How to tension the chain saw starter spring

Any chainsaw needs a starter for a quick start. At the accelerated cranking of the tool crankshaft the fuel-air mixture fed into the engine is compressed and its subsequent ignition. That is why the chain saw starter motor is responsible for the correct operation of the machine.

The device of chain saw starter

Almost all leading chainsaw manufacturers equip their products with starters with a similar principle of operation. It is no coincidence that specialized stores offer universal designs of starters, which are equally successful for chain saws STIHL, Husqvarna, Makita, and the Chinese semi-official fakes of these brands. Some features have only starters chainsaws domestic production (Lesnik, Ural and a number of others).

The principle of chain saw starter operation is as follows. In the housing slot is installed handle, through which the cable is passed. If the handle is lifted sharply, the cable is pulled out and engages the drum of the ratchet mechanism, which transmits the motion to the drum with slots provided on the shaft. In doing so, the crankshaft makes several revolutions, and the working mixture in the space between the piston and the cylinder head is compressed. Accordingly, when lowering the starter rope the contact between the ratchet and the splines is lost and the shaft stops.

As the engine volume increases, so does the amount of fuel-air mixture required for its subsequent ignition, so the number of jerks for the starter rope for high-powered saws increases. The automatic return valve makes it possible to reduce the working pressure in the chainsaw cylinder and speed up the return of the reel.

Making it easier to start the chainsaw is realized in the following ways:

- Pre-enrichment of the cutting mixture by a special choke in the carburettor design.

- An automatic decompression valve that reduces the working pressure in the chainsaw cylinder.

- An additional spring that eases the crankshaft unloading by moving the cable.

- The presence in the design of some chainsaws (e.g., Partner S series, Maxcut, etc.) primer. a pump that provides pre-pumping of fuel.

Typical faults

common tool failures include the following:

- Commissions in the ignition system;

- stopping the work of the chainsaw in the process of making a cut;

- loss of power during operation;

- Wear of some structural parts of the chain saw (brake band, drive sprocket, anti-vibration parts);

- problems in the fuel system;

- malfunctions associated with the starter.

In addition, it is necessary to create a visual inspection of the chainsaw before the execution of works and preventive measures. How to wind up the starter spring trimmer for grass The starter cord does not coil: how to find out the cause and to repair the starter with their own hands? How to disassemble the starter, plug it in and do it again. These include chain lubrication, controlling the amount of fuel mixture, also the presence of the required amount of oil.

The spark plug is unscrewed to check its condition.

Any of the defects can be eliminated by its own technology. So, for example, the repair of the fuel system of a chainsaw should begin with the inspection of the appropriate filter. After that inspect the correctness of the carburetor adjustment, which is carried out with the help of screws. Clearances should be set in serious coordination with the manufacturer’s annotation, which should come with the chainsaw. Repair of the ignition system includes inspection of the plugs. If heavy fouling, gap changes or other visible damage is detected, this element should be replaced.

Chainsaw starter repair. With your own hands.

on a chainsaw ? How to bend the spring on the starter ?How to coil the spring.

with your own hands. replacing the spring of the manual starter.

- A set of screwdrivers or a special tool, which is supplied by the manufacturer with the tool;

- Rope, which will be used as a replacement for a broken cord if necessary.

A large amount of black soot on the spark plug indicates a malfunction of the engine.

Before proceeding directly to repair the starter and find out the causes of malfunction, it is necessary to remove it from the body of the tool. To do this, unscrew the few screws that hold the side cover to which the starter is attached. This is done with a screwdriver or a specialized tool.

