Cover for angle grinder for a vacuum cleaner with his hands

When cutting metal with an angle grinder sparks occur, and when processing concrete, stone, granite, and other similar materials, there is a formation of dust. If you use an angle grinder to cut wood, you get a lot of chips in the process. To process concrete and wood grinder angled grinder performed with minimal clogging, you need to make a cover for the angle grinder under the vacuum cleaner. Such an attachment for a cutting power tool can be bought, but to avoid the expense will help to make an independent device.

Before you start working on concrete and wood, you need to imagine what you are going to end up with. Cutting with an angle grinder generates dust, which is not only deposited in the room, but also gets into the human respiratory organs. That is why you must wear only a respirator and safety glasses when working with the tool. To protect the room from excessive dust, you need to work with a special nozzle, to which the hose from the vacuum cleaner is connected.

Use the nozzle on the angle grinder should be in the following cases:

- When grinding concrete, brick, cinder block, slate and other similar materials. If shaving is performed at the stage of construction, then the settling of dust in the room is not as dangerous as when carrying out repairs. When cutting tough materials, they are crushed, which causes dust to settle all over the room

- Cutting tiles and ceramic tiles. when processing these materials also forms dust, which is especially dangerous for human health. Tiles can be cut with special tile cutters, and no dust is generated, but if the work is performed by an angle grinder, it is better to install a special attachment

- Woodworking. when sawing wood, not only dust is generated, but also sawdust, which can be easily and quickly eliminated with the hood installed on the angle grinder

Manufacturers make special hoods for angle grinder with disc diameters of 125, 150 and 230 mm. These are the most common types of cutting tools, so it is for them manufacturers produce special hoods for dust extraction.

This is interesting!If you do not have an industrial vacuum cleaner, it is not recommended to use a household vacuum cleaner for dust extraction when working with an angle grinder.

The fact that the hood on the angle grinder is necessary, masters and experts do not even doubt it, because it is enough to try once to make a cut of concrete, to be convinced of the need to purchase or manufacture a dust collector. What is better, to buy or make your own hands a cover for collecting dust on the angle grinder, here everyone must decide for himself. After all, the protective cover is relatively inexpensive, but to avoid the expense, then the nozzle should be made independently.

Algorithm of connecting a vacuum cleaner to an angle grinder

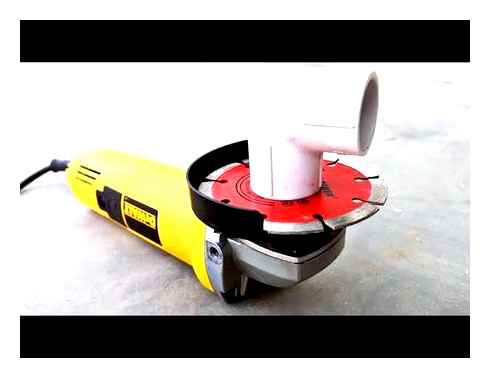

The main principle of instant dust collection when sawing is based on creating a special cover, in which the debris will accumulate, which will be pulled out later by the hose of the vacuum cleaner.

The algorithm, how to connect the vacuum cleaner to the angle grinder with your own hands using improvised means, provides for the presence of such materials:

- Scotch tape. It is desirable to take a reinforced version, as it is considered the most reliable and durable.

- Branch. Such detail is used in sanitary works, it is important to use exactly the polypropylene version, it is lightweight and durable enough. Parameters of the branch. the bend in 45 degrees and a diameter of 45 mm.

- Scotch tape, which is used for painting works.

It is not necessary to use these particular consumables, you can replace them with suitable analogues.

The step by step process of how to connect the vacuum cleaner to the angle grinder:

- Place the tool on a firm, stable surface so that the disc is on top. It is important to hold the angle grinder securely in place to prevent injury during operation.

- With pliers, fix the branch from one end, turn on the angle grinder and carefully saw a small socket in the plumbing part along its body. The length of the cut should be approximately 3-4 centimeters.

