Signs and causes of failure of the starter mechanism

There are two faults in the starter mechanism.

- Broken cord. With regular use of lawn mowers, this element is frayed and torn, which will be easily noticed by the user when trying to start the trimmer. To correct the situation, you need to replace the cord.

- Spring wear and subsequent breakage or release of the hook from the groove. It is possible to determine the malfunction by the cord, which does NOT return and does NOT wrap around the pulley after starting the engine. To repair the trimmer in this case, just install a new spring.

In rare situations, the starter mechanism breaks when the tool is used carelessly. The consequences can be unpleasant: a deformed cord is wound around the flywheel of a running engine, the pulley breaks, and the spring breaks. But these are isolated cases, a complete replacement of the starter is very rarely required.

Diagnostics and elimination of breakdowns

To diagnose the starter mechanism for the purpose of its subsequent repair, the unit must be disassembled. This is not difficult to do; you only need a screwdriver. But during this operation, you need to be careful. with careless movements, the spring can fly out and cause injury to the user.

Other malfunctions

Sometimes after the repair, the spring still flies. There are two solutions to fix this problem:

- To prevent the spring bend from jumping out of the groove, you need to insert a small fragment of a metal plate between the bend and the wall of the seat. This will provide a tighter fit for the spring.

- A self-made fastening also helps to keep the spring in the groove. It is necessary to drill holes in the coil on each side of the groove, place a spring bend in them and fix it with a piece of wire. These steps should be performed so that the wire does NOT touch the starter cover and does NOT slow down the movement of the pulley.

Collection and installation in place of the starter

To assemble the starter and install it in its original place, you must:

- The pulley is returned with the spring down and placed inside the body so that the spring bend hits exactly the groove of the body;

- Install the washer, then the spring, on top of it. the second washer;

- Floor washers place the cup with the tendril and screw in the screw.

When assembling, be sure to put in both washers, otherwise the plastic cup will be damaged by the spring after some time, and when pulling the cord, users will notice that it is jammed. It will look like a spring has come off. To eliminate such damage, you will need to install a larger screw or another washer. If it is not possible to find the required parts, loosen the screw just a little, after which the starter will stop jamming. However, you need to understand that these are temporary measures, and the malfunction should be repaired as soon as possible.

Spring winding

Coiling a spring is not an easy procedure. Not everyone succeeds in installing the part in place the first time, so you should not be upset if it fails. It is necessary to repeat attempts until the action is not successful. If you wish, you can look at the Internet, where craftsmen tell in detail and show how to easily and quickly perform this operation.

To wind the spring, you need to place the bend in the groove, and then, while turning the coil, carefully lay the part along the inner diameter of the bobbin. In this case, the spring must be constantly held with your hands. if it is NOT fixed, the part slips and jumps out, then the winding has to be done again. When done correctly, the spring is firmly seated in its seat.

How to repair a starter for trim tabs

One of the key components of a lawn mower is the starter, which is designed to make starting the engine of the device easier. Like other parts, it breaks down periodically. In this case, there are two solutions to the problem: repair the trimmer starter or replace it completely. The second option is simpler, but more expensive. In addition, the required part must first be found on the market, since different lawn mowers use different starters for different models. If you have free time and a screwdriver with a suitable tip, you can restore the functionality of this unit yourself if you know how it works, what malfunctions are typical for it, and how to fix them correctly. All this is in this material.

Prevention of problems

Sooner or later, problems with the starter arise on any trimmer. Stihl FS 55, MTD 790 or another brand. It is possible to delay the appearance of such a malfunction, but for this you need to handle the instrument with care. In particular, you should not make too sharp jerks, this will lead to a break in the cord or to the release of the spring. It is not recommended to subject the lawnmower to shocks or other physical influences. If the starter housing breaks and the cord breaks, it could wind up around the engine flywheel. This will lead to a torn pulley and a bursting spring.

So, having discovered that the starter mechanism has broken down on lawn mowers, you should not immediately rush to get help from specialists. Knowing how the malfunction is eliminated and / or the part is replaced, the repair work can be performed independently. This does not require any specific tool. At first, the procedure may seem complicated and tedious, but the numerous on the Internet dedicated to starter repair will help to solve the problem as quickly and simply.

Removing and disassembling a node

The order of disassembling the starter consists in performing a certain sequence of actions:

- First you need to find the screw that connects the starter cover to the pulley, and Unscrew it;

- Then you need to remove the spring, antennae and washers;

- Then you should carefully remove the pulley, keeping the structure away from your face so that the accidentally bouncing spring does NOT injure the user;

- Then you need to inspect the spring: if it is damaged, then you need to put a new one (the cost of such a part is low), and if it jumped out of the hook, you need to return it to its original place, having previously made bends, if they broke off.

Replacing the cord

To replace an element, you need to find a hole in the coil for it, through which the cord will pass, and then tie a knot. Next, you need to charge the coil with a spring, performing several turns.

For example, if the cord is wrapped around the circumference six times, then to tighten the spring, you need to turn the coil counterclockwise six times. After that, it remains only to thread the rope through the hole and fix the handle on the cord.

Installing the protective cover

We combine the holes in the protective casing and in the fastening bar.

Fastening the cover to the bar with screws and washers using the supplied wrench.

In this model, the casing is fixed with metal plates on both sides. This guarantees additional reliability and durability of the trimmer.

The casing itself is made of dense but elastic plastic. Such material will definitely not break off when hitting small obstacles. We advise you to pay attention to this if you are just going to choose electric trimmer or trimmer.

Installing the line reel

First, we combine the hole on the washer with the hole in the gearbox cup and the stopper with a special rod.

Unscrew the fastening nut from the hub clockwise.

3. Remove the cup from the shaft and the pressure washer

We twist the spool of line counterclockwise until it stops, holding the rod.

Fastening the shoulder strap

One of the simplest manipulations when assembling a trimmer. Many will understand how the shoulder strap attaches intuitively. For those who are not sure, we decided to add a few basic points to the instructions:

We connect the carabiner with the ring for fastening the belt

2.Adjust the position of the mounting ring on the rod

3. Fix the ring with the fixing screws

How to assemble a trimmer. Step by step instructions PHOTOS

Garden trimmers are similar in design. Detailed instructions for one model will help you understand the intricacies of installing analogs. Consider the main stages of assembling a trimmer using a model example FUBAG FET 1200R.

Before we start, let’s figure out what we have in our hands after the purchase. The tool is sold disassembled:

- Boom with motor

- Braid handle

- Trimmer head cover

- Trimmer head

Also included is a shoulder strap, three-blade knife and a tool kit.

Sturdy tool grip

Unscrew the thumbscrew

2. Remove the top cover of the fastener

Insert the handle into the fasteners

Installing the cover

Tighten the screw

To adjust the handle you need to loosen the thumbscrew and move it. Then fix the screw.

Trimmers FUBAG Equipped with rubberized handles, which increases the convenience and safety of use. They allow you to hold the tool securely even in wet hands.

Assembling the trimmer step by step. FUBAG trimmer assembly

So, all 4 steps of the trimmer assembly instructions have been completed. The tool is completely ready to run. It took us about 5 minutes. And how much it will take you depends on practice. To consolidate the information, we recommend that you look at the manual for the FUBAG FET 1200R trimmer.

How to put an electric starter on a tiller

If you cannot figure out how to put an electric starter on an agricultural unit, follow the recommendations below:

- To remove the engine flywheel, it is necessary to remove the tiller air filter to open access to the “native” manual starter for dismantling.

- Remove the protective cover of the unit, Unscrew the fastening screws of the starter basket and dismantle the flywheel using a special wrench. Behind it is a key that must be unscrewed.

- Next, you need to install a generator for which the engine has a seat. All wires are easily threaded through the hole in the side of the motor housing.

- Put the generator magnets inside the flywheel in such a way that the holes coincide, fix them in this position using fasteners.

Heat the crown with a gas burner and install the device. - The resulting assembly is installed on the internal combustion engine, the keys and the fixing nut are screwed in.

- Fastening the basket will replace the filter and protective cover.

- Install an electric starter, connect to the battery. In this case, connect the generator wires to the charging relay. Check the health of the system, started the tiller.

DIY repair and installation of a starter on a tiller

Many farmers ask how a starter is for a tiller. When operating a motor-cultivator, starters are used: main and auxiliary.

How to repair a starter motor cultivator with your own hands

Consider how to repair a tiller starter with your own hands. Before you start repairing a recoil starter, you need to find its instruction manual, which contains a diagram of the device. Then you need to prepare a wrench to unscrew the mechanism.

