Safety rules

The approaches to how to properly cut glass with a roller or diamond glass cutter are the same. The main thing is to follow certain rules and remember about safety:

- Put on protective equipment: gloves and glasses;

- Put the glass on a flat surface and check that it fits well to it and does NOT vibrate;

- Tap the ends of the cut line with your finger to relieve pressure and avoid edge chipping;

- The diamond glass cutter is taken at the base of the handle and is driven without much pressure along the intended mowing line;

- The roller glass cutter is pinched with a pinch between the thumb, ring and middle fingers, and the index fingers are responsible for the pressure. It should be pressed to Get a whitish cut;

- On the reverse side, lightly tap on the mowing line and cut;

- Slide the glass to the edge of the table and break off along the cut line.

Expert advice! Smooth line of the cut can be obtained by using a ruler. To prevent the ruler from sliding, it is glued with double-sided thin tape. It will ease the break too.

There is a ratio between the width of the glass and the width of the strip that breaks off freely:

| Glass width, mm | Strip width, mm |

| 3 | 3 |

| 4 | five |

| five | 7 |

| 6 | nine |

| eight | 12 |

Craftsmen have their own handwriting in working with glass surfaces, but you should adhere to some general recommendations on how to cut glass correctly:

- There is NO strong pressure on the glass cutter so that the edges of the cut are NOT crumbled;

- One line. one cut, it is impossible to “cut” again in one place;

- The movements of the glass cutter Must be quick and confident. Optimal: 1 m in 2 seconds;

- The pressure is reduced to the edge, which allows NOT to crush the edges;

- Mark the table, not the glass itself.

Technology and operating principle of the tool

Glass is a fragile material, it is very problematic to work with it. Cutting such material requires a delicate attitude, and not everyone succeeds. For cutting glass, in order to give it the desired shape, today they use several types of glass cutters, but most often the classic version is preferred. It leaves a neat scribbled line on the glass surface, and it remains only by drawing the break-off contour the desired piece.

Plexiglass: glass or plastic

But not all types of glass are cut with a glass cutter. There are materials on the construction market that either cannot be cut at all at home, or to cut them you need to familiarize yourself with some of the rules, and some are cut very simply.

One of the most pliable materials for cutting is plexiglass. It is a transparent plastic with thermoplastic properties. The material is very easy to process, but there is one feature: low thermal conductivity, due to which the edges of the cut are immediately heated. Therefore, before cutting acrylic glass, you need to consider how to cool it.

Basic tools for cutting plexiglass:

- Hand saw for metal;

- A circular saw;

- Cutter;

- Milling machine;

- Stationery knife.

The choice of tool directly depends on the thickness of the glass: thin. with a knife, the thickest with a circular or on a machine. The saw blades are used special for plexiglass, but will do for d, aluminum.

It is necessary to work quickly with a hacksaw or stationery knife. Unlike window glass, the cut can be made several times along the mowing line. During cutting, the blades are cooled so as not to melt the cut edges. The resulting cut will have roughness, which are removed when processing with sandpaper.

A low melting point makes it possible to cut plexiglass with a jigsaw and get a wide variety of shaped products. In a jigsaw, the saw is replaced with nichrome wire. Which is connected to a transformer with an operating voltage of up to 4 V. The heated wire easily and gently passes through the plexiglass along any path. The spray is smooth and even, and does not require additional processing.

Features of working with non-standard glass

Tempered glass is NOT amenable to processing at home, when exposed to mechanical stress, it crumbles or breaks into pieces. Corrugated glass cutter is cut in the same way as usual, but on the smooth side.

Corrugated glass is cut from the flat side

Acrylic glass is NOT actually glass. Thin material is cut with simple scissors or an ordinary knife. A thick sheet can be drawn along a line of debris of a hacksaw blade, several times, and then overtake and break along the mowing line grooves.

Acrylic glass is easy to cut

How to cut a circle out of glass

In order to be able to cut a circle out of glass, you can use several different methods, which may differ depending on the diameter of the future circle and, of course, the thickness of the glass.

