What you need to know about sharpening angles

The geometry of the teeth of band saws can be modified depending on the characteristics of the material being processed. This is expressed in the shape of the tooth and the distance between the individual elements of the cutting edge.

The band saw profile is determined by the markings applied by the manufacturer. It looks like this:

How to Use a Band Saw | Woodworking

- WM. a universal version designed for sawing soft and hard wood;

- AV. used for longitudinal cutting and sawing of hard materials, such as frozen wood;

- NV. has a narrow blade width, so it is ideal for shape cutting;

- NU. a cutting edge with a wide tooth pitch, which provides high performance when cutting soft wood;

- PV. almost a complete analogue of the previous blade, but has a flattened tooth shape;

- KV. the profile is used for wide band saws intended for softwood;

- PU. wide saw blade for cutting hardwood.

The pitch of the teeth is selected individually, depending on the material. For example, when cutting hardwood and metal, only fine-toothed blades are used to avoid damaging the cutting edge. Soft raw materials and thick-walled materials are processed with saws with a large tooth spacing, which allows to speed up the production process.

Sharpening

This is the main step in cutting edge dressing and can be done in two ways.

Full-profile saws are sharpened with an CBN wheel installed in a special sharpening machine.

This is a fully automated operation used by professionals. The work of the machine for sharpening band saws for wood is controlled by electronics, and the sharpening wheel processes the entire band in one pass. The disadvantage of this method is that the CBN wheel is selected individually to the profile of the saw, therefore, for dressing different tools, the sharpening element must be present in the assortment.

Sharpening of teeth is performed manually or on specialized equipment.

Note! It is this method that is used for self-sharpening band saws. A regular emery wheel or file can be used here.

In the first case, the sharpness of the teeth can be restored in the shortest possible time, but the work requires certain skills. In the second, painstaking work: 4-5 movements along the edge of each tooth.

For automatic sharpening, diamond, CBN and corundum wheels are used. It is important to understand that when performing this procedure, only sharpness is given to the teeth, the geometry created after setting the blade should remain unchanged.

Saw material

Band saws are made from different materials. depending on what material they are intended for cutting.

Saws for wood are made of tool alloy steel with a hardness of 40-45 HRC. Domestic manufacturers use steel 9HF, B2F (for band saws for metal), etc., foreign manufacturers use their own steels (C75, Uddeholm UHB 15, etc.). When the teeth of such saws are hardened by high-frequency currents, they can acquire hardness up to 64 HRC and higher.

Hardened Band Saw Teeth

Saws for cutting carbon steels and non-ferrous metals of small thickness are also made of tool steel with mandatory hardening of the teeth by high-frequency currents. However, more often for cutting metal, bimetallic saws are used, in which the blade is made of spring steel, and the strip on which the teeth are cut is made of high-speed steel with high tungsten and cobalt. After hardening, it acquires hardness up to 65-69 HRC. High speed steel is electronically welded to the base of the saw.

Making a bimetallic band saw

Bimetallic saws are capable of cutting thick metal from tool, stainless, heat-resistant and other steels, titanium alloys and other metals.

Bimetal Band Saw

Teeth with higher wear resistance are obtained by surfacing them with stellite (an alloy based on chromium and cobalt with additions of tungsten and / or molybdenum) or by soldering hard alloy plates to them. Such saws are superior in their cutting abilities to bimetallic ones. They are used to cut fiberglass, car tires, cables, reinforced plastics, high temperature alloys, graphite, aerated concrete, bricks and other materials that are difficult to cut.

Carbide Tooth Band Saw

Design features of band saws

- , which has a hardness of 40 to 46 HRC.

- . When cutting cheap wood, this moment is not so noticeable, but when cutting valuable and exotic types of wood, it is critically important.

- . At the same time, the band tool works quickly and creates a high quality cut.

- .

note!

In order for the machine to work always stably and efficiently, you should approach its maintenance with the utmost responsibility.

Sharpening and setting of band saws on wood should be carried out in a timely manner and competently.

How to sharpen a band saw correctly

Immediately, we note that if there is no experience and skills in performing such work, it is better to entrust saw sharpening to professionals. Violation of the geometry of the teeth of the cutting edge, the appearance of dross on the metal or incorrect setting will significantly reduce the life of the blade.

Having decided to sharpen the band saw with your own hands, it will be useful to first familiarize yourself with the key definitions, the knowledge of which may be required in the process. So, for the correct formation of the cutting edge you will need:

- setting. deviation of the teeth from the plane of the main saw blade;

- the height of the teeth is the distance between the top point and the base;

- pitch. the distance between the teeth, usually varies between 19-25 mm.

- sharpening angle. depends on the intended purpose of the tool; for example, the recommended sharpening angle of carpentry saws is 35 °, indexing. 18-22, intended for sawing a bar. no more than 15 °.

The sharpening angle is determined by the manufacturer, therefore, when self-dressing the saw, it is recommended to adhere to these parameters.

Here are detailed instructions that will help you sharpen a closed saw correctly without resorting to the services of specialists.

Did you like the article? Subscribe to our channel Yandex.Zen

Profile, teeth and sharpening angle

International classification of tooth profiles.

Tape devices have different geometry of teeth, which depends on the type and characteristics of the cut materials. Wood tools can be carpentry and dividing. There is also a third type, designed for sawing timber, logs. All these subspecies have their own parameters and the shape of the teeth.

The sharpening angle of band saws for wood is chosen by the manufacturer based on several points. The main one is that the harder the material, the smaller the rake angle. Below is a table with the main parameters of the saws.

Wiring

Setting band saws into wood is the first step in restoring the profile of the cutting edge. During operation, the location of the teeth can change, so until the correct geometry is achieved, it makes no sense to sharpen the saw part.

There are 3 ways to open the saw:

- classic. the teeth alternately deviate to the right and left sides;

- stripper. the 1st and 2nd teeth deviate in different directions, the third remains even. This profile is created for sawing hard materials;

- wavy. the most difficult option, resembling a wave in shape. Here, each tooth is individually shaped, and this type of setting is usually performed only in specialized workshops.

It should be noted that when wiring, not the whole tooth is bent around, but about 2/3 of the upper part. The procedure is performed on a special band saw setter. The cost of such a tool is quite high, so they buy it if you need to adjust several tools. Its presence can become the basis of a sharpening business.

Of course, the first time you can do everything correctly, even on an adjustable machine, it may not work, so at least the geometry of the profile should remain the same as before the start of work.

Sharpening and setting the saw

The main cutting element of any hand saw. a series of teeth cut into the blade and representing wedge-shaped cutters. Wood, in the manufacture of all kinds of products from it, is sawn along, across and at an angle Θ to its fibers, in this regard, transverse, longitudinal sawing and sawing at an angle to its fibers are distinguished and in each case use the appropriate type of saw, which differs from others in shape teeth.

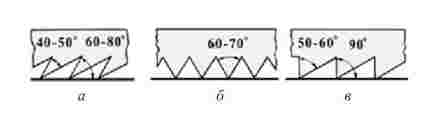

When transverse sawing, transverse saws are used, the cutting edges of the teeth of which, when moving in the wood, cut its fibers like a knife and form a cut. Longitudinal sawing differs from transverse sawing in that the direction of movement of the saw is parallel to the grain of the wood. The leading edges of the rip saws cut the wood like knives in a plane, and, going deeper, form a cut. When sawing wood at an angle Θ, universal (mixed) saws with teeth that are an intermediate form of teeth for cross and longitudinal saws are used to its fibers.

Saw sharpening

Saw teeth sharpening. a kind of art that requires loyalty of hands, a good eye, and attention. It is not difficult to learn this business, you must have the desire and clearly adhere to the following rules:

- The saw blade must be firmly fixed in a special device made of wood, which is also firmly installed on a well-lit work table. Sharpening saw teeth on stools or on your knees does not give a satisfactory result.

- You should use a personal file, followed by cleaning the sharpened edges of the teeth with a velvet (with a fine notch) or file. It is desirable that the file is new, sharp and with a fitted handle. If at the right time there was not one, then you can also use a second-hand one, but it must be brushed with a steel brush and rubbed with charcoal so that the file does not get clogged and does not become dull. When sharpening a tooth, the file should grip its metal and remove its layer depending on the pressure. And if it slides over the tooth without removing the metal, then the saw teeth are overheated or the file is worn out. In this case, it is necessary to repeat the sharpening with a new file. If in this case he slips over the tooth, then it remains to take another saw.

