Insert the free end of the file into the sleeve that is inserted into the bearing.

To sharpen the chain with the resulting chain sharpening device, proceed as follows. First you must secure the saw, preferably by clamping the guide bar in a vice and loosening the chain so that it can move freely. It is advisable to mark the first tooth with a marker before sharpening. Now place the file into the rounded edge of the cutting element, focusing on the desired sharpening angle which is usually marked with a ridge on the outside of the teeth. Next, holding the homemade device with two hands (one by the handle of the drill or electric screwdriver, and the other by the outer cage of the bearing), turn on the power tool and, bringing the file to the edge of the tooth, make the sharpening. Sharpen each cutting link in the same way, gradually moving the chain along the bar of the saw.

In the story. Chainsaw chain sharpening with an electric screwdriver

No problem copes with the task at hand and the chain saw chain sharpening machine for their own hands. There are different variants of using such a tool. automatic or manual sharpening.Hand sharpening machine

With such a machine is set, fixed the optimum angle of sharpening. Allows you to get the best results without removing the chain from the chain saw.

No effort is required for sharpening: you set the angle and depth and turn the machine on. Work gets done fast and with high quality. vary greatly depending on the manufacturer and the range is large.What sharpening on the manual is inferior to the electric machine:

- Sharpening by hand on a machine tool is a very long and laborious process.

- Manual sharpening requires some skill, perseverance, care and accuracy.

- The manual method is less accurate, since there is a human factor.

If you own a professional chain saw that you use on a regular basis, it makes sense to get an electric automatic sharpener. It will save you time and extend the life of your tool.

Oregon’s unique PowerSharp system for sharpening amateur chainsaws and power saws includes:

- Plastic box with pressure mechanism and compartment for sharpening stone installation;

- A bar with an extra hole for later securing the plastic box of the sharpener;

- Low profile chain;

- Sharpening stone.

PowerSharp kits are available in a variety of sizes. To find the right size, simply remove the chain headset from your saw and choose a bar that matches the length of the pattern.Install a chain on a new bar, and assemble your saw. You can use it instead of your “native” chain saw until you need sharpening for the first time.To sharpen the sharpener, you must install the sharpening stone in the box and fasten it to the bar with a latch, and then turn on the saw at full power and set the pressure mechanism of the device vertically down into a hard surface (stump, log, stone, earth), lightly press. Thus, the abrasive stone will touch the chain teeth and sharpen them in just 3-5 seconds. You can return to work after removing the sharpener.

In the story. Oregon Powersharp automatic chain sharpening system

Consequences of using a chain that has not been sharpened

If the chain saw chain is not sharpened in time, it becomes increasingly difficult for the user to work and the cut is uneven. Such operation will lead to negative consequences such as:

- Lower efficiency. cutting requires more physical effort and can lead to slower working speed;

- Increased fuel consumption. fuel overruns can be as much as 30%;

- Reduced life of the chain saw. the chainsaw quickly wears out and the motor overheats, increasing the likelihood of tool failure;

- Risk of injury to the user. chain can break if the saw becomes unstable.

Preventing rapid dulling of the chain

You can extend the life of a chain without periodic sharpening if you pay special attention to careful maintenance of the headset. In particular, it is required:

- Use of specialized oil, which must be added when filling up the chainsaw. To choose the proper oil concentration, it is advisable to consult the instructions for the oil itself.

- All unused oil must be disposed of.

- During operation, it is advisable to periodically check the clearance dimensions between the stop and the tooth edge. Ideally, it should be 0.7 mm.

- To minimize the risk of distortion or single-sided abrasion, you might periodically turn the bar 180 degrees.

- Lubricate the drive sprocket systematically. This should be done before each use of the saw. The oil to be selected is that which is diluted with petrol and added to the fuel tank. But the best performance is in the M8 grade.

- Watch for proper tensioning. The chain must run straight down the bar grooves.

Basic mistakes when sharpening a chainsaw

If the saw does not work satisfactorily after sharpening, it is likely that sharpening errors were made:

- Incorrect sharpening angle: more or less than required. To avoid such a mistake, it is necessary to use a special template.