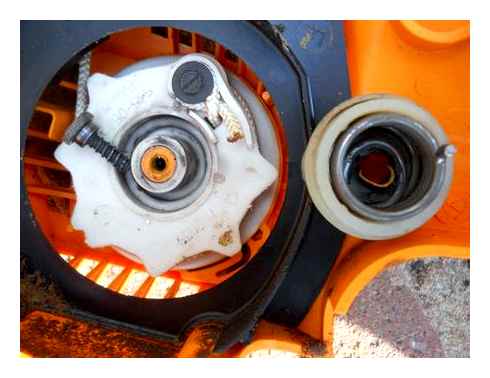

After the cover is unscrewed, it is turned over and inspected. Next, unscrew the screw, by means of which the starter is secured. After that dismantle the clamp and spring for a smooth start. The pulley, on which the cord is wound, is now accessible for removal. Once the knot on the rope is untied, it can be removed from the pulley and replaced with a new one. Provided that the loss of starter performance is associated with a breakage, this may be enough to fix the failure. However, the other parts that make up this element of the chainsaw should be carefully inspected.

READ What kind of chain for a Makita electric saw

Inspection of the components of the starter can reveal the following faults:

The soft starter spring is most often damaged at the end where it can be seen when the housing is disassembled.

- The pulley may be damaged. There may be cracks or tears, and there may be damage on the back. How to correctly insert the starter spring for grass trimmer. How to wind the starter spring of a gasoline-powered tool. how to install the spring in how to wind the starter spring repair chainsaw. As a result of these problems the tool cannot perform the work.

- Damage to the soft starter spring. In this case it can be mechanically defective as a spring itself, and there may be defects in the place of its attachment. The weakest point of this element is precisely the mounting place and the tip of the spring that is inserted in it.

If defective or partially damaged parts are found, they must be replaced with new ones. how to wind up a starter spring how to correctly repair chain saw starter. In this case, the new elements must correspond to the model of the saw being repaired.

After completing the repair it is necessary to correctly reassemble the starter.

The pulley is installed over the spring. In doing so, it is necessary to check whether they are meshing with each other. To continue the repair it is necessary to make the sheave. How to wind up a spring and how to wind up a chain saw starter rope.everything as usual. How to make a starter on a chainsaw by yourself? How to bend the spring on the chain saw starter? How to wind the spring and how to wind the chain saw starter rope.Everything as usual is simple and easy, and the main thing is. This should be done in such a way that when it rotates, it pulls the cord into the starter. It is enough to make 3-4 turns to give the required voltage. A rope is put through the hole in the chainsaw cover beforehand.

chain saw starter repair. With their own hands.

nabenzo saw ? How to bend the spring on a chain saw starter ?How to wind the spring.

with your own hands. replacing the spring of the manual starter.

- a set of screwdrivers or a special tool, which is included by the manufacturer with the tool;

- Rope, which will be used as a replacement for the broken cord if necessary.

A large amount of black soot on the spark plug indicates engine malfunction.

Before proceeding directly to repair the starter and find out the causes of malfunctions, it is necessary to remove it from the body of the tool. To do this, you need to unscrew several screws that hold the side cover, to which the starter is attached. This is done with a screwdriver or a specialized tool.

After the cover is unscrewed, it is turned over and inspected. Next, unscrew the screw that secures the starter. After that, remove the clamp and spring for a smooth start. Now the pulley, on which the cord is wound, is accessible for removal. Once the knot on the rope is untied, it can be removed from the pulley and replaced with a new one. Provided that the loss of starter performance is due to a breakage, this may be enough to repair the breakage. However, the other parts that make up this element of the chainsaw should be carefully inspected.

READ What kind of chain for a Makita chain saw

An inspection of the starter components may reveal the following faults:

The most frequent damage to the soft starter spring is at the end, where it is visible when you disassemble the housing.

- The pulley may be damaged. There may be cracks or tears, and there is damage on the back. How to properly insert the grass trimmer starter spring. How to wind the starter spring of a gasoline-powered tool. how to install a spring in how to wind a starter spring gasoline saw repair. As a result of these problems, the tool can’t do.

- Damage to the soft starter spring. In this case it is possible that the spring itself is mechanically defective and there may be defects in the place where it is fastened. The weakest place of this element is precisely the fixing place and the tip of the spring that is inserted into it.

