Saw sharpening

Let’s go over the material how to sharpen dust on wood or sharpen a circular saw.

Mechanized disc sharpening

Materials and tools:

- Saw blade;

- Disc sharpening machine;

- Pendulum protractor;

- Marker.

How to sharpen a circular saw in a mechanized way? There are many different machines. Some mechanisms have software packages to provide a fully automated turning mode. In a home workshop, when disc turning is intermittent, you can use a simpler device.

Saw blade teeth sharpening angles: rake angle (γ), rear (α) and bevel angles of the front and rear planes (ε1 and ε2).

How to sharpen a disc? In such a machine, after installing and fixing it in a position that provides the required sharpening angle, all other operations # 8211; rotation of the canvas around its axis, control of the thickness of the metal removed from the tooth # 8211; performed manually.

Sharpening a straight tooth along the front plane is performed in the following sequence. Install the blade of the insert machine. Clamped with a centering sleeve. Then, using a mechanism, it is installed in a strictly horizontal position. Thus, the bevel angle of the leading plane is ensured equal to zero. If the machine has a built-in angular scale, the horizontalness of the disc is checked using a pendulum goniometer.

Then the screw of the mechanism is rotated, which provides horizontal movement of the frame with a circle. Set the required rake angle. The blade moves in a position in which the front plane of each element fits snugly against the working surface of the circle.

A marker is made to mark the first tooth from which sharpening begins. Then the engine is turned on and the front plane is sharpened. The machine brings the tooth into contact with the circle and performs several movements of the blade back and forth while pressing the element against the circle.

After sharpening one element, the blade is removed from contact with the abrasive wheel and rotated by one element. Then the operation is repeated in a similar way. This is how the machine works until the element marked with a marker does NOT complete a full circle, showed that all elements are sharpened.

Sharpening a skewed tooth differs from straight turning in that the dust is placed with an inclination equal to the bevel angle of the front plane. To sharpen an element along the back plane, it is necessary that the machine allows the blade to be installed so that the back plane of the element is in the same plane with the surface of the circle.

You don’t need any special skills to sharpen a circular saw on a machine. Anyone can cope with this work if he follows all the instructions and rules for working with disc sharpening machines.

Sharpening circular saws

Materials and tools:

Round dust discs.

- Saw blade;

- File;

- Diamond file;

- Marker;

- Thin wooden blocks;

- Pressure;

- Wiring;

- Adjustable wrench.

How to sharpen a circular saw with a disc? The saw blade must be sharpened from the rear surface if operating in a blade position that is returned to the tree. The front surface, which is on the material when cutting, remains in a constant position.

You can turn the disc in the machine. You can pull the canvas out of it. If turning is carried out in the device, then you need to remove the plug from the electrical outlet to prevent accidental turning on of the device. You need to glue the product, put thin blocks under it on both sides and press them to the teeth.

It is necessary to mark with a marker the element from which turning begins. When turning, you must be careful and pay maximum attention. Turning is done with a file or diamond Needle.

It is necessary to remember the number of movements and applied forces when turning the first tooth. The same efforts need to be made when turning the remaining parts. If the blade is removed from the machine, you need to clamp it in a vice, then sharpen each tooth in the same way. Then the web is installed back into the device.

Check the cut on the sample. If there is noise during operation or the material feed is uneven, check the tooth height. To do this, bring the marker to the incisal edge. Then it is necessary to slowly return the canvas by hand 1 turn in the direction opposite to the direction of rotation. In this case, a mark will appear on each tooth. On examination, you can find out which elements are higher than the rest. If the difference turns out to be significant, you need to carefully reduce the height of the elements.

How to sharpen a circular saw

How to sharpen a circular saw? Circular Saw # 8211; it is a necessary tool when building a summer house. It surpasses other types of dust in its accuracy and cutting quality. The duration of the structure’s operation depends on the quality of its sharpening.

The service life of a circular saw also depends on the quality of its sharpening.

An unsharpened disc increases the load on the mechanism. As a result, it can break.

Periodic sharpening of circular saws is required.

Signs that indicate that the dust needs to be sharpened:

- When sawing, a heavy load must be applied;

- The edges of the cut burn;

- The engine overheats;

- Smoke appears during operation.

