If the battery overheats

Strong heating of the battery indicates either poor contact between the cells, or the failure of one storage cell. But you need to panic only if the temperature is very high (over 40 degrees), because charging the battery is always accompanied by the release of heat. Almost all devices are equipped with a temperature sensor that does not allow overheating.

If the battery is heated above 40 degrees, this indicates a malfunction either in the temperature sensor, or in other battery elements. It is best to take the device for repair to diagnose and replace faulty parts.

How to properly charge the battery

You can find out the rules for charging the battery for each specific model of the screwdriver in the instruction manual. This must be done before using it. Let’s take a look at the advantages and disadvantages of different types of batteries. Each has its own characteristics of charging, discharging and storing for a long time.

In terms of composition, the most popular varieties are:

- Li-Ion lithium-ion

- Ni-Cd Nickel-Cadmium

- Ni-MH Nickel-metal hydride

The most common and affordable battery is nickel-cadmium (Ni-Cd). All manufacturers Provide a wide range of models with just such batteries. Using their example, we will consider the basic rules of charging.

When charging a new battery or after a long period of inactivity, it may not be fully charged. This is normal, although it may seem like there is some kind of defect. The battery will be fully charged after several full discharges. This battery has a so-called memory effect. That is, the ability to acquire a capacity that will be equal to the capacity of the first charge and discharge cycles.

To make the most of the battery capacity, it is recommended that you do the first five charge and discharge cycles. That is, fully charge after fully discharging the device. It is recommended to charge the battery before the first use, or when it does not provide the required supply voltage.

The battery may heat up slightly while charging. This is normal and does NOT indicate a problem. It must be charged in a heated room. The temperature can vary from 4 to 35 degrees. Store in a room with normal humidity at temperatures below 5 degrees. The battery must be charged at least once every 3 months.

Lithium-ion models are rapidly occupying their niche in the market. This is because there is no memory effect in them, and the charge rate is much higher than that of nickel-cadmium. You can recharge at any time and DO NOT worry about the battery capacity. The main disadvantage of lithium ion is the price. But for a professional tool, price is a priority indicator.

Nickel metal hydride ones are found, but they are much inferior in popularity. The advantage of THESE models is that there is no “memory effect”. But there is a big drawback: high self-discharge. This is a phenomenon in which the battery itself discharges over time.

By time, the charging speed of each individual device is individual for each individual screwdriver model. This information can be found in the instructions. For example, if it is an 18 V battery with a capacity of 1.5 A / h, then it takes 1 hour to charge. In this case, 14.4 V with a capacity of 2 A / h is charged for 3-5 hours. But do not keep the battery on charge for too long. If charged for a very long time, the battery can become very hot and begin to lose its properties.

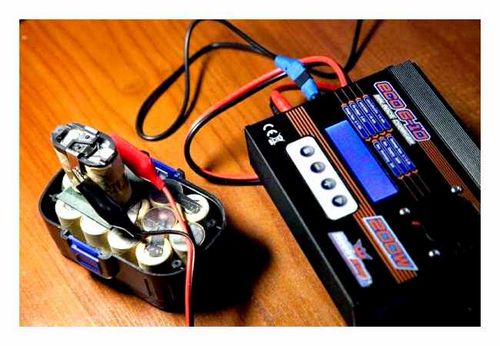

If you need to charge a screwdriver, but there is no charger at the same time (broken, lost, stolen. there may be different cases), then you can resort to using a universal charger. With this method of charging, you must strictly adhere to the instructions so as NOT to spoil anything.

It is important to understand that the charging time directly depends on the current strength (indicated by the Charger). So, with a current of 400 mA, a 2 A / h battery will be charged for 5 hours. If the current strength is 2000 mA, the same battery will be charged in 1 hour. Weaker and more gradual charging increases the battery life. High charge current saves time, but the battery heats up more.

In some cases, it is possible to charge the battery with a screwdriver using a car charger. Remember that car charging supplies 12 volts. Therefore, only 12-volt screwdrivers can be charged with it. In rare cases, 14.4 volts, but not more. And be sure to remember that the current strength should not exceed 1-2 A.