Before starting to dismantle the device, it must be photographed in order to then correctly assemble all the parts and components.

After that, unscrew the washer, which is located in the middle of the body. Having opened the lid, you must carefully inspect all the parts that are located inside the drum and determine which ones are damaged. It is necessary to inspect small parts very carefully and accurately so as NOT to accidentally spoil them and NOT to lose them.

In most cases, repairing a kickstarter on a tiller is to update components that are out of order. For example, the cord is replaced if it is torn or frayed.

If a large spring has failed, then you need to remove it from the drum. There are usually hooks where the spring is attached. If they are not in the design, then it is necessary to Heat the ends of the spring and bend them in the desired direction. If the spring is completely out of order and there is pronounced metal fatigue, then it is not necessary to try to restore functionality to such a spring. In this case, it is best to replace it with another one. After that, the device is installed in its place.

In addition to the manual starter, there is also a spring and electric starter for the tiller. The spring mechanism has a simple structure and is easy to start. The device starts up after moving the handle of the cultivator. The motor accelerates by means of a semi-automatic spring operation. You can replace the manual starter with a mechanical one yourself.

The tiller’s electric starter is connected to the battery, from which it receives power. The device is electrically started using the start button. The battery determines the power of the electric starter and the duration of the device. The electric starter is installed according to the electrical diagram of this design. Tiller with electric starter is durable, reliable, long-term.

Unfortunately, not all designs of manual cultivators can be converted into spring or electric ones. Therefore, before starting work on replacing the manual mechanism, you need to study the instructions and capabilities of the tiller and find out if such a rework is possible.

Farmers should be aware that at the beginning of work, all cultivators are working properly. Gradually, on the assembled unit, various components fail. In order to extend the service life of the tiller and all its parts and assemblies, regular technical inspection of the mechanism and proper care of it is necessary. All units and components Must undergo periodic lubrication with machine oil, check their performance. To increase the productivity of the cultivator and extend its life, constant proper care of this technique is necessary.

DIY electric starter on the tiller

In order to make an electric starter on a tiller with your own hands, you must:

- Select the main structural elements: body, coil, small electric motor and cam mechanism;

- Prepare wires, bolts, nuts and other fasteners to connect parts;

- According to the Wiring diagram and drawings of the factory device, connect the motor to the working elements by connecting it to a 12-volt rechargeable battery;

- After checking the circuit for operability, put all the components of the future starter into the case;

- Install the resulting electrical devices on the tiller and connect using wires.

Installing the starter on the tiller

There are various designs of starters:

- Manual;

- Spring;

- Electric.

The most common is a manual starter for a tiller, since this device is very easy to put on a tiller, and its repair is easy to do yourself. If such a device is used correctly, then its durability is several years.

Consider what elements a starter for a tiller consists of:

- A drum-shaped body;

- Springs: large and small;

- Washers;

- Coil;

- Cord;

- Tongues;

- Fastener parts.

In the center of the drum there is a reel on which the cord is fixed. A large spring is located in the body around the axis and is designed to return the coil to its original position after scrolling.

Tiller operation with a manual starter is as follows. The driver starts the mechanism by pulling the handle of the device. In this case, the device starts to work and starts the engine. In order for the device to successfully transmit the initial rotation of the motor, the handle of the device must be pulled twice.

But despite the fact that the manual starter on the tiller is considered a reliable device, it also sometimes fails. If the structure breaks down, you can repair it yourself.

How to make a manual starter on a tiller

As in the case of making an electric starter from improvised means, making a manual starter for a tiller (Neva, Oka, Kaskad, Patriot and others) will be an easy task for a craftsman with the appropriate knowledge.

To assemble a homemade kickstarter, to the materials and procedures described above, add the installation of a handle for transferring force manually, which will replace the operation of the electric motor. The kickstand of the manual starter can be made from a thin metal pipe, which will need to be driven out in the shape of the foot and installed in the reel hole in the polo. Having assembled the device, be sure to weld it.

What starter is installed on your tiller?

Installing or replacing the starter spring for lawn mowers, motor-drill, trimmer

But what if everything is in order with the rope, and the reel (pulley) of the starter does not unwind? Let’s consider this issue step by step using the example of the starter of the gasoline ADA GroundDrill motor drill, which has a pulley with two metal tendrils for 2 hooks.

