Chain sharpening for chainsaws with your own hands with photos and videos

While working with a chainsaw, even the best quality tool, the chain loses its initial sharpness over time and needs to be sharpened. What are the signs to realize that the electric chainsaw or chain saw chain has blunted and it’s time to sharpen it?

Here are the main signs that it is time to sharpen your chain:

- During work the saw loses stability, pulls out of hands and strongly vibrates;

- A chainsaw or electric saw produces only small chips, but does not produce coarse chips;

- the saw binds in the material, it is impossible to cut qualitatively and quickly;

- deepening of the chainsaw into the wood does not happen by itself, in order to make a longitudinal cut, the tool has to be “sunk” by hands into the material, applying force and pressing the blade;

- During sawing, a curved cut is formed;

- The chainsaw heats up quickly and severely;

- wear of the chain is much faster;

- increases fuel consumption.

If you have noticed several of these signs on your home tool, it is time to sharpen the chain.

A genuine chainsaw chain can be sharpened several times and will retain all its operating characteristics. sharpness of cut, quality of cut, speed of rotation along the bar.

A few important tips to help you avoid sharpening the chain on your chainsaw longer:

- Do not use a new chain with an old sprocket and vice versa;

- If you have already cut two chains while using the chain saw, replace the sprocket with a new one;

- The chain should be run-in before normal use with a normal load (run-in immediately before sawing, 1 minute at low RPM and then 1 minute at medium RPM);

- after a new chainsaw chain has cooled down, you should check its tensioning degree;

- Always use chain lubricant for your chainsaw and high-quality oil;

- Keep the chain taut, because chainsaws are often tilted in different directions while working, which increases the chance of the chain slipping off the bar;

- Check the position and orientation of the kerf limiter, check the limiter settings after the 3rd or 4th sharpening.

Signs of a dull chain and consequences of continued use

You should not confuse the difficulty of working with a blunted chainsaw with the difficulty of cutting hardwood or severely over-dry logs. In all of these cases, the speed of the operation is reduced, but the blunt tool has a certain pattern of behavior. signs by which you can judge the need for sharpening:

- the chainsaw does not immediately gnaw into the trunk of the tree, as if grinding, shifting away from the point of contact;

- During the sawing of soft wood, the tool sluggishly enters the thickness of the wood and has to be pressed on the bar;

- the chips turn from coarse with characteristic oblong particles into a fine teardrop, which very rarely crumbles;

- The chain heats up quickly, you can hear the unpleasant smell of burning oil to lubricate the guide bar.

In addition to these alarms, always after hitting metal nails, wires or burying a chainsaw in the ground, you can be one hundred percent sure that the cutting edges need to be sharpened afterwards.

What can happen to the tool later on if the problem is ignored? The most innocuous. it will be impossible to work with a chainsaw, eventually it will become boring and will force to service the machine after all. But adherents of a proverb “the power is the mind is not necessary” can come to the following result:

- extra strain on your body, because you have to, frankly speaking, put pressure on the tool to make it cut;

- Fuel overrun of up to 30%, which is explained by the need to go through a larger cycle of revolutions to achieve the same result;

- accelerated wear and tear on the tire and other parts of the chainsaw.

How To Sharpen A Chainsaw Chain. Raker Height Filing Very Important!

In addition to all of these negative consequences of a dull saw, there is a great chance of the chain jamming in the trunk and injuring the operator doing the work.

In this video, you can get acquainted with the sharpening process, the most popular ways and tools used for this.

A person who has a chainsaw in his house, must know how to sharpen the chain of a chainsaw with his own hands. There are several ways:

- Sharpen with a file (the most common sharpening method, t.к. allows you to sharpen the tool directly at the place of sawing work.)

- Sharpen with a special machine (this method is used in service centers, but can also be used in the private household)

- Sharpening with angle grinder. To sharpen by this method, you need to have certain skills. This method is not very common, because the chain is sharpened with the hands of a chainsaw.к. It is difficult enough to sharpen with an angle grinder correctly.

1 way. file

The first thing you need to sharpen the chain or tweak it a little is special files.

File

For sharpening and dressing chains for saws two kinds of files are used. The first one is a circular file with a diameter corresponding to the diameter of the cutting edge of the saw blade.

For sharpening saw chains of household tools, round files having diameter of 4, 4,8 mm are used, it is conditioned by the fact that they have small tooth. For professional models stronger chains with bigger tooth are used and accordingly files with 5,2, 5,5 mm diameter are needed.