How to discharge the battery

The battery of a screwdriver can be discharged naturally. Namely: just let it run idle or with a small load. Loss of power or torque already indicates a complete discharge of the battery. Further discharge can only harm the battery, and a complete discharge will significantly reduce its performance. In lithium-ion models, there is a simple circuitry that will NOT allow the battery to completely discharge or overheat.

How to properly charge a screwdriver battery

One of the most versatile power tools in our time is the screwdriver. A variety of attachments, adapters and accessories makes it an indispensable assistant in any repair.

But the main advantage of the screwdriver is its mobility. Using a battery for a screwdriver allows you to work quickly and not worry about extension cords and sockets. On-site or just on the street. However, batteries have a limited lifespan. In order to extend the life of the battery, it must be properly charged.

If your device is charging too quickly

Fast charging (like discharging) may indicate that the capacitive properties of the battery have already been reduced. This happens over time. On average, it is 2-4 years and depends on the intensity of the use of the instrument. The resource is measured in discharge-charge cycles. The battery appears to be outdated and needs a complete replacement.

- Ni-Cd Nickel-Cadmium is 2000 cycles

- Li-Ion lithium-ion. approximately 3000 cycles

- Ni-MH nickel-metal hydride. 1000 cycles

Decreased operating time may be due to mechanical damage.

I would like to note that when choosing a cordless screwdriver, it is very important to know the differences and features of the installed power source. There are professional and household tools. For household use, nickel-cadmium will be enough. But it is better to charge it once every 3 months when not in use. For permanent use, Li-Ion units are better suited. The price will be higher, but the convenience and reliability will be higher.

- Types of batteries used to operate the screwdriver

- Battery charging features

- How long does it take to charge the screwdriver batteries?

- Do I need to charge batteries before storing?

- What to do if the screwdriver battery does not charge?

Tools

Among power tools, both household and professional, the screwdriver is one of the most demanded. With its help, it is impossible not only to unscrew and screw in self-tapping screws, but also drill holes. It is not always possible to use tools powered from the network and NOT everywhere, and the cord interferes with work all the time. Cordless screwdrivers are relieved of these shortcomings. You can move freely with them and does NOT depend on the presence of an outlet in the room.

An important element of every cordless tool is the battery, which allows you to work with it autonomously. This is very convenient, but sooner or later, each owner of such a power tool faces the question of how to charge the battery of a screwdriver.

Do I need to charge batteries before storing?

If the cordless tool is not used for a long time, experts advise you to carefully consider the battery cells.

Nickel-cadmium batteries are recommended to be discharged before storage, but not to zero, but to such a state when the tool stops working at full strength. During long-term storage, to restore the capacity of the battery, it is necessary to carry out 3-5 complete cycles of its discharge and charge. In the process of using the tool, it is also advisable to make sure that the battery before charging is NOT partially discharged, but completely.

Nickel-Metal Hydride batteries have a higher self-discharge rate than previous parts. They are recommended to be kept charged, and after a long “rest” charge for about a day. Partial discharge is preferable for this type of battery. Their capacity decreases after 2-3 hundred charge-discharge cycles.

Lithium-ion batteries, which have no memory effect, can be charged at any time, whatever the degree of discharge. These batteries have the lowest self-discharge rate at the highest capacity. It is not recommended to completely discharge them, as this can lead to the disconnection of the protective circuit. Power tools with such batteries are equipped with control electronics that disconnect the element from the load when the temperature or voltage rises. It is recommended that these batteries be kept 50 percent charged. The number of charge-discharge cycles does not affect the capacitive characteristics of the cells, however, their life is limited by time and is about two years.

Types of batteries used to operate the screwdriver

Before purchasing new batteries for the screwdriver, you must carefully study the instructions for the device. The tools needed for work can be professional, household and semi-professional. Batteries for them differ from each other in capacity, quality and price.

For certain jobs, certain types of cordless tools are also intended, designed for different loads, therefore, different batteries are needed for them. The higher the power rating of the battery, the longer it can work. For convenience, it is better to have two batteries, so that you can recharge the second when working with one. Often a second battery is already included when the instrument is sold.