The simplest and most common way to cut an even circle is to use a circular glass cutter. Usually, the presence of such a tool on the farm is quite rare. But for THESE purposes, you can use the usual tool.

How to cut a circle from glass glass cutter

First of all, you need to designate the central part of the future product and fix a special suction cup on it. Then to this suction cup you need to tie a strong thread or fishing line with a length equal to the radius of the planned circle. At the end of this rope you need to tie the glass cutter itself. Stretch the rope as much as possible and then draw the line with the tool in a circle around the suction cup. When the circle is drawn, it is very important to additionally make more beam mowing lines, which will eliminate unnecessary pieces of glass around the finished product.

Workplace

Convenience and success of work largely depend on the place where the glass will be located during cutting. An unsuitable work surface can result in uneven chipping, cracks, scratches and even injury to the glass. There are several simple rules that will help you to save material and get a decent result.

The most important thing is that the work surface is level. There should be no bulge or indentations on the table, floor or other place where you will cut glass. If there is a void between the material and the surface, then under the pressure of the glass cutter, fragile glass can simply crack.

The table, workbench, stool and any other structure must be stable so that the glass cutter does NOT jump off the mark when the line is being guided. For greater adhesion to the surface and to avoid cuts on the glass, it is better to place a piece of cloth between it and the working area. Place a sheet, bedspread, or any other soft cloth on the table, slightly larger than the glass being processed.

How to replace a glass cutter

Not only professional tools will help when cutting glass, but also not quite ordinary ones, such as scissors or an angle grinder. They can easily cope with such work under certain conditions.

Scissors do not cut glass in the air, but you can cut glass with scissors in water. In a liquid, the force of gravity is less and the scissors do NOT make an incision, but microcracks. This crack plays the role of a capillary in which water will enter. Capillary water has a wedging effect on weak crystallization points and the glass breaks off in pieces.

Interesting! If it is necessary to cut curly parts, the glass is placed in cold water and then boiled for several hours. After cooling, the tension inside is removed and the material becomes soft.

There are several ways and options for how to cut thick glass. The easiest one is to use an oil glass cutter if the thickness is NOT more than 20 mm. But as an option, you can use an angle grinder. Tool dimensions Should be small and handy. The diameter of the circle is the smallest, then it will be easier to work with it.

Safety compliance

To avoid injury, work with gloves. Pay attention to shoes, which should be durable so that accidental glasses don’t cut your feet. It is necessary to dress in dense overalls made of thick fabric.

Glass cutting glass cutter

At its core, the glass cutting process is quite unusual, but at the same time it may seem complicated only at the first attempt. If you perform the necessary actions in the correct order, and also cut with a certain speed and force, everything will definitely work out. The following guide will walk you through the steps on how to properly cut with a glass cutter, but while the theory is complete, we recommend that beginners practice on the less valuable shards first. It is better to start with the main material, at least after a couple of successful cuts.

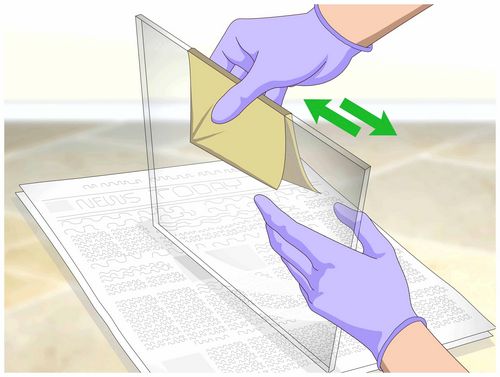

The first step is to prepare the glass for work. For this, its surface must be cleaned of dust and dirt. The line will be cut more evenly on clean glass, which will increase the chances of even chipping. The washed surface should be wiped with newspaper and degreased with alcohol or kerosene. After all procedures, leave the glass for 10 minutes to evaporate the remaining moisture.