In the case of other types of manual starters of a similar design, which are widely used in gasoline lawn mowers, trimmers and motor drills, the whole process of repairing a starter will look similar, differing only in some nuances.

How to repair a gasoline tool starter with your own hands?

In the case of a break in the starter cord, everything is clear: We take out the old rope, take it that is suitable in length and thickness (you can use it for linen), thread it through the hole in the reel, tie a knot. Next, the spring is cocked to the required number of revolutions, only after that by securing the handle. and voila! details on how all this is done is clearly shown below.

Do-it-yourself starter repair with a gas drill, lawn mowers, trimmer

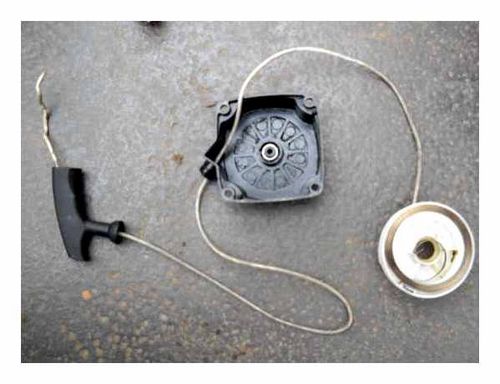

Today we will consider the most common case when the breakdown is not so serious and show how to repair the starter with our own hands, if the cord breaks off without any destructive consequences or does not wind up due to the fact that the spring inside just flew off, out of engagement. At least initially I want to believe in it. But in order to find out whether this is so or not, you need to disassemble the starter.

Starter repair: disassembly

We unscrew the screw with which the pulley is attached to the starter cover. We take out the antennae, the spring. We pull out the pulley itself carefully so that the spring does NOT bounce into the face. Even with the most careful disassembly, as a rule, it immediately flies out of the coil and abruptly unfolds into a long metal strip or twists into rings.

Pull out the white starter coil carefully. do not get hurt by the spring!

If the spring bursts or one of its hooks breaks, then repairing the starter will NOT work simply and quickly. the spring needs to be replaced. In order not to spend money on buying a new starter, you can search only for it on sale.

If the starter spring simply fell off, i.E. One of the hooks is out of engagement, it is enough to insert it, if necessary, slightly tightening the hooks more tightly (just not breaking off!) Install the spring with an outer hook into the pulley groove and start twisting it, while holding fingers inside the coil and don’t let it jump out.

Refueling the starter spring

Presses the spring against the pulley, in a circular motion Wind the spring inward

It may not seem so easy to insert the starter spring the first time, but everything comes with experience. With a little practice, you can easily wind the spring into the pulley in a maximum of a minute.

The starter spring is wound. It remains only to assemble the starter and charge the spring to the desired value

How to assemble a starter?

The most important thing in the process of self-repairing a starter is to assemble it correctly.

After the spring is fully wound, you need to carefully turn the coil over and insert it into the starter housing so that the second spring hook enters the housing groove.

When installing the pulley (in this photo. black), we look through the hole in it so that the spring hook falls into the groove on the starter cover

Then, if there is a spring under the screw, we first install it, and not forgetting to put washers on the bottom and top of the spring.

Carefully insert the cup with the Usyk into the grooves of the coil and tighten the screw.

Make sure that the club that is on the spring does not fall out. Why is it important? The fact is that the spring scratches the plastic cup with its end, as a result of which the latter wears out and begins to press the screw more tightly against the coil. For this reason, a situation may arise that is very similar to a spring break, the handle is pulled out of the starter, but does not come back. However, loosen the starter screw this problem disappears. It is easy to fix such a starter malfunction: just pick up a spring of the same diameter, but a little longer, or put an additional washer. If we just loosely tighten the screw, then it will twist and fly out, and this will already increase the likelihood of the spring breaking, since the pulley will not fit snugly enough against the starter housing.

We screwed the coil to the body, now we need to tighten the spring. Before this, it is necessary to remove the starter handle from the rope in advance. If the knot is too strong, then you can simply cut it off or try to untie it, for example, using a pair of pliers. This is done so that after you have cocked the spring, you can thread the rope through the hole in the starter cover. The other end of the rope must be fixed in the reel even before it is inserted into the body; it is NOT required to wind the rope onto the pulley before pulling the spring. do this after.

Before charging the spring, estimate how many revolutions of the coil the rope should be wound. Let’s say the length of the rope in the starter of the Ada GroundDrill-5 motor drill corresponds to 5.5 turns around the reel. In this case, we make at least 6 turns of the coil in the direction opposite to the direction of winding.

So let’s get started. DO NOT reel, insert the rope into the groove in the reel specially designed for it. Everything is ready, we proceed to tensioning the spring. To do this, we rotate the coil counterclockwise. in the direction opposite to the direction of rotation of the coil when winding the rope. It is more convenient to do this not in the knees, but pressed the starter with one hand to the floor, and with the other, turning the reel directly by the rope attached to it. If experience is not enough, then you can rotate the pulley itself with both hands, but the rope will get in the way, which can create additional inconveniences. After the required number of revolutions is made, threading the end of the rope through the hole in the starter cover, we put on the handle, securing it with a knot. It is more convenient to do this together with a partner, so that the end of the cable does NOT accidentally wind up inside the starter.

By the way, on your own, you can make some modifications to the design of the starter in order to more reliably fix the end of the spring inside the coil. Here, whoever has enough imagination for that. Now I will explain why this is needed. It often happens that the spring in starters of this type, after the first such independent repair and installation of the starter on the unit, flies again after a few jerks. the hook does not hold in the coil groove. And this is despite the fact that the coil almost snugly adheres to the starter cover and the spring there certainly doesn’t have to hang freely up and down, and even more so until the spring leaves the engagement. It turns out that when the cable is pulled, the spring pulls out, pulls it out of the groove. In this case, you can do the following: cut out a narrow strip of metal, which, in thickness, could fit tightly into the groove of the coil along with the spring hook itself. So the hook will not dangle freely in the groove, which means it will not be so easy for it to break out.

A metal plate tightly inserted into the gap between the spring hook and the groove walls will securely hold the spring

Another solution to the problem: drill small holes in the coil on both sides of the groove and, insert the spring hook, fix it with a thin wire threaded through these holes. But here you need to manage to make sure that this wire does NOT touch the inside of the starter cover when rotating and does NOT slow down the pulley. Alternatively, loosely tighten the screw or replace it with a similar slightly longer one. You can think of an option with the installation of some kind of gasket between the lid and the coil.

Does your power tool starter design differ from the above? Faced another malfunction, or do you know the best way to repair a starter yourself? Ask questions, share your experience with others. together we can solve the problem of frequent starter breakdowns once and for all!

Lawn mowers starters: device and installation features

The recoil starter for a lawn mower or petrol trimmer is a mechanical unit that includes a pulley fitted to a ratchet. A rope is wound on the pulley in the initial position. At the start, it is pulled outward. The pulley is spring loaded. as soon as you let go of the end of the rope, it will reel back. A flat strip rolled into a ring is used as a spring. It resembles a spring in a large mechanical watch that is wound once a day. The starter itself is located more often at the rear than closer to the front end of the mower or trimmer. To correctly perform all manipulations with the starter for lawn mowers, you need to know the features of the device and installation.

How does the starter for lawn mowers or trimmers work??

The starter is a generally single and universal mechanism for lawn mowers, trimmers, gasoline and diesel generator sets. It is not a problem to equip them even a car, motorcycle or scooter, if your vehicle has free space for its installation. It was not in vain that many Soviet cars and trucks were equipped with a starter tool that remotely resembles a crowbar bent twice.

The starter assembly has the following parts:

- Hook ignition spring;

- Cord wound on a reel;

- Return spring;

- Ratchet drive and main spring;

- Mechanism housing protecting the ratchet;

- Locking bolt.

Worst failure scenario

There are times when the starter is still operational, but it can break, for example, a worn out cord. The ratchet has not yet worked when the engine is started, and the remnants of the cord are immediately wound onto the coil, the return spring loses its hooks, the grooves in the starter housing break. Bottom line. replacement of both springs and housings.

How tight the spring is cocking?

To give the spring the required potential force required for a clear and fast winding of the cord, you can determine the length of the cord in turns. To prevent the wire handle from hanging, add 1-2 more turns to the number of turns. So, if the cord has a length of 5 turns of the coil, then when charging the spring, turn the coil 6-7 full turns.

How to assemble a new lawn mower starter?

To assemble the starter, do the following manipulations.

- Pass one end of the cord through the opening at the beginning of the spool and tie it in a knot. The knot must NOT go through the hole. Otherwise, you will disassemble the starter again.

- Wind the cord onto the spool itself.

- Install the spring into the starter housing, hooks in the groove at one end and wind it. For convenient winding, twist the body counterclockwise.

- Place the ratchet on the spring.

- The hook on the ratchet itself is the hook of the return spring, fix it on the coil.

- Install the main spring and housing with the assembled ratchet, connect the starter parts together and tighten with the main bolt.

Having finished assembling the starter, pass the free end of the cord through the hole in the housing for the coil. Re-pass the same end through the hole in the handle that is pulling the cord. Tie a strong knot on the handle. Check the operation of the starter handbrake.

How to replace or replace the starter spring?

If everything is in order with the rope on the starter, suspicion falls on the reel itself. It is driven by a tape spring, coiled into a roll. Certain steps must be taken to change the spring.

- Remove the starter from the lawn mower.

- Remove the starter coil.

- Unscrew the main bolt holding the pulley to the housing.

- Pull out the gripping tendrils and the spring, the ribbon spring is almost fully extended or coiled into rings of a larger diameter.

- Hold it in advance.

- Check if the spring is intact (rusty streaks, fractures, etc. May be present). If the hooks at its ends are broken, it will NOT be possible to bend new ones. high-carbon steel breaks when trying to bend it. Loose hooks are suitable for slight bending.

- Make sure the auxiliary (regular) spring and washers are in place. These parts protect the coil frame from being punctured by the end of the main spring. If the washers and spring are broken, and there are no new ones available, do not tighten the coil bolt tightly, but watch it. it can unscrew and get lost.

- If the main (flat) spring is damaged, insert the same new one. Place the hook on the end of the spring in its place and bend it, inserts coil by coil into the space where it should be.

The rewinding of the spring takes a minute. Dexterity in this action is acquired quickly.

How to replace or replace the starter spring, see the following.

Assembling the starter lawn mowers

When servicing and repairing a starter, it is important to assemble it correctly. as if the assembly was carried out by the manufacturer. Any part that is incorrectly installed, and will not allow you to fully use the trimmer or lawn mower.

- Turn on the spring, turn the coil over and place it so that the second spring hook falls back into place. To control the correct installation of the spring, there are technological windows on the coil itself.

- Install the starter pulley and make sure that one of the spring hooks fits into the groove located on the starter cover.

- Insert the spring and washers on the sides so that the spring does NOT wash away the plastic compartment in which it is located. If the spring is broken, and another is the same, an additional club is placed instead.

- Insert the cup with the tendril into the grooves of the coil.

- Install the coil in its place, tighten the bolt until it stops, but without fanaticism.

If you do not shield the mainspring with washers from the compartment where it moves when the cord is wound and unwound, the spool will often jam when you try to start the Trimmer or Lawn Mower. Loosening the coil bolt will result in its loss.

See how to assemble a lawn mower trimmer starter.

How to change the cord?

It happens that the inability to start the starter is not to blame for the spring, but the cord itself. He can run over or even break. Dismantling the starter lawn mowers or trimmers are universal in their steps.

- Remove starter block from trimmer or lawn mowers.

- Remove the main bolt holding the handbrake.

- Pull out the spool and rewind the remnants of the worn out cord from it.

- Untie the knot on the cord handle and pull the end out of it.

- Untie the knot at the other end (at the beginning of the spool) and remove the old cord. Knots that have become tight are untied with pliers or pliers.

- Tie a knot at one end of the new cord, pass it through the hole at the beginning of the spool (closer to its axis).

- Wind a few turns of the new cord onto the spool. If it is long, then cut off the excess.

- Load and charge the spring-loaded cord tensioner (if removed) and the spring-loaded elements in the correct sequence.

- Replace the spool and thread the free end of the cord through the starter outlet and handle.

- Reinstall the starter block.

Twist the starter by the cord, start the engine on lawn mowers or trimmers. The larger and more powerful the engine, the more jerks of the cord will be required at startup, the norm is no more than 7 times. The result is a quick and smooth engine start, the readiness of the unit for operation.