- The front angle of the tooth is tilted forward or backward. This can be caused by improperly filed sharpening. It is advisable to use a different sharpening method or try to maintain the same pressure when sharpening manually and select the correct file diameter.

- The chain teeth differ in length from each other. To avoid this situation, you should mark a reference tooth before you begin sharpening, and “adjust” the rest of the cutting elements to match it.

- The height of the cutting depth stop of the cutting links is too low or too high. In the first case, it is necessary to refine the limiter, using the sawing Calibre. In the second case, sharpen the cutting links or replace the chain.

You can increase the service life by alternating between manual sharpening and the use of a special sharpening machine. The latter allows for the most accurate alignment of sharpening angles on the machine. Grinding depth should not be too deep.

Safety precautions should be observed to ensure that wood of all sizes is sawn with maximum efficiency and minimum risk to personnel:

- Before assembling a chain tool and installing the headset, it is advisable to read the instructions for use. This is because each tool has its own distinctive characteristics.

- Carry out work with the use of the saw must be in gloves and safety glasses.

- choose close-fitting clothing made of thick natural materials and shoes that are as sturdy as possible.

- To saw wood with a chainsaw, you need to be in a stable and safe position, and the material itself should be positioned as steadily as possible. A toothed stop on the log will help assure stability.

- The saw must be held with both hands during work and the cutting process must be constantly monitored.

Modern chainsaws are used in domestic and industrial applications. It is important to maintain the productivity and high efficiency of the tool, which is directly related to the condition of the sharpened chain headset.

Why a chainsaw chain dulls

A chainsaw chain can quickly become blunt for the following reasons:

- If you work with the saw too often;

- When the operator puts too much pressure on the saw while sawing;

- If the chain is made of poor quality metal or if the steel is not properly heat-treated;

- when frequently cutting wet or resinous wood;

- when sawing hardwood trees such as: oak, birch Karelian, cherry, acacia, elm, ash and others;

- if the chain encounters an obstacle in the form of sand or stones;

- If the chain is not properly sharpened or has insufficient tension during operation.

How to properly sharpen a chainsaw chain with your own hands using a file or sharpening machine, tool selection

A chainsaw just like any other machine depends on the proper functioning of all its components. The quality and speed of woodcutting is determined by the sharpness of the working chain that is driven in rotary motion by a two-stroke internal combustion engine.

Too much use of the machine can wear down the cutting edges of the chain and this can lead to reduced performance and efficiency. Sharpening is particularly severe if there is contact with the ground and stones and other hard particles in the ground.

A chain in good condition ensures a fast cut of wood

How to sharpen a chainsaw chain

Any chainsaw needs periodic maintenance: this applies to both internal mechanisms and cutting equipment. The saw chain is the main working element of the saw. The frequency with which it is recommended to sharpen it depends directly on the intensity of use. Proper sharpening of the tines affects the quality of the cut and the service life of the chain.

Any chain, even the most expensive one, needs to be sharpened after a certain period of use. How you can tell if a tooth edge is blunt:

by the nature of the wood shavings: if they are very fine, almost dusty, it is time to start sharpening;

There is a big drop in cutting speed and cutting performance in general;

This procedure can be done at home, because it is very easy to sharpen a chain saw yourself. It is necessary to sharpen in time. This saves on tooth material, effort, and time required for the job.

Tooth shape

Sharpening begins with determining how the cutting teeth work. The immediate cutting part of the tine cuts a layer of wood like a planer, and the depth of cut is controlled by the limiter above.

Hand tools (files and templates) are usually used for sharpening, but it is also possible to machine the chain.

Sharpening should be done only at a certain angle, it directly affects the performance of the chainsaw.

Blades are angled for efficient cutting. The back of the tooth creates a back angle and allows the cutting edge to cut into the wood easily.

The back blade is needed for cutting laterally to the wood fibers. That is why it is sharpened at a back angle.