In order to sharpen properly, it is not enough only to sharpen the cutting edges of the tooth, it is also necessary to make adjustments to the depth of cut limiter. If this is not done, the chain will not cut into the material to be sawn to the required depth, which will significantly reduce the speed of the work and just as in the situation with the blunt chain can lead to overheating of the saw engine because of the insufficient load on the motor. This work is done with a flat file.

It is worth remembering that the use of blunt chain, can lead to overheating of the engine and the formation of scoring on the cylinder.

Description of the process

The first step in straightening a saw chain is to put the tool on a table or on a flat surface. In forest conditions a log of large diameter is good for this. Then it is necessary to inspect the saw chain for any defects, it can be cracks, completely broken off teeth. After the inspection it is necessary to set the brake in the working state, thereby blocking its movement on the bar.

The chain should be taut while sharpening with a file.

It is desirable to put a support under the bar, as it can be used a log, a piece of branch of suitable diameter, or manufacturers of sharpening tools have special clamps to hold the bar in the process of sharpening the chain.

STIHL saw clamp

the chain is sharpened by filing from the inside to the outside of the tooth. The file must be parallel to the chain according to the marking on the chain. This mark is provided by the chain manufacturer to indicate the standard sharpening angle.

The cutter to be sharpened should be located approximately in the middle of the bar for ease of sharpening, and the chain should be pushed along the bar while sharpening, making sure to always return the brake to the working position.

Work on sharpening the chain on a chainsaw, it is necessary to carry out with gloves from a rough material, otherwise it is easy enough to injure yourself, t.к. The working surface of the teeth is very sharp.

Ideally, the manufacturer advises to make the same number of file movements for each tooth, but in practice this is not always possible, because.к. The teeth have varying degrees of damage to the working edge.

To facilitate sharpening the saw chain with a file, special holders with marked corners can be applied. Markings are not only made for standard cross-cutting, but also for longitudinal cutting.

Holders are also handy if you are not experienced enough in sharpening. Experienced sharpeners do not use holders for sharpening, they can only use special devices to support the file.

Another device designed for sharpening is the manual chain sharpening machine. As a sharpening tool it uses a regular file, which can be replaced by yourself. The machine is mounted directly on the bar, it also has a possibility to adjust the angle of sharpening a tooth and a special stop that holds the sharpened tooth.

A manual sharpening machine, perfect for beginners. Along with electric models for sharpening, manual sharpeners have their undeniable advantage in the form of low prices. Depending on the manual grinder manufacturer, they may look different, but the working principle is the same for all.

Correcting the depth of cut is done using a flat file, so that there is a difference between the upper cutting edge of the tooth and the height limiter.

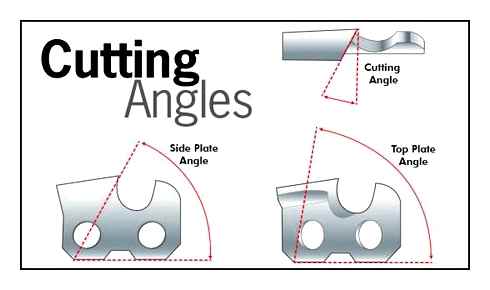

As can be seen in the illustration, the depth stop is resharpened to bring the clearance to the factory setting. The table below shows the basic values of the angles as well as the clearances for the most common types of chains.

The clearance is usually corrected by using a special die. It is placed on the chain during sharpening, after which the depth limiter is ground.

Using an angle grinder as a chain saw sharpening tool

You can sharpen the chain of a chainsaw with an angle grinder, but in this case you will need to be accurate, because the use of this technique does not involve the use of limiters. Beforehand, the equipment is fixed on a workbench or table, for which it is better to make some kind of clamp. After fastening the power tool, check for vibration. The fixed power tool is checked for vibrations, which are not permissible when carrying out precise operations. The sharpening technique consists of guiding the links on an abrasive wheel.

Attention! The tool shaft rotates at high speed and transmits the load to the chain, which can be dangerous for the sharpener.

Chainsaw Sharpening How To. Bestest Fastest Cheapest!

In addition, when using an angle grinder, there is also a risk of making a few mistakes:

- the thickness of the layer to be removed is not controlled;

- there is a high probability of making mistakes when sharpening the teeth;

- there is a risk of cutting through the connecting lug that holds the links.

When clamping the angle grinder with a clamping bar or vise, position the disc vertically. An alternative method is to clamp not the angle grinder but the saw in a vise, while the tool is brought to it.

