Wheels for a power tiller: overview of types, how to make with your own hands

Choosing a single-axle tractor for their homestead, users pay attention to the technological characteristics of its mechanism, such as power and weight. Few people are interested in what wheels are installed on it, because the quality of work and duration of operation depend on the mechanism.

Sold standard wheels are good for working on soft soils. In difficult conditions, they quickly fail, and new ones are quite expensive. Our article will tell you how to make wheels for a power tiller with your own hands.

Wheels on a single-axle tractor with their own hands

and more gardeners. owners of power tillers make changes in the running gear of their machines with their own hands. This makes it possible to improve the cross-country ability of the cultivator, to adapt it to all different types of soil, to successfully expand the track and many other things, which are not always possible in the factory set.

Neva motocultivator

Wheels for power tillers are of the following types:

- Pneumatic, used for plowing and removing roots from the soil, as well as for transporting the cultivator. Often instead of the factory narrow they are installed from “Zhiguli”, “Oka” and “Moskvich” cars;

- metallic or grouser wheels are ideal for clay soil, as they have steel teeth that provide excellent passability in soft soil;

- solid rubber are also installed on mini-tractors, thanks to the aggressive tread pattern have an increased cross-country capability;

- supporting. as a rule, it is a single supporting wheel, taking all the load from the engine;

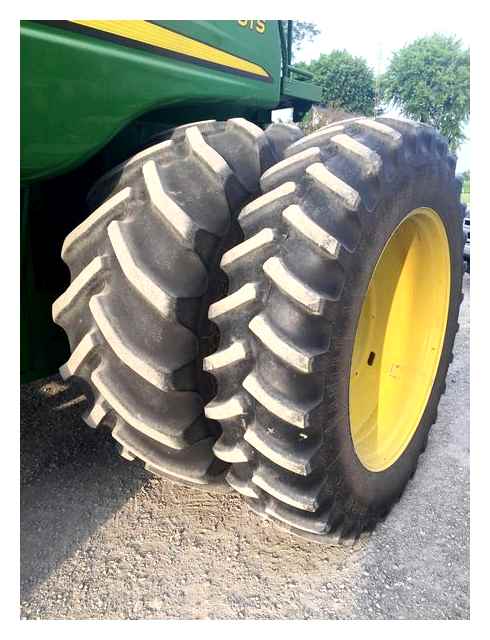

- coupled, helping to increase cross-country ability on difficult terrain and significantly increase speed.

Making wheels for a motorcycle block with your own hands

It is impossible to make wheels for motor blocks without blanks. the track must be prepared, which is subsequently modified and improved.

Simple recommendations for making:

- as a base, you can use wheels from a motorcycle or automobile. Special axle extensions are used to change the track width. They can be used to make wheels for specific tasks;

- Tires for a motorcycle block are selected according to the type of soil. For sticky, uneven ground, studded tires with an aggressive tread pattern are suitable;

- Homemade wheels are quite large. Otherwise they won’t do the job. Small-diameter wheels slip, so you have to pull them out of the wet ground often;

- It is optimal to make wheels from automobile discs.

- Two wheels will take four discs from the car. They are deburred with a file;

- Disks are welded to each other convex sides;

- Rubber tubes are put on the prepared wheels;

- Finally, the wheels are inflated with air and mounted on a single-axle tractor.

To make it easy to do, it is worth watching the video.

Making dual wheels with your own hands

When using machinery in conditions of increased complexity, you need to get hold of dual wheels.

Twin elements are made according to this scheme:

- Treads are cut out on suitable wheels;

- From steel pieces are welded 2525 cm squares, which are installed in the central part of the rim;

- After welding, the second rim is mounted. The result should be a vase-like product;

- Tires are mounted on the combined rims.

To make paired parts, you will need the same size rims.

Making wheels with cleats

Parts with a tines are installed on tractor models with a power of 6 liters or more. с. This prevents the engine from overheating during heavy loads.