- Without removing the plumbing tap from the disc, secure it with reinforcing tape. It is important that the winding is made in tension and very tight. It is possible to make a small overlap on the angle grinder disc itself.

- Next, use masking tape to wrap the entire side of the casing covering the disk. It is important to continue all the way down to the tap, joining the two parts together.

The last step is to connect the hose of the household cleaning equipment directly to the plumbing outlet. Only a construction vacuum cleaner can be used for this, ordinary household models are not suitable. To collect dust when working with the angle grinder, it is sufficient to turn on the vacuum cleaner, which will extract the dust arising when sawing.

Removing the bit

Before setting the disc on the angle grinder, it must be removed. To do this, you must first disconnect the tool from the power grid. Then you can begin to solve the problem. Here you need a wrench with pins, which is included in the obligatory complete set of the angle grinder.

The cutting wheel is attached to the spindle rod with a special nut. It has a threaded hole, and its outer edges form an even circle. To screw it on or twist it off the rod, there are 2 small holes on the plane for the aforementioned wrench with pins. This is a tool, the working part of which is represented by two horns. The pins are fixed on them.

It so happens that to install the disc on the angle grinder is not possible to use a wrench. In this case, masters as an alternative consider a pipe wrench (gas or plumber’s wrench). It has a foot, the position of which can be changed. With the help of this device is securely clamping the nut. With a little effort, the latter will not be difficult to unscrew.

- tapping with a hammer on the holes with the additional use of a nail or chisel;

- a similar approach, only the impact is on the nut edges (but so there is a risk of damaging them);

- the use of homemade pins device made of a rigid rod or nail and, for example, pliers (metal workpieces enough to bend so that the feet of the “bracket” exactly hit the holes in the nut).

If you use only a wrench, the mechanism of the angle grinder turns. To lock the spindle position the machine has a special button above the working part. Pressing it causes the cotter pin to be displaced and moves into the hole in the gearbox. The position of the angle grinder’s rotational mechanism therefore becomes immobile.

The process of unscrewing the nut with any tool follows the same principle. One hand should fix the position of the spindle with the button, the second performs unscrewing the nut. Here it is enough to displace it a little to continue working without tools.

Disc jamming

It is not uncommon to have to replace the head because it becomes jammed. This generally occurs when the cutting wheel is caught in the workpiece. Disk integrity is compromised as a result.

In such a situation, the first action before removing the disk with an angle grinder will be to break the head with an adjustable wrench or pliers. Next, two clamping jigs are needed at once. One fixes the position of the spindle, the other unscrews the nut. Less frequently, the gearbox has to be disassembled to access the threaded part of the mechanism.

Experienced craftsmen find other solutions to the problem. For example, you can use a penetrating lubricant, a gas burner for heating (expansion) of the fixing nut. Others work only with a cutting wheel. It is broken apart and sawed out with a hacksaw blade. This eliminates resistance from the disk and makes it easier to remove the nut. The extreme solution is to saw down the clamping nut and replace it with a new one.

How to correctly place the disk on the angle grinder

Before you put the disc on the angle grinder, you need to determine which side it should be facing the tool. This point is particularly relevant when it comes to the cutting wheel. Let’s take a closer look. is there a difference between the position of the nozzle with the marking directed outwards or towards the mechanism.

Reference points

The accessories for angle grinders are now available in great variety. On some of them the manufacturer indicates the direction of rotation with arrows, so as not to make a mistake, how to properly install the disk on the angle grinder. These include circles for cutting stone or wood. Many diamond-coated bits are also on the list.

There is a tooling, which is easy to determine by performance. Here the wrong side is made in a single plane, and the front side is a working. The most striking example are variants that have an abrasive coating. Grinding in this case can be carried out only one side of the nozzle.

