Manual router: step by step instructions

If, when working with wood, you have the task of cutting a groove or a circle, you should not go and buy an expensive router. Having shown ingenuity, you can easily solve this problem and turn a screwdriver into a manual router by creating a lower frame with your own hands – a structure that would hold the tool vertically. Production attachments for milling with screwdrivers (drills) are on sale, but their purchase is not always financially justified.

The most readily available material at hand for a home craftsman is plywood and wooden blocks. Here we will make the attachment frame for milling from them, following the step-by-step instructions:

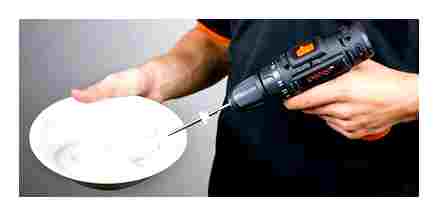

- Let’s make the bottom of the bed. Take plywood with a thickness of 8 mm and cut out a ring from it with an outer diameter of 10 cm, with an inner diameter of 5 cm. For this work we use a screwdriver with a “crown” for wood.

- On the sides of this ring, screw two wooden bars 4x2x10 cm with self-tapping screws. Put the structure made with the bars up. It will resemble a stool with its legs up..

- Let’s make the top of the bed. Cut another ring out of plywood with an outer diameter of 9 cm, and an inner one about 4.5 cm (to fit the size of the screwdriver body).

- We fasten the upper part of the bed with self-tapping screws to the bars with the lower part.

- We put the attachment-frame on the screwdriver body. It fits snugly into the round hole in the top of the bed.

- Insert the required cutter into the chuck and adjust the cutter cut. We tighten the cartridge.

The manual router is ready. You can get to work!

The self-made design of the milling attachment described above – the bed for the screwdriver allows you to keep the tool off-weight and strictly vertical. And the lower part of the bed serves as a supporting function when performing milling work.

Electric snowmobile

How much fun winter days bring to children! Skis, skates, sleds. How many times do kids ask adults to ride them on a sled? It is difficult to deny children such a pleasure. Home craftsmen approached this issue more thoroughly and made the sled “self-propelled”.

All that is needed for this is a source of torque. This source, or rather the base, will be a screwdriver with a working battery.

First, the iron construction of the “sleigh” itself is selected. It can be a real sled with steering control. Or maybe homemade products that are installed on frames and also have a handlebar, sometimes a bicycle one. But be sure to install a handle on the steering wheel, which will serve to turn the engine on and off. Outwardly, it will look like a brake handle on a sports bike..

Since home craftsmen come up with different designs of snowmobiles, the systems for attaching a screwdriver to an iron platform are also different. Only by generalizing it is possible to bring together the principle of installation and action, which looks like this. On the back of the sled, a wheel is installed using a special metal structure, and a screwdriver above it. In fact, a screwdriver gives a torque to the wheel through a system of two sprockets and a chain. The screwdriver shaft rotates the drive sprocket. The sprocket transmits the rotational motion through the chain to a second sprocket that is mounted on the wheel. Thus, the screwdriver makes the wheel turn and push the sled..

It remains only to bring the control system to the steering wheel. The control is a cable system, one end of which is connected to the power button of the screwdriver, the other is attached to the handle on the steering wheel.

By squeezing and squeezing the handle, we turn on and off the screwdriver mechanism.

Of course, it will take effort and time to cope with this kind of work. Purchase a sled or base material, the cordless screwdriver itself. But the efforts that you make will more than pay off with childish joy and those emotions that are not described in words and are not calculated in monetary terms..

Electric scooter and electric bike

It is difficult to deny a child the pleasure of riding a scooter. But what will be the surprise and happiness when he sees this scooter in an improved, or rather in a “self-propelled” form. No physical effort is required to ride. Only a smooth road and balanced movement.

So how do you make an electric scooter with your own hands, while spending a little money? The options may vary. They are united only by the fact that the source of movement, the motor is a screwdriver.

The structural part can be made individually, from an old overcooked bicycle with an extended handlebar or from a scooter. But the most important thing in an electric scooter is the propulsion part..

Let’s summarize the principle of its operation. There is a leading sprocket, inside of which the rod is hammered. This rod is installed in the chuck of the screwdriver.

The screwdriver turns the drive sprocket, which, through the chain, transfers rotation to the second sprocket mounted on the wheel. What could be easier? How to attach a screwdriver to a bicycle, each craftsman decides differently. It all depends on the possibilities and imagination.

The on-off system is displayed on the steering wheel. Many different solutions have been invented for this: cable systems, hydraulics from a hose and two syringes. Everything in order to turn on or off the screwdriver with a handle or a button on the steering wheel. It makes no sense to list those and delve into their technical features, let it remain the prerogative of motorists..

Circular saw or angle grinder

The design of the screwdriver allows you to turn it into a circular saw (angle grinder). However, due to the low power of the screwdriver, this “circular saw” is rarely used for small jobs – to cut fiberglass reinforcement, a steel chain or a drill stuck in the ceiling for drilling concrete slabs, steel strips of small thickness.

A bolt, nut and two washers allow you to clamp a small disc for metalworking – that’s all it takes to turn a screwdriver into an angle grinder.

Of course, such an invention has the right to life, especially when the master is not able to afford the entire range of industrial cutting tools..

Electric car

How to stay indifferent to a passing small car? Such “homemade transport” will interest both adults and children.

What kind of cars do not create the talented hands of our craftsmen. They use PVC pipes, gears from motorcycles, wheels from a garden wheelbarrow, frames from a bicycle. Amazingly, all these not very necessary parts turn into a wonderful “adult” toy.

There are various designs – three-wheeled, four-wheeled, made of metal, wood, plastic. The driving mechanism of all these little cars has the same tool – a screwdriver with a battery..

The screwdriver transmits torque to the rear-wheel drive wheels by means of a chain drive (a large sprocket on the wheel and a small drive sprocket on the screwdriver shaft, a chain from a bicycle). The screwdriver turns the leading small sprocket, through the chain, the twisting movement is transmitted to the large sprocket, and from it to the rear-wheel drive wheel. Thus, the rear wheels push the front wheels to move and the car moves..

On-off control is output to the pedal by means of a button, which is pressed by the pedal lever. A small foot pressure is enough – the button is pressed and the “vehicle” is set in motion!

Bench drilling machine

A bench drill is essential for many craftsmen in garages and workshops to accurately drill holes in wood, metal, plastic, etc..

Talented craftsmen do not spend money on purchasing production equipment. It takes a little effort and engineering skills, ingenuity and desire. As a result, you can get a solid design of a tabletop drilling machine from scrap materials..

The basis of the tool can be a gearbox from a screwdriver. The rod (rack) of the bed can be made by craftsmen from various materials. Everything goes into action: metal rods, typewriter carriages, wooden structures.

The mechanism for raising and lowering the gearbox vertically is also performed in a variety of ways. Even the springs from the expander are not superfluous.

To fasten the gearbox to the bed rod, make homemade clamps from textolite, or use suitable parts from other devices or even cars.

Each design is individual and interesting in its own way. The main thing is that the task that is set before the drilling machine is carried out with the utmost precision and at the proper quality level..

Do not use broken and old screwdrivers for the machine, since the backlash in the chuck does not allow you to achieve the desired hole diameter.

Wind generator

Using a screwdriver motor, you can design a small wind generator for a summer cottage or a personal plot, and be independent of the power supply. And also he will help with a power outage in the network..

It will take a little time to create a wind generator. The rotor part is removed from the screwdriver. The motor shaft is braced to a plastic plate. We attach the flywheel to the end gear with bolts and attach four blades made of PVC pipe to it. For the case, you can use a tea can, carefully plugging the cracks with a sealant. The wind generator is ready to provide you with electricity that costs you nothing.

5 ways to use a screwdriver at home in a non-standard way

The cordless screwdriver really is almost the main tool in every home. With its help, tasks are performed around the house, in the garden, in the garage, etc. It is also much more convenient than network models, since it does not require constant connection to the mains. In this case, the “charge-discharge” cycle is not eternal, whatever the rating of the device.

The man is in the kitchen. it is strong!

Did you know that a screwdriver can perform much more functions than you expected from it? Its true purpose, of course, is to drill holes and tighten fasteners. But the most creative owners have come up with a whole list of other uses for this device..

Screwdriver mixer

A real man not only perfectly owns both of these devices, but can also make one of the other. In this case, the time spent will be no more than five minutes. There are some tips.

All that is required for such a “modernization”. remove the drill chuck and insert the whisk from the mixer into the vacant socket. If the whisk is not at hand, an ordinary fork will help out..

We make an electric grinder

This rework will be a real salvation when your sander’s blades are hopelessly dull. So, to create an electric grinder from a screwdriver, you will need:

- old hand grinder;

- electric screwdriver;

- metal bolt without a head with a hexagonal top.

Next, you just need to get the shaft out of the old grinder and insert it into the screwdriver along with the screw. The result is a really powerful high-speed unit..

Universal tool

An ordinary screwdriver will become a real find not only when performing your direct duties – drilling holes and tightening fasteners, but for many other tasks. Let’s take a closer look at some of them..

Sharpening knives with a screwdriver

How to sharpen a knife if there is no familiar bar and show the class? In this case, you can improvise and use a regular drill / screwdriver. To sharpen a knife with a screwdriver, you also need a glue gun and sandpaper.

- cut a small strip of sandpaper and attach it to the drill sleeve with a glue gun;

- put the screwdriver on a flat surface and fix it with a vise;

- turn on the tool at minimum speed and run several times with the side of the knife on the sandpaper;

- turn the knife over and slide it over the rotating sleeve a few more times.

Drill attachment for grinding

Construction work often requires specialized tools. But in the case of rare use, the acquisition of unnecessary devices is unprofitable. In this case, your screwdriver will again become your faithful assistant, or rather, special drill bits, expanding the capabilities of this tool..

The most popular is the grinding attachment for the drill. With its help, you can perform a wide range of related work.

According to the shape, the following types of grinding attachments are distinguished:

- cup – to remove old coating and corrosion;

- disc and plate – differ from the cup in the direction of the bristles. They have Velcro, which allow you to fix the abrasive material on them. The most convenient are plate nozzles, since they allow you to adjust the angle of inclination and follow the contours of the product;

- petal – with their help you can handle holes and hard-to-reach places, since the product can take any shape;

- end – for working with glass, metal and wood.

We cut metal with a screwdriver

No matter how it sounds, you can cut metal with a screwdriver. For this, a special scissor attachment is used for cutting metal. The advantages of using such a nozzle over manual scissors are:

- minimum cutting radius;

- the possibility of obtaining round holes;

- high-quality edge that does not require further processing;

- elimination of deformations;

- saving.

DIY Powerful Electric screwdriver | N20 Gear Motor

The disadvantages in this case are noise during operation, limitation on the thickness of the processed materials, difficulty in performing an even cut.

In general, such a cricket nozzle will be the best solution for a home craftsman..

Safety engineering

When performing any work with a screwdriver, do not ignore safety precautions:

- to avoid electric shock, do not touch grounded objects while the tool is running;

- check the drilling sites for hidden wiring;

- do not touch the rotating parts of the tool and do not try to stop them manually;

- connect the tool only to a network with a suitable voltage;

- do not turn on the tool until it comes into contact with the material;

- immediately before work, make sure the workpiece is motionless;

- do not wear loose clothing or jewelry before work. they can get caught in the moving parts of the tool.

Remember that following simple safety rules will save not only your health, but also your life..

How to remake a screwdriver for an ice screw at home

Ice screw – a device required to create a large number of holes in a thick layer of ice

Battery requirements for a screwdriver

The quality work of an ice screw is largely determined by the battery. It must have a high capacity and withstand low temperatures.

Important! It is recommended to have two batteries when preparing for fishing. Main and spare, in case of discharge of the first.

There are several types of batteries on the market.

- Lithium-ion. They feature high charging speed, light weight and large capacity. The main disadvantage is sensitivity to low temperatures and high price.

- Nickel-cadmium. The main advantage is stable operation in the cold. They are large in size, small in capacity.

- Metal hydride. Capacious batteries, tolerate low temperatures well.

Metal hydride batteries should be purchased. They better meet the needs of the tool.

What is better screwdriver or wrench

The screwdriver most closely matches the rework requirement, but some anglers use a screwdriver. This is due to a number of advantages of the tool.

- The impact wrench has a more massive body.

- The impact wrench is a direct alternative to the screwdriver.

- No difficulty in making an adapter.

In the absence of screwdrivers, anglers can also alter a drill or chainsaw. But they require work skills and are not always safe..

Capacious metal hydride batteries are better suited for making an ice screw.

18V screwdrivers

There is a large selection of 18V screwdrivers on the market that meet the price-quality ratio.

How to make Powerful Electric Screwdriver

- Makita 8414 DWAE. The device weighs less than 3 kilograms. Torque 63 Nm. The set includes 2 batteries.

- Makita 8434 DWFE. Differs in small size. The torque is 64 Nm.

- Hitachi DS18DSFL. A quality screwdriver with a lithium-ion battery. Battery capacity of only 1.5 Amps.

- Bosch GSR 18 VE-2-Li. The kit includes 3 Amp lithium-ion batteries. Weight no more than 3 kilograms.

- Bosch GSR 18-2. It weighs 2 kilograms. Battery type – nickel-cadmium.

Before buying, you should study the information about the top models and take into account their characteristics.

Fitting a screwdriver to an ice screw

Screwdriver-adapter-ice ax – tool creation sequence

The adapters are equipped with a shaft on the side of the drill and a hex head in which the cutting part is clamped. The average shaft length is 6.8 centimeters, the distance from the screw attachment point to the end is 2.6 centimeters. The correct connection diagram has a sequence of screwdriver-adapter-ice ax.

Note! Preference should be given to adapters with handles and one stop. You should not take constructively complicated options..

Features of choosing a screwdriver

Before making an ice screw from a screwdriver with your own hands, you need to choose a tool that matches the operating conditions in terms of characteristics.

The main selection parameters are:

- resistance of the battery to frost;

- voltage (18 volts);

- torque – the more it is, the better;

- battery capacity – the higher this parameter, the longer the ice screw works without recharging;

- ergonomics – comfortable grip and well-thought-out body shapes provide a secure grip and ease of use.

The choice of a screwdriver is made according to the technical characteristics and type of battery

Advantage of an ice screw for winter fishing

In winter, most water bodies freeze over. A thin crust can be cut, but an ice screw should be used for thicker layers. If there is only one hole, then the device can be manual, but for successful fishing it is necessary to make at least 10 holes. The best solution to reduce labor costs is to use ice augers..

Required materials and tools

Anyone who has minimal experience in working with metal is capable of building such a drill for winter fishing. For this you will need:

- Normal manual ice screw;

- Angle Grinder;

- A cylindrical metal blank with a diameter equal to or slightly less than the thickness of the drill pipe;

- A metal disc with a diameter greater than the diameter of the auger;

- Screwdriver;

- 8mm threaded bolts and nuts.

The cordless screwdriver must operate at a voltage of at least 18 V, and the torque is needed from 40 to 80 Nm. Often on one fishing trip you have to change the place several times, which means that the battery capacity should be about 3 A / h. For convenience, it is better to choose a screwdriver with an additional handle at the chuck. If it is not there, you will have to add it yourself.

How to make a screwdriver for an ice screw from a conventional screwdriver?

For avid fishermen, even the most severe winter cannot become an obstacle for their favorite hobby. It is impossible to imagine real winter fishing without an ice screw. But the screwdriver is usually not found in the equipment. But thanks to this power tool, you can significantly speed up the process of making a hole..

How to do it yourself

It is not difficult to make such a lotion for fishing with your own hands, although you will need turner skills. First of all, you need to cut off the handle from the ice screw – the auger with a straight shank should remain. At a distance of 2 cm from the cut, a through hole must be made across the pipe. A bolt of 8 mm should freely pass through it..

To fix the drill in the screwdriver chuck, you need to make a special adapter for their metal cylinder. The diameter of the blank should be adjusted so that it can effortlessly pass into the hole in the ice auger tube. Then, on one side, the same transverse bolt hole is made..

It is important to maintain the alignment of the holes. At the other end of the blank, you need to make a hex shank for the screwdriver chuck. It is better to entrust this to an experienced turner, but you can try to carve the hexagon yourself on a grinding wheel. It is unlikely that it will be possible to make the shank neat, but all the same, the lotion will have a positive effect on the speed of ice drilling.

Before inserting the adapter, it is advisable to supplement the ice drill with a drowning protection. This will require a metal disc to be secured above the auger. This will prevent the fishing tool from sinking into the hole..

You can now attach the adapter to the hole, but before testing it is best to sharpen the angle of the cutting edges. To do this, you just need to put a few washers under their mount. This approach will make it easier for the power tool to bite into the ice..

Throwing away the handle is completely optional. For it, you can make a fixation at the end of the pipe. With this approach, even if the screwdriver’s battery is discharged, the fisherman will still be able to make a hole in the traditional way..

How to make a generator?

A screwdriver with small improvements can be used as a generator, and much effort is not required:

- first, the battery is removed, a corresponding wire is connected to each terminal with crocodile clips and connected to the consuming device;

- before connecting, it is imperative to test the correct polarity of the connection using a multimeter;

- a hex key is clamped in the chuck, which is used when furniture is assembled; a comfortable handle is attached to it, since it will take a long time to generate current;

- current will be produced, but the voltage will be so low that it will only be enough to charge the mobile phone, yes, to illuminate with a small low-power LED lamp.

You can also use wind energy – this will already be called a wind generator. True, the disadvantage of such a circuit is also low voltage..

Unless it will be possible to install such a wind generator in a constant wind somewhere on the seashore or a lighthouse.

How to assemble an engraver?

The cordless version of the electric screwdriver or the mains-powered version easily turns into a device that is called “engraver”, “dremel”, “drill”, “mini-drill”, “straight grinder”. As with upgrading a screwdriver to a grinder, there are two ways to convert it:

- a special nozzle is purchased in retail chains;

- a homemade fixing device is used, suitable for the use of the dremel rig.

Drilling machine

In the manufacture of an amateur desktop drilling machine, you can also use the parts of a screwdriver, namely: a motor, a gearbox and a chuck. It is most practical to fix the drilling head (chuck) with two textolite clamps. It is important that all the holes of the clamps are on the same axis, distortions are unacceptable here. Limiting struts are made of bushings with an internal thread. Bushings are selected of the same size, exactly corresponding to the clearance of the clamps. Additionally, it will be necessary to make a textolite clamp with two nylon bosses, which is put on the bar. Then a wooden lever with a spring is installed, which is used to retract the drill head. Power is supplied from a 150-watt transformer, its output voltage should not exceed the characteristics of the units of the power tool used. You will also need to install a diode bridge and a capacitor..

How to upgrade equipment?

Winch

To a homemade electric motor from a screwdriver, as an addition, it is quite possible to make a homemade small winch for an anchor.

The assembly principle does not change, the drive mechanism is the same screwdriver, fixed on clamps with self-tapping screws. The cartridge is replaced by a reel with an anchor flexible cable or a strong rope, thrown over the block.

Reverse function is used to drop / raise the anchor.

Electric drill

The transformation of a screwdriver into a drill occurs with one wave of the hand, since these tools are largely interchangeable..

Although it is necessary to take into account certain nuances:

- the screwdriver’s planetary gearbox fails if a force is applied to the tool for which it was not designed: it was not originally planned to use it for drilling hard materials;

- as a rule, the power of its electric motor is lower than that of a drill.

If, on the contrary, the electric drill is planned to be used as a screwdriver, then you should be careful and remember that:

- the drill will quickly unscrew / tighten the nut or self-tapping screw;

- she will be able to screw the screw into a harder material.

There are also certain disadvantages:

- the size and weight of the drill is larger, it is not so convenient to work with it in narrow places;

- it is not possible to use a drill when assembling furniture and when working with thin plastic, drywall, etc.;

- the use of PPE (glasses, gloves) is necessary;

- due to the inconsistency of the design with the tasks set, the tool wears out more.

Next, see how to make a mini-drill from an old screwdriver.

What can be done from a screwdriver?

The screwdriver is a slightly transformed electric drill. It is quite suitable for creating the most primitive motor, drive, or even engine. In addition, this device easily turns into many completely unexpected things using the principle of its operation. A number of examples and non-standard ideas for its application can be cited..