Which way to put the chain on the chain saw?

It began to be used relatively recently, it is considered new, if not advanced. Differs from the classic wrench, as follows:

Instead of a 13mm wrench nut, it has a wing nut (swivel cap) with a knob for tightening by hand. It also has a nut, but it is hidden inside. Instead of the screwdriver adjustment screw on this system, the tension is adjusted using the tension wheel (adjustment knob).

The first of these systems appeared on German STIHL chain saws.

sprocket and tension washer instead of pinion shaft.

- the mechanism itself is more complicated than a traditional wrench;

- the installation of the cutting headset causes additional problems, t.к. Mating all the parts in the right order makes it difficult;

- The chain can be adjusted for a shorter stroke, a slightly stretched chain will still work with the traditional tensioning system, but here it will sag and become unserviceable.

The only positive side is that you don’t need a screwdriver or wrench, and can adjust and tighten by hand. there is no positive feedback on this system. The negative ones, on the other hand, are numerous. For those accustomed to traditional adjustments, the keyless system seems like a technical puzzle to assemble.

The chain comes off the bar: why does it happen??

Among the most common problems associated with the chain headset is that the chain slips off the bar of the tool. The occurrence of this problem may be due to incorrect installation of the consumable on the chainsaw, tension or insufficient fixation of the drive sprocket. The algorithm for solving the problem depends on the cause that provoked it.

Loosening the chainring will cause the guide bar itself to loosen. To check the condition of this element it is necessary to carefully inspect the space between the plate that is on the protective cap and the inner plane of the gasoline saw body. If the screws are not tightened enough, the bar will wobble. This problem can also be noticed during operation. It is manifested by increased vibration loads during the sawing process.

In order to fix the bar securely, first of all lower the chain brake. It is necessary for protection against accidental chain rotation. Secure the bar by tightening the bolts all the way. Next, turn the adjusting bolt. The flow element must engage in the grooves with its teeth. Check tension.

The problem with a loose bar occurs in inexpensive amateur and premium professional tools that come under well-known brand names. If you use the tool regularly and put it under a lot of stress, don’t forget to check the tension of the chain and make sure it is securely fastened before you start the engine.

Installing the chain on the chainsaw: tips and nuances, video

The chainsaw chain is the element that is subjected to the greatest stress and overheating.

It can break, come off the guide bar or just get dull from extended use.

For preventive maintenance or replacement with a new chain, it is important to know how to remove and install the saw chain on your chain saw. A step-by-step procedure for these steps is shown below.

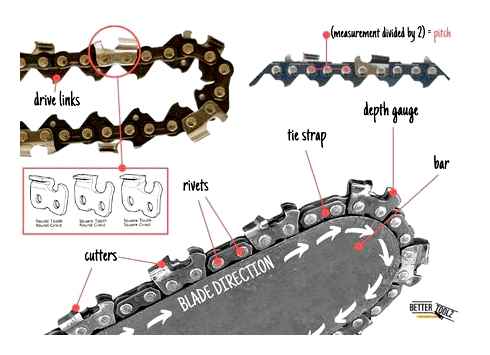

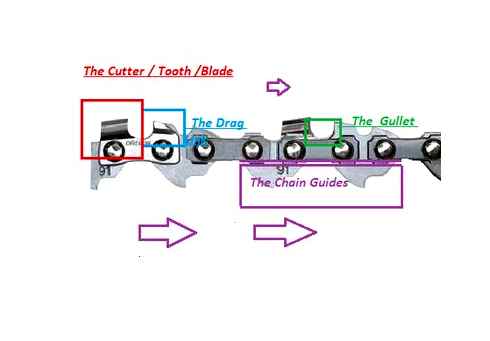

Chain orientation and which way to put it on

A chainsaw chain, if you look closely, has the saw teeth pointing in one direction.

Therefore, the correct direction of the saw teeth on the guide bar is very easy to determine: if you position the chainsaw itself in the plane it is in when working, the row of teeth located on top of the guide bar, the sharp edges should be directed towards the end of the bar. While, the row of teeth that is at the bottom of the chainsaw, the sharp edges should look in the opposite direction, in the direction of the drive sprocket.

It is not possible to put the chain with the teeth facing inward against the grooves in the guide bar, it simply will not fit on the bar. That’s why the chain on the guide bar has to be slipped on so that the guide lugs of the saw blade links are turned to the guide bar.