It is better to draw markings on glass with a felt-tip pen or a steklograph. To do this, simply measuring the dimensions we need from both edges, apply a ruler to the indicated points and outline the line of the future cut.

The most important step in the whole process is cutting the glass. We take a roller or oil glass cutter (the diamond is described below) and draw a short line, up to 5 mm from the top edge. Next, from it we lead the cutting roller to the end of our mark. We move the glass cutter over the glass with a precise, confident movement with a pressure force slightly above average. If the incisor is sharp and the force applied is optimal, you will hear a slight crackling sound. The resulting fishing line should be uniform and translucent. Intermittent expansion or breakage of the line may be caused by a blunt cutter or too much pressure. It is not recommended to spend twice in one place. Better to retreat 5-10 mm from the original mark and make a new cut.

The culmination of cutting the glass is splitting it. There are several correct methods for controlled cleavage. It is always better to read with the most delicate exposure, and in the absence of a result, a higher load (within reason).

We put the glass on a table or other more or less flat surface, so that the cutting line is parallel to the edge and extends a couple of centimeters beyond it. Next, take a glass cutter and lightly tap with an iron tip at one of the edges of the cutting line on the back of the glass. When a small crack forms, simply break off the hanging piece of glass with a slight movement of the hand.

If, after a couple of dozen blows, cracks have not formed, go to plan B. Put a match, nail or toothpick at the end of the glass, along the cutting line of the cut and lightly press on the blade from the sides. If, after moderate pressure, the glass remains intact, you can resort to the roughest method. Align the line of the cut with the edge of the table or other surface and press on the part to be broken off with your hand. This should be done with gloves and goggles. It is not worth overstraining. If the glass does not break, then the cutting line is not deep enough and it is better to try to make a new one and pay attention to the sharpening of the cutting roller of your tool.

After a successful glass chip, it remains only to secure it, cleaned the edges with fine-grained sandpaper or a bar. Hopefully the above guide will help you make an accurate cut of glass. For greater clarity, we recommend looking at how to use a glass cutter with a wheel and a diamond.

Figured

Curly line is a zigzag, wave, broken line or curve in any form. So, for example, colored glass is cut, which serves as a decoration. Shaped glass cutting is used for laying glass mosaics, for example, on non-cured, freshly laid cement plaster. The cutting process is NOT much more difficult than conventional cutting.

Figured cutting is performed according to a pre-prepared template. Oval, flowing fishing line is made from chipboard or plywood. The pattern is fixed on the glass sheet by means of double-sided tape. it will not allow it to move over the glass during cutting. The glass cutter is an average of 2.5 mm from the precision mowing line. Having drawn a furrow of a given curvature, the glass sheet is cleaved using a glass cutter or a hammer. Separating a piece within the letter may require additional cutting the glass cutter from the outer edges of the sheet to the inner mowing line of the cut.

How to cut other materials?

A glass cutter is not needed for acrylic glass. It is an organic material that can be cut and chipped with second cutting tools. down to a simple knife. Thickened, more than 2 mm, acrylic sheet is drawn several times in the same place. Accurate scrapping along the mowing line is carried out due to weakening, thinning of the material at the point through which the cut line passes.

Tiles or thin tiles are cut with a glass cutter in the same way as ordinary glass. The tiles are made from baked clay. Thin, up to 3 mm, sheets and squares of tiles can be cut with an ordinary glass cutter No worse than a simple window glass.

This is a reinforced and enlarged (in size) version of a conventional glass cutter, which has a roller (wheels) that is larger than a simple tool and thickened along the axis of rotation. In some cases, the number of rollers reaches five. the more there are, the longer the running footage of the cut materials.

Floor tiles are cut without unnecessary chipping using roller glass cutters or diamond. Like any fired clay product, ceramic tiles can be easily cut using glass and tile cutters, an angle grinder or a stationary machine. Any glass cutter is suitable for cutting a bottle, except for a circular cutter, as well as folk methods based on sharp heating and cooling of glass. In the latter case, the glass will burst from the temperature drop, if it is NOT hardened, but the cut line will NOT be quite even.