The following elements are needed:

Prefabricated plates are welded to the wheels and securely fastened to the rim. Cut into toothed pieces that are also welded to the rim. A minimum distance of 15 cm is necessary from the plates to the tines. Rubber tires are then installed on the rim, and the wheels are then attached to the axle of the power tiller. Using the above tips, you can make your own wheels for machinery Neva, Agro, Mole and other well-known brands.

Drawing with instructions for the manufacture of wheels on a single axle tractor

Without a clear plan and vision of the final result and the drawing to produce wheels for cultivator with their own hands will be difficult. So it is necessary to determine the blueprint and then proceed to work.

The drawing of self-made wheels for the cultivator You can make twin wheels, between which will be inserted the weighting agent.

As the basis for a homemade wheel, you can take a wheel from a Zhiguli or Moskvich. You need four of them as a result. The rubber tires are removed from them. Several steel plates of iron up to 5 cm wide are welded to the rim, from which you can form a square. The rim of the second wheel is welded to it, and the rubber is put on the ready-made structures.

You will be interested in winter tires for Kia Sportage 17 radius

Homemade twin wheels on motor blocks can be made in any variety of variations: seating diameters, weight, width, profile height. all depends on the needs and capabilities of the owner of the machine.

Drawing with instructions for making wheels for a single-axle tractor

Without a clear plan and vision of the final result and drawing it will be difficult to produce wheels for cultivator with your own hands. Therefore, it is necessary to determine the drawing and then proceed to work.

Drawing of self-made wheels for a cultivator You can make twin wheels, between which will be inserted the weight.

As the basis for the homemade wheel, you can take the wheel from “Zhiguli” or “Moskvich”. You need four of them as a result. Take off their rubber tires. Several steel plates of iron, up to 5 cm wide, are welded to the rim, from which you can form a square. The rim of the second wheel is welded to it, and the rubber is put on the ready-made structures again.

You will be interested in winter tires for Kia Sportage 17 radius

Homemade twin wheels on motor blocks can be made in any variety of variations: planting diameters, their weight, width, profile height. all depends on the needs and capabilities of the owner of the unit.

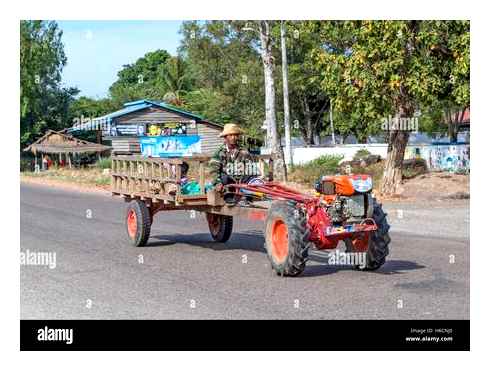

On 4 wheels

The 4 wheels can be mounted differently on the unit. The first option is to turn the machinery into a mini-tractor and equip it with a seat. The second option is more common in homemade machinery. In this case and the use of unsuitable machine or motorcycle parts, two identical pairs are mated to each other.

The standard conversion of machinery into a mini-tractor is a common procedure if the machine is powerful enough. A free axle is created for this process, which is mounted on the extended body. Paired equipment is placed on this axle.

When using the paired version, the two native pairs are split and paired with the second wheel. It is also possible to install weights between adjacent discs, but in homemade work most often discs are paired with a small gap with a small rectangular window, which is then the weights.

Important! The paired versions can be all-rubber or pneumatic, but one pair necessarily has an aggressive tread.

When fully created, each part will be a twin element that is created from equal parts. It turns out that the elements must be the same shape and size.

- higher level of productivity;

- quick removal of the outer parts;

- ease of creation;

- high level of contact with the surface.

The main pluses are increased flotation and increased speed.

A single-axle tractor on 4 wheels is considered the most practical to create at home.