Consequences of using a chain that has not been sharpened

The operator should take care of sharpening in a timely manner, focusing on the main signs that the sharpness of the teeth is decreasing. If this is neglected, then he will face a heap of problems, expressed in the following:

- crooked cuts;

- high load;

- Inaccurate cuts and unclear contours;

- Higher fuel consumption;

- shortened saw’s service life.

How to correctly sharpen a chainsaw chain with your own hands. step by step instructions

To sharpen your chainsaw correctly, you need to follow some rules. Knowing how to correctly remove and secure the chain is an important factor in successful sharpening.

What you need to sharpen your saw at home

You can sharpen the chain of a chainsaw either by hand or on a special machine. Most people perform this procedure by hand.

However, professionals advise not to do this very often, as it can lead to rapid wear and tear. But there are still times when it is necessary to sharpen the saw by hand.

For this purpose, special devices for sharpening chainsaw chains are sold, which include:

A template is needed to adjust the depth stop to be sharpened. And the hook is for removing dust and sawdust from the chain. All gardeners will need such a chainsaw chain sharpening kit.

While you are sharpening, the jig is positioned on the tooth you are sharpening. Use a flat file to work with the depth stop.

- Manual sharpening does not grind the teeth evenly and creates an imbalance;

- Old chains wear out over time and sharpening by hand becomes virtually impossible;

- The cutting edge can lose its normal shape;

- there is a risk of the chain breaking over time.

There is also a third way to sharpen a chainsaw chain. This method is fairly new and probably the easiest. Just buy a special chain sharpening wheel for chainsaws together with a special chain. This is a small device that is put on the end of the tire and secured in a stationary position. In the middle of it is an emery stone, which will sharpen your chain while you just press the button.

This stone is placed with the concave side facing the bar. There are links on the chain that grind the stone and do not let the oil get on the saw. How to sharpen the chain with your own hands by this method you can watch on video.

Removing the chain from a chainsaw

To remove the chain from the chainsaw, you first have to pull the chain guard toward you. As soon as you hear the clicking sound, get a screwdriver and loosen the chain. After that with a wrench we unscrew the nut and remove the bar together with the chain. There is nothing difficult in this procedure, but it is necessary to tension the chain correctly when you put it back. if you over tighten it, there is a chance of breaking. Well, if you don’t tighten it properly, the chain can fly off the bar.

But you must also know how to tension it correctly. After you put the chain on the tire and put everything together, make sure it fits snugly at the bottom of the tire. A normally tensioned chain should come off the bottom of the tire by 3-5 mm when pulled by hand.

How to fix and sharpen a chain at home

To understand how to properly sharpen the chainsaw chain with a file, and learn how to do it at home, you need to adhere to the following step-by-step instructions. The first thing to do is to fix the chain correctly. There are a few methods of fixation. The first method is to fix the bar in a vise. this is the most correct method.

This way you can be sure that the chain stays in place. However, there is a second method. You can simply sit back, put the saw between your legs and at knee level and start sharpening. The most important thing is that the bottom of the bar is not below the level of your knees.

Here is a step by step instruction on how to sharpen a chainsaw chain with a file:

- Clamp the chain saw bar so it’s in a stationary position.

- Make sure you have the right round file and bit holder so the file tip protrudes no more than 20% when sharpening the cutting edge.

- Mark where you want to start sharpening to avoid going around and around again.

- When sharpening, pull the file in only one direction and twist it regularly about its axis for even wear.

- If necessary, sharpen the depth stop with a flat file.

And it’s important to remember the chain saw chain sharpening angle. The angle of the file in the vertical plane with respect to the chain should be 90º and in the horizontal plane 30º or 10º, depending on saw parameters (saws that are designed for longitudinal cutting of logs are sharpened at 10º). A file holder will help you hold the file at the proper angle and position.

Important! If you see that the depth of the sharpening of the teeth is already quite large, it is better to change the chain for a new one to avoid breaking it in the process.

If you or your neighbor has a chain sharpening machine you’re in luck. With the sharpening stone you can sharpen your saw quickly, accurately and without much effort. Here’s an approximate order of sharpening on the machine:

- Loosen the chain on the chain saw by twisting the side screw with a screwdriver.

- After that you should position the chainsaw in the machine so that the teeth are facing the sharpening stone.

- Next, you need to choose the sharpening angle (it depends on the type of chain saw).

- Set the polarity.