Precautions

When cutting glass, and not using protective gloves and goggles, the worker can cut both hands and eyes with glass dust and small fragments of blockages. It is forbidden to try to cut the glass sheet, put it on your lap or questionable support structure. Glass cannot be carried over the edge with bare hands. the edges, sharp as a scalpel, cut the skin in seconds. Lifting the letter, they take it not by one edge, but by two. A large sheet is easy to break if transferred carelessly.

Shoes and trousers Must be closed type. in case of an accidental fall, unprotected skin is easily cut. There are cases when a worker, with careless movements, cuts the veins with sharp edges on the arms or legs and leaves further work for a long time. A protective suit or overalls should be made of dense fabric. it will protect the human body from injury. After work, shoes and clothes Must be sent for cleaning. this will prevent the spread of glass particles throughout the house or the site, their accidental ingestion.

How to cut glass and other materials glass cutter?

It is much more difficult to do without a glass cutter when cutting glass than to use one. There are several methods that allow you to cut glass without a glass cutter, many of them are simple, but take time for the master, whose work is put on stream.

Ordinary

A roller, diamond or glass cutter with oil supply is used to draw a furrow along which a chip is cut. From the beginning to the end, the furrow marked by the mowing line is drawn with uniform speed and force. The cutting part must not be blunt. Effort is slightly above average. The furrow should be Translucent, no breaks in and NOT too deep.

Excessive force can quickly disable the cutter. One of the correct results is a slight crackle. It is recommended that, when a furrow breaks, retreat half a centimeter from the previous mark and perform a new tracing. It is optimal to start with a little effort and quickly build up the desired level of impact on the glass sheet. A beginner will quickly learn this and will soon begin to cut sheet by sheet.

Gradually increasing the intensity (force) of tapping the glass cutter or with a hammer in the place where the groove is drawn, they achieve the appearance of an even crack, which splits the glass in the correct direction. When the crack reaches the opposite edge, the piece of glass will separate itself. It is not recommended to chip the glass with small fragments. this will complicate the separation of the necessary and unnecessary parts of the glass sheet.

If tapping the glass cutter does not give results, put a match or a toothpick along the mowing line. The worker presses on the glass on either side of the drawn furrow. When the glass does not crack along the mowing line the cut is cut, and is aligned with the edge of the table. The hand of the protective glove exerts a breaking force on the glass sheet. If the third attempt is unsuccessful, this letter must be cut through the glass cutter again. It may be worth changing the cutter or replacing the blunt roller with a new one.

If you have a glass cutter, you can use a concrete drill instead. If a roller or oil glass cutter does NOT fit, then you should resort to a diamond one. The new furrow is cut by a fully serviceable and working glass cutter, not a worn one. If too narrow a strip is broken off, the excess letter to be removed is chipped off with pliers or side cutters. Sharp edges are blunt to prevent injury with fine sandpaper or a fine-grain sharpening bar.

Cutting technology

Despite the seeming uncommonness, glass cutting is not difficult for a person, as, having worked for more time, he has mastered and has the necessary skill. Cutting glass sheets is not a job where haste and efficiency go hand in hand. For the process to be successful, speed and strength must be matched with each other. A beginner, for the first time in his life, taking a glass cutter in his hand, practices on fragments or pieces that are waste from the main cutting and are of no value.

The guide line, along which the cutting is performed, is applied with a felt-tip pen or using a glass recorder. In the vast majority of cases, if this is NOT a decorative window with an original frame, the curvature of which is arbitrary, the line is drawn along a ruler. Before starting work Make sure that the glass cutter is in good working order.