The edge of the upper blade should create a 60 to 85 degree rake angle relative to the underside of the blade.

Upper blade can have an inclination of 50-60 degrees, depending on the type of the saw.

Angle of sharpening may depend on the type of work the chainsaw is doing. A sharp angle (but not less than 25 degrees) is needed to cut very hard, frozen wood effectively!), for soft wood this parameter must be increased. In addition to a faster cut, this solution reduces vibration during work and helps the chain to run smoother.

The distance between the end stop and the top edge should be within 0,5 to 0,8 mm. Increasing this distance with excessive sharpening leads to slow cutting speed, excessive vibration and an increased risk of kickback when you are sawing. That’s why it’s important to know how to properly sharpen your chain saw to make cutting easier and more productive, and to keep the chain in good working order for longer.

How to hone a chain saw with a file

To sharpen a chainsaw chain manually, you will need a whole set of special tools.

A flat file. you need this to sharpen the depth stop.

A round file is used for sharpening the cutting edge and the work requires a suitable thickness of the tool.

Holder. has guides of the mowing line, on which the file slides during the sharpening of teeth.

Template. required for grinding along lines and correcting work.

Hook. needed to remove sawdust from the chain.

Special tools for sharpening the chain can be purchased as a set or individually. Some chain saw models come with this kit.

Place the template on the chain so that it fits into the kerf at the bottom. Place the round file on its rollers under the cutting edge of the tooth. Movement of the sharpening tool will be along a straight mowing line parallel to the sides of the template.To grind the limiter to the correct height, apply the template so that the stop fits into the hole in the limiter.

The limiter is machined based on the type of wood you’ll be sawing. For soft wood you need to set the stop next to the word “SOFT”, for dense wood you need to set the stop next to the word “HARD”. Use a flat file for the job. Move the tool smoothly and evenly, away from you.

How to sharpen a chainsaw on a machine

A chain saw sharpener is often used in the following situations

you need a fast and quality sharpening of the chain of one or more units;

After hitting the working saw on gravel, stones, sand.

Machines for sharpening can be manual and electric.

Electric machines have in their design a motor that rotates the abrasive wheel. No effort is needed to sharpen the teeth, just attach the chain to the base at the desired angle and turn the machine on. This sharpening option is usually used in production, allows you to quickly and conveniently process several chains. The question of how to properly sharpen the chain of a chainsaw on a power tool will not cause difficulties, because this procedure does not require any special technical knowledge of the person.

Manual devices are put on the chain attached to the bar, or attached to the workbench. At the bottom of the structure is a file, which is replaced if necessary (round to flat, for example). Tooth sharpening is carried out in two or three movements. With a manual machine, the chain can be sharpened and dressed and the teeth can be adjusted to the same length.

Sharpening as a business service. what you need for this

To provide mass sharpening services, that is, to create a business in this area, requires a lot of equipment and conditions. The following are the basic materials, equipment and supplies that will be needed to create a mini-workshop:

- room, heated, with electricity, space for the machine, a chair, racks (minimum area of 2 square meters.meter, voltage in the network of 220 volts);

- Machine tools with washers for various disks (electric grinder);

- sharpening discs, including diamond;

- wheel grinding;

- mounts for tools such as skates, scissors, chain saws;

- Meshalko. dies for manual sharpening;

- hammers;

- small tools (hacksaws, screwdrivers, wrenches, etc.д);

- vise;

- spindle oil;

- lights;

- cutter;

- storage boxes, baskets, furniture.

Anyone who has ever worked with a sharp chainsaw will quickly know when the chain needs sharpening. There are several ways to determine this:

- wood chips are replaced with almost dust when cutting wood;

- the time required for the operation increases;

- you feel the strain on your hands;

- fuel consumption increases;

- It is not just the chain that gets jammed or gets out of your hands;

- The cuttings turn out crooked.

Sharpening should be done as soon as possible, and not only because it becomes difficult to work with the tool. Unsharpened chain shortens its service life and the chainsaw mechanism itself wears out quicker and fails earlier.