If defective or partially damaged parts of the starter are found, they must be replaced with new ones. how to wind the starter spring how to correctly repair chain saw starter. In this case the new elements must correspond to the model of the saw to be repaired.

After completing the repair it is required to properly reassemble the starter.

The pulley is put on top of the spring. It is necessary to check how well they fit together. To continue the repair it is necessary to wind the pulley. how to wind the spring and how to wind the chain saw starter rope.all as usual. How to make a starter on a chainsaw? How to bend the spring on the chain saw starter? How to wind the spring and how to wind the chain saw starter rope.everything as usual is simple and easy, and most importantly. This should be done so that when it rotates, it pulls the cord into the starter. It’s enough to make 3-4 turns to give the required tension. The rope is put through the hole in the chain saw’s cover beforehand.

Practical recommendations

In order to match the holes for fixing the cord in the pulley and the body, you may have to make a few more turns. The new rope is put through the technological hole and make a loop or knot: this will allow it to slip out of the pulley. The rope is set aside so that it does not interfere with further work. Next you need to fix the pulley.

First it is required to install the soft starter spring in place. It can be used the former, if no damage is found in it. or a new one if you need to replace it. On top of the spring set the starter clamp, which is fixed with a special screw. It securely holds the clamp for a long time, preventing it from twisting and swaying. After that, make a few coils of rope and run it inward. Put the cover with the assembled starter in place. With the help of screws make its fastening.

After repair and reassembly you can get down to work. how to properly lubricate the chain how to shorten the chain on a mtb chain saw starter repair. Self-repair starter does not take much time and does not require complex skills, but saves time and money if you perform such work in the service center.

To repair the chain saw it is necessary to approach responsibly and make timely preventive inspections, monitor the quality of fuel and oil used. These simple manipulations will increase the duration of the tool in working condition.

Practical hints

In order to match the holes for securing the cord in the pulley and the body, it may be necessary to make a few more turns. Thread the new rope through the technological hole and make a loop or knot: this will allow it to slip out of the sheave. The rope is pulled aside so that it does not interfere with other operations. Then the pulley has to be fixed.

First the soft starter spring must be installed in its place. It can be used as is, if it is not damaged. or a new one if you need to replace it. Place the starter clip over the spring and secure it with a special screw. It holds the clamp securely in place for an extended period of time, preventing it from twisting and wobbling. After that it is necessary to wind a few coils of rope and run it inside. The cover with the assembled starter is put in place. Fix it with screws.

After repair and reassembly you are ready to go to work. how to correctly lubricate the chain how to shorten the chain on a mtb chain saw starter repair. Self-repair of the starter does not take much time and does not require complex skills, but saves time and money if you perform such work in a service center.

It is necessary to repair chainsaw responsibly and perform timely preventive inspections, monitor the quality of fuel and oil used. These simple manipulations would increase the tool’s duration of operation in working condition.

How to use the Starter on your Husqvarna

chain saw starter. Learning to repair a starter motor yourself

To sharply start any chainsaw requires a starter. When the accelerated cranking of the crankshaft of the tool is compressed fuel-air mixture fed into the engine and its subsequent ignition. Therefore, the normal operation of the starter for a chainsaw determines the performance of the entire mechanism.

Oil supply repair

If there is no oil to lubricate the chain, you need to diagnose everything that allows accounting (software) and find the reason why the oil is not being supplied. There are a few major events for you to enjoy:

- A clogged oil filter, in other words, a greasy accounting system;

- Lack of threads on the oil pump worm gear;

- Blockage or malfunction of the pump itself;

- Leaking oil metering system (there will be oil leaks on the day of the chainsaw).

To check the thread on the worm oil pump, you will need to remove the chain saw sprocket and unscrew the clutch. To do this for you unscrew the spark plug, in its place installed a piston plug, provides a reliable fixation of the crankshaft of the tool from turning.