Features of working with different types of glass

Before cutting the glass with a glass cutter, make sure that the glass in front of you is exactly the type with which you are working. It does not matter whether it is old or new. on its surface there should be no traces of foreign substances and particles that interfere with cutting it accurately and evenly. Tempered glass cannot be cut at home. Tempered, it is no longer subject to processing: it is easy to break, since such a glass sheet has lost the properties inherent usually in window glass.

It is connected with its unsuitability for cutting with a bending impact force exceeding the same force in simple glass by 7 times. Being resistant to breaking, it resists any mechanical stress, including cutting.

The slightest pinching will immediately lead to cracks, diverging in all directions. Cutting of tempered glass is carried out only on very precise machines, and does not allow lateral and tangential overload, which easily transforms the tempered letter into a small crumb, consisting of cubic blunt fragments. Tempered glass sheets and products are processed in annealing process, which deprives the glass of the ability to cut into pieces, rather than cracking in all directions.

Corrugated (corrugated, wavy, patterned) glass is cut from the smooth side. Trying to cut the letter from the decorative, “Curly” side, the master will NOT achieve the continuity of the furrow along which this sheet breaks. An intermittent furrow will, at best, make the cracking line uneven, at worst, a section of the glass sheet will simply break. It is better to entrust its cutting to a roller glass cutter, which has a perfectly smooth blade rotating around its axis.

Scratching the furrow is possible even with a regular steel nail. A red-hot, sharp knife also helps to quickly cut the blade, spending special effort.

Acrylic glass is easy to saw and cut, even standing on an edge and having a thickness of NOT more than 2 mm. It is not necessary to heat the knife in this case. Thicker clear acrylic can be easily cut with an angle grinder or a gripping machine. A sharpener or file will allow you to quickly and efficiently level the edge along the required mowing line of the cut.

Large sheets, exceeding a few square meters, are cut to the glassworks using devices that supply high-pressure fluid. Plexiglass is easy to cut with the help of a constantly heated thin wire pulled into a string. it quickly and evenly enters it, like a fishing line in butter at a temperature of 5-10 degrees Celsius.

Training

To cut glass with a glass cutter quickly and efficiently, the glass sheet is pre-cleaned. A new sheet of glass only needs wiping. A crumpled newspaper will give the best results. newsprint does NOT leave lint, even though it is a dusty environment in and of itself. Glass rubbed with newspaper will remain dry. A high-quality washing result is achieved using non-abrasive detergents, which removes most everyday stains and smudges, but maintains a glossy, perfectly flat surface.

Grease can be easily removed with kerosene, dried paint can be cleaned off with a razor blade, utility knife, or removed with solvent 646. It will cope even with dried paint. Traces of polyurethane foam can be removed using any fuel and lubricant. After cleaning, washing, wait until the glass is completely dry.

The second stage is glass marking. Particularly difficult to cut and separate segments in the form of curved lines used in decorative insulating glass, installed on special occasions. These cases also require careful calculation. You may need two different glass cutters that differ from each other in the shape and execution of the workpiece. A competent and individual approach will allow you to reduce the amount of waste or do without it altogether.

As a workplace, they use a table with a chipboard or natural wood tabletop, covered in the place where the glass sheet itself lies, with a dense and thick cloth. It will not allow the glass to squeeze dust and debris, which will be easy to notice when cleaning the table. And it will also hide it NOT a perfectly flat surface, to which the glass sheet does NOT fit everywhere.

Useful Tips

The secret of a successful cut lies in the following.

- If the running life of a roller or oil glass cutter is insufficient, purchase a diamond one. Its peculiarity is that the master learns to work with him longer. To adapt to a specific product, the footage of the test furrow often reaches 200 m.This is the angle of sharpening and the direction of the edges depends on how quickly the worker begins to work with the diamond.

- If you’ve got a diamond cutter, examine the edge of the cutting edge under a magnifying glass for nicks and chips. A diamond is recognized by the shape of the teeth. flat and straightened, plus a steep dihedral. A sloping and straight edge should face the master.