Various types of batteries can be used for screwdrivers. The most commonly used nickel-cadmium (Ni-Cd) and nickel-metal hydride (Ni-MH), and recently also lithium-ion (Li-Ion).

The most common of them are nickel-cadmium batteries, which are compact in size, large in capacity and at an affordable price. These batteries can be effectively charged more than a thousand times, depending on their design, purity of materials, operating mode, including correct charging. However, these devices have a so-called memory effect, and if you charge them rather than waiting for a full discharge, the battery capacity will gradually decrease. In addition, the production of such elements is so toxic that the European Union abandoned it on its territory.

In second place in terms of frequency of use. nickel-metal hydride batteries, representing a new generation of similar devices. From the point of view of ecology, both production and disposal of THESE batteries are practically safe. The advantages of batteries of this type include the fact that the memory effect is less pronounced in them, and a minus. High self-discharge current. These batteries must be kept charged and, if not used for more than a month, must be fully recharged.

recently, more powerful lithium-ion batteries have been used for cordless tools. They also do not have such a disadvantage as the memory effect, which requires periodic discharge cycles to restore capacity. However, these batteries do not tolerate low temperatures well, and it is undesirable to work with them in cold weather. Despite their fast charge and high capacity, they are not very popular yet, as their price is quite high.

How long does it take to charge the screwdriver batteries?

As a rule, the charging time of the screwdriver battery is indicated in the instructions for the tool. THESE recommendations should be followed carefully. Often the charger has a special display system to help you understand how the charging process is going. Thanks to this, you can easily determine with how much to charge the battery of the screwdriver. When charging is complete, you need to interrupt it in time so as not to damage the batteries. On average, the charger battery for a screwdriver can recharge from about half an hour to 7 hours. Practice shows that a Ni-Cd battery with a capacity of 1.2 Ah is charged with a current of 250 mA for about seven hours. Charging current is maintained using the mains adapter.

It should be borne in mind that there are two types of battery chargers. conventional and impulse. A standard conventional charger is more often used in a non-professional tool, it charges the battery in about 3-7 hours. Pulse. more suitable for professional devices. Thanks to him, the battery performance can be restored in a maximum of time.

Battery charging features

How to properly charge the battery of a screwdriver so that it lasts as long as possible?

Batteries need to be recharged before first use as they are discharged during storage. To make the battery capacity of the screwdriver the maximum possible for the nickel-cadmium cell, it is recommended to charge it three times and then discharge it. Thus, since the capacity of a new battery is incomplete, it must be brought up to its working full capacity. After that, the batteries will need to be charged as soon as their capacity becomes minimum. Lithium-ion batteries are easier to use. They do not have a memory effect, so you can not bring them to full discharge and charge when it is convenient.

When charging, you need to take into account the optimal temperature regime of the process. It is better that the ambient temperature is above ten degrees and NOT over forty. Batteries sometimes heat up during charging, but this does not have to be done, as overheating adversely affects their performance and needs to be cooled. It is undesirable to leave batteries in the charger. And it is better to store them by disconnecting them from the screwdriver, separately from the instrument itself. If the batteries are not used for a long time, they should be recharged once a month.

It is better to buy rechargeable batteries at specialized points of sale. Correct use will help increase their service life. During operation, it is undesirable to discharge the elements completely until the engine stops. They will need to be charged as indicated by their markedly reduced performance.

What to do if the screwdriver battery does not charge?

If the battery of the screwdriver does not charge, perhaps the reason is to look for its deterioration or in the malfunctioning of the charger. However, often the problem lies in the disruption of contact between the battery terminals of the screwdriver and the charger, as they unbend over time. In this case, you can disassemble the charger and adjust its terminals.

In addition, after some time of use, both the battery contacts and the charger contacts may oxidize and become dirty. Even minor changes of this kind can prevent the batteries from charging properly. This usually translates into a significant reduction in both the charging time and the operating time of the cordless power tool itself. To avoid this, you need to periodically wipe the contacts of the battery, the charger for the battery of the screwdriver and the tool.

Unfortunately, battery cell performance degrades over time. So, if nickel-cadmium batteries, most often used in household screwdriver models, are used improperly, they quickly lose capacity. Experts sometimes advise such batteries to “overclock”. The battery pack is disassembled and problematic items are identified. After that, they need to be charged. What current to charge the screwdriver battery in this case? Experts recommend that you first charge such elements with a higher current than it should be, then discharge x and charge it again, but with a small current. If the electrolyte has NOT evaporated in Ni-Cd batteries, such “therapy” may help bring them back to life.

In addition, you can restore one battery pack from two that have partially lost their capacity, by selecting from them and soldering together whole “banks”. After that, to equalize the charge, it is required to fully charge and discharge the recovered unit several times.

Also, the reason is that the unit is not charging, it may be in the temperature sensor.

How long does it take to fully charge

How long does it take to charge the screwdriver battery? It should be clarified for what purpose it is being charged. Manufacturers are looking to speed up charging times to reduce interruptions and increase competition. Therefore, the maximum permissible values of the charging current are set. Often they sacrifice 10-20% of the capacity at the end of the charging cycle.

This can be seen on the graph of the charge of the lithium battery. Where, during the first charging time, 70% of the capacity is recruited, in the second time. another 20%, which is already 90%, and the set of the last 10% takes another 1 hour, only 3 hours. A standard charger “Bosch” from China charges the lithium battery in just 30 minutes. Taking into account THESE subtleties, now you can answer the question asked.

The battery will be sufficiently charged once to operate the tool. If necessary, you do not have to wait for the end of the charging time, and after half the standard charging time it will start working. Undercharging of batteries in isolated cases DOES NOT bear negative consequences.

To carry out training cycles, the maximum battery charge is required, and even more so to restore its capacity. How to do this on a standard charger if it turns off automatically? After the voltage stabilizes, after 20-30 minutes, you can continue charging the battery again on the standard device. He will take another amount of energy. The charge cycle costs three times. This will charge the battery to almost 100%. It is important that the entire volume of electrolyte is used in the subsequent training discharge cycle.

New Ni-Cd and Ni-MH cells are charged on a standard device from 1 to 8 hours, according to the passports of different manufacturers. This variation in time is caused by different settings for the value of the charging current, depending on the position of the manufacturer in this matter. In addition, chargers of even one manufacturer can have a spread of up to 2 hours due to an error in settings, because at the final stage of charging, the current decreases extremely slowly. And the minimum current will always be.

New lithium (Li) batteries take between 30 minutes and 120 minutes to charge. This also depends on the charger settings for each manufacturer.

Dependence of the charging time of the lithium battery on the charging current

General requirements for charging and features of different types of batteries

First in what is useful for charging the batteries of screwdrivers of any type.

- Complete discharge and charge cycle.

- Once a month, preferably more often, full discharge when operating the instrument and full charge.

- Discharge in cycles with interruptions to restore charge. For every 3 minutes of work. 3 minutes of break. With this method of discharge, the battery will give the maximum amount of accumulated energy. Consequently, it will charge in the maximum amount.

- Once every 3 months, conducting training cycles, and at least three times, if more, then better.

- A new battery needs to be discharged and charged at least three times, more is better.

- Store in a cool place between 5 and 15o.

Each power source has a minimum voltage level at which it is considered 100% discharged. By discharging the battery, we mean exactly discharging to the minimum permissible level. Further discharge. deep discharge leads to the beginning of destructive processes. And there is a voltage value at which it is considered 100% charged. Overcharging the battery is also harmful. as a result of electrolysis, its chemical components decompose. Please note that the voltage is indicated for 1 battery. Battery The screwdriver consists of several elements connected in series.

The voltage of one battery cell of a different type at different charge levels

The batteries can have different voltages: 12 V, 14.4 V, 18 V and others. Therefore, the voltage value at different charge levels is different in them. For example, in a nickel-cadmium battery (Ni-Cd) with a voltage of 12 V, the number of cells inside is 10 pieces. A fully charged battery has a voltage of 12.5. 13 V. After a 50% discharge, the voltage is 11.5 V (1.15 x 10). In discharged. voltage 9 V (0.9 x 10).

How to properly charge a new battery the first time and during exercise

How to charge the Screwdriver for the first time after purchase? Many manufacturers of lithium battery (Li) screwdrivers recommend simply charging the cell completely before first use. Few recommend doing 3 training cycles. discharge-charge. In general, for lithium batteries, a training cycle will be beneficial.

Unfortunately, none of the manufacturers, not even Bosch, writes how to properly discharge the battery during training cycles. Why this is important has already been said above.

If a power tool with Ni-Cd and Ni-MH batteries is protected against deep discharge, then the screwdriver is discharged before turning off. If there is protection, then to the undervoltage level. This is 0.9 V for each battery in the battery.

In screwdrivers on lithium batteries, protection against deep discharge is necessary, but it will be useful to know that the minimum voltage should be at least 2.8 V. Below this threshold, the destruction of lithium cells occurs. Manufacturers insure themselves and set a cut-off limit of 3.2-3 V.

Summarizing all of the Above in this article, outline the procedure for conducting training cycles that are useful for a new battery. It is recommended to carry out such a cycle at least once every 6 months, preferably more often.

- Discharge of the battery with a current of 0.1 of its capacity, or with the current of a working tool without load. With alternating working time and pause for 3 minutes.

- Will charge the battery by disconnecting the charger.

- Wait 20-30 minutes.

- Will recharge to disconnect the charger.

- Wait 20-30 minutes again.

- Will charge a third time in unplugging the charger.

- Wait 20-30 minutes for the voltage to stabilize.

- Now discharge in the manner described in clause 1.

- Repeat pp. 1-8 three times.

- Recharge or fully charge for storage based on battery type. If the tool will be used in the near future, it will fully charge until the charger is disconnected.

Battery charging recommendations from manufacturers: Sturm (Ni-Cd), RedVerg (Li-ion), Hammer (Ni-Cd)

What to do if there is no charge

If there is no battery charge, there may be the following reasons:

- Charger malfunction.

- The battery does not contact the charger.

- Protection sensor failure.

- Residual capacity is very small.

- Failure of SEPARATE battery cells.

The serviceability of the charger can be checked with a voltmeter or other battery.

Batteries and chargers have 3 contacts or more. Additional contacts provide connection to the protection sensor (s) located in the battery. In nickel cells, this is a thermal switch. If the battery reaches temperatures above 40. 50 °. Then the thermal switch disconnects the charger. The thermal switch must be closed. If it is open all the time, this is a symptom of a malfunction. You can short-circuit the “T” contact to the “minus” of the battery and charge without overheating protection. But it will be necessary to control the temperature of the battery and turn it off if the temperature is above 40 °. In lithium, there can be a whole integrated circuit with many protection elements. They control not only the temperature of the elements, but also the degree of charge of each.

Lithium battery protection integrated circuit

The failure of an individual cell is identified by the voltage of the charged battery. Even a battery that does not have a capacity should be charged to the nominal voltage. If the rated voltage matches, then all the elements have some capacity and give out a voltage close to the rated one. Carry out training cycles: if the capacity increases, then the battery is amenable to recovery. Continue training cycles until charge and discharge times do NOT stop increasing.

When the voltage of a charged battery is less than a multiple of the voltage of 1 cell, there is a high probability of failure of SEPARATE batteries from which it is assembled. The battery is disassembled and each element is tested. Defective ones are removed, and a serviceable one is soldered instead. From two defective batteries, you can collect one of the remaining serviceable cells.

Reduction of battery capacity due to incomplete discharge, and check of battery cells

Lithium ion (Li-ion) and polymer (Li-pol)

Store half discharged, 40-50% charge. The lower the storage temperature, the lower the self-discharge current.

Lithium battery discharge depending on state of charge and storage temperature

Nickel-cadmium batteries (Ni-Cd)

Ni-Cd batteries have been in serial production since the middle of the last century. Capable of carrying a very deep discharge. But this does NOT mean that they need to be discharged to zero at the final voltage.

Nickel-cadmium batteries (Ni-Cd) have a “memory effect” of the lower discharge value due to irreversible chemical processes. It consists in the fact that if the battery is completely discharged and charged, then it will give as much energy as it received when charging. The effect does NOT occur immediately, but with regular underdischarge, the capacity decrease will occur quickly.