- The file handle is clamped with the right hand, and the end of it is held by the left hand and the file is directed to the saw teeth. Working with a file, depending on the type of saw, is described below.

- The pressure of the file on the teeth should be smooth and even and only to one side from you. When returning the file to its original position, it must not touch the teeth.

- It is necessary to try to grind the metal from the edges of the teeth of at least the same thickness, driving the file the same number of times with the same pressure, which allows you to maintain the angles, pitch and height of the teeth after sharpening.

- Burrs form on the edges of the tooth from the side of the file exit, which reduce the sharpness of the tooth, and if they are not removed, then during the operation of the saw, they crumble, and the teeth become significantly dull. To remove burrs, the edges of the teeth are sharpened with a file with a velvet notch and deburred from the side edges with a wet donkey.

- After sharpening the teeth, check their sharpness. Look at the tip of the needle and the edge of the razor blade: they are sharp and do not shine in the light. And if they are blunt, then rounded surfaces appear at the tip of the needle and on the edge of the blade, which reflect light and shine well. The quality control of saw teeth sharpening is based on this principle. To do this, put the saw in front of your eyes and examine its teeth along the blade. If their cutting edges and tops are not shiny, then the saw teeth are sharpened satisfactorily, and if some of the teeth are shiny (this often happens), then they must be sharpened with a velvet file, deburred and re-check the light reflection from their edges and tops.

Cross saws. The teeth of the cross-cut saws are sharpened using a triangular file with a fine notch with a 60 ° apex angle.

To sharpen the teeth, the saw is clamped into a special device that allows its blade to be installed at an angle of 45-50 ° to the plane of the desktop. The file is led parallel to the working table at an angle of 60-75 ° to the saw blade and thus the left edge A1A2B2B1 is sharpened in the first tooth.

Saw teeth are sharpened in several stages. First, with a file, they pass along the left edges of the odd teeth located in the far row, adjusting the hands to the same movement. Then they pass the file along the right edges of the same odd teeth, completing the sharpening of the main cutting edges with very sharp tops. After finishing the sharpening of the odd teeth, the saw blade in the sharpening device is turned over and thus the even teeth that are in the far row are sharpened. When sharpening the teeth of cross-cut saws, it is necessary to carefully ensure that sharp main cutting edges with a dihedral angle φ = 60-75 °, a short cutting edge and a sharp point are obtained in each tooth.

Longitudinal saws. Rip saw teeth in which the angle π

How to sharpen a saw for wood: a simple step-by-step instruction | (Photo Video)

A sharpened hacksaw for wood cuts itself. any professional carpenter or joiner will confirm this. If you do not agree with this, then it’s time to sharpen the tool.

Sharpening a hacksaw for wood also includes setting the saw teeth. For this, there are special adaptations, as well as improvised tools.

What should turn out

When sharpening, you need to ensure that the teeth of the hacksaw are sharp and resemble a shark’s tooth in shape. Only such a tooth saws well. the hacksaw will not slide on the tree, but will “bite” into it. And then it will become clear why the “correct” saw cuts itself.

Saw set

Setter Pliers

The setter pliers are a good tool It is very convenient to use, the saw tooth drift to the side will be just what you need.

Hacksaw set. It is also a good thing and is inexpensive. average. The design is elementary: several slots and an adjustable protractor. The tooth is inserted into a suitable slot and set by pressure on the handle. The positioned goniometer ensures the uniformity of the spreading.

Hacksaw set

The technology is simple: the blade is inserted between two teeth and by turning the ax, the teeth are bent to the sides.

Setting the teeth with an ax

The saw can be set using a self-tapping screw. It is more secure. This requires a long screw to make it easier to hold. Before work, it needs to be slightly modified. You need to grind off his hat a little on one side. to make it flat. This is necessary so that when it is applied to the tooth, it does not slip and deform the latter.