Chain tension

A chainsaw chain, together with the guide bar, is the part that is most stressed during use, unlike other chain saw parts. Over time, it lengthens in size due to the boring of the gaps in the connecting links. This process occurs with every kind of chain, so it is necessary to periodically check the chain for proper tensioning and wear while operating a chainsaw.

If the chain is too tight, sawing efficiency is reduced, and the motor and transmission are subjected to increased stress. The guide bar gets very hot because of increased friction, the chainsaw goes into overdrive.

What to do if the chain sags

If the chain slackens, it can lead to personal injury because the bar can break or come off the guide bar. Sure, modern chainsaws have safety and emergency-stop systems, but these systems do not always work properly.

It is important not to install a chain on a chainsaw with defective or damaged saw links, in addition to the danger of breaking at any time, such a chain will sharpen the guide bar grooves, which will lead to its warping, uneven cutting and failure of the guide bar.

The chain can sag during even a short period of use?

- There can be problems with the guide bar. Sometimes due to operator negligence or due to severely worn threads of the fixing bolts where the guide bar is attached, vibration can occur which causes the chain to loosen. The fixing bolts should be checked and renewed if necessary. This problem will not occur if the screws are sufficiently tightened.

- If you are reasonably careful with your chainsaw, any chain will wear out over time. Trying to repair it or put it back together is a futile endeavor. If the chainring is stretched due to natural causes, it is best to buy a new one.

- The sprocket is misaligned. The chain can sag because of misalignment of the sprocket teeth. If this is the case, it is best to have the sprocket repaired and repositioned. Fixing the drive sprocket in the correct position is quite difficult, because you have to dismantle many small parts, remove the guide bar, and then reassemble everything in the reverse order.

Step by step installation procedure

Not all chainsaws today come with a setting wheel that makes the saw blade much easier to fit. Systems with a mounting wheel are generally rare among home chain saws. That’s why it’s important to know the process and the chain fitting sequence on the chain saw.

The main points to which you should pay attention:

- Prepare a level surface on which you will assemble the chain and guide bar. This will minimize the chance of damage to the chainsaw or loss of small parts. Lay the guide bar and the chain next to it in parallel on the prepared surface.

- Remove the sprocket guard, on modern chainsaws it is sufficient to unscrew the wing nut, on older models you may need an appropriate size ring spanner.

- At the base of the guide bar, turn the tensioning sprocket all the way to the right. Only in this position install the chain.

- Then the chain is fitted onto the guide bar one chain link at a time. install the chain from the top of the guide bar, turn it gradually so the bar is always on top and the chain is always on the bottom, that it is always taut and can fit in the guide bar groove without any problem. Be sure to wear thick protective gloves when you do this step, because your fingers will be in contact with the cutting edge. When viewed from above, the cutter is always positioned forward toward the end of the guide bar.

- Put the bar and chain on the drive sprocket.

- Replace the chain sprocket cover. Make sure that all mounting pins are aligned with the holes. Fit the bar and chain on the drive sprocket correctly. skewed or loose fit may cause noise, rattling, etc.

- Make sure that the guides “fit” into the special mounting groove.

- After mounting, check that the chain is locked in place on the chainsaw and on the guide bar. Everything must be mounted securely with no backlash.

Rules of choice

No matter how many times you sharpen and tension the chain, sooner or later the life of the chainrings will be exhausted and you will have to replace the chain for a new one. The following criteria should be considered when selecting a replacement:

The main selective characteristic that directly affects the efficiency of the device in the given conditions. defined as the space between the tips of the working teeth. The bigger is the pitch, the more productive is the chainsaw, but at the same time the motor has to be more powerful. Parameter value is given in inches.

There are the following basic patterns between these values:

- 0.325. for chainsaws with a maximum horsepower of 3 liters. с.

- 0,375. for amateur models with engine power up to 4 liters. с.

- 0.404. designed for professional chainsaws with 5 liters and more engine power. с.

- 0.750. for very powerful special seldom used saws.

In most domestic cases 0.325 and 0.375 chains are enough.

The second important parameter that allows you to choose the right chain for a chainsaw is the profile of the cutting tooth. There are 2 basic versions:

- Chisel. The cross-sectional area of the tooth resembles the number “7. its main feature is minimal contact with material during cutting. Increased cutting depth in one pass and improved productivity. Minus. the complex shape does not allow for self-sharpening.