- The task of the master is to determine the slope at which the cutting of the mowing line of the cut will be extremely lightweight. The groove from the diamond is significantly thinner than from the roller, and the cutting process itself is characterized by glass clinking, rather than crackling.

- The deviation of the diamond even by a degree is unacceptable. the groove will get coarser, blurred edges on both sides. When chipping, irregularities in the edge are formed, which require extensive smoothing. A diamond glass cutter is able to cut through more than one linear kilometer of glass. along the mowing line of the cut.

Not every master will learn to cut quality glass the first time. Practice will quickly develop a certain skill in a beginner. It is better to pass unsuccessful attempts on the glass remnants formed after cutting by the second master.

How to cut glass correctly, see below.

Preparatory activities

In order for the cut to be of high quality, you must first prepare the material for work. If the glass is new, then just wipe it down. A newspaper is best suited for THESE purposes, mainly it wipes the surface dry, and also does not leave lint and stains behind.

If the glass was previously in use, then before cutting the glass cutter material, it will take a little more time to prepare it. First of all, such a surface will need to be washed well, using special glass cleaning products. This is followed by a thorough degreasing process. Alternatively, you can use kerosene. To do this, wipe the glass thoroughly with a cloth soaked in kerosene and wait until it dries completely.

At the same time, the stage of glass preparation also includes its cutting. There is no doubt that you will be able to achieve the final result without waste, especially if you need to cut an item of irregular geometric shape. But if you make the calculation as correctly as possible, then you can reduce the amount of waste several times.

Also, make sure that the work surface is sufficiently flat and without slopes, but not too hard, it is advisable to make the work surface of plywood or fiberboard, and cover it with oilcloth or soft cloth on top.

How to cut a circle out of glass

In order to be able to cut a circle out of glass, you can use several different methods, which may differ depending on the diameter of the future circle and, of course, the thickness of the glass.

The simplest and most common way to cut an even circle is to use a circular glass cutter. Usually, the presence of such a tool on the farm is quite rare. But for THESE purposes, you can use the usual tool.

First of all, you need to designate the central part of the future product and fix a special suction cup on it. Then to this suction cup you need to tie a strong thread or fishing line with a length equal to the radius of the planned circle. At the end of this rope you need to tie the glass cutter itself. Stretch the rope as much as possible and then draw the line with the tool in a circle around the suction cup. When the circle is drawn, it is very important to additionally make more beam mowing lines, which will eliminate unnecessary pieces of glass around the finished product.

How to cut glass without glass cutter

You can cut glass without using a glass cutter. Very often, the simplest scissors are used for this procedure. To cut fragile material with scissors, place it in warm water and cut out pieces of the size you need underneath. Regular glass will NOT be harder to cut with scissors than cardboard or other sturdy paper.

If a large piece of glass needs to be cut, it can be placed in a large basin or tub. Then run the sharp part of the scissors over the glass, breaking off unnecessary parts of the glass. In order not to cut myself on the sharp edge, be sure to put on gloves first. At the same time, it is also desirable to protect the eyes.

In this way, you can cut glass no more than 3 mm. Shapes can only be cut with straight contours. In advance, it is imperative to prepare a template and glue it to the glass using glue. It is worth noting one interesting point: the more water is above the glass, the easier it will be to cut the future product.

You can also use twine, some kind of hot liquid and a small vessel that needs to be filled with cold water. You need to make the necessary marks on the glass, then soak the string with alcohol or gasoline, Fold it on the marks and set it on fire. Immediately after the fire goes out, pour a thin stream of water over the fishing line. At this point, the glass must necessarily crack. Then break off the glass along the cracks that have turned out, and sand all the edges with sandpaper. If cracks DO NOT appear, then you need to repeat the whole procedure again. In this way, you can cut very complex shapes, everything will depend on how you lay the twine.

How to cut a glass cutter at home

Sooner or later, the household may need to replace the glass on its own. But working with such a fragile material is very traumatic. In this connection, in order to avoid injuries and excessive consumption of material, you should know the basic rules for working with this material and the selected tool.