It is recommended to charge the battery with a current equal to its capacity. 1 C (where C is the capacity of the battery). In this case, it will reach its maximum capacity. Standard chargers are charged with a current from 1.0 ° C to 0.2 C. A further decrease in the charging current leads to a decrease in capacity.

Influence of the charging current on reaching full battery capacity

A discharge with low currents, on the contrary, allows the battery to give maximum energy. Therefore, to restore the capacity of the Ni-Cd source, it is useful during training cycles to limit the discharge current to 0.1 C. If this is unacceptable due to lack of time (0.1 C is a 10 hour discharge), then you need to discharge the Screwdriver at idle in cycles : discharge, pause, discharge, pause. The optimal discharge and pause time is 3-5 minutes. During the pause, the cell will recover its charge. The more he will restore and give, the more he will take.

Influence of the discharge current on the amount of energy allocated by the Ni-Cd battery

How to store the battery. charged or discharged

Nickel-cadmium (Ni-Cd)

Stored in a discharged state. The charge level is close to 10-20%. It is caused by the presence of a self-discharge current and the memory effect, given that a deep discharge is not very harmful. In the discharged state, the self-discharge current is minimal. After storage before working, finally discharge and then fully charge.

How to properly charge Li-ion, NiCd and NiMh screwdriver batteries?

Everyone knows how to charge the Screwdriver. insert it into the charger and wait for the charging indicator to change color. But few people know that rechargeable batteries need to be serviced and be able to properly discharge. Unfortunately, power tool manufacturers provide very little information in their manuals. How to properly charge and maintain the battery Screwdriver, we will tell in this article.

Types of batteries

In order for the battery to last a long time “like a clock”, you must first familiarize yourself with the instructions attached to the device. It should be noted that screwdrivers differ Not only in price, power, manufacturer, but are also divided into professional and semi-professional. Accordingly, batteries will also have different prices, quality and charge capacity. Professional types Equipped with a more capacious power supply, which will cost one level more, but will also last longer than normal ones. Manufacturers use various batteries in the manufacture of their devices, each of which is endowed with certain parameters and features, which should be taken into account during recharging. Batteries for screwdrivers can be classified into the following types:

Lithium Li-Ion

They are considered the most powerful batteries. They charge quickly enough, and they also have a complete lack of memory effect. Recharging this type of battery is easy. Whenever it is necessary to recharge it after complete discharge, it is allowed to recharge it as needed. The high cost and intolerance to low temperatures discourage many people from buying, so they are NOT too much in demand. Charge batteries at temperatures between 10 and 40 ° C. If the battery heats up during charging, it must be cooled to avoid further damage.

Nickel-cadmium Ni-Cd

Nickel cadmium battery is endowed with compact dimensions and large capacity. By following the attached instructions, they can be recharged over 1000 times. There is a memory effect, if you charge it before a full discharge occurs, this can reduce energy consumption. Before the first use, you need to charge and discharge the battery at least three times. In the future, it is also recommended to completely discharge and charge the device, this will make it possible to bring the capacity to the required operating state. The same rule applies when storing the instrument.

Nickel Metal Hydride Ni-MH

They belong to the newest generation of batteries, for this reason, the memory effect is somewhat weaker than the previous version, which is an undoubted advantage. The disadvantage of the NMGB is the highest self-discharge current. In order for the battery to function for a long time, it must be kept charged. In case of long-term non-use of the screwdriver (about a month), it must be completely recharged.

As you can see, each rechargeable battery is endowed with characteristic features, taking which, it will be possible to properly charge the screwdriver.

What is the optimal amount of time for charging?

The recharging period is usually specified in the device manual. In most cases, the device has a special indicator, which helps to understand how long it takes to charge. After charging is completed, disconnect it to avoid damaging the batteries. The average charge for a screwdriver is between 30 minutes and seven hours. Longest period in 1.2 V Ni-Cd, 250 mA feed approximately seven hours.

There are also two types of battery chargers: ordinary and impulse. Standard charging is most often completed with non-professional tools, the charge lasts about 3-7 hours. The impulse device is designed for professional models and is able to power the battery in a maximum of 1 hour.