Wheels for ditching on a single-axle tractor

A special kind of wheels will be required for a power tiller when setting a task such as ducking. Dip wheels, also popularly known as dipwheels, are used for both planting and dipping various crops, such as potatoes, carrots, beets, rutabagas, radishes, turnips. The four most commonly used types of wheel models are

- The lister. easy to make with your own hands. They have a number of varieties, among them the non-adjustable type, consisting of two plates, arranged in a mirror and diverging at an angle with a common stiffener. And also the adjustable type, with which it is possible to change both the width and the depth of the tillage;

- discs. the principle of their work is built on the fact that the discs capture the soil and then fill the same places of plant growth;

- Propeller. representing the propeller type. They are valuable because, due to the toothed shape of the blades, they are aggressive to weeds and perfectly comb them out of the soil, making them ideal for weeding. This type of weeder can also be made by our own hands, individually for the tasks strictly set for him;

You will be interested in the size of the wheels on the Honda CR-V

Propeller-type rear hoe

- With variable width. its use allows you to perfectly adjust the width of the row spacing, which makes this type of mower simply indispensable for the processing of beds.

As you can see, there are many choices for a single–axle tractor in operation. for different tasks, types of work and soil conditions. Some of them can be bought, some of them can be installed from other cars and motor vehicles, and some of them can be made by your own hands. To everyone who chooses and selects the right wheels for his/her power tiller. have a good choice, easy work and a high harvest!

Metal wheels with tines

These wheels from the motorcycle block are not large, but have weighting agents, which make them quite powerful and durable.

The wheels have steel tines to push the tractor forward and keep it from spinning even in the softest of soils.

How to make weights for a cultivator undercarriage yourself

There are weights for this problem. You can make them yourself. You will need:

- disc weights (5 kg and more);

- pancakes from a sports bar (10 kg each);

- clutch baskets for cars;

- hexagonal profile;

- angle grinder;

- welding machine;

- electric drill.

Homemade weights

The process takes place in the following sequence. Holes are drilled in two small sections from the profile, boom discs are attached to them, clutch baskets are welded to the booms and then weights are attached. Weights are ready, you can hitch them on the cultivator.

Block: 4/8 | Number of characters: 630

How to choose a rubber for your power tiller

Choosing the right tires for your power tiller is key to its proper performance. In order to choose the right one, you need to know the width of the tire. It is indicated by the first digits in the marking and is usually measured in inches, and you also need to know the planting diameter of the rim.

Its characteristics

The main characteristics of rubber are its parameters. width, diameter, tire weight, the maximum weight of the load it can withstand.

Varieties

Rubber for power tillers differs in size. The following are available on the domestic market:

Rubber, which is installed most often on power tillers, is presented on the domestic market in the following variants:

- Tires “Kama-421” can withstand a possible load of 160 kg, width. 15.5 cm, the weight of one tire. about 7 kg;

- “L-360” weighs 4.6 kg, diameter. 47,5 cm, can withstand a load of up to 180 kg;

- “L-355” has similar parameters;

- “L-365” can withstand up to 185 kilograms, diameter. 42.5 cm, weighs only 3.6 kg.

Block: 5/8 | Number of characters: 1095

How to make wheels for a power tiller with your own hands?

It is necessary to understand that it is impossible to make wheels from scratch with your own hands. It is necessary to find the basis and only after that you can proceed to the formation of improved and useful devices.

As this base one should use the wheels from a motorcycle or car. It is possible to create a self-made version only with a load hook, because if the weighted wheels are not used that often, there is no point in buying new, expensive products. On our website you can find a specialized article, where all the features of the creation of grottozateli own hands are considered in detail.

To expand the wheel base it is recommended to use extensions for the wheels of a power tiller, because it is necessary to adapt the device properly to the individual needs of the farmer. over, to broaden the possibilities one can create iron dual wheels with a cavity inside for placing a weighting agent of some kind.