The easiest reference point for the correct installation of the disc on the angle grinder is the condition of the surface. The outside can be marked, labelled or roughened. Especially relevant is the last point. The fixing nut slides on the smooth part of the jig, and the abrasive creates the necessary resistance for reliability.

There is another reference point. After installing the wheel, attention must be paid to the tightness of the connecting assembly. There should be no empty space between the nut and the nozzle to prevent debris from entering the rotating mechanism. Also, solids in the gap can cause a skewed wheel, resulting in increased vibration of the power tool. Increased risk of tool breakage, poorer cutting quality, lower safety during assembly work.

Crimping ring

The crimping ring is an important element and a reference point to determine how to properly place the disk on the angle grinder, which side. The main purpose of the part is to increase the support area in the clamping nut area. This more evenly distributes the load on the nozzle and reduces the possibility of breaking it during fixing or work. Additionally, the ring protects the clamping nut from overheating and from so-called “boiling over” with the abrasive surface of the wheel.

Often in order to ensure safety, especially novice craftsmen try to tighten the clamping nut as tight as possible. In this case, the metal ring serves as an obstacle to bending and breaking the tool. Damage to the abrasive coating is also prevented.

How to work correctly with an angle grinder: safety precautions operating instructions

Are you planning to use a power tool for home repair, but don’t know how to operate the angle grinder correctly so as not to injure yourself?? You will agree that it would be unwise to break the disk without knowledge during the first minutes or, even worse, to hurt yourself.

Or you have just decided to get an electric tool and study the rules of its operation in advance? In this case, pay attention to the products of reputable manufacturers who sell really high-quality devices of excellent construction with a long-term warranty.

After all, it is safer to work with a reliable tool. One great option is the brand products Bosch, DeWALT, Makita, as well as Metabo angle grinder sold in a wide range of myo. Rules of operation and basic mistakes when working with this type of power tool, we will consider in detail in our article.

In addition to recommendations for use of angle grinder, the material contains visual photos on working with the angle grinder and useful video tips from experienced users. Familiarizing yourself with the latter and observing the rules of personal safety, you will be able to cope with your own forces with concrete wall grind, cutting tiles or bricks, without attracting professionals for these tasks.

Types and features of use of the angle grinder

Popularly known as an angle grinder. this is nothing like an angle grinder. This power tool, according to philistines, is necessary for every self-respecting owner.

No wonder, because in addition to grinding, the device is able to perform high-quality cutting of various materials, ranging from simple wood to metal corners and fittings.

Most often in everyday life, this tool is not used for grinding operations, but precisely for cutting materials.

Fittings, metal angles, metal pipes and other metal products are most often cut with an angle grinder. Therefore, its presence in the arsenal of the owner of the house or apartment is quite justified. not to invite the same for elementary work by a stranger

Processing of brick products. a popular phenomenon, especially in the period of repair. For this purpose, the angle grinder should be equipped with special discs. a device for cutting metal and fittings in this case is not suitable

For concrete or concrete products like walls, floors, individual elements you have to use the cutting disk recommended by the manufacturer for these specific tasks. over, in view of the increased dustiness it is necessary to protect the olfactory organs

For wood and its derivatives it is necessary to use special discs, which the manufacturer offers to work with wood. You also need to wear the proper type of guard to protect you from heavy sawdust, chips, and wood dust

Rules of application of the tool

Practitioners who often use an angle grinder are divided in their opinions. The basic question of how to use an angle grinder when cutting metal, there is no single answer. Some users cut toward themselves, while others cut away from themselves. Both opponents are correct if certain guidelines are followed. Т.е. the machine can be used in right- or left-handed position, if the disc is rotated in any direction. The main thing is to “get a feel for it”.

Cutting on your own

The movement of the disc is “clockwise. the main disadvantage of this method is that a shower of sparks and a shower of dust is directed at the operator. Therefore, when working with bricks or concrete it is necessary to wear a respirator to protect the respiratory system. Clothing should be buttoned up tightly to minimize the risk of the waste streaming from under the disk onto your body.