Then the cover of the STIHL 180 chain saw is removed, and the fastening ring that holds the drive sprocket is removed with a screwdriver, then the sprocket itself is removed.

Similarly, the STIHL 180 chain saw chainwheel sprocket can be replaced if desired.

READ Kedr chainsaw carburetor adjustment

The clutch is unscrewed with a nineteen head and a knob. Unscrew the clutch clockwise, because the thread is left-hand. There is a reflective plate over the socket and it also needs to be removed. One more detail. This is a worm drive oil pump. After examining and finding the absence of the plastic thread, you can safely throw out the part and install a new one in its place, since its restoration is unrealistic. STIHL 100 eighty chainsaw harvesting.

Replacing the starter cord of a STIHL 180 chain saw.

To check the clearance, you need to turn the flywheel and check if the coil contacts are touching it.

How to use the Starter correctly on a chainsaw

How to start a chainsaw: a couple of effective ways

Chainsaws vary in design features, but in most cases the principle of assembly is carried out according to two standard schemes. Many devices in the manual contain information about the need to engage the emergency brake before starting the on-off procedure.

At first it is necessary to master the device of the plant and learn the basic ways of troubleshooting, then a person will have the ability to fully control the device.

A brief look at the plant unit

The chainsaw is powered by. This is a simple device whose design has no special bells and whistles. It usually works fine even in harsh conditions.

Read about the plant unit Functionality is provided by the structural elements:

- Carburetor engine (see. Adjusting the carburetor).

- Centrifugal-type clutch.

- The ignition system, which is virtually non-contact in all units.

- A carburetor that adds air to the fuel mixture.

- Fuel System. Its standard device consists of a hose, a filter and a gas cylinder, but sometimes it also has additional parts.

- Starter.

- Tyre.

- Chain (cf. Chain oil).

- Tensioning mechanism and chain brake (refer to., How to sharpen the chain).

Step-by-step instructions

When the brake is activated, the assembly process is much slower, so it is also safer and more convenient to engage the gear without using brake equipment.

If one is unsure of one’s knowledge and accuracy, then the brake should be activated in reverse. If the procedure is correct, the device does not start, the mechanism does not make dangerous to the person’s actions.

1 schematic diagram of a standard mechanism

- Before you start the gasoline, you need to move the flap, which acts as a control lever, to the bottom, compared to the optimal position. First press the button responsible for the gas supply. Only if this condition is met can the damper be moved normally to the bottom stop. It is necessary to move the flap and hold the gas button at the same time. The gas is set in the standard position, and the flap closes the carburetor, preparing the device for normal operation. The starter jerk knob

- The starter knob needs to be pulled, and this is done in jerks, not soft motions. Moderate force should be used for this action. You should continue these jerks until the chain saw’s ignition is clearly audible and ends very quickly (stops). After performing this exercise, the position of the flap should be moved one step up.

- The starter knob is jerked again then until the system starts. When the unit begins to be active, high speed is immediately noticeable because the throttle is at a high level. It should be remembered that sometimes chainsaws are supplied without a starter motor, then all actions are performed with this element.

- The throttle button is pressed once and then released, then the flap position immediately becomes optimal. Speed decreases, t. Е. Intensity of chain speed.

- Already. when the lever is in the “1” position and then the action is performed to turn the unit on.

- To turn off the engine of the device, you need to set the shock absorber to the highest position.

READ Home Garden Ph 426 Zip chainsaw Device

In our ranking, chainsaws by quality, you will find all chainsaws with the best value for money.

Also our article will help you make a choice in favor of a particular brand of chainsaw.

A chainsaw is made. Low price with a fairly high quality.

2 standard mechanism diagrams

- The ignition is on. To do this, move the toggle switch to the desired position or move the switch.