Advice: The Interskol screwdriver is distinguished by its versatility, besides the main function, it can also be used as a drill.

Should I charge before long-term storage?

DO NOT use a screwdriver battery for a long time? Experts give the following recommendations.

- Nickel-cadmium batteries, before being stored, need to be discharged to the point where the screwdriver ceases to function at full strength. For long-term storage, you need to carry out 3-5 full circles of charging / discharging.

- Nickel-metal hydride ones are provided with a higher self-discharge value, in contrast to the previous parts. Experts advise keeping them charged, and after a long break it will recharge for a day. The capacity decreases after 200-300 charge-discharge cycles. Partial discharge allowed for this type.

- Lithium-ion devices are distinguished by the complete absence of the “memory effect”. The battery can be charged whenever you want. It is not recommended to completely discharge them, as a result, you can disable the protective circuit. Equipped with special controllers, which at high temperatures disconnect the element to prevent overload. You can keep the cell charged only 50%.

Features of charging one type or another

The initial charging of the screwdriver is considered a very significant factor, since it depends on it whether the full charge capacity becomes active or not. Any type of battery has its own characteristic features of primary charging. The process of recharging a nickel-cadmium battery is somewhat complicated. Initially, it needs to be recharged three times in a row, and so that the charge capacity remains full.

Nickel-metal hydride species for the first time is recommended to fully discharge, and also fully charge. The circle of full charging / discharging is repeated 4-5 times, then you can safely charge and discharge the battery regardless of the capacity of the capacity.

There are no special rules for lithium-ion, the capacity remains unchanged for a long time.

Advice! Do not allow the power supply to overheat over 50 degrees.

How to properly charge the Screwdriver

The screwdriver is one of the most demanded tools used by professionals and amateurs. Using power screwdrivers is not always convenient, especially if you are away from 220 V. With a cordless tool, this problem is solved, you can move freely with it, and do not drag the cord along.

One of the main elements of any cordless tool is the battery, which ensures autonomous operation. But how to properly charge the battery so that it lasts as long as possible? Further in detail in the article.

What to do if the battery does not charge? (2)

The reason may lie both in wear and tear and in the breakdown of the device. It often happens that the contacts between the terminals of the charger and the battery are broken. Then you can independently disassemble the “charging” and adjust the terminals.

As you know, all contacts oxidize and get dirty over time, for a screwdriver with a charger. This is no exception. This usually results in a significant reduction in charging time as well as in the duration of the power tool’s activity. To eliminate the oxide, you need to carefully wipe the contacts with a special substance or, in extreme cases, with alcohol.

Very often nickel-cadmium batteries lose their capacity, especially when it comes to non-professional models. Experienced users prefer overclocking such batteries. First, the battery pack is disassembled and problem areas are found. Then they need to be recharged. It is better to immediately use a higher current than necessary, and then re-discharge. If Ni-Cd still has NO electrolyte disappearance, the procedure can restart the power supply.

And some connoisseurs even use a car charger to recharge the battery.

How to store nickel cadmium screwdriver batteries

The performance of cordless screwdrivers is the same as for networked models. The advantage of cordless types of screwdrivers is their mobility. However, in order for the power tool to serve for more than one year, it is necessary to figure out how to properly store its battery. In particular, know how to store nickel-cadmium screwdriver batteries.

How to store the battery

Any master who takes good care of a power tool is concerned about how to properly store the battery from a screwdriver. Compliance with the maintenance rules applies to all types of batteries.

Points to remember:

- If a decision is made to send the screwdriver for storage, then before this there is a discharge several times and will charge the tool.

- The optimum positive temperature for storing the battery is 10 degrees. Freezing of the device must be avoided.

- Charging is recommended every six months. This procedure extends battery life.

- It is advisable to disconnect the power source from the screwdriver, while removing all dirt from its surface. Remove oxide from contacts with a special cleaning agent or alcohol-based liquid.

- Nickel cadmium batteries Must be slightly discharged. This is done due to their rapid self-discharge.

- Avoid exposure to direct sunlight and moisture. High temperatures can melt the plastic housing, damage it and cause loss of efficiency. Water ingress will also damage the internal battery cells.

