Cutter Assignment

Cultivation is one of the most important processes in land cultivation. During this work the soil is tilled, but there is no superficial tillage. the lower layer is not moved to the surface. The technique (in this case, a single-axle tractor) makes passes of a specified depth, while loosening and crumbling the top layer of land. Outwardly the field looks trimmed. The roots of weeds are also cut at the same time. And after that it is possible to apply fertilizer. There are other advantages of cultivation, improvement of air access, acceleration of soil warming, saturation of soil with useful elements, holding the flag. This is what a tiller is for.

Deep cultivation

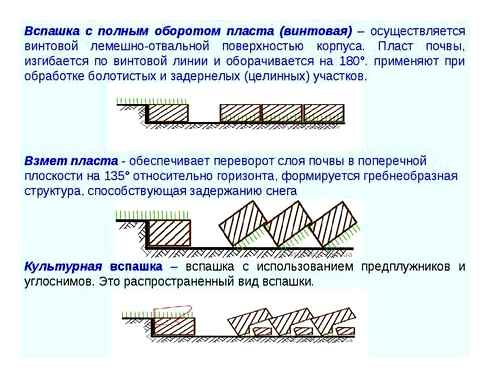

At the development of new areas it is necessary to develop virgin lands. It is usually heavily overgrown with turf, perennial grasses and weeds. It’s quite difficult to cope with such areas with ordinary tools. often recourse is made to cultivation with the help of deep tillage with the layer turning. When reversing ploughing, part of the layer is undercut, lifted and turned around on its own axis. As a result, the soil from the lower layer is on top. Weeds can’t grow for a while. Cultivated plants get a head start.

Similar work is carried out in autumn. Rhizomes of nettles, creeping couch grass, dandelion and other weeds freeze in November-December, when the air temperature gets lower.15-17 ⁰С (no stable snow cover yet). Later they lose the ability to grow.

This method is repeated every autumn afterwards. In 2-4 years autumn autumn autumn autumn plowing weeds on the plot are many times reduced.

- Wrap the soil layer and give the plants a chance to use nutrients which are gradually shifted to the lower horizons in a season. Such an operation can reduce salinity of the soil with mineral fertilizers, as well as reduce the amount of fertilizers applied;

- Aeration of the lower layers of soil promotes aerobic processes of decomposition of plant residues. Usually in the lower layers the access of oxygen to the air is limited. Therefore conditions are created when the decomposition of roots of the rod type is stretched for several years. Anaerobic processes (without air access) occur with slow accumulation of humus;

- When the layer is turned over, the weed seeds end up in the lower layers of the soil, and they cannot germinate. The roots remaining on the surface freeze out. As a result, the clogging of soils decreases sharply;

- Frozen clods of earth in winter crumble more easily in spring. A light, loose surface layer is formed in which cultivated plants can receive more abundant nutrition;

- Introduction of organic matter before plowing allows to organize active decomposition of manure or green manure, if they are sown after harvesting of main cultivated crops.

milling materials

Before assembling a tiller on a single-axle tractor, it is necessary to measure the parameters of the area to be cultivated, and then, based on the data obtained, to assemble the mechanism. For the design to be as correct as possible, you need to have the following list of materials available:

- A not very long tube of metal, having a diameter of 42 mm;

- Parts that will act as elements of loosening the ground;

- welding machine;

- angle grinder.

Figuring out how to properly assemble the cutters on a single-axle tractor, many owners wonder about the device of soil rippers. The basis of these parts may well be the springs for the car, which are bent and then welded to the main tube at the desired angle.

Powertrain. Electric motor or internal combustion engine. The electric drive can be taken from an old ventilation system or industrial compressor, such power units have a decent resource and high reliability.

If you use an internal combustion engine (for example, from a moped), it must be forced to cool, so take care to install a fan. Chainsaw motor has improved cooling system, so there is no problem of overheating.

Setting Blade Cultivator ( Pasang Blade Mini tiller )

Gearbox. Required on any power tiller or cultivator. The high speed of the motor output shaft (whether electric or gasoline) is too high, and the torque in compact power units is insufficient for tillage.

Reduction gear unit lowers RPM and increases input force.

Frame and gantry for the attachment.

Important! Even if you build a single axle power tiller, it can always be fitted with wheels and any tool you like. from a weeder to a plough. That’s why a mounting bracket for various implements should be.

Handles for control. As well as holding the machine in its working position, the handles are also used to control the power unit. The design must be robust and easy to handle.

If you decide to assemble a cultivator with their own hands. the drawings can be taken from technical literature or develop their own. Binding to a ready-made project, you will be forced to look for exactly those components, which the author of the design has provided.

We offer for consideration two designs with a different concept:

In agriculture, power tillers have long held a leading position in operation, distinguished by the fast processing of land and the possibility of automatic harvesting. Each model, regardless of the country of the manufacturer, includes additional power units. As a rule, they are quite enough for quality work on any plot, and there is almost no need to make milling cutters for motocultivators by yourself. But there are situations when the capabilities of the purchased unit, do not correspond to the Russian realities.

