Creating a machine for sawing wood

Here the corner is cut off two pieces of a piece (45×45 mm). precise dimensions should be viewed according to the dimensions of the angle grinder gear unit. In the corner, 12 mm holes are drilled (an angle grinder is screwed to them). If the factory bolts are too long, they can then be cut off. Sometimes, instead of bolted fasteners, studs are used, this does not in any way affect the quality of the connection. Often, the corners are welded, such a mount is the most reliable.

A special support is made for the lever, the unit is attached to it; for this, two pipe segments should be selected so that they enter one into the other with a small gap. And to make the markings more accurate, it is recommended to wrap the fragments with adhesive mounting tape, draw a mowing line with a marker. A cut is made along the mowing line, a pipe element with a smaller diameter should be smaller (1.8 cm). For the inner diameter, it will be necessary to find two bearings, which are inserted into a more massive pipe, then a pipe with a smaller diameter is inserted into a pipe of a larger diameter. Bearings are pressed on both sides.

A fastener is placed in the bearing, it is imperative to put a lock washer in the fastening bolts. After the pivot assembly is prepared, a small piece of the corner should be fixed.

The vertical mount for the swivel unit is made from a corner of 50×50 mm, while the segments must be of the same size. The corners are fixed with a clamp and cut.

Now you need to figure out how long the lever will be needed. an angle grinder will be mounted on it. A similar action is performed using the selection technology, while the parameters of the impeller should be taken into account. Often, parts are pre-laid out on a flat plane and analyzed, then the configuration and dimensions of the product become clear. The pipe is most often used square with a size of 18×18 mm.

The pendulum unit is easy to place on any plane. It can be a wooden table, which is sheathed with a metal sheet. rigid fastening is provided by welding two small fragments into which holes are drilled.

During installation, one of the main working moments is setting an angle of 90 degrees between the plane of the disc and the supporting surface (“base”). In that case, you should use a construction square, which is attached to the abrasive wheel (it is mounted on an angle grinder). For the welder, a fragment at an angle of 90 degrees is not difficult, it will take a little time.

An emphasis should also be made so that the workpiece is rigidly fixed during operation. Pressure is often placed on a flat surface, which provide a reliable fastening. After all the operations performed, a protective coating (casing) should be made. Consider the size of the disk here. Before starting work, an exact template for the future part should be cut out of cardboard.

The protective screen can be made from two gesture fragments. An aluminum corner is attached to one of the blanks, it will allow you to securely fix the protective screen, using the crossbar. Such accessories are necessary for normal operation, since the angle grinder is a tool of increased injury.

Small holes are made on the screen, the prepared fragment is fixed with nuts and bolts. The protective cover can be painted with oil paint, and if done correctly, it will serve for a long time and reliably protect the worker.

The base-stand for the machine is sometimes made of silicate or red brick.

Grinding machine for metal elements

There is another option, which will allow you to process metal parts. To do this, take profile pipes (2 pcs.), Attach them by welding to a rectangle made of steel sheet 5 mm thick. Holes are drilled in the uprights and in the lever, and the dimensions can only be determined empirically.

Consider the stages of work.

- The lever is attached.

- Spring is attached.

- Drilled holes for bolt fasteners.

- The rod is also drilled (the drill will fit 6mm).

- After preparatory work, the turbine can be mounted on the working plane.

For a more secure stop, an additional corner is screwed on. It is also possible to attach a small angle grinder to a metal strip (5 mm thick), while it is also reasonable to use a clamp fastening.

To remove dust during work, a dust collector is most often used. For an angle grinder, you can make an effective nozzle from a PVC container with a volume of 2-5 liters. A frame is made on the bottle with a marker, a rectangular hole is cut to the sides. The dust collector is attached to the turbine, an exhaust hose is mounted on the neck.

An exhaust device is necessary: it significantly helps in work when an angle grinder is used to clean various surfaces from old paint, insulation, rust, cement mortar. You can use various attachments with a metal mesh. These works are associated with the formation of a large amount of dust, so you should use personal protective equipment.

Manufacturers

The most common and popular attachments are cut-off wheels. Good discs for metal are produced by Makita and Bosch. The best diamond bits are produced by Hitachi (Japan). such discs are universal and can successfully cut any material.