Important! The shear of sparks from cutting is sometimes too intense and can cause burns on clothing. therefore, it is best to wear protective clothing. It is advisable to keep the sleeves at the cuffs and the leg cuffs of the pants buttoned up tightly to keep sparks from getting on your skin.

The main argument of the supporters of this method of operation of the angle grinder is the high degree of safety. When the wheel jams, the wire feeder jerks in the opposite direction to the cutter, i.e.е. to protect against it, which significantly reduces the risk of injury.

Tip! Changing the direction of movement of the grinding wheel is done by turning the guard 180°. The handle is twisted on the back side of the gearbox. It is very important to screw everything in meticulously and make sure it works.

Cutting toward you

If the wheel is moving “counter-clockwise”, the correct cutting direction is “toward you”, otherwise the machine is blocked and the disc could break up.

The main disadvantage of this method is the high probability of injury. tool is thrown by the driving force of the tool towards the cutter when the grinding wheel is jammed. If you do not hold it at this point, you can get bruised or cut. Before you work with an angle grinder by this method, it is important to fully concentrate, distract yourself from minutiae, steady your hands and strictly control the course of the wheel. The slightest sensation of strain in the operation of the machine should signal the need to sharpen one’s attention to the limit.

The advantage of this method is that the direction of the dust or sparks is in the opposite direction of the worker. The safety precautions are maintained, but the problems of dust or sparks on clothing or in the eyes are no longer a concern.

the gearbox of the angle grinder is located at the side of the employee when working “towards yourself”, which reduces the risk of winding the overalls on the rotating parts. This is for right-handed people. Left-handed people adjust the machine individually.

Recommendation! Often, after a disc is jammed, the jam nut is difficult to unscrew. To make it easier, a washer under the nut is usually cut from cardboard or rubber and inserted. The nut will then become easier to turn and no piercing or heating processes are required.

Necessary safety precautions

Before how to use the angle grinder, you should strictly learn all the safety requirements. It is not important in what direction the dust and sparks fly, when the rules of operation with the angle grinder are not learned and the necessary safety precautions are not observed, which implies the possibility of serious injury.

Necessary measures to prevent injuries during operation of the angle grinder:

Availability of a non-hazardous place to perform work

Before you work with an angle grinder on metal, you must take time to prepare the work area. The chosen area must be free of debris, any combustible materials or flammable substances must be removed and the area must be inspected for any exposed electrical wiring.

You will also need good quality natural or artificial light for the work.

Work with the machine only in dry conditions. Any use of the machine in rain or in a building subject to flooding must be excluded.

Important! No jewelry items (chains, trinkets etc.) should be worn when working with the angle grinder. objects), capable of being tightened (coiled) by the mechanism of the machine.

Before you work with an angle grinder, you should be concerned about the presence of “on hand” fire extinguishing. It can be any class of fire extinguisher, as well as a container of water, sand, etc.д.

Use of personal protective equipment

All equipment must be carefully secured, fastened and tied to keep it from falling into the working part of the machine.

Particular danger from a flying shower of sparks. Therefore, it is important to protect eyesight and exposed body parts by using goggles, masks, gloves, special shoes. To protect your hearing, earplugs or construction headphones are recommended. A respirator comes in handy when working with “dusty” materials. Special construction shoes will prevent damage to your feet from falling metal parts.

Homemade casing from a saucepan

In some cases, it is worth using a welder and independently make a cover on the angle grinder for the vacuum cleaner from a thin sheet of metal. Such a construction will turn out beautiful and durable, but requires welding skills and expensive materials. If there is an old aluminum pot in the workshop, you can make a quality cover without using a welding machine.