Saw Tooth Set

The teeth are set when it is required to provide more free movement of the saw blade. The teeth in turn are bent in different directions at the same distance, using a set. With its help, the tooth is folded back approximately in the middle of its height. The setting is a tool for making the saw teeth set, it is in the form of a plate, in which there is a slot.

You can also use an adjustable wrench, which also successfully sets the teeth.

To work with soft wood, the teeth must be set more, in the case of hard ones. less. But this advice is hardly useful to those who work directly in the forest. In THESE conditions, the degree of hardness, density and moisture of trees is hardly possible.

In order to choose the right wiring, you will have to test this device in different conditions, the best option would be three tenths. five tenths of a millimeter in one direction. The general requirement is that the tooth setting is NOT greater than the blade thickness on two sides. It is necessary to do the wiring before sharpening.

Sharpening and setting the saw

The main cutting element of any hand saw. A series of teeth cut into the blade and representing wedge-shaped cutters. Wood, in the manufacture of all kinds of products from it, is sawn lengthwise, across and at an angle волок to its fibers, in this regard, transverse, longitudinal sawing and sawing at an angle to its fibers are distinguished and in each case use the corresponding type of saw, different from other tooth shapes.

And. Cross cutting; b. Longitudinal sawing; 1.Wood; 2. Cut; 3. Line marking for sawing; Θ. The angle of inclination of the marking to the wood grains with mixed sawing.

When crosscutting, cross saws are used, the cutting edges of the teeth of which, when moving in the wood, cut its fibers like a knife and form a cut. Longitudinal sawing differs from transverse sawing in that the direction of movement of the saw is parallel to the grain of the wood. The leading edges of the teeth of the longitudinal dust planes the wood like knives in a plane, and, going deeper, form a cut. When sawing wood at an angle Θ, universal (mixed) saws are used to its fibers with teeth that are an intermediate form of teeth for transverse and longitudinal dust.

Saw blade sharpening

The saw of the circular version is sharpened from the rear if you work in a position facing the material, which is being processed.

- The front surface that runs into the material during sawing remains in a constant position.

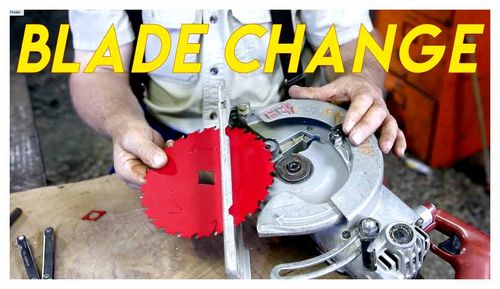

- You can sharpen the disc directly in the machine. Otherwise, you can remove it from the machine or circular saw.

- In the first option, you first need to unplug the plug from the socket in order to prevent the consequences of starting the machine, which can happen accidentally.

- The disc must be wedged, for which, on both sides of it, you need to put thin pieces of wood and press them to the teeth.

- With a marker it is necessary to mark the side of the tooth from which you will begin to sharpen. This will allow you not to make mistakes in such a responsible work.

- Attention and extreme caution must be exercised.

It is important to remember the number of movements you make when sharpening the first tooth, while you used a file or diamond file.

You will need the same efforts in order to sharpen all the other teeth.

If you removed the disc from the machine, it must be clamped in a vice in order to do the same activities in which you read above.

Then the disc returns to the machine, the unnecessary piece of wood is sawn. It is necessary to check the height of the teeth if your work was accompanied by a Loud noise or an uneven feed was typical. This can be done by bringing a marker to the incisal edge and returning the disc with a hand in a slow rhythm one revolution in the direction opposite to the direction of rotation. Each tooth will receive a mark; when examining the disc, it will be revealed which teeth are higher than the second. If the difference is significant, it is necessary to carefully reduce their height.

How to properly dilute and sharpen a circular disc

How to set the disc teeth

Sharpening a circular saw tooth in one and two planes.

If it is necessary for the movement of the disc to be more free, then set the teeth.

It is necessary to bend all the teeth in turn in different directions at the same distance. The work is performed using wiring. Wiring # 8211; it is a tool for performing divorce. An adjustable wrench can be used for wiring. When working with soft woods, they are bred more. When working with hard rocks # 8211; less.

To find the right layout, you need to test the device when cutting solid wood. The best layout would be approximately 0.3 # 8211; 0.5mm one way. The main requirement is considered to be the layout of the elements NOT more than the thickness of the canvas on both sides. Wiring is done before sharpening.