A simple example: not all Western manufacturers take into account the depth of soil in other countries, specific crops, weather conditions and other things that can complicate the work process and increase the likelihood of a quick breakdown.

In such cases, you can always buy an additional milling machine for your specific area or make it your own hands. It is worth noting that in many cases homemade parts work much more efficiently than the factory ones! Visually, any tiller looks as follows: two parts of the module with a special set of tillage blades are attached to the wheel base, and then adjusted so that one structure does not interfere with the other. Thanks to this simple technology, the single-axle tractor is able to move independently on the territory and engage in processing.

It is worth noting that there is a second type of mounted milling machines, working with the PTO. Such units are attached to the back of the main structure, and are often found on such models as MTZ, Pro Arab, Agro and others. Despite the differences in installation, all cutter types are made according to the same scheme.

Depending on the type of operation, additional devices may differ slightly from each other. The main purpose of milling machines is to destroy weeds and level the ground surface of the plot, but they can also perform other tasks in parallel. For example, to wrap fertilizers, process the soil or even fertilize it with special devices. Let’s take a closer look at what types of tillers are most common.

Goosefoot

These models appeared on the market relatively recently. With their help any virgin soil can be processed, they are also effective in the cultivation of hard and difficult soil.

- A solid design that provides high accuracy performance;

- The equipment is good at fighting weeds;

- ease of operation, the possibility of replacing parts at home.

Such models, unlike sabre milling cutters, are made of carbon steel, which in terms of durability is slightly worse.

Sabre cutter and its assembly

Before assembling a cutter on a single axle tractor, you need to understand well the concept of motor cultivator. It is a welded frame made of pipe with a diameter of at least 23 mm with a fuel tank and engine mounted on it. They are attached to the frame with brackets. The engine is otherwise called the power unit. It is equipped with a gearbox and a clutch mechanism. Each brand of cultivator has its own power pack with different capacity.

The cutter bar is most often sabre-shaped. This is currently the most popular powerpack design and is even called the standard powerpack. The effectiveness of sabre blades has been proven over many years of use on a wide variety of soils. Many applications are possible by mounting it on a single axle tractor. The durability of blades made of carbon steel is very high. The cutter is of collapsible construction. Each knife is thermally hardened with high-frequency currents during the manufacturing process.

How is the assembly of tillers for power tillers? Each tiller is made of 2 units. Each of them contains 12 cutters. The block consists of 3 knots. Each leg is made up of 4 legs at right angles (picture). They are inclined at 30° from one another. Each blade is made of 5mm thick steel. They are fixed to a leg made of 63×40 mm square angle bar. The other end of the stand is welded to the flange so that the 4 blades fit together. All blades are bolted together with washers and flanges. This construction is very reliable. It is able to withstand quite high loads. If you plan to use the cultivator all the time, it is better to use a factory-made cutter.

When installing the cutter bar on a single axle tractor, some craftsmen have difficulties. That is why it is recommended that only two of us carry out this work. Assembly is usually done on a purpose-built wooden trestle about 50 cm high. They help you get the job done faster. the single-axle tractor is carefully supported on the coulter bar and tilted at an angle of approx. 45°. Place the trestle under the handlebar grip. In this position, the wheels are removed from the motoblock and the cutters are installed (image ). On the outer ends of the right and left, you need to install the plates on the cutters for the power tiller. They improve the machine’s performance and make it run smoother and more stable.

How to make self-made cutters for a cultivator with your own hands?

Before you begin to build your implement, you must be certain of the type that is best suited to your conditions, so that the design features can be taken into account during assembly.

Having chosen the type of attachment, you need to carefully study the drawings, in which you will find the order of installation and method of attachment of parts of the cutter. Then you need to prepare the materials and equipment necessary for production.

If there are shaped elements in the chosen design, it is best to order them from a turner, or make them by hand, using the blacksmith’s tools available in the household. All other parts can be made by hand or purchased at an agricultural store.

In the manufacturing process, great attention should always be paid to the correct sequence of assembly. In case of an error, the finished cutter will pull the cultivator to one side, or the other.

Most experts agree in the opinion that the size of parts of a homemade tiller for a cultivator should not exceed 50 cm. Such a tiller will be able to deepen into the ground to a distance of 26 cm, which is more than enough for effective plowing of the plot.

It should also be taken into account that the saber type cutter is safer for the farmer in case he accidentally falls on the construction. In addition, the knives for the cultivator in such a device are placed alternately, so they enter the ground without strikes and jerks.

To use your power cutter for as long as possible, it is absolutely essential that you follow the instructions on how to use it. The tiller should be positioned above the ground level each time it is switched on again. Starting the revolutions, the blades of the device should slowly deepen into the ground and start plowing the plot.

Cutters on a single axle tractor

Such equipment as a tiller is essential for any power tiller, because it can be used to perform most of the work associated with tillage. A tiller generally comes with the machine, but if you need to change the width and depth of cultivation, you should buy the equipment separately.

Additional tillers allow increasing the functionality of a power tiller and simplify its operation. Experts recommend having several pairs of cutters in your arsenal.