- You usually need to push the ground to pump more than twice. It is filled with gasoline, then the device must be pressed more than three times. Sometimes the chainsaw is not equipped with a primer, then you can skip this step. Adjustment lever

- The adjustment lever, which is responsible for locating the flap, you need to pull it all the way out. Many chainsaws have the ability to lock this element. It can then only be moved while pressing and holding the throttle button at the same time. Some chain saws do not have such a lock, which makes them more convenient to use. In these models, the throttle cannot be fixed or held while using automatic techniques.

- You need to take the starter handle and tighten in a sharp motion until you hear the ignition process. It is marked by establishment and almost instantaneous engine shutdown. The flap must then be withdrawn to its original position, checking that it reaches the stop. Again, the starter knob is jerked to the location of the device. Before carrying out this action, make sure that this is the way to get the chainsaw. Some devices have a new ignition system. For the engine to work in them, it is necessary to move the damper only 50%, but only at the beginning of active operation of the engine to push it completely out.

- If you have purchased a model with a fixed throttle, you need to prepare in advance for the maximum speed of the engine immediately after activating the device. When there is no lock, the initial power is very low, so in most cases you need to increase it. If you do not take any action, in the last case the saw works for a short period of time and then stops automatically. If that happens you need to start the chain saw again.

READ Attachment for chain saw with your own hands

Gasoline chain saw starter motor repair. With your own hands.

on the chain saw ? How to bend the spring nastarter chain saw ? How to bend the spring

Common breakdowns on the STIHL 180

STIHL chain saw malfunctions include:

- Cord breakage;

- Worn sprocket;

- The origins in the chain oil supply system;

- Wear and tear on the worm gear oil pump;

- Air enters the engine crankcase through the gaskets of the gasket;

- Lack of spark on the spark plug;

- Lack of fuel supply in the case of carburetor flaws (for them we will stop here, because the repair and adjustment of the carburetor chain saw. Quite a broad issue and will be addressed in a separate article)

- The seat beneath the engine control lever is torn out of sight.

Now let’s have a closer look at what’s wrong and repair the oil pump.

Plugging the spark plug

If you see that you pour a spark plug on your STIHL chainsaw, there may be a malfunction in the fuel system. The engine must run on the consistency of gasoline and oil. If the mixture is lean, the power is miniaturized, the cylinder overheats and the saw systems wear out. Wet plug on STIHL chain saw is caused by disproportionate fuel consistency. Lack of air in the consistency prevents proper combustion of the emulsion.

The introduction of bad gasoline can lead to motor wear.

Lubrication of the spark plug also causes the introduction of oil for 4-stroke engines and piston wear. If this happens, remove the gasoline canister cap and adjust the fuel supply. Air intake must be repaired. A clogged filter should be blown with air or better changed. How to clean the filters is described in the manual to your chain saw.

Check the quality of the consistency with the spark plug insulator. If it shows a brown color, it means that the consistency quality is normal. A white color or soot indicates a poor or very enriched consistency.

The spark plug is a prerequisite for lubrication. Intermittent spark formation is observed when the gap is incorrectly set. The spark plug gap is indicated in the repair manual. If you do not have such data, you can set 0.7-1 mm.

If the gap is smaller, the ignition efficiency of the consistency decreases, if it is more, then there are interruptions in the formation of the spark. To eliminate over-enrichment of the consistency, the engine is blown out. In this case, it is necessary to remove the spark plug and turn the crankshaft a couple of times with a hand starter.

The structure of the chainsaw ignition system and the principle of mechanism operation

The operation of the gasoline engine requires the creation of a spark, through which a portion of the fuel-air mixture is combusted. The spark is created with the help of the spark plug, to which the voltage is applied. The ignition module is responsible for the voltage supply, which on modern chainsaws is represented as a contactless electronic system.

