Converting a screwdriver to mains power: 5 ways Converting a screwdriver to mains power with your own hands. Power supply options. Required materials and tools. How to remake a homemade power supply unit, purchased unit, laptop charger, computer power supply and other options.

How to do it yourself

Before remaking a screwdriver, it is necessary to clearly determine what power and what voltage the tool needs to work. From this it will be necessary to proceed.

Then the tool body is opened. The two halves of the case can be fastened with screws or with glue. A knife can be very useful when disassembling.

After opening the case, a power supply or a wire is inserted inside, the contacts of which must be soldered to the charger. Soldering should be as effective as possible, using special solutions.

The other end of the wire must be designed for power supply. So there should be a fork. It is recommended to make a hole in the housing in advance, through which the cable will pass.

A homemade power supply can be obtained in several ways. In any case, you will get a full-fledged tool that can be used to perform work after connecting to the network. It is advisable to pre-prepare a diagram that will help you avoid mistakes when creating a block.

Required materials and tools

Materials and tools for reworking a screwdriver completely depend on the type of tool and the type of power source, as well as its features. But to summarize, there are several main tools:

- Screwdrivers;

- Pliers;

- Knife;

- Insulating materials;

- Cable for supplying electricity;

- Soldering iron and soldering materials;

- Any case for the future power supply.

Transformer

common power supplies that have proven to be reliable and efficient in many areas. The device consists of a step-down transformer and a rectifier through which the reduced voltage passes. The rectifiers vary depending on the number of diodes used.

Such elements are easy to manufacture, cheap and reliable. Therefore, they are often preferred. They provide stable voltage without interference with high maximum power. But there are also several disadvantages. The main disadvantage is bulkiness, with much lower efficiency than pulsed sources. This fact requires the selection of a power supply for the screwdriver with a power greater than that required by the tool. Since part of the capacity will go to side processes.

Screwdriver device

This mechanism consists of the following parts:

- DC motor. It has the shape of a cylinder; instead of the field winding, there are permanent magnets in the housing. This simplifies the design and provides sufficient torque at low revs. The drive (sun) gear of the planetary gear is put on the electric motor shaft;

- Reversible speed controller. The adjustment circuit is assembled on a PWM controller and a field-effect transistor. The reverse is carried out by switching the polarity of the power supply to the motor brushes;

- Planetary reductor. Made in a separate building. It got its name from its similarity to the solar system. Consists of a ring gear, a central (sun) gear, satellites and a carrier. The ring gear transmits the force through the spring loaded load regulator balls. There are models with two-speed gearboxes. Increased speed is enabled when using the device as a drill;

- Rotary force limiting mechanism. Serves to limit the force when tightening screws. Transmits torque through balls pressed by an adjustable spring;

- Removable battery. Consists of separate elements in one body. The voltage in different models ranges from 9 to 18 volts.

Battery cell types

These devices use elements of different types and voltages, each of which has its own advantages and disadvantages.

The most common nickel-cadmium (Ni Cd) voltage 1.2V.

Advantages:

- Low price;

- Stored in a discharged state.

Disadvantages:

- Have a memory effect;

- High self-discharge;

- Small capacity;

- Small number of charge / discharge cycles.

advanced 1.2V nickel metal hydride (Ni-MH).

Advantages:

- Lower memory effect and self-discharge;

- Large capacity and number of charge / discharge cycles.

Disadvantages:

- Higher price;

- Do not tolerate low temperatures and storage in a discharged state.

The most advanced lithium-ion (Li-Ion) 3.6V.

Advantages:

- Lack of memory effect;

- Very low self-discharge current;

- High specific capacity, allowing to reduce the weight and dimensions of the device;

- The number of charge / discharge cycles many times higher than other types of batteries.

Disadvantages:

- High price;

- Loss of capacity three years after manufacture.

Screwdriver battery design

The battery device does not depend on the brand. In all devices, the design of the batteries is similar and differs in appearance, body and contacts.

The body contains several elements connected in series. Their number depends on the voltage of each cell and the battery as a whole. When using the most common nickel-cadmium cells with a voltage of 1.2V, 10 pieces are needed to power a 12V device. Battery capacity is indicated in ampere-hours.

DIY screwdriver alteration

Consider the option with an external power supply.

Battery case power supply

Mobility remains, you are limited only by the length of the network cable. The only problem is how to squeeze a sufficiently powerful transformer into a small case.

We recall Ohm’s law again, and understand that a powerful 220 volt electric motor can be compact.

Using a power supply from a personal computer

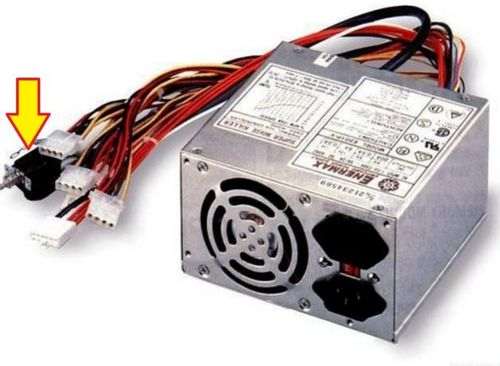

On the radio market, you can purchase an old power supply from a personal computer for a small cost. We need a variant of the AT format, which had to be turned off with the key after exiting the operating system.

Experienced users remember such system blocks. The advantage of such a power supply is also that it indicates an honest power. If it says 300W, it means you can safely remove 15-16 amperes from the 12-volt output (again referring to Ohm’s law). This is enough to power an average screwdriver.

Such blocks have a power button in the kit. Another advantage is the presence of a cooling fan and an advanced overload protection system.

If you will hide the power supply in a beautiful case, do not forget to leave a hole for ventilation.

The connection is very simple. Black wire (-), yellow wire (12V).

Limitations A screwdriver with a supply voltage higher than 14 volts will not work.

DIY screwdriver from the network

Required tools

Tester

- A network screwdriver what is the advantage of such an assistant?Choosing a network screwdriver what to look for?How to safely use a mains screwdriver?How to make a screwdriver mastering an electrician

How to make a screwdriver from the network

The mains screwdriver is the dream of many DIYers. In principle, it happens that in a home workshop there is no need for a cordless tool. You can have access to the outlet at any time. Of course, it’s convenient to have a cordless screwdriver in your hands. But when you work, you hold in your hands, in addition to the tool itself, also a battery. And it will be harder.

Also, batteries often break, break. And since on sale you are unlikely to buy a battery separately from a screwdriver, you have to puzzle over how you can provide your screwdriver with the necessary power from the outlet, bypassing battery devices.