The hacksaw should lie flat on soft wood (pine, spruce). Holding the screw by the leg, apply a hat to the tooth and hit it with a hammer. The tooth is folded back. The operation is performed through the tooth. After the saw blade is turned over, and the operation is repeated in the same way.

Tooth setting with a self-tapping screw

Tool used

Since the saws differ in shape and purpose, they also have different teeth. And in order to sharpen a hacksaw with high quality, you need a different tool.

Triangular file with one working side. The profile of this tool is not standard, if for an ordinary triangular file all sides are equal and are working, then this file has one working side, and in shape it is an isosceles triangle with a very large base.

With such a triangular file with one working side, it is convenient to process fine or oblique teeth. When working, it acts only on the surface to be treated, on others it only slides. There is no risk of grinding the adjacent tooth.

Plain triangular file. A compact tool that is convenient for sharpening most standard wood saws.

Making a homemade Band Saw (part3 / blade guides)

Plain triangular file

Triangular file. Ideal for sharpening large-toothed saws.

Sharpening process

For sharpening, the saw must be firmly fixed so that it does not vibrate when exposed to a file. Otherwise, the quality of work will be low.

They fix the hacksaw blade vertically, often in a vice, in homemade clamps, but if there is neither one nor the other, then you can do without them.

The fixing method without special devices is “at the edge of the workbench”. The hacksaw blade is laid so that only the saw teeth hang from the edge of the table. However, the handles of the saw are always thicker than the blade, and therefore the place next to it cannot be put tightly to the workbench. Therefore, you need to use the corner of the table, and then the saw handle will not interfere.

If there is a clamp, then you can fix it like this.

And this is a method without a clamp, fixation is done only by the hand of the sharpener. It is quite convenient and safe.

Fixing the saw without a clamp

A file or a file is taken in the right hand, and, pressing the hacksaw blade with his left hand, they begin sharpening.

Sharpen the saw teeth through one. The movement of the file with this method is made upside down. The file is applied to the sharpened tooth and is forced downward with a downward movement.

The file must be held tilted in two planes. In the horizontal direction, it is about 30 degrees. Vertical. about 60 degrees. The angles of inclination are individual for each saw, because they can differ both in the shape of the tooth and in its size.

Sharpening the left edge of the tooth.

Sharpening the left edge of the tooth

Sharpening the right edge of the tooth.

Sharpening the right edge of the tooth

This is what should be obtained: to the right of the file pointer. processed teeth, to the left. no.

To the right of the file pointer. processed teeth, to the left. not

How to quickly and easily sharpen a hacksaw with a file

How to sharpen a saw for wood: a simple step-by-step instruction | (Photo Video)

Feedback from our readers is very important for us. Leave your rating in the comments with the reasoning for your choice. Your opinion will be useful to other users.

Band saws for woodworking: instructions for use

Wood band saws are a cutting tool that is used on wood band saws. The band saw is a closed flexible steel band with teeth on one edge. Band saws for wood are most often used for longitudinal sawing of logs (on band sawmills) as well as for transverse, longitudinal and figured cutting on band saws for wood (vertical arrangement) or jigsaws. For each of the applications, there are advantages over alternative cutting methods. The use of band saws on sawmills allows cutting with minimal material loss and high processing performance due to the small thickness of the tool. The use of saws on band or jigsaw machines (as a rule, vertical layout) allows cutting workpieces with a large section, as well as shaped cutting.

In general, band saws, in comparison with circular saws, have a lower cost, ease of operation and maintenance, and can be repaired and restored many times.

Main technical parameters of wood band saws

The thickness of the canvas;

2. Width of the web;

3. Tooth pitch;

4. Tooth height (cavity depth);

5. Back angle of the tooth;

6. Front angle of the tooth;

7. Setting the teeth;

8. Tooth divorce line.

Recommendations for the selection of the canvas

Blade thickness

In theory, the thinner the web, the longer its service life. This is due to the occurrence of bending stresses and the fatigue strength of the web. In practice, there is a high risk of failure of the web due to improper operation, solid inclusions in the material (for example, a knot, frozen wood).

Thicker blade produces a straighter and smoother cut. The choice of blade thickness depends on the geometrical parameters of the drive pulleys (diameter and width of the working part), cutting conditions and the type of wood. For soft wood, a thicker blade is recommended, and for hard wood, a thinner.