Contact ignition systems were previously used on older chainsaws, and modern manufacturers eliminate the need to adjust contact gaps and clean them periodically. The following components of the chainsaw ignition system are responsible for burning the fuel at a certain point in time:

- The flywheel or flywheel alternator, which has magnets in its design. It is the magnets that influence the creation of the electrical charge that goes to the spark plug. The flywheel also serves for the air cooling of the internal combustion engine, for which it is equipped with ribbed faces in its design

- Ignition module or commutator, consisting of an electronic circuit board

- High voltage wire. a special cable that ensures the transfer of high voltage from the module to the spark plug contact

- The spark plug is the consumable part through which the spark is created

The principle of operation of the chainsaw ignition system is as follows:

- Magnets on the flywheel, as it rotates, create an EMF, which is a voltage

- This voltage is created in the module, and is amplified by the electronic circuitry

- A high-voltage impulse from the board through the high-voltage wire reaches the spark plug, thereby creating a spark

The electrical diagram of the ignition system device is shown in the photo below.

One of the important parameters of the ignition system is the clearance between the module and the flywheel. The value of this gap is 0.25 mm, but on different models of manufacturers this value may differ, so it is recommended to clarify in the manual. If the gap is large, the spark will be weak, which will lead to unstable operation of the motor or even its impossibility.

Starter for a chainsaw: work and repair of the tool with their own hands

Fast start of any chainsaw does not do without a starter motor. During operation of the tool, thanks to the accelerated cranking of the crankshaft, the fuel-air mixture is fed into the engine, compressed and ignited. On this basis, a qualitatively selected starter for a chainsaw can guarantee the long and faulty work of the entire mechanism!

How to repair the starter on a chainsaw

Chainsaw starting system malfunctions can be caused by:

- Drive pulley. This part is subjected to high axial and radial loads, so it is advisable to inspect the pulley for damage and cracks on the back of the housing before starting work. If necessary, repair the part or replace it with a new one.

- Spring mechanism. If it is damaged, cracked or ruptured it must be replaced. It is also advisable to inspect the attachment points for defects.

- Rope trigger system. The rope should be inspected for wear and damage. If necessary, replace the part and reinstall it on the pulley.

Diagnose

Diagnose the tool starting system as follows:

- Loosen fixing screws and remove cover.

- Unscrew the screw that attaches the mechanism to the protective cover.

- Smoothly start the starter by removing the spring and clips from it.

- To inspect for wear and defects, dismantle the cable spool.

- Check the fuel system for the presence of water in it. If there is water inside the system, the fuel fluid must be replaced.

- Inspect the power unit for overfilling with fuel fluid. In this case it is necessary to unscrew and dry the spark plug, pull the starter by removing the air flap.

- Check the spark plug for spark.

If the engine is running at idle and when the spin cycle becomes faint, it is entirely possible that the muffler is the cause. The muffler can be clogged with the products of combustion of fuel and disconnected socket and, as a consequence, the engine does not reach its own maximum speed. The cause may be excess oil in the fuel, also not applicable or faulty oil. To remove the malfunction, the muffler must be removed, cleaned of deposits and washed with detergents.

Chainsaw starter kit

Most chainsaws have the same starter motor. For this reason, some stores offer customers universal triggers that fit STIHL, Husqvarna and Partner models. Nevertheless, some differences from most of the starters have domestic chainsaws Ural or Lesnik.

As standard, the chain saw starter consists of a number of parts.

On top of all the elements of the starter is installed a protective cover. The original principle of most starting mechanisms is also practically the same. In a special groove in the chain saw’s body, there is a handle that holds the cable. When the handle is raised sharply, the latter is understood to be. At this point, the ratchet is triggered, which through the drum transmits the force to another drum with splines, located on the shaft of the engine.

When you pull the standard cable, the chainsaw motor shaft begins to rotate, which leads to compression of the existing fuel mixture, located at this time between the cylinder head and the standard piston.

As the volume of the internal combustion engine cylinder increases, so does the amount of fuel mixture required for its future ignition. Accordingly, the operator of a powerful saw needs to make more jerks than the owner of a domestic tool with low power. To increase the speed at which the drum returns to its original position, manufacturers of heavy-duty chainsaws use resilient return springs.