How to correctly align the ignition on the trimmer

The electric circuit of the scooter Muravey is quite simple and does not contain heavy nodes. Due to this action, there is a movement of the piston, which transmits torque to the flywheel. Ant’s electrical equipment is a system with one wire, and the other is the body of the moped itself. All equipment has excellent insulation, eliminating the possibility of short circuits and harm to the driver. Maintenance of the electronics on a motorcycle consists only of regular cleaning of the terminals. Nevertheless, in order to find the problem that has arisen, it is necessary to keep a tester at hand. It will accurately identify the problem that is preventing the operation of the electrical equipment. Installing the ignition Installing the ignition on the scooter Muravy, as on any motorcycle with a single-cylinder engine and battery-operated ignition system, requires little knowledge or effort. All you need is very thin paper, a thin rod, and a set of wrenches. Put the paper between them and clamp.

For the lawnmower to start well in the future, you need to provide it with good storage and operating conditions:

- during operation, pay close attention to the cooling system, carefully and in time clean the ducts in the body and the starter ribs;

- if necessary, use solvents, kerosene and other detergents for cleaning;

- do not clean the tool “hot”. let it cool down;

- Always follow the operating instructions or you may overheat the engine;

- If you don’t plan to use your lawnmower for the next month, you need to drain the fuel mixture from the mower, i.e. к. over time, it breaks up into heavy fractions which will definitely clog the carburetor passages;

- After draining the fuel, let the trimmer work at idle speed until it stalls, this will help completely remove the residual working mixture.

Before winter storage, do the following steps:

Chainsaw Repair. Replacing the Ignition Coil (Poulan Part # 545090601)

- Completely disassemble the mower, rinse and clean all the parts you can;

- Inspect the parts for damage, if necessary remove misalignments, rips, bends and any other malfunctions;

- Pour enough oil into gearbox and clean air filter;

- You can partially disassemble the motor, flush, purge and lubricate all moving parts;

- To lubricate the piston, you need to unscrew the plug, lift the starter piston to its dead center, pour a little oil into the candle hole and twist a couple of times the crankshaft;

- If you store the lawnmower out of the house, wrap the engine with an oiled rag.

does not start the grass trimmer gasoline? Prerequisites and remedy

In the near future, the gasoline grass trimmer

Has gained the status of the 1st major tool in the arsenal of gardeners. And this is logical, because the motorized grasshopper allows you to quickly bring your garden plot in order. But from time to time it happens that the grass trimmer does not start in hot and even in cool. In such situations, it is necessary to establish the cause of the malfunction without the help of others. Let’s find out what to do if the grass trimmer does not start. Preconditions, which more often lead to such troubles, will be considered further.

How to Set the Ignition on a Chainsaw?

Quite often the owners of chainsaws are faced with a problem in which the engine of the tool does not start. One of the main reasons for this malfunction is a malfunction in the ignition system, namely a failure of the factory settings of the unit.

First of all, the owner of the saw will need to unscrew the protective rubber cap and check the spark plug under it. It is quite possible that it is filled with oil, which prevents electricity from penetrating the spark plug. In such cases the problem is not in the ignition system, but in the fuel system, namely in the depressurization of the channels.

However, if the spark plug is completely dry, this may mean that you may need to adjust the ignition on the chainsaw. To do this, we unscrew the spark plug and remove the protective cap. Then measure the gap between the flywheel and the ignition coil. The instructions for each chainsaw model specify the optimal gap between these elements. In most cases this is between 0.2 and 0.4 mm. Because the flywheel of the tool is round, it is not possible to use a car feeler gauge to adjust the gap. It is best to use a special template in the form of a gasket. However, it is not so easy to find it. Therefore, many experts recommend using a cut strip from a plastic bottle as a template.

Adjusting the ignition of the chainsaw is quite simple;

- To begin with, we unscrew the bolts fixing the ignition system;

- Place a plastic bottle plate between the coil and flywheel;

- Tighten the bolts fully.

Design and principle of operation of the household chainsaw ignition system

Every chainsaw that runs on a gasoline engine is necessarily equipped with an ignition system. The main function of this unit is to ignite the fuel inside the cylinder in time. To do this, the chainsaw‘s ignition system creates an electrical discharge that pierces the space between the electrodes of the regular plugs. The correctness and efficiency of a chainsaw‘s engine depends largely on the serviceability of this component. Because of this, special attention needs to be paid to checking this important part of the tool.