Cutting ordinary glass is very simple and it will NOT cause any problems for a person. You can cut such glasses with special glass cutters or even ordinary scissors.

If you have NO clue on how to properly handle this tool, then you can look at our Numerous site on this topic. They will help you cut the desired shape and provide the necessary information for working with a rather complex and fragile material like glass.

How to cut glass glass cutter: detailed instructions

If you are planning to carry out work on cutting glass, then first of all you should decide which glass cutter is best suited for your case. At the moment there are two types of tools. diamond and roller.

The diamond model is considered to be the leader among the tools of this type. If you are going to use it at home, then the model that has a beveled edge is perfect, which is very convenient for breaking off cut pieces. You can cut glass with such a glass cutter for almost ten kilometers of material, with a thickness of up to one centimeter. But at the same time, it should be borne in mind that there are also cheap types in which an artificial diamond is installed, which allows cutting glass with a thickness of NOT exceeding 5 mm.

Unlike diamond, a roller glass cutter has a working element in the form of a small roller, usually made of carbide materials, usually a tungsten-cobalt alloy, which is capable of cutting material up to 4 mm thick. The advantage of this type of tool is that the roller can easily move on the glass, while, and not applying great effort to lay the furrow.

The work process is carried out in the following order:

Clean and dry glass is laid on the surface of the working table. The necessary markup is made with a marker. Further, at both ends, small cuts are made along the marked mowing line. Please note that the material used must be in close contact with the surface of the work table.

After that, you need to put a ruler on the glass and draw a fishing line along it with a tool. It is worth holding a diamond glass cutter in your hands in the same way as a regular pencil, when passing along the marked mowing line, only a little effort should be applied. As a result, only a barely noticeable trace remains on the glass, which looks like scratches. If the instrument is in good working order, then a characteristic crackle-like sound must be present. If the sound is creaking, then this means that its cutting element needs to be sharpened on a bar specially for this.

Hold such a tool during operation at a slight angle, the correctness of which is determined empirically. Please note that a tool that is in the correct position for the glass leaves a colorless thin line.

A roller glass cutter, unlike a diamond one, must be held strictly at right angles to the surface of the glass, while pressing it with the middle and thumb, and pressing it with the index finger. Please note that the roller tool is pressed a little more than the diamond one, and the notch itself should turn out to be white.

In order to get a high-quality and, of course, an even cut. remember a few simple rules that must be followed while working with glass with the introduction of a diamond tool:

- Do not press on the glass while moving the cutter, otherwise the cut will be too deep, and its edges will be uneven.

- In no case should you make another cut on the resulting mowing line. Otherwise, the glass may break. The incision should be done as quickly as possible. For example, if we cut a length into a meter, then you need to spend no more than two seconds on it.

- In order for the workpiece to break off quickly and accurately along the mowing line of the cut, you need to lightly tap on the back of the glass. After which you will not need any effort to break it off.

If you are just a beginner, it is best to practice on small pieces, this will help determine the correct angle of inclination of the instrument, gain experience, reduce losses, and also avoid mistakes in the future.

Safety compliance

When cutting glass, it is very important to observe safety precautions, because the material is quite fragile and dangerous. You can not only cut yourself, but also hurt your eye with shrapnel.

In no case should a glass cutter cut glass on your knees or on unreliable objects. Never touch the edge of the glass, as raw edges can be very sharp. If you want to raise the workpieces, then you should make a coverage with your hands from the sides.

Wear protective gloves and goggles before handling to avoid cuts. It is also important to wear closed shoes so that the glass does NOT cut your foot if it falls accidentally. Clothing should be made of dense and thick fabric, which will also help to avoid accidental injury.

In order to prevent small glass fragments from falling within the working room, clothes and shoes must be changed at the end of the work.

What is needed to get the job done?