For this work you will need the following materials and tools:

First, the main part of the dust collector is cut out. Carefully fit the cover to the electric appliance. It is worth immediately accurately calculate the maximum depth of penetration of the cutting disc, because it directly affects the height of cut. From the other part is cut a special landing axis for mounting on the angle grinder. Right on the angle grinder is made fitting the diameter of the hood. Its size must be the most accurate, so that the homemade cover does not jump off from the great vibration during the work. Experts advise using a strong tightening clamp when securing the fixture.

The same method is used to assemble a universal hose nozzle for a household vacuum cleaner. All edges of the product are neatly bent inwards in a single line to fasten the side walls. Robust walls can be made of any kind of material, for example, metal sheet. It is worth giving the device aesthetic appearance, clean the joints and paint.

How to choose a nozzle

Choosing a cover for angle grinders with a vacuum cleaner comes down to considering the size of the working disc in the first place. A cover larger than the blade itself will be of little use, because it will be more difficult for the vacuum cleaner to collect all the dust. It is a good idea to make three different nozzle sizes to fit the three basic sizes of discs or plates

The next criteria in choosing a cover will be the type and quality of work to be done.

- Sanding a surface treated with filler creates a cloud of fine dust. A hood with its edge firmly fitted to the surface to be sanded and a suction unit with a high suction rate are needed for this type of work.

- When cleaning metal from rust it makes sense to use a hood that is small or transparent, for better control.

- Work with wood or removal of old paintwork requires a small diameter shroud, but with a large sized outlet. sawdust is larger than dust, a smaller diameter will clog faster.

- Rock sawing or tile cutting also requires high suction speed, because the vacuum cleaner’s thrust creates extra cooling in the area enclosed by the shroud.

An exhaustive answer to the question of choosing the size of the guard will be the formula: “diameter of the shroud = diameter of the tool (disc or platter) 1-2 cm.”.

For the housing diameter of the angle grinder, take the diameter of the housing at the place of attachment of the original protective construction, or the outer diameter of the seat of the bearing.

The depth of the housing is chosen so that its soft parts, attached to the base, are no longer than 0.5-1 cm. A long soft edge can bend inward and get under the working body. the operator will feel a strong unpleasant jerk, and the construction will be out of order.

How to choose a nozzle

Choosing a hood for an angle grinder for a vacuum cleaner comes down, in the first place, to taking into account the size of the working disk. A larger shroud than the tool itself will be of little use, making it harder for the vacuum cleaner to collect all dust. A good solution is to make three nozzle sizes to fit the three basic sizes of discs or plates

The next criterion for choosing a cover is the type and quality of work to be done.

- Sanding a surface treated with filler creates a cloud of fine dust. For such jobs, you need a hood with a tight fitting edge and a vacuum cleaner with high suction power.

- When cleaning metal rust it makes sense to use a smaller or transparent shroud, for better control.

- Work with wood or removal of old paintwork requires a small diameter blade, but with a large diameter outlet. larger diameter sawdust is larger than dust, smaller diameter will clog faster.

- Sawing stone or cutting tiles also requires a high suction speed, because in this case, the vacuum cleaner’s thrust creates extra cooling in the space enclosed by the shroud.

An exhaustive answer to the question of choosing a shroud size is the formula: “diameter of the guard = diameter of the tool (disc or platter) 1-2 cm.”.

The housing diameter of the angle grinder at the attachment point of the original protective construction or the outer diameter of the bearing seat is taken as the housing housing seat size.

The depth of the housing is chosen so that the soft parts, which are fastened to the base, are not more than 0,5-1 cm long. A long soft edge can bend inward and get under the tool, and the operator will feel a strong, unpleasant jerk, and the tool will break down.

Causes of dust formation

angle grinder is a universal tool. It can be used to cut metal, stone, ceramic granite and tile, to process wood and other materials, using various nozzles. But one disadvantage is the generation of huge amounts of dust. Works that cause the formation of large amounts of fine debris:

When the repair is complete, dust has to be removed from all possible crevices and cavities. To protect neighboring rooms from construction dust, protective screens made of polyethylene film or light fabric are installed in doorways. Also use special devices, which you can make yourself.