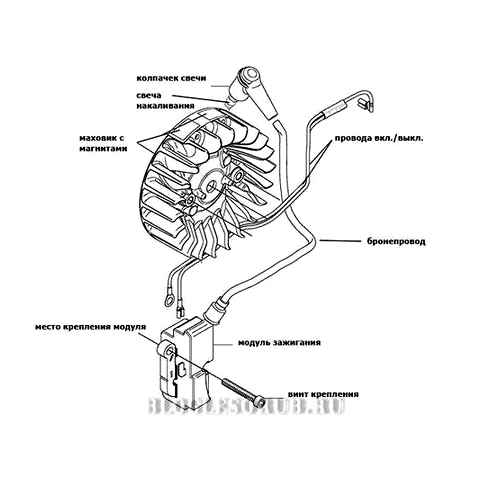

The electronic ignition of the household chainsaw as standard consists of a number of the following parts:

Magneto is a separate type of alternator that works with alternating current. When it works, it creates electrical energy and delivers it to the chainsaw‘s spark plug. The magneto device includes an inductor coil, on which a fixed winding is wound. It also contains a permanent magnet attached to the flywheel. When the chainsaw is running, the flywheel turns simultaneously with the engine crankshaft.

At the right moment, a certain standard part of the device dilutes the available contacts. This leads to a sharp increase in voltage and spark between the electrodes of the factory spark plug.

This increases the risk of overheating the contacts. To exclude this, as well as oxidation of the wiring, the circuitry of the standard ignition system is equipped with a capacitor.

The ignition circuit of a chainsaw equipped with a non-contact base magneto is based on the action of the control coil. It acts as a voltage regulator. The electronic assembly of such an ignition system is supplemented by a capacitor, a diode and a thyristor. The latter is necessary for passing current with certain voltage parameters. During the opening of the thyristor, the capacitor begins to discharge, thereby creating current within the turns of the primary winding.

How to set the ignition advance angle

The ignition system in the car is characterized by a high degree of sensitivity, and it is enough to remove the distributor of ignition (tramler) once, so that to reset all factory options. After such an intervention the engine begins to work improperly, and in some cases may even finish starting. For many motorists very much alive question, how to correctly align the ignition, because every time drive the car in the service is not very comfortable. At the same time you can do it without the help of others, it is enough once to understand the correct method of action. Indeed, for example, incorrectly set the ignition advance angle can lead to malfunctions in the ignition system and as a consequence, such dilemmas as: the loss of speed, the formation of shots when the engine runs. This situation is often seen after the work of an inexperienced craftsman in the service, or independent attempts to put the ignition.

Mesh There are only two problems with this element:

To determine the cause of the malfunction, unscrew the fuel filter cap to remove the strainer. If it just has dirt accumulated on it, a gasoline wash or purge will help.

Be sure to install a new filter if there is any visible damage. There may also be damage to the fuel line (check this item during repair).

The carburetor starter will not work in most cases due to clogs. Use acetone or the same gasoline for washing.

Blowing out carburetor parts with clogged air is an acceptable and convenient repair practice.

How to Properly Ignite Your Lawnmower

No matter what kind of equipment, and especially gardening equipment that operates in quite difficult any conditions, it asks for maintenance. Even a regular and small service it significantly increases the life of this equipment, and the work itself makes more ordinary and straightforward. And the engines start like clockwork and run smoothly without rattling or rattle.

This little service own equipment provides her owner, without the need to take it in a special service. Using this article as an example, I will discuss the necessary work that needs to be done on a gasoline lawnmower. With other gasoline mowers, our client will be about the same.

After the last season and wintering in a cool shed, the lawnmower needs to be cleaned and lubricated. The external cleaning was made in the fall, before storage, at the same time need to spend it more meticulously and prepare the lawnmower to the battle with grass and weeds.

First of all, you need to remove the protective guards from the gasoline lawnmower motor. This will provide easier access to the main components and make the work easier. Also, we can look around the starter unit, remove dust, particles of dry grass and other debris that interfere with the normal cooling of the motor. It is no secret that the cleanliness of the motor affects its quality.

The motor cover (in my model MTD SP 48) is attached with 4 screws ( pos. 1 in the photo). We pass the starter handle through the gap and remove the cover.

Now our firm can remove the starter unit and gain access to the main nodes of the motor. For this purpose, unscrew the 3 screws that secure both the starter starter and the flywheel fan cowling.