When deciding how to properly cut a glass cutter at home, you must first purchase all the necessary elements. In addition to a glass cutter, you will need a ruler if the cut is straight and a curve, if it is curved. Without a normal pattern, you will not be able to make an even curvilinear cut of both simple and tempered glass.

You need to buy a good diamond glass cutter and then, in order to cut tempered or plain glass, you just need to make one pass.

Cheaper models may need to do multiple passes.

In addition to the quality of the glass cutter, care and accuracy of work is of great importance.

Of no less importance is the surface on which the cutting is carried out, plain or tempered glass. It should be flat and the glass is firmly attached to it. Some people believe that cutting tempered glass at home is impossible.

Everything will depend on the degree of hardening, if it is high, then there is a high probability that it will crumble into small pieces.

It is especially difficult to cut tempered glass with an angle grinder. If you nevertheless decide to use an angle grinder, then you need to use a diamond disc and supply water to it.

But please note that the slightest deviation of the angle grinder or glass cutter from the mowing line when cutting tempered glass, it will crumble. If it becomes necessary to work with tempered glass, then it is better to do this on a machine with a diamond wheel, while a cooling emulsion must be supplied to it.

Before starting to perform this work at home, you need to decide on the type of glass with which you plan to work. Regular glass is easily cut with a glass cutter or even scissors.

If it is necessary to cut corrugated glass, this must be done from the smooth side, for THESE purposes it is better to use a roller glass cutter.

If the glass is organic, then it can be cut as a glass cutter or angle grinder, or with a regular saw.

If the thickness of the material is less than 2 mm, then it can be dealt with with a clerical knife.

When choosing a glass cutter, you need to pay attention to its sharpening angle, it is within 77-165 degrees.

For thin glass, take an instrument with a sharper angle. At home, it is difficult to properly cut glass that is more than 6 mm thick.

You can purchase a universal tool with replaceable rollers with different sharpening angles. In expensive models, a better quality roller, which facilitates the cutting process. The quality tool in the handle has a container for oil.

Features of the work

First you need to prepare the foundation on which the work will be carried out. It is better to put thick fabric, cardboard or newspapers in several layers on a flat table.

Marking is carried out with a marker, the line should be even, and the glass at the cut is clean.

The thickness of the ruler should ensure normal sliding of the tool, so that the ruler does NOT slide over the tool from the side that is adjacent to the glass, you can stick electrical tape.

In order to get a perfect cut, professional craftsmen use a special oil, but it can be successfully replaced with ordinary kerosene.

The use of kerosene allows even a person who does this work for the first time to normally cut glass even 6 mm thick.

Special oil or kerosene is poured into a container that is in the handle of the glass cutter, if it is not there, then you can simply moisten the tip of the cutter in kerosene.

When working with thick material, it is necessary to moisten the cutting line abundantly and then you will get it even.

The ruler must be of sufficient thickness, and the glass cutter is attached to it in such a way that its cutter moves exactly along the mowing line of the cut.

Moderate force should be applied to the instrument, it should not be very strong or weak.

It is necessary that the cutting line is continuous, you cannot stop while driving the glass cutter. It is impossible to use the tool several times on one mowing line, everything must be done in one pass.

Features of cutting glass with a glass cutter

Very often, when carrying out construction or repair work, it is required to cut the glass to size, although this is a complex process, it can also be done at home.

Many home craftsmen are worried about how to cut a glass cutter. if the technology is followed, then you will succeed.

Breaking process

It is necessary to break the glass immediately after the line has been drawn, since over time it cools down and will be worse than the Riot of the clerks. The material is placed on the edge of the table along the mowing line of the cut and the necessary piece is broken off with one push.

In order for it NOT to break, you can press it from above with a wooden bar, and you just need to spread the thin one to the sides.

To break off a thick glass or narrow strip, you can place a pencil or similar object under the break line. Some people prefer to tap the back of the glass with a hammer before breaking the glass.

To grind the resulting edge, you can use a touchstone or sandpaper, but during work, so that the glass does not burst, they must be Moistened with water.