Grinding attachments from the American DeWalt company are appreciated. They differ in the material from which they are made, can be: from a sponge, matter, felt.

For working with stone and metal, special peeling nozzles are used. The highest quality of them is considered to be the products of the DWT (Switzerland) and Interskol (Russia) companies. The products of the latter company stand out for their combination of price and quality. The named companies also produce good roughing discs, which are diamond-coated.

In addition, DWT manufactures high quality angle grinder attachments called roller cutters. They are used to remove old paint, cement, primer.

Fiolent produces a variety of very good quality turbine nozzles. for attachments from this manufacturer are low. “Fiolent” appeared on the market relatively recently, but has already managed to gain a good reputation and authority.

The company “Bort” from China (Bort) also makes good attachments for grinders. As you know, the products of Chinese manufacturers traditionally have a low price.

How to do it yourself?

Before doing, for example, any machine with the introduction of an angle grinder (the device is quite simple), it is recommended that you familiarize yourself with the schematic drawings, which can be found on the Internet or special literature. They will help you better understand the principle of the device of the grinders themselves, as well as with how the various attachments that may be required are made. The nodes will have to be selected empirically, focusing on the actual dimensions that are available in this particular turbine model. Such a unit can be ideal for cutting and facing various workpieces.

There are dozens of different attachments, which can be of very different sizes, so the parameters of the working elements should be selected when this particular model is in front of your eyes.

From the bike

Craftsmen often make a cutting machine from a piece of a bicycle frame and a turbine. Old Soviet-made bicycles are ideal for THESE purposes. But more modern ones are also suitable, the frames of which are made of strong metal with a wall thickness of 3.0-3.5 mm, which allows you to withstand heavy loads.

On the Internet or in special literature, you can see drawings for the implementation of vertical mounts, and pedals can be used as a swivel mechanism. I took the sample you like as a basis, you can independently bring a new drawing “to mind”.

It is optimal to use 12 mm reinforcement for THESE purposes.

The frame is freed from the steering wheel (you can cut off a fragment from it and use it as a handle). From the side of the fork, an element with a length of 12 centimeters is cut. The fork is shortened in accordance with the parameters of the impeller. Then you can start to mount it using a metal base (a piece of metal 5-6 mm thick).

The base of the machine is made with the introduction of a quadrangular fragment of chipboard (3 cm thick), which is sheathed with sheet metal. A vertical post is welded to it. Two rectangular pipes are cut (arbitrary size is chosen), they are welded at the corners of the future base at an angle of 90 degrees.

Insert a fragment of a bicycle “fork” into the vertical mount (which is already fixed on the “plate”). On the reverse side of the rack, a rudder element is fixed. A plate is also attached to the fork with the help of a quarrel, on which the impeller is held.

Finally, stop strips are attached to the base (they are made from a corner). The finished block is carefully sanded, painted with an anti-corrosion compound and enamel.

Making a pendulum saw

The pendulum saw is done as follows.

For a rigid attachment, brackets are suitable, with which you can fix the angle grinder. To make the device, you will need five identical pieces of metal reinforcement. They are welded to form a bracket-mount. A clamp-type mount is created that will fix the handle of the grinding head. A vertical support (“leg”) is attached to the front edge of the rods in order to be able to fix the bracket. The bracket is mounted on hinges, which makes it possible to rotate the assembly at any angle in relation to the work plane.

All About Angle Grinder Accessories

Angle grinder attachments greatly expand its functionality, they can be placed on impellers of any size. With the help of simple devices, you can make a cutting unit or a machine for cutting grooves (grooves in concrete), which will ensure the quality of work at the highest level. The need to purchase an expensive professional tool disappears, since a good job can be done with self-made improvised means.

Varieties of devices

Angle grinder attachments exist with a wide variety of functions:

- For smooth cutting;

- For grinding;

- For cutting bar and pipes with a diameter of 50 to 125 mm;

- For peeling old layers from surfaces;

- For cleaning and grinding;

- For polishing;

- Chain saw for cutting wood;

- For collecting and removing dust during operation.

Plywood

Plywood can be a reliable aid in the creation of equipment. From several sheets of plywood, fastened together, you can make a mounting table, its thickness should be at least 10 mm. And also plywood is ideal for creating a protective screen or casing. If the material is treated with a special primer, painted with metallic paint, then such a knot will be durable and will serve you for a long time. If plywood is treated with a primer in several layers (3-5), then He will not be afraid of changes in temperature and humidity. This material has a number of advantages:

- Low price;

- Good strength factor;

- Moisture resistance;

- Light weight.

Several sheets of plywood sheathed with sheet metal can withstand high mechanical stress. Such a base is reliable; rather massive working units can be attached to it. In this case, the equipment will weigh a little, it will be easy to transport it.

For how to make a do-it-yourself angle grinder stand, see the following.

Do-it-yourself wall chaser from an angle grinder

A groove is a groove that must be cut in a wall to lay an electrical wire or cable. The difficulty of this work lies in the fact that the groove must be of constant width and depth. Then the wire will fit evenly and less solution for the bookmark will be required.

A wall chaser is rarely used in practice, so it will be expensive to buy it for a home. But it can be made on the basis of an angle grinder. our favorite angle grinder.

The main task is to install two diamond discs on the shaft of an angle grinder with a distance of at least 1 cm:

- Install the first disc and fix it with a nut;

- Install the second disc and fix it with a nut;

- Measure the resulting distance between the disks;

- We install protection on the angle grinder;

- Checking the work.

But, if for some reason it is not possible to install two discs on the shaft, the strobe can also be cut using the usual method with one installed disc. You just have to cut a second parallel line.

Work with a wall chaser is carried out indoors. This creates a huge amount of dust. Even a respirator does NOT save from it. To eliminate this negative phenomenon, it is necessary to make a protective casing, which would cover both discs and have a branch pipe on top for connecting to a vacuum cleaner. There is a similar device on an electric jigsaw for collecting small sawdust.

Sometimes, lovers of the rational use of the tool adapt 2 or 4 rotating rollers to this casing. When the wall chaser moves along the wall surface, it will move on rollers, and not create additional loads on the hands.

To make a tool for a wide groove, it is necessary to make special bushings for mounting discs to the desired width. With such a wall chaser, you can make grooves for pipe laying.

But the protective casing will also need to be made wider. On the cover of the wall chaser for both wires and pipes, you must install the screw for adjusting the immersion of the cutting tool into the wall. In this case, the casing will consist of two parts connected by hinges and a submersion adjustment unit.

Milling cutter from angle grinder

Sometimes it becomes necessary to mill a hole or surface, but there is a familiar milling machine operator, and there is nowhere to look. But there is an angle grinder. an angle grinder. This is the solution to the problem. We choose a machine from two options. a movable machine and a movable table.

In the first case, we fixing the workpiece or material, which needs to be milled, and the angle grinder is attached in a vertical plane to the frame. On the frame there is the possibility of shifting the plate to which the angle grinder is attached to the left. right and forward. backward. In other words, we can move the angle grinder to the workpiece.

In another version, the angle grinder is rigidly fixed, and the workpiece moves by analogy left. right and forward. backward. These are the main directions for milling. For milling along the up and down axes.

Having chosen the version of the machine, you can start implementation. The only place that requires a turner is the cutter holder. It is turned from a hexagon of at least 16 mm, because the thread of the angle grinder is 14 mm. Collet type holder. It is easy to manufacture and does not have large beats. Regular chuck does worse.

The advantage of such a machine, like all machines based on an angle grinder, is that they are easily transformed back into an angle grinder. As a type of milling cutter from an angle grinder, you can make a drill.

What accessories for an angle grinder can be made by hand

The well-known angle grinder, with its cutting, grinding and cleaning capabilities, proved to be capable of several more functions. Expanding the functionality requires you to do some work with your own hands in order to get the necessary devices for work.

Angle grinder stand

This device is a small machine with which you can easily, safely and very accurately cut metal pipes, profiles or rods. It consists of a base or a small table attached to the ground or to a locksmith’s table.

The machine is assembled in a simple sequence:

- We install a hinge on the base;

- We weld the supporting pipe to the hinge;

- Lining to the pipe U-shaped plate for fastening the angle grinder;

- We put on a rubber handle on the supporting pipe;

- Install the disc and check its position.

As a result of simple work, we got a machine or stand for an angle grinder. The angle grinder can now swivel up and down on the part set for cutting. To lift the angle grinder up without loads, Install a spring on the pipe.

Two fixing corners must be installed on the table. At the base of one corner we make a groove for the bolt around the circumference. It will be needed when a pipe or profile needs to be cut at a certain angle. Then we install this corner with a slot at the same angle to the plane of the cutting disc angle grinder.

Parallel to the corner with the arc slot Install the corner, which can be moved to the part to fix it on the table. The pipe or profile will simply be nested between the two corners. This is enough for a fast and accurate cut.

Installed a supporting transverse metal bar on the machine table, you can clean the material using a steel brush mounted on an angle grinder shaft.

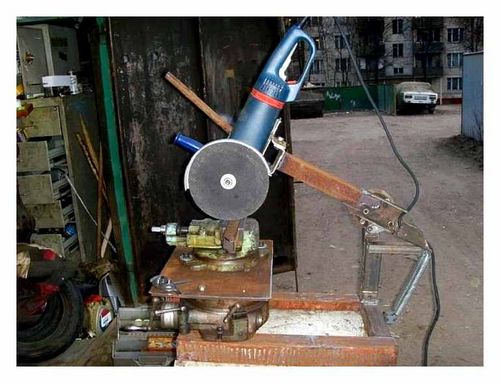

Simple cut-off machine

A cut-off machine based on an angle grinder can be made by hand in one day. For the machine, you need to choose a bed. a metal base plate. Fix the hinge on it. To the hinge Weld support frame with plate for attaching angle grinder.

Any suitable part can be used as a hinge. In this case, the hinge is made from the swivel hinges of a passenger car. The hinges have already served their time, but they fit the machine very well.

Pendulum saw

It is not difficult to make adaptations for an angle grinder with your own hands. It doesn’t even need blueprints. It is enough to know the principle that is incorporated in this or that machine. The pendulum saw based on the angle grinder is NOT an exception. This is the same cut-off machine, but its weight is distributed almost in half.

It is somewhat similar to a children’s swing. A frame is located on the movable sleeve, and an angle grinder is installed on it. Any weight in combination with a return spring can serve as a counterweight.

Attachments for angle grinders: tool improvement

The angle grinder has become widespread due to its variety of functionality. This type of tool is versatile, as it is capable of performing such work as cutting, grinding, cleaning. The functionality of this tool can be expanded, but this will require some adaptations. These are such devices for an angle grinder, which will make it possible to make a milling machine, a wall chaser, a cutting machine and others from a tool.

Milling cutter from angle grinder

The angle grinder can also be used as a router. It is important to take into account the fact that the tool must be able to be removed from a homemade device. To manufacture such a structure, you will need to fix an angle grinder under the made table (or workbench), and bring the tool shaft into the hole of the workbench using an adapter with a collet clamp for cutters. With the manufactured tool, you can carry out various woodwork, depending on the cutter used.

Angle grinder stand

Such a device for an angle grinder, like a rack, is not difficult to make with your own hands. Its manufacture will allow you to use the tool to perform more accurate sawing work on various types of materials. When making a cutting machine, you must perform the following tasks:

- Reliability of tool clamping.

- Reliable fixation of the tool in the upper position.

- Ensuring minimal deviations from the cutting plane.

Threaded connections are well suited for secure attachment of the angle grinder. Additionally, you should also worry about safety, so the tool should be equipped with a homemade casing.

For grinders for circles with a diameter of 115 mm to 150 mm, it is possible to attach them to the rack using clamps. Tools for wheel diameters over 150 mm Must be securely fastened Not only to the moving arm, but also to the work table or bed. To reduce vibrations and increase the cutting accuracy, it is recommended that the bed is rigidly fixed to a workbench or other base. Below is another version of the stand with a fixed angle grinder.

Circular from angle grinder

An angle grinder can be used to make a circular saw for working with wood. To do this, you will need to make a reliable bed or base, to which the tool will be attached.

If, in the manufacture of a cutting machine, the cutting tool must be above the work table, then when designing a milling unit and a circular, the opposite is true. The angle grinder should be placed under the worktop, from which a certain part of the disc exits through the corresponding hole. In addition, a ruler can be screwed to the tabletop, with the help of which a more accurate sawing of wood will be carried out.

What you need to make homemade angle grinder attachments

To make any device for an angle grinder with your own hands, first you need to decide on what materials for manufacturing are available. It is also necessary to decide what exactly should be made: a milling or cutting machine, a chasing cutter or a dust collector for working with a tool indoors.

For the manufacture of such devices, it is usually necessary to buy additional materials or parts, since absolutely any simple materials at hand will do. For the manufacture of some accessories, such as a dust cover, it is enough to use a plastic canister of oil or brake fluid. Using a tin can, you can design a hand mill for making coarse flour.

About homemade dust collector

A dust container or cover for an angle grinder can be made from an old aluminum saucepan, pieces of thin metal, or a plastic canister. The casing will be more reliable from the pan, but at the same time the plastic structure is much easier to make.

For the construction of a dust collection board, a galvanized letter is also suitable, which is required to be scolded based on the size of the existing tool. An important condition is the reliability of fastening such a homemade product to an angle grinder. In addition, the hole for collecting dust can be made with the most convenient angle of inclination, in contrast to purchased dust collectors.

Do-it-yourself pendulum cutting machine

For the manufacture of such adaptations from an angle grinder, such as a pendulum cut-off machine, it will be necessary to ensure the automatic return of the moving console to the reverse position. This is achieved by installing a special spring, rubber band or counterweight, which will automatically return the used angle grinder to its original position.

The production technology of such a machine is almost identical to the previous one. The difference lies in the addition of an auto-return mechanism of the moving part on which the angle grinder is fixed. This makes human labor easier.

Do-it-yourself wall chaser from an angle grinder

The angle grinder can be used to cut cuts in the wall. They are made so that wiring, pipes and other elements can be laid in them. When working with a stock angle grinder, it is very difficult to control the immersion depth of the disc. To solve this problem, you can make a special frame.

Such a frame is a sole with a stop, by means of which it is possible to move the tool along the wall with a uniform deepening, thus obtaining a groove of the required depth. When making such a Stroborez, pay attention to a protective cover and a special dust collector. You can use a bag as a dust collector, but it is more convenient to connect a hose from a vacuum cleaner. With its help, dust will be sucked out, making such work much more pleasant and dust-free.

Protractor for angle grinder

A protractor for an angle grinder is also called a rail cutter. For the manufacture of such a device, a metal profile or channel is most often taken. To design a protractor, it is required to build a structure from the corners of the metal, as shown in the photo below.

Now it remains only to fix the tool to the resulting product, resulting in a full-fledged protractor, through which you can adjust the cutting depth.

In conclusion, it should be noted that only the main types of devices are presented in the material. In fact, the angle grinder is such a versatile unit that ideas for its modernization are constantly being updated. Choose from the proposed list the adaptations you need and Turn them into reality.

How to avoid 4 mistakes during operation, grinding / surface grinding and second machines

In order for the machine to perform its functions for a long time, the following simple rules must be observed:

- NOT increasing the load more than planned.

- Use the correct replacement tips provided by the Official Manufacturers Instructions.

- Remove dirt in time so as not to impair the air cooling mechanism.

- Maintain perfect electrical insulation, protective device functionality.

Option 2

Another version of the device for an angle grinder, with which you can cut metal workpieces, is done as follows.

-

Take 2 sections of profile pipe of the same height and weld them to a rectangle pre-cut from sheet metal.

Drill holes in 2 racks and levers (the length is selected experimentally), and then fix the latter with a bolt, as shown in the photo below.

Attach a spring to the back of the lever.

Drill a through hole in the intended place of attachment of the angle grinder to the rod.

You can now attach the angle grinder to the table.

Thus, we have a simple cut-off machine. To give additional rigidity to the attachment of the device to the levers, you can use clamps, having previously laid between the body of the angle grinder and the pipe, for example, a wooden block.

For a small angle grinder, a similar version of the device is also suitable, only the angle grinder will be mounted on a metal strip: on the one hand, with a bolt to the angle grinder itself, and on the other, with a clamp.

For a powerful angle grinder, the adaptation is made according to the same principle, but from larger profiles than in the figures above.

How to make a very accurate machine with high tolerance requirements and other answers to 5 frequently asked questions

Below are recommendations for the Most common thematic questions:

- How to make a machine with increased tolerance requirements?

Dampers for noise reduction and vibration reduction are NOT used in the attachment points of an angle grinder, so as not to degrade accuracy. All moving parts are designed to maintain geometry over a long service life.

- What material the platform is made of?

Wood is easier to process than metal, so the table and many other parts can be made from this material.

- Is it necessary to use an angle grinder of 1.5 kW or more?

Increasing power consumption is not always justified. The exact calculation is done taking into account the required number of revolutions / torque.

- What parts can be damaged by increasing the frequency of the working shaft?

Cutting speed too high can damage polymer and other workpieces.

- Do I need to use safety glasses when machining workpieces with a machine?

Sheet steel cutting machine

For cutting sheet steel, long sheets of PCB, chipboard using an angle grinder, a different design is needed. In this case, the angle grinder must be able to move along the material being processed. This becomes possible by attaching the angle grinder to a movable carriage.

The carriage can be made on the basis of roller door blocks. Angles or channels of small sizes are used as guides. They are strictly parallel welded to the base. Instead of a quarrel, a screw connection to the platform is possible, while the screws Must be countersunk, the nuts are fixed with Grover washers or locknuts.

: Stand for angle grinder

How to make a stand for an angle grinder with your own hands

Angle grinder (angle grinder or angle grinder), which has received the unofficial name “angle grinder”, is one of the most common universal tools designed for abrasive processing of various products made of metal, wood, stone. It is an “angle grinder” because it first appeared in the USSR from Bulgaria, where it was produced at a plant in the town of Lovech. To perform an angle grinder various precise work, many craftsmen make a stand for an angle grinder with their own hands.

Pendulum cut-off machine

The machine platform is made of sheet steel. For the pendulum arm, a profile pipe is suitable, to which the transverse shaft is welded strictly perpendicularly. Two bearing assemblies are rigidly pressed onto this shaft at both ends. After that, the pendulum is welded.

A bracket is made of a steel strip for fastening the gearbox housing of an angle grinder. For fastening, holes are drilled along the edges and in the center. To ensure rigid fixation of the body to the pendulum, a clamp is made from a steel bar. The metal clamping bar is fixed with bolts. The finished bracket, made in the form of the letter “P”, is attached to the console.

A bracket with a clamp and attachment for an angle grinder is welded to the pendulum arm, while a protective cover is installed. To automatically return the angle grinder to its original position, a return spring is used, which should be selected in accordance with the weight of the angle grinder.

After the machine is assembled, it must be turned on and, at idle, check if there are vibrations and backlash. Then cut the groove for the cutting tool with a cutting wheel of maximum thickness. On the platform, the stops are bolted for the main directions of the saw. 45 ° and 90 °.

TOP 6 drawings for a cutting machine from an angle grinder with your own hands: the best designs with a description of the assembly

Is it possible to make a homemade miter saw from an angle grinder: verification test with answers based on the presented materials

- What are the switches for the emergency stop of the machine?

B) hand and foot.

- Which angle grinder are suitable for creating a cutting machine?

A) pneumatic and electrical;

- Minimum power of angle grinder motor for cut-off machine of angle grinder:

- What kind of machines can be made on the basis of an angle grinder?

A) trimming, cutting;

B) grinding, milling, sharpening.

- Where to place an angle grinder in a cut-off machine?

A) above the countertop;

B) under the countertop.

- The correct option is b). Footswitches are more convenient as they operate quickly.

- Theoretically, there will be enough power in all three versions. In practice, a). electrical and pneumatic models are used. The battery for the stationary machine is not needed. For the pneumatic drive, you will have to purchase a compressor of the appropriate capacity.