The starter carefully cleaned from debris and examine the starter rope. If it is damaged, it will have to be replaced with a new one by disassembling the starter itself. There is a variant to return light “fluffiness” of a cable with some elastic glue (rubber, PVA). Т.е. one that would glue the lint to each other, but the adhesive place remains elastic.

How to set the ignition?

After removing the fan cowl thoroughly clean the cowl and fan blades from debris with a stiff brush with a long-natured pile. Now let’s move on to the engine components.

The ignition system of the lawnmower is arranged as follows. In the flywheel of the motor there is a permanent magnet. When it “flies” past the magneto poles (pos. 4.5 in the photo), magnetic flux is closed and the electromotive force is induced in the magneto coil. By means of the electrical circuit, the impulse is shortened in time and a strong impulse is formed, sufficient to electronically breakdown the spark plug gap (pos.1)

Specifically speaking, the quality of the spark and provides the ease of starting the lawnmower motor. That’s why we do these operations.

At first unscrew the spark plug and inspect it. If in the last season mower had to work well, it is better to change it at all to the newest, to sell if the ancient still looks decently. The new one will be better from now on. Obviously the gap between the electrodes of the spark plug must be checked beforehand. Normally set it by bending the L-shaped electrode to 0.5. 0.6 mm, already. Otherwise, the magneto power may not be enough, and the spark will be as they call it weak or it will not be at all.

Now let’s take care of the magneto. If the lawnmower started without much effort before, it is better to clean it and check the cable. In the case of earlier problems, check the gap between the magneto and flywheel. The smaller it is, the better the spark. But you can not press the magneto to the flywheel against the flywheel. There is a common method of checking and setting such a gap. We take dural beer can and cut a strip from it. Loosen the magneto and put a strip of aluminium between the magneto pole and the flywheel. Therefore, with the help of pliers we take out a strip. I’ve used this method many times and it always gave a positive result.

BriggsStratton 450 small repair

Now let’s look at the brake system. (pos.3 in the picture). It’s designed to sharply stop the motor when it’s turned off. The brake shoe is pressed against the flywheel of the engine, at the same time the ignition wire is shorted to the common ground.

Appreciated by women, and the pad and flywheel are made to tinker unscratched. If necessary replace or adjust the brake shoes. Clean and lubricate cable and spring of brake mechanism. It is a good idea to use a can of grease.

Change the oil in the engine crankcase. It needs to be created according to the gasoline and lawnmower manual, but not less often than once a season, even if you mow a little. Because oil oxidizes and its lubricating properties deteriorate.

To drain the old oil, the lawnmower is tilted toward the drainage hole (item 1 in the photo), placing a log or something else under the wheels. If you want to be that the old oil does not drain into the protective casing, from a plastic bottle cut a small groove where the old oil will drain into a suitable container without soiling the casing. When the oil has run out, the hole is closed and new oil is poured through the oil filler neck until the correct level is reached. You should use the oil with the manufacturer’s recommended viscosity. As a rule it is 10W40 for 4-stroke engines. It makes no sense to use more watery and expensive oils, because the engine has no oil pump and the lubrication is done by an oil mist. And the lawnmower is operated at positive temperatures. expensive oils reveal their properties only in extreme situations.

How to fix a bad Stihl, Dolmar, Husqvarna chainsaw Bosch ignition on the cheap!!

All guards are assembled and installed in the reverse order.

The final step of the “routine inspection” is the knife inspection. There are mutually exclusive views on various forums as to whether or not to sharpen them. I am a “don’t sharpen” supporter. Appreciated by women, if there are bumps and kinks left by stones that you tried to mow, they must be removed. But it doesn’t make any sense to sharpen the edge to razor sharpness. And the reasoning here is. First, for example, a line for grass trimmer trimmer is generally round. And that’s okay, it cuts the grass just fine. Secondly, the grass itself is better when it’s not cut, but plucked. The cut tip usually turns yellow and withers. And the plucked tip quickly overgrows and heals the wound. And another thing, no matter how much you sharpen your knives, in half an hour they will go back to their professional, normal working condition. Т.е. it will be a metal edge with a 0.5 mm rounding. In this condition they will work for a very long time. The knife cuts the grass with its force of impact, its inertia, not its sharpness. Therefore with a knife to remove only the more conspicuous burrs ratfilm or abrasive bar, it will be enough.

Why do I need to adjust the ignition

In some cases when the engine is not running, it will be necessary to control the ignition. Of course, you must first check that the spark plug and the high voltage cable are working properly with the plug.

Ignition control on a two-stroke engine is necessary to ensure timely ignition of fuel in the engine combustion chamber. Below is a diagram from which you can understand how an internal combustion engine works.

The spark in the spark plug should appear when the piston is compressed when it reaches TDC a little. When the piston passes TDC, the fuel mixture is ignited, causing the piston to drop with the energy of the explosion.

Consequently, if for any reason (mainly due to a shift of the flywheel on the shaft relative to its original position) the fuel is ignited before the piston has passed TDC, it goes back and the crankshaft rotates in the opposite direction. This movement can damage the starter assembly, cut the starter cord, etc. Д. In this case it is an early ignition of fuel.

It can also be late ignition on the trimmer: after compression of unburned fuel, the piston lowers and a spark appears. In this case, the engine will either not start or significantly lose power and does not gain speed.

How to set the ignition on the trimmer

It is not uncommon for owners of gasoline-powered scythes to face the fact that the ignition does not work on their technique. In most cases, the problem is really in this node. To correct it, you need to adjust the ignition on the trimmer. But at the same time, it is not uncommon that the ignition coil is serviceable, and the breakdown should be sought elsewhere. The ignition system is arranged similarly on four-stroke and two-stroke internal combustion engines, so the correction of malfunctions of this node is performed in a similar way. In addition, the equipment of different brands has almost the same design of this most important component of the tool, which means that the adjustment process will be identical for trimmers “Union” or “Prorab”, as well as for Huter or samples of other brands.

The role of the gearbox is to transmit the torque from the motor shaft to the cutting tool via 2 toothed gears with different numbers of teeth. The torque is transmitted at an angle of 300. The speed of the lower saw blade is 1.4 times the engine speed. Gears must be clean and lubricated. There is a hole at the top under the screw for the oil supply to the teeth.

First remove earth and grass where the plug closes the hole. Unscrew the plug using the tool supplied with the saw. We use grease from a tube. You can choose either the manufacturer’s original grease or well-known, high-quality compositions, such as Oleo-Mas, Lithol.24, Azmol 158. Open the protective layer of the tube and put the tool on its side. Slowly turn the knife and squeeze the grease into the gear housing. The gears, turning, spread the compound with their teeth over the entire surface. The grease can also be applied with a special grease gun.

Too little or too much grease can cause the gearbox to heat up. Audible knocking and backlash signal destruction of bearing or ingress of dirt because of damaged dust covers. Bearings replacement must be done with a puller, not with heat method.

If the Geareducer wobbles and rides on the boom, you need to replace the housing, or temporarily clamp the assembly to secure it to the pipe. If the blade stops turning, it means that the gears don’t mesh. the teeth are worn or splintered. It will be necessary to replace the pair with a complete disassembly of the assembly.

When replacing the gearbox, a new assembly must be selected, guided by:

How to determine early or late ignition of the car engine

The operating principle of every internal combustion engine in automobiles is based on the use of energy released through the dynamic expansion of the ignited fuel mixture.Moment of fuel ignition in the cylinder (cylinders) affects the performance of the engine, but also whether it will start at all.It is the timing of fuel mixture ignition that is the essence of the definitions of “early” and “late” ignition. Let’s take a closer look at how the ignition timing affects the operation of the internal combustion engine, and how to determine early or late ignition by the nature of engine operation.

Stability, engine performance, fuel economy, etc., depends on a properly aligned and smoothly functioning ignition system.д. the air-fuel mixture in four-stroke engines should ignite at the end of the compression stroke, just before the piston reaches the top dead center. This ignition timing is due to the fact that the mixture needs a certain amount of time for combustion, after which the energy of the expanding gases pushes the piston down and the working stroke begins.

Late or early ignition should be understood as a delay or advance of the ignition system in relation to the position of the piston in the cylinder. In other words, the spark spark plug forms and ignites the fuel-air mixture not at the optimal moment of the piston approaching TDC, but before or after that moment. This phenomenon is called early or late ignition. For this reason, the owners of vehicles, which have the possibility to adjust the ignition timing (advance angle of ignition) independently, often face the necessity of ignition adjustment.

Algorithm of ignition adjustment

The ignition on the trimmer is adjusted quite simply.

-

Remove the cover from the motor by loosening all the bolts holding it in place. For example, on the Patriot (Patriot) PT 2540 chain saw, to remove the cover, you will need to unscrew the air filter housing, and a flat screwdriver to remove it from the latches. The plastic housing is then easily removable.