Web width

The selection of the tooth width directly depends on how and on what equipment the saw will be used. When choosing a tape blade for a figured cut, it should be borne in mind that the width of the blade, due to the peculiarities of the cutting process, will affect the minimum cutting radius.

The dependence of the width of the blade and the permissible radius of cut is given below:

Web width, mm.

Minimum radius, mm.

For sawmills, the width of the belt should be selected so that it is wider than the drive wheels by a tooth height of 1-3 mm. A large number of factors affect the choice of the size of wide saws. The selection of their parameters must be approached comprehensively, therefore it is advisable to contact the specialists of the company “Zolotoe Runo, Ukraine”.

Tooth pitch

Tooth pitch is considered to be the distance between the tops of the teeth. For band saws for wood, the pitch is most often indicated in “mm”. Tool carbon steel bandsaws have a wider range of applications, can be used for cutting metal, wood, plastic and other materials, the pitch markings in these saws indicate the number of teeth per inch (25.4 mm.).

It is worth choosing a step based on the characteristics of the wood being processed. The common tooth pitch is 22.2 mm. This is a versatile step that allows you to handle any type and size of wood all year round.

It is worth noting that with a small number of teeth involved in cutting, damage to the material being cut and saw teeth may occur, and with a large number. filling the cavity with chips, which will lead to overloading and overheating of the blade, and in the worst case, its breakage.

Tooth height

The height of the tooth is the distance between the top of the tooth and the line of the base (cavity). Increasing the area of the cavity makes it easier to cut softwood, as it allows you to remove more chips from the cut.

Tooth geometry

Depending on the hardness of the wood to be treated, the geometry of the tooth changes. When cutting soft wood, an increased feed is used, the amount of chips increases, so the rake angle of the tooth should be 10-15 °, the rake angle should be 30 °, which increases the volume of the chip cavity and allows you to accommodate more chips. Conversely, when cutting hard, frozen or exotic wood, the feed is low, but higher tooth strength is required. This is achieved due to a smaller clearance angle, a reinforced tooth and a reduced cavity, all this has a positive effect on the preservation of the saw resource.

Most wood saws are made with a “Hook” tooth shape. They have a 10 ° rake angle. a posterior angle of 30 ° and a large depression. This tooth shape is considered universal, provides good penetration into wood of different hardness, excellent chip removal from the cutting zone, thereby reducing the load on the blade and increasing its service life. The geometry of the tooth allows it to be sharpened as efficiently as possible, which increases the service life of the blade.

Blade parameters depending on the cut wood.

Hardness of wood

Front angle of sharpening

Wiring

Set (Width of Cut). the tilt or angle of rotation of the tooth in relation to the plane of the blade to ensure free movement of the blade and the edge of the tooth. There are several types of wiring. This is the so-called “standard”, when the teeth are bent alternately to the left, right and “cesspool” when the teeth are located to the left, right, center. The second set is used on most wood saws. Depending on the type of wood to be cut and the width of the tape, the amount of setting should be selected, taking into account that the softer the wood, the wider the teeth need to be set.

Blade parameters depending on the cut wood.

The strength of the tree

Wiring, mm.

Recommendations for use

Rules for installing the tape on the machine.

When installing the blade and setting up the equipment, the machine must be turned off. Care should be taken when handling the band blade.When installing the band, do not grasp the cutting parts of the tool without protective gloves.

Handle the blade with extreme care, never throw it away, as this can lead to chipping of the teeth and breakage of the blade.

Before installing a new (sharpened) blade on the machine, you must pay attention to the technical condition of the equipment.

Namely:

– The condition of the rollers or guide blocks. It is necessary to remove all debris, dirt, sawdust from them. The rotation should be smooth without biting or jamming. If necessary, rollers and (or) bearings must be replaced;

– The condition of the support rollers. There should be no backlash in the bearings and in the places where the rollers are attached;

– Pay attention to the machine pulleys. They must be in the same plane, be clean and have no backlash on the mounting axis. Check the drive pulley belt. It must be the same in thickness, the presence of cracks, breaks is unacceptable.