- Select whether you want to sharpen the chain in series or across the tooth.

Now you can begin the sharpening process.

There is no need to worry about how to sharpen the chain on the chain saw sharpening machine as accurately as possible. All modern automatic sharpeners are brought almost to perfection. So you just have to follow the instructions above.

Features of sharpening teeth with a file

Sharpening with a file begins with the correct choice of the device diameter. A 4 mm file can be used for 1.3 mm chains. A file with a 5.2 mm diameter is needed for cutting teeth of 1.6 mm.

Sharpening with a round file

Sharpening with a file should be done directly on the tool, with the bar clamped in a vice and the handbrake applied. To be able to process this quickly, the teeth need to be sharpened first on one side at an angle, and then on the other side. The beginning of the file must be marked with a chalk or marker.

File types

Use reciprocating movements of the flat file to remove the limiters from the teeth. Beginners are recommended to use a special template, which is attached to the tire, and it remains only to make reciprocating movements with a circular file. Skilled craftsmen carry out sharpening using only a file, making a reciprocating motion of 1-2 times for each tooth.

How to sharpen a chainsaw chain correctly

Chain sharpening for chain saws is as important as lubrication and other care. Never work with dull chains, because only with a sharpened chain will the cut be effective, accurate and safe. We strongly recommend learning how to sharpen and you will know how to sharpen your chainsaw yourself so you do not have to go to specialists in this area and save some money. Of course, chain saw repairmen have a special chain sharpening tool, but you can do without it if you know what to use. A sharpened chain is often more important than a strong engine when it comes to quality sawing.

How often should a chainsaw chain be sharpened?? There are no specific time limits; it all depends on how often you use your saw. When you begin to realize that the sawing becomes slow, or the saw “takes away” to the side, and the sawdust is shaped like needles and there is a lot of dust in the shavings (this does not happen with a sharpened saw). So it’s time to sharpen.

What kind of device is needed for sharpening chain saws at home? You can do this with a cylindrical file. the size should correspond to the chain: for example, for a chain with parameters 1,3 mm; 3/8″ a file with diameter of 4 mm should be used; for a chain 1,6 mm; 3/8″ a file with diameter of 5,2 mm would be better. Chains with a pitch of 0,325 mm and a tooth height of 1.3; 1.5 or 1.6 mm round files with a diameter of 3.8; 4.2 and 4.8 mm respectively are recommended.

And how, in fact, to sharpen a chainsaw (more precisely, the chain of a chainsaw)? If the question is what to sharpen, then the Oregon chain saw chain sharpening machine or other device for sharpening chain saws will help. But you can also use a file. Take a round file with an appropriate size (or a strip file), a flat file (which you will need for shaping the limiter tooth). It is better to use a sharpening set, suitable for your saw (it is better to buy it together with the saw); it includes: a bar with a circular file, on which the necessary angle of sharpening of chainsaw chain is already marked; a template and a file for the tooth-restrictor. Your work is made much easier if you clamp the guide bar in a vice.

First we sharpen the cutting teeth. We put the sharpening template on the chain and sharpen with light measured movements, pushing forward at a certain angle to the saw bar. Sharpen one tooth on the right, one on the left; the same amount of movement and only forward. As for sharpening the limiter tooth. We put the template (file Kalibr) on the limiter tooth, observing the chain sharpening angle of the chain of a chainsaw, and with a flat file we cut the protruding part of the limiter tooth. Main. Not to cut too low. Sharpening chainsaw chains Oregon machine will help with professional precision perform sharpening, because the quality of the device for sharpening chain saws. the key to long and efficient operation of your saw.

How to sharpen a chainsaw on the machine

A chainsaw sharpening machine is usually used in such cases:

It is necessary to quickly and accurately sharpen the chain on one or more machines;

After hitting the working saw on gravel, stones, sand.

Sharpening machines can be manual or electric.

The sharpening machine has a motor that turns the wheel. No need to apply force to sharpen the teeth, just attach the chain to the base at the desired angle and turn the machine on. This type of sharpening is usually used in production and allows fast and convenient processing of several chains. The question of how to properly sharpen the chain of a chainsaw on a power tool will not cause difficulties, because this procedure does not require any special technical knowledge from a person.

Manual devices are put on the chain, fixed on the bar, or attached to the workbench. A file is located at the bottom of the unit and can be exchanged as needed (round for flat, for example). Sharpening the tine in two to three movements. You can sharpen and dress the chain and adjust the teeth to the same length with a hand saw.