Yes, these objects are unlikely to be used for the trailer of the motoblock, but they will be very useful for the machine itself, because they can be created in the case where a person has no wheels from a motorcycle, but are available from the UAZ or “Moskvich”.

- reduced towing, and as a result, a higher level of productivity

- the possibility of a quick removal of the exterior wheels;

- ease of creation at home;

- maximum surface contact.

Dual wheels are gradually becoming more and more popular, because you can spend a little time to create them yourself.

How to choose a rubber for power tiller

The right choice of rubber for power tillers is the key to its proper work. For the right and correct choice you need to know the width of the tire. It is indicated by the first digits in the marking and is usually measured in inches, and you also need to know the planting diameter of the rim.

Tyre specifications

The main characteristics of rubber are its parameters. width, diameter, tire weight, the maximum weight of the load it can withstand.

These characteristics and assigned to the cultivator tasks need to be considered when choosing tires.

Varieties

Rubber for power tillers differs in sizes. The following are available on the domestic market:

Rubber, which is installed most often on motocultivators, is presented on the domestic market in the following variants:

- Tires “Kama-421” can withstand a possible load of 160 kg, width. 15.5 cm, the weight of one tire. about 7 kg;

- “L-360” weighs 4.6 kg, diameter 47,5 cm, can withstand a load of up to 180 kg;

- “L-355” has similar parameters;

- “L-365” withstands up to 185 kilograms, diameter. 42.5 cm, weighs only 3.6 kg.

How to choose rubber for a power tiller

The right choice of rubber for power tillers is the key to its proper work. For the right and correct choice, you need to know the width of the tire. It is indicated by the first digits in the marking and is usually measured in inches, and you also need to know the seating diameter of the rim.

Its characteristics

The main characteristics of rubber are its parameters. width, diameter, tire weight, the maximum load it can bear.

These characteristics and tasks of the cultivator should be taken into account when choosing tires.

Varieties

Rubber for power tillers differs in size. On the domestic market the following are presented:

Rubber, which is installed most often on motocultivators, is presented on the domestic market in the following variants:

- Kama-421″ tires can withstand a possible load of 160 kg, width. 15.5 cm, the weight of one tire is about 7 kg;

- “L-360” weighs 4.6 kg, diameter 47,5 cm, can withstand a load of up to 180 kg;

- “L-355” has similar parameters;

- “L-365” withstands up to 185 kilograms, diameter. 42.5 cm, weighs only 3.6 kg.

How to make twin wheels yourself?

Particular interest among farmers has gained a simple and even a little rough, but effective way:

- Then it is advisable to cut small treads on them;

- The next step is that people buy a strip of steel 5x50mm, weld squares with a side of 250mm and insert them into the rim;

It is not difficult to get such useful devices, the main thing is to decide what options are needed and pick up all the necessary “ingredients”.

Weights for your own hands

Solve the problem of shallow plowing, dipping or slipping of the machine on clay soils by installing weights to the wheels. Parts of brake pads are used as weighting elements.

Weight your single axle tractor according to the following scheme:

If necessary, remove and install homemade weights when performing various farming activities. Another option for weighting farming small equipment is to weld plates of thick steel or cast iron to the wheels.

The selection of rubber on the wheels

When the tires on the wheels of your small farm tractor are worn out, change the tires. Before choosing a tire, determine the tasks you will perform with your power tiller. For plowing, tuber harvesting, choose wide bars with a radius of at least 20 cm and the same width.

For power tillers and trailers the universal variant is models for 4-10 inches with spikes. Studded tires do not slip on clay and have good traction. Select the rubber, taking as a basis the factory parameters of machinery. Do not exceed the diameter foreseen by the manufacturer. Aggressive tread pattern eliminates the problem of clogged tire cavities. For domestic power tillers Zubr, Aurora, Kentavr, Dobrynya, foreign cultivators ZIRKA possible putting chamber wheel designs for 5-12 inches.