Having fulfilled the above requirements, you can start installing a new or sharpened blade on the machine. Work on changing the tape should be done in protective gloves and goggles.

Top 5 Uses for a Band Saw | How to Use a Bandsaw

Algorithm for replacing the tape blade:

– Disconnect the power supply;

– Loosen the blade tension (using the screw that adjusts the tension, loosen the movable pulley and bring it closer to the drive pulley);

– Open the protective covers;

– Remove the blade from the pulleys;

– Remove chips from guides and pulleys.

– Expand New Canvas (Don’t Drop).

– Install the blade (check the direction of the teeth, the teeth should be directed towards the rotation of the drive pulley)

– Install the blade on the pulleys; the main working load should be centered on the saw along its entire length. Make sure the blade is in the same position along the entire length of the pulley. To do this, having installed the blade on the pulleys, it is necessary to turn them manually several times, if necessary, align the blade. Also take into account that the tooth should extend beyond the edge of the pulley to the entire height plus 1-3 mm;

– Insert the canvas into the guides. If on the machine, block guides need a gap of about 0.1-0.2 mm between them and the saw body;

– Close the protective covers;

– Set the blade tension (watch out for pinch zones);

– Turn on the machine (scroll for a few minutes so that the blade is finally installed on the pulleys);

Recommended maximum tension values

Sizes of canvases

When choosing a saw, additional recommendations are taken into account:

- Rip sawing is handled by wide band saws for a smooth cut.

- For a thin workpiece, choose a thin blade, since a thick one will damage the material.

- For curly cutting, a certain saw blade is selected. A saw with an average size of 35-40 millimeters is best suited.

Sharpening level

Before work, you need to check whether the teeth are well sharpened, since blunt teeth not only require an increase in motor power, but can also spoil the material. It is better to purchase a blade made of carbon steel, as it retains the sharpness of the teeth for longer.

Before purchasing a saw band for wood, you should inquire whether sharpening is required for it, since it is undesirable to sharpen some in order to avoid breaking their teeth.

Bison zpl-350-190

Another inexpensive Russian band saw got into the rating due to its powerful motor and high quality sawing wood. This tabletop model is used in small private workshops and in the country. There is a protractor scale on the swivel stop, allowing precise cutting. The maximum speed of the saw band is 882 m / min. The saw stand has special holes for secure attachment to the workplace.

Jet jwbs 9x

The inexpensive band saw has earned a spot in the rankings for its excellent woodworking performance. Its disadvantage is low power, but it does not interfere with the work. Thanks to the belt drive, the machine generates a minimum of vibration. Workpiece thickness. 2 cm. The band saw is easily controlled and adjusted before each job. Equipped with a wing screw for quick adjustment of the band tension. The working area is illuminated by a lamp for comfortable work in a dimly lit room. A graduated scale is available for cutting the workpiece at the desired angle.

Sawing and feeding speed

Sawing speed is measured in meters per minute. Feed is the speed at which the saw frame is lowered.

The higher the speed during sawing, the more the motor, band and workpiece heat up. A machine operating in this mode for a long time may break down.

Too high a feed rate can cause a strong vibration of the band saw, dull teeth and break the blade, to prevent this from happening, you need to reduce the feed.

A weak feed can deform the workpiece and dull the teeth, so you need to control the feed along the chips, it must be thin, curly and elastic.

Technical parameters and design features

The band saw consists of:

- C-shaped cast or welded bed.

- Upper and lower pulley.

- Toothed blades.

- Electric motor.

- Brake mechanism.

- Guide ruler.

Machines with horizontal saw installation are considered the most powerful, they are able to cut not only frozen wood, but also hard tree species. The best band saws for wood are used in sawmills.

Makita lb1200f

The Japanese band saw is equipped with a 2.5 meter long cord, which allows you not to look for a place for it next to the outlet. For convenience, there is a branch pipe for connecting a vacuum cleaner, which reduces the cleaning time. It is not cheap because of the high build quality and materials, which means it will last several years without breakdowns. A powerful motor is installed, protected from overheating and overload. A special feature of this saw is the figured cutting of wood. The working table tilts to any side up to 45 degrees. There is a spot illumination of the working area. If something goes wrong in the work, the machine can be stopped by pressing one button.