- Chipper. the most common. The profile of the cutting part has a rounded, simple shape, making it easy to sharpen, even with a file.

Chisel-shaped chains are destined for professionals, when they need to get a large amount of work done in a short time, chipper is more suitable for household tasks, especially that no special tool is needed for sharpening its teeth.

The parameter is set by the thickness of the shank, which moves in the slot of the guide. Structurally, this element has a smooth surface and holes for oil intake and tire lubrication.

They are differentiated in size by the following modifications:

- 1,1 mm. fit for standard saw models.

- 1.3 and 1.5 mm. the most common, suitable for semi-professional and professional models.

- 1.6 and 2.0 mm. used on extremely powerful professional saws that operate with high and continuous loads.

depth of cut is the amount by which the cutting part sinks into the material in a single cut. Determined by the height of the prong and limiter. There are 2 versions. low profile at 0,635 mm and high profile at 0,762 mm.

There is a special people’s rating to determine the best chainsaws. It includes precisely those companies whose products the majority of consumers prefer to buy.

- Oregon. Produces saws, chains and accessories. Good quality and low price. Chains are fitted with tungsten carbide inserts and anti-vibration protection.

- STIHL. Professional woodworking saws. Their products are highly resistant to cutting part wear and pulling. Also features special grooves for high-performance lubrication.

- Carlton. High service life of the links due to the special technology of production. shot blasting.

- Vindsor. Innovative developments in the field of special high-strength and highresistance refractory alloys are used in production.

- Husqvarna. Only the best proven developments are used in production.

Important! Malfunctions with the chain mechanism often arise not only due to faulty bars and other major components of the saw, but also due to illiterate sharpening of its cutting teeth.

Proper chain installation on a chainsaw. Chain tension.

Incorrect chain tensioning on gasoline and electric saws greatly reduces sawing performance and the service life of the chain, bar and drive sprocket. there are cases, especially in winter, when incorrect chain tensioning led to replacement of crankshaft, and this is a serious repair.

The chain tensioning procedure is usually described in detail in the chainsaw manual, but by no means always, so I will summarize the main points.

When tensioning the chain, there should be no chain slack on the underside of the tire. A loose chain will cause the chain to wobble while sawing and bump the bar closer to the bottom sprocket. You can see it on the guide bar at a glance. Bumps appear at this location. Shocks cause the chain to break.

After installing the chain on the bar and tensioning it for the first time, check that it slides over the bar after first removing the chain brake. The chain should glide smoothly on the bar. Next, make a test cut of the wood and check the tension in the chain again. If there is slack in the chain, tighten it again.

Do not overtighten the chain. The chain must turn freely without great effort.

In winter operation, the chain gets hotter than the tire and the chain will sag due to thermal expansion when it is put in operation. Remove any slack in the chain. And after work, the chain must be loosened. Otherwise the chain links will break from compression. There can be up to ten of them accumulated. But the worst thing is that the compression of the chain can bend the crankshaft.

chainsaw parts, huge variety: go to any link and type in the search box (BENZOPILA PARTS)

1.Huge selection of chains, both in price and quality http://ali.pub/4k3vw2

2.Digital laser tachometer for chainsaw adjustment: http://ali.pub/4hlr72

CHAIN REPLACEMENT on a Stihl chainsaw MS 250. How to

3.Wi-Fi endoscope for hard-to-reach places works with a smartphone: http://ali.pub/3hez2z

4.Chainsaw carburetor adjustment screwdriver set: http://ali.pub/4jmdzr

5.Digital wired tachometer for chainsaw adjustment: http://ali.pub/4jmjux

If you notice any inaccuracies, please let us know in the Комментарии и мнения владельцев.

how to tighten the chain on a chain saw, what is the chain tension chain saw, chain tension chain saw, chain tension on the chain saw, what is the chain tension on the chain saw, chain tension chain on a chain saw STIHL 180, the correct chain tension chain electric saw, chain chain saw, how to tension the chain on the chain saw,repair chain saws,trivia,bar chain,Victor Polev,chain tension on electric saws,tension the chain on the chain saw,installation of chain on the chain saw,installation of chain on the chain saw

To sum up

There are now many models of chainsaw chains on sale. To begin with you need to know what size fits your chainsaw and not to make a mistake in buying. To this end, we suggest reading a number of interesting and useful articles, such as how to choose a chain for a saw, or a review of the chains manufactured by STIