Homemade snow blower for a tiller with your own hands

To create a snow blower for a tiller, first of all, you need to think over all the structural elements and develop a drawing. After that, they carry out the assembly according to the scheme with their own hands and test the finished device.

Useful Tips

After assembling the structure, you need to test it. They check: how the blades carry the snow along with them, how the wheels go, whether the runners are catching. In order for a self-assembled car to serve as long as possible, it is recommended to take into account several useful tips:

- Even during assembly, safety bolts should be used to help prevent dense snow and ice from getting inside the mechanism..

- It is especially important to carefully approach the choice of bearings – they provide the reliability of the design.

- The belt drive is more practical, because if a hard object hits, it will simply jam. It’s also easy to disassemble and replace..

- After each cleaning, it is better to store the tiller in a room with a positive temperature. Then there is no need to additionally warm up the engine, which takes extra time..

- Serving your car is easy. One of the requirements is the regular oil change in the gearbox. In winter, you need to use only liquid, loose oil, because in the cold it will quickly thicken.

Fan-auger (combined) snow blower

This tiller snow blower consists of the following elements:

- Auger – pipe with two trunnions.

- Rotor with steel blades 3-4 mm.

- The body is a metal box that can be welded by hand.

- Ejection pipe made of metal sheets with a curved head.

Combination unit helps to get rid of even packed snow.

The device and principle of operation of a snow blower for a tiller

The device for a snow blower for a tiller is quite simple, so you can make it yourself. The source of energy is a gasoline engine that rotates the auger. The mechanism breaks the snow mass, and the rotor blades rake it under themselves and push it through a special passage – a branch pipe. Thanks to this, the snow can be thrown aside for several meters..

The operator holds the machine by the comfortable handles and pushes it forward. Smooth running is provided by a pair of wheels on tires with a relief surface. By gradually moving the snow blower forward, the operator clears the entire area of snow.

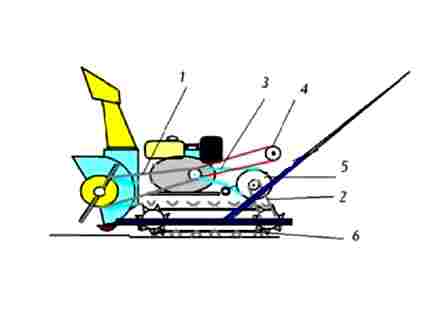

The schematic diagram of the device can be represented in the form of a figure, in which the numbers indicate:

- Auger drive.

- Track drive.

- Drive belt.

- Parasitic roller (to ensure the reverse of the machine).

- Intermediate shaft.

- Belt tension roller (for forward movement).

A home-made snow removal unit is in demand, since in many regions the winters are quite snowy

In practice, four versions of the snow blower are used. All of them can be designed at home:

- Adapter unit.

- Snow plow.

- Ventilator.

- Screw-fan.

How to make a snow blower for a tiller with your own hands

A do-it-yourself snow blower for a tiller is quite easy to design at home. The engine from a chainsaw is taken as a basis. You will also need a metal case with runners, a screw mechanism and a pipe for removing snow..

- The device and principle of operation of a snow blower for a tiller

- tiller with adapter

- Snow plow for tiller

- Fan (rotary) snow blower

- Fan-auger (combined) snow blower

- Homemade snow blower for a tiller with your own hands

- Required materials and tools

- Snow blower drawings for tiller

- Step-by-step manufacturing instructions

- Useful Tips

- Conclusion

Snow plow for tiller

Another simple option for a snow blower is a unit with a screw (rotary) mechanism. It consists of several main elements:

- screw;

- shaft;

- pipe (branch pipe) for ejection of the snow mass;

- open metal box;

- reducer (optional);

- sprocket with chain – transmission mechanism.

This snow blower is made independently on the basis of metal pipes and steel sheets. First, the box is welded, its lower edges are bent to make smooth runners. In the middle of the shaft, a grip is welded from U-shaped bent plates, which should “look” in opposite directions at an angle of 180 degrees.

A screw is fixed to them, on each side of which there are two rings. In this case, the end of one is welded to the beginning of the other. A hole is cut on the back of the gripper, through which a pipe for removing snow is suitable. It is also welded, and the upper head is bent to the side..

A schematic diagram of a snow plow will help you understand the installation of the structure

tiller with adapter

A simple snow model based on an adapter and a tiller will help you quickly clear the surrounding area

A snow removal nozzle is mounted to the unit – it is pre-designed by hand. A metal sheet with sharp edges is used to make a knife..

The main elements need to be cut out of steel and then welded. A snow knife is mounted from the bottom. The next stage is the assembly of the blade to the main block. It should be fixed with rods and a bracket. After that, the rods are attached and brought out to the operator’s handle through the ears.

Snow blower drawings for tiller

To design a snow blower for a tiller, you first need to draw up a drawing. It can be printed or drawn, after which they do the assembly with their own hands. You can take the following options as a basis:

- Rotary snow blower for a tiller, assembled by hand according to a simple scheme.