The following steps are required to install a new drive after cleaning the enclosure:

After all the actions taken, you can safely continue to perform the work.

One of the most frequently asked questions on the assembly / disassembly of equipment angle grinders sounds like this: What side to put the disk on the angle grinder?

This question is usually asked by inexperienced craftsmen. Is it possible to install the circle on the underside Yes. Firstly, if the disk is not flat, and, for example, petal, you can not install it incorrectly, with the wrong location of the petals you just need to rotate the hood and the handle on the angle grinder. That is, the question disappears by itself.

If the disc is still flat, then you should be guided by its label, so called Shirt.

If the angle grinder rotates against itself, you should install the disc. Shirt outward, if the disc is unscrewed from itself, then accordingly you need to install it Shirt inward.

If you do not adhere to this algorithm, there is a high probability that the disc will fail very quickly or will deform at once.

How to remove, change a jammed disc from the angle grinder?

How to remove the disk with an angle grinder angle grinder (further. angle grinder), popularly referred to as a grinder, is probably the most popular tool, which is present in the arsenal of almost every craftsman, regardless of his qualifications.

This tool is actively used in abrasive machining: cutting, grinding, cleaning workpieces made of stone, metal and many others. Widely used in areas such as: construction, woodworking and other similar types of work. Like any other tool, angle grinders are also divided into several classes.

This refers to domestic, semi-professional and professional tools. This classification is determined by the power resource of the tool, its characteristics, the presence of certain additional options, material and quality of assembly, etc. Д.

The consumables for angle grinders, in addition to various types of cleaning brushes, are cutting discs and various grinding discs. Types of equipment for the angle grinder: how to make the right choice?

How to use an angle grinder tips and tricks from the experts

Manufactured nozzle on the angle grinder allows not only to eliminate the formation of dust, but also acts as additional protection for a person from the negative effects of the power tool. An angle grinder is a life-threatening tool and is used for a variety of applications. When carrying out these tasks, it is important to observe safety precautions to prevent injury.

Specialists recommend following a number of recommendations when working with power tools:

- Only hold the tool with both hands

- Only use suitable cutting wheels and discs depending on the material to be sandered

- Do not get addicted to wood processing, using an angle grinder for this purpose. An angle grinder is not a good choice for woodworking

- Work in protective gear. goggles, respirator, gloves, etc.п.

- Periodically pausing to allow the tool to cool down

- When using the hood, make sure it is securely fastened to the power tool. If it vibrates, it can get caught under the spinning wheel and become damaged in the process

To make a homemade cover under the angle grinder to connect the vacuum cleaner, you need to show a little ingenuity and imagination. To make a device is not difficult, and it is only worth choosing a suitable material, taken as a basis. It can be not just plastic or metal, but also wood, such as particleboard or fibreboard. And in this case you do not need to buy a homemade device in order to eventually carry out one-time work on the processing of concrete, wood or tile with an angle grinder.

The purpose of a dust collector for an angle grinder

Using an angle grinder (angle grinder) to carry out repair work on concrete in the home creates a lot of dust.

If you want to level a wall, grind it for painting or other finish coating, all the bumps or irregularities become airborne concrete particles.

In spite of the personal protection used, they penetrate into the mouth, eyes, respiratory organs.

In addition, the dust settles on all pieces of furniture, walls, ceiling and other surfaces, requiring time-consuming and labor-intensive cleaning. Dust from brick walls gets into surfaces, irreversibly damaging their appearance.

There are several designs of hoods with a nozzle for connecting a vacuum cleaner, which significantly improves the process. They are purchased in the store and installed on the angle grinder, connected with a vacuum cleaner. Working with these devices virtually eliminates dust dispersion and greatly reduces indoor air and room pollution. Externally, they look like the usual protection, but with a closed body and an outlet for attaching a vacuum cleaner hose.