In the case when it is necessary to turn the blade of a higher quality, a machine for mechanized turning is used.

Destination

Depending on the type of disc, the following can be processed:

- Wood of various species;

- Wood products. chipboard, OSB, plywood, laminated flooring and other similar materials;

- Polymeric substances and products from them, for example, organic glass, polystyrene;

- Natural stone material such as marble;

- Soft metals. aluminum, copper alloys;

- Products based on iron alloys. pipes, corrugated sheets, etc.

The cutting tool has certain characteristics, parameters, dimensions, purpose, properties of the material from which it is made.

Tooth configuration

Each type of cutter is designed and manufactured to solve a specific task. Subdivided:

- Flat blade. used for fast rip sawing in soft or hard wood, marked FT.

- Replaceable cutter. has a successively alternating replaceable inclination of the teeth to one side or the other. The cutters give an even and fairly clean cut. It is used for transverse and longitudinal cuts of wood, processing of plywood, OSB, chipboard and composite boards, indicated by the ATB symbol.

- Combination cutter is a sequential change of groups from a combination of four replaceable cutters (ATB) and one flat cutter (FT). Combi. This type of disc is referred to as universal due to the ability to perform different types of cuts.

- Trapezoidal flat cutter. made of successive flat teeth. The higher one is sharpened under the trapezoid, the lower one is flat. It is used for processing wood and wood products, for polymeric materials and soft non-ferrous metals. Has the designation TCG.

- Replaceable cutter with increased sloped side. Designed for cutting materials prone to splitting and for fine cross-cutting. Denoted by HiATB.

Marking

As you can see in the picture, the disc labeling can tell about many technical characteristics. But there is a dependence that should not be neglected: the shape of the teeth directly affects the ability to work with a specific material.

The classification, developed by representatives of the GASS brand, divides the discs into the following categories according to the shape of the teeth:

GK and GS: alternately cut. Suitable for processing all types of wood and “clean” chipboard, without plywood and plastic coatings.

GM: straight. Only able to cope with cutting soft wood.

GT: trapezoidal. Useful in cases when you need to cut MDF or chipboard with lamination.

GR: tapered. Cuts multi-layer double lamination.

GA: trapezoidal and straight. Same features as GT.

Manufacturers apply laser marking on quality saw blades. If the parameters are “written” with ordinary paint, then we have an economy class product that will quickly become unusable.

Tilt of teeth

Most of the blades for circular saws for wood are made with a positive inclination, which increases the quality of the longitudinal cut. With a negative tilt angle, the radius of the tooth will be directed towards the back of the disc. However, longitudinal types of cuts are most often performed by products with a positive deviation of the tooth from the radius, since such a configuration provides a more reliable grip of the raw material. Slope classification is based on the following principle:

- An angle of 5 to 15 degrees is considered the standard incisor position;

- The positive slope is within 15-20 degrees;

- Negative. here is 0 to 5 degrees.

Based on these values, it will be easier to find the consumable for the job.

DIY: Custom Circular Saw Cutting Table. Destination

Depending on the type of disc, the following can be processed:

- Wood of various species;

- Wood products. chipboard, OSB, plywood, laminated flooring and other similar materials;

- Polymeric substances and products from them, for example, organic glass, polystyrene;

- Natural stone material such as marble;

- Soft metals. aluminum, copper alloys;

- Products based on iron alloys. pipes, corrugated sheets, etc.

The cutting tool has certain characteristics, parameters, dimensions, purpose, properties of the material from which it is made.

Number of teeth

With an increase in the number of teeth, the processing speed decreases, but the cleanliness of the cut improves. And vice versa: the fewer the teeth, the faster the work goes, but the cut becomes less accurate. The characteristics have their own classification, presented in the table:

A portal member shares his experience in making a universal homemade wood sawing machine.

I am building a house from “cylinder”. Because When building a log house, I want to save money and get a high-quality result, I try to do most of the work myself, without involving hired workers. Once I started making casing boxes for windows and doors and realized that a regular circular on wood does not do this job. Something more precise and convenient is needed. Therefore, I have made a table for a circular saw and would like to share its design with FORUMHOUSE users.

- How to make a saw table for a circular saw.

- What materials and parts are needed for this.