Experts in such cases recommend overclocking with such a battery. To find out what is the reason for the decrease in work efficiency, the battery is sorted out, problem areas are calculated. Then the cells are charged again. For charging, first a large current is selected, then, after another discharge, a small current.

If electrolyte is stored in the batteries (it may evaporate), this procedure will help to revive the battery.

How to charge batteries to extend battery life

To properly charge the battery, remember the following:

- It is best to charge the battery when using the tool for the first time. It happens that during storage they are discharged.

- In nickel-cadmium batteries, the maximum capacity appears after the third charge-discharge cycle. Then the drive is charged when the minimum power occurs.

- Lithium-ion batteries are recharged as needed, regardless of charge level, as they have no “memory effect”.

Features of charging nickel-cadmium batteries

Immediately before using any power tool, you need to study the instructions with the recommendations of the manufacturer. All tool brands such as Makita, Metabo or Interskol have them.

In THESE instructions for charging nickel cadmium batteries, you will find a number of similar points:

- It is necessary to charge the battery taking into account the temperature regime (the air temperature is NOT lower than 5 degrees)

- It is advisable to store the charged battery separately from the screwdriver so that the contacts do not oxidize;

- Monitor the charge level using an indicator built into the charger;

- Nickel-cadmium batteries are always charged to maximum and discharged to minimum.

How the screwdriver battery works

A rechargeable battery is a chemical source of current used to operate cordless types of power tools. The accumulation of electricity occurs due to the electrolysis occurring in the battery. This process creates a constant voltage of the required level.

The voltage in the battery arises from the potential difference between the cathode and the anode. The unit of capacity is the ampere hour. This value indicates the amount of current that is provided by the battery in an hour.

The device of the battery pack (battery) does not depend on the type of screwdriver model.

It includes the following structural elements:

- The case on which the contacts are located;

- Series connected power supply elements (batteries)

- Thermistor that protects the battery pack from overheating.

Thermistors Not available on all models. Tool body, two-piece, plastic. It contains a dozen energy storage devices (in some cases, there are more). The batteries are interconnected in a single serial circuit.

The extreme terminals are connected to the contacts located outside the housing. THESE pins connect the tool to the charger. The output voltage of the battery pack is the sum of the voltages of the strings of batteries.

There are four contacts outside the battery case:

- Two power contacts (positive and negative), the purpose of which is to charge and discharge the battery;

- Contact located at the top to control the thermistor;

- A contact capable of charging with the help of a special station and equalizing the sizes of charges of each storage unit included in the block.

There are rechargeable batteries of the following types:

- Nickel metal hydride (or Ni-MN). They have an output voltage of 1.2 V. Manufacturers of such batteries position them as environmentally friendly. This applies to both production and further disposal. Despite the small dimensions in comparison with the batteries of the second types, they have a larger capacity. Another plus of this type of drives is performance at low temperatures. The disadvantages of Ni-MH batteries include high cost, limited service life and increased self-discharge. When working, it is not recommended to discharge them completely.

- Lithium ion (or Li-ion). The voltage of this type of battery is directly proportional to the number of storage devices included in the battery. The range is from 1.2 to 3.6 V. Li-ion batteries have a control board and a special controller that monitors all power supply links included in the unit. The advantage of lithium batteries is the absence of a “memory effect”, large capacity, low weight. Lack of “memory effect” allows you to charge the battery as needed. It is desirable to charge it well before prolonged work. The charge can be stored for a long time if the battery is at least half charged. The disadvantages of this type of batteries include their high price, short service life, the inability to work at low temperatures. Batteries of this type are the most common. most construction tools are equipped with them.

- Nickel-cadmium (or Ni-Cd). This is the battery standard for all power tools with battery. The advantages of Ni-Cd-type batteries lie in their: low price, fast charging functions, functions of transferring the maximum load current, the ability to maintain high capacity at temperatures below twenty degrees, the ability to perform a charge-discharge cycle up to a thousand times.

If you do not neglect the information on how to store Ni-Cd batteries in screwdrivers, you can significantly increase the life of the tool.