- 900 watts or more. Correction is done if it is supposed to process workpieces made of soft materials, or at high speed.

- Both options are correct. Powerful angle grinder suitable for a variety of home and semi-professional machine tools.

- Two mounting options are available. Professionals prefer the top.

The electric angle grinder performs many different work steps. To reduce labor costs while increasing accuracy, it is used as the basis for the machine.

“Angle grinder” is a common name for an angle grinder (angle grinder). By changing the disc, this versatile machine is converted for cutting, performing other work operations.

Stand drawings for angle grinder

And the very design of such devices quite often raises doubts about the use of such a drawing without a certain correction.

Alteration of interior doors and more. Secrets of the master. Attachment for angle grinder

Greetings to all readers and visitors of the site “Secrets of the Master”!

I probably will NOT surprise anyone if I say that today an angle grinder is one of the most common tools among masters of different directions.

The correct name for this tool is an angle grinder, popularly. an angle grinder.

In this article, I will show you how to make a quick fix for an angle grinder.

For work we need a minimum of tools.

- Drill with drill set.

- Angle grinder with metal cutting disc ø 125 mm.

- Hacksaw for wood.

- Screwdriver.

Also needs material.

- Wooden blocks.

270 × 28 × 35 mm. 1 pc. Frame detail.

120 × 60 × 23 mm. 1 pc. Lever.

- Dural corner.

30 × 30 × 420 mm. 1 pc. Frame reinforcement.

- Dural plate.

300 × 120 × 2 mm. 1 pc. Base of adaptation.

You can use a textolite plate at least 3 mm thick.

- Metal corners.

55 × 30 × 75 mm. 1 piece.

60 × 60 × 45 mm. 1 pc. Angle grinder mount.

- Screws with nuts and washers M4 × 15 mm. 2 pcs.

- Bolt with lock nut М 8 × 20 mm. 1 pc. Angle grinder mount.

- Self-tapping screws for wood.

3 × 20 mm. 4 pieces.

3 × 35 mm. 2 pieces.

3.5 × 16 mm. 2 pieces.

Assembly procedure for angle grinders

Preparation of a platform from a duralumin plate.

✓Cut out a plate 300 × 120 mm.

✓ We drill six holes ø4 mm from the recess for the self-tapping heads. These holes are needed for attaching corners, a bar and a handle.

✓ From an aluminum corner 30 × 30 × 420 mm we make a corner.

To do this, we make a cutout in the form of an equilateral triangle in one of the shelves in order to bend it at a right angle 90º.

✓ Separately we fasten the handle (120 × 60 × 23 mm) with a bar (270 × 28 × 35 mm) using self-tapping screws 3 × 35 mm. 2 pcs.

✓The obtained L-shaped parts and the duralumin plate are assembled together.

Everything is fixed with self-tapping screws 3 × 20 mm. 4 pcs.

The base of the fixture is ready.

Final assembly of the angle grinder attachment

✓ Now you need to install metal corners 55 × 30 × 75 mm. 1 pc.

60 × 60 × 45 mm. 1 pc. On the received platform for fastening the angle grinder.

Pay attention corner 60 × 60 × 45 mm must be sure to bend a little from 90º to 60º.

Otherwise, DO NOT secure the angle grinder.

The angle grinder is attached to the angle on one side with its own handle, and on the other side with a bolt with a lock nut M 8 × 20 mm.

The lock nut is necessary so that the bolt does NOT loosen during operation.

The handle does not need a lock nut. You hold it with your hand.

That’s it. the angle grinder cutting attachment is ready. I think that many will have a reasonable question: “Why make such a device when there is a hand-held electric circular saw?”

I agree with this statement of the question, but if you use such a saw often, then you can buy it. And when from case to case, it is better to have such a device.

By the way, such a device can be used not only, for example, for shortening doors, but also for working with ceramic tiles or with plastic panels. You just need to change the cutting disc.

That’s it for this article. If you have any questions, please contact through the feedback form (blue button on the left) or through the “Contacts” page.

Sometime later I will write on how you can make a small sawing machine from an electric jigsaw. So subscribe to the site news. it’s free.

You can also read more articles.

All the best! Best regards Filippov Yuri.

To be continued.