- Drawing of a screw snow blower for a tiller, which can be made at home with your own hands.

- Trailer-mounted snow blower option with blade.

Snowmobile from tiller on tracks

a crawler tiller to convert to a snowmobile is a little more difficult, but possible. Using the tiller motor, you can make a structure with great stability and passability. For this, the frame and transmission are mounted. Make sure the engine has enough power, you need a tiller of at least 6 horsepower. To make a snow motonart with an engine, you need to use:

- reducer;

- fuel tank;

- steering;

- centrifugal clutch.

It is good if you have tracks from other snowmobile machines in your household stock. If not, then don’t give up. It is quite possible to assemble the caterpillars on your own, using improvised tools and materials.

Next, you need to decide on the location of the engine: front or rear. Try to keep the structure as light as possible and keep the ski soft. All this will make it possible to achieve high cross-country ability in deep snow. The principle is as follows: inside the caterpillar, when driving, 4 wheels roll along the conveyor belt. Special soil hooks are attached to the tracks to enhance traction. Caterpillars can be made at your discretion, but you should carefully consider the dimensions.

Wide or too long tracks will unnecessarily stress the engine. This, in turn, will complicate the handling of the snowmobile on tracks in the snow. A track that is too small will not be able to support the weight of the entire structure with the driver. It will become unstable and sink into loose and deep snow. For the manufacture of tracks, the simplest materials are used: plastic or plastic pipe of small diameter, wheels, bearings.

Workpieces with a length of 0.5 cm are made from the pipe, from which ground hooks are obtained. They are attached to the tape at the same distance from each other. Then they are bolted into the holes on the conveyor belt. The frame is made using square pipes or a channel. Use a tie rod without ball ends, as the steering and ski axes lie in the same plane.

On the front of the frame, bushings are attached to allow the skis to turn. They can be made from steel couplings with small diameter nipples and threads. Racks of skis and tie rods are welded to the pipes. To control the snowmobile, corners with a metal undercut are attached to the skis, which will allow you to move on ice or snow crust.

The weight of such a snowmobile is no more than 100 kg, and it is very simple to operate the vehicle. Since the power of the motor is low, the speed does not exceed 10-15 km / h, so no brakes are provided. The end of the movement occurs due to the reset of engine speed or the so-called engine braking.

How to make a snowmobile from a tiller?

- What it is?

- Self-production

- Tiller snowmobile on wheels

- Snowmobile from tiller on tracks

- Snowmobile from Tiller on tires

- Safe driving advice

What it is?

A snowmobile is a power-driven vehicle. The most famous are small-sized models equipped with track skis and controlled by the principle of motorcycle. However, in fact, there are many varieties of all-terrain vehicles on low-pressure pneumatics and caterpillar tracks, snowmobiles. Tillers are also divided into wheeled and tracked. You can make a snowmobile from a tiller with your own hands with any chassis, only in this case, different methods and materials are used.

Snowmobile from Tiller on tires

Another economical option for making a diesel snowmobile from a tiller and tracks. Motonart on tires from the MTZ-80 or Belarus tractor can easily move on the snow. This design is equipped with two additional wheels and pieces of metal pipe. Consider the benefits of such a snowmobile:

- efficiency – cheap or used materials are used here: wheels from a VAZ car, a square tube, used tractor tires;

- the ability to make a car at home using a welding machine, angle grinder, drill, knife;

- high maneuverability of the resulting snowmobile, which has the ability to turn like a tank in one place;

- good cross-country ability in deep and viscous snow;

- active brake right or left track.

In order to make tracks, you need two tires from a tractor, used ones are quite suitable. Side parts are cut from each tire with an electric jigsaw or just a sharpened knife. The structure is made of a square tube and two additional wheels. It is required to securely fix the tiller and the structure with wheels. Then the caterpillar obtained from the tire is sequentially pulled onto the front wheels, then onto the rear wheels. It turns out a diesel snowmobile on a caterpillar track, that is, on tires. In order to make it more comfortable, you can fit a small seat, which will not weigh down the structure. Otherwise, you will have to stand up to overcome the snowy expanses..

Fans of outdoor activities, hunting and fishing will appreciate the homemade snowmobile. The advantage of this incredible device will be high traffic at a low cost..

Self-production

Let’s consider step by step how to make different types of snowmobiles with your own hands.

Tiller snowmobile on wheels

To turn a wheeled tiller into a snowmobile, you need to take:

How to make electric power Tiller Machine for Agriculture

- an iron connecting structure-trailer;

- wheels for winter use, able to overcome snow obstacles.

A strict condition for the whole idea – the trailer must be rigidly coupled to the snowmobile frame. A metal channel about half a meter long must be welded parallel to the axis of the snowmobile. To do this, two holes are drilled at the edges of the channel. Hole clamps on the edges provide additional fastening and structural rigidity. They are attached to the axle of the snowmobile with bolts with a lock nut, using a cross welded to the structure..

This mount will act as a stopper that holds the trailer in place, preventing it from shifting at an angle. Such an element, although it reduces the ability to maneuver on the snowmobile, makes it more stable. Thus, a two-wheeled mechanism on one axle can be easily converted into a stable four-wheeled vehicle. At the same time, you will not need any diagrams and drawings, or additional costs..

A snow scooter with a motor will also require the correct selection of wheels. The easiest option is to purchase them in a retail network for a winter purpose, but it is not always advisable to look for easy ways. A more economical solution would be to make the wheels yourself. The budget option is to equip the snowmobile module with cameras designed for trucks. Deflated cameras are put on each wheel and fixed over the chain for driving on snow and ice. One is not enough, you need about five. An inflated chamber in a cache of chains will be an ellipse with a surface divided into segments like a daisy..

Another option for using ingenuity and saving the family budget is to use metal hoops over the cameras. They should be wide enough, twice as wide as the snowmobile wheels. The diameter of the hoop must match the inflated wheels of the tiller and trailer. Several metal plates are welded on the inside of each hoop. The thickness of the plates must be made about 2-3 cm. After lowering the cameras, you should put hoops on the wheels of the snowmobile and pump them up again. The inflated chambers will squeeze as much as possible against the metal circles. Plates like dirt lugs help increase traction on snowy roads.

Safe driving advice

Do not forget that any vehicle, even one made by yourself, requires attention and care. You cannot overestimate your capabilities and move in the dark or in bad weather conditions. If visibility is poor, you may not notice changes in the topography of the ground, holes, ditches covered with snow. The low stability of the snowmobile when hitting any obstacle (stones, stumps, metal objects) can lead to overturning, throw off the rider and / or press down with its mass, cause injury, or even death.

Care is required when overcoming slopes and when driving under any overhanging obstacles: sagging wires, stretch marks, fallen trees. The blow will hit the rider’s chest, so if there is a backrest, injury is inevitable. Be aware of possible road obstacles and take safety seriously.

For how to make a snowmobile from a tiller with your own hands, see the next video..

Trailers and adapters for OKA tiller. Conversion of OKA into a mini tractor

Steering

The steering adapter provides the ability to turn an ordinary tiller into a real mini-tractor. Engine power will remain unchanged, but the number of functions performed will increase significantly.

Attachment takes place thanks to a hitch that is placed in front of the adapter.

The design includes the following elements:

- a pair of wheels;

- clutch mechanism;

- brake and gas;

- operator’s seat;

- frame.

At the back there is a mechanism to which additional equipment can be attached if necessary.

Owner reviews

Ruslan, 42 years old:

Hello. I bought the Oka tiller 4 years ago, six months after the purchase, I also forked out for the trailer. I took a model from the same plant, PMG-300-1. A very convenient unit, easy to assemble and dismantle. Stable self-ejection.

Eugene, 29 years old:

How to make a Cultivator Mini Tiller with 49cc 2-Stroke Engine

I decided to turn the tiller into a tractor, my Oka plowed for 3 years, it’s time to modernize. At first I thought to make all the details myself, but I looked through the drawings (which do not always correspond to the job descriptions on the internet), estimated the cost of materials, electricity and decided that the factory design would not be more expensive. I decided to give preference to the domestic manufacturer, stopping at the Kharkov Agromarka. The purchase cost a little over UAH 7500. The instruction is more than understandable, there is a guarantee (which was required) the tractor turned out to be glorious, all-wheel drive, hardy, cross-country ability and traction characteristics at a height.

Tiller adapter: functions and new solutions

As you know, a tiller is a unit that greatly simplifies work on a personal plot.

But there is one nuance – you have to follow the tiller and make significant efforts to implement the workflow. Here, to solve the problem, an adapter is needed.

The design is completely collapsible, the steering wheel of an automobile type serves for control. For the operator’s convenience, the attachment is equipped with a headlamp, which allows working in the evening. Collapsible front adapter weighs 65 kg.

Making an adapter to the tiller with your own hands

If the design of the tiller can be called simple, then this cannot be said about the process of its manufacture. When developing a homemade adapter for a tiller, you need to pay attention to the drawing diagram and adapter dimensions, which play a key role in further development.

First of all, you need to have the following tools and parts with you:

- welding;

- drill;

- file;

- saw;

- screwdriver;

- metal plates;

- 2 wheels;

- metal corners

- fastenings.

When developing a drawing of a future adapter for a tiller with your own hands, it is necessary to take into account what constituent elements are included in the design:

- frame;

- suspension;

- portal;

- hitch;

- seat;

- steering.

- circuit design – at the very beginning, it is necessary to calculate everything so that all systems and mechanisms are in equilibrium, and to prevent cases of overloading the system. You can use the already drawn diagrams, but you can do it yourself;

- creation of the main parts – during the practical implementation of the drawing, it is necessary to pay special attention to the rotation of the body. It should be easy, unimpeded. The frame is based on metal pipes and corners. The adapter body is made of a metal plate;

- installation of a driver’s seat. It is placed on the beam at a distance of 80 centimeters from the front of it. The design can be supplemented by seat adjustment, additional levers.

The design can also be supplemented with additional agricultural tools:

- plow;

- digger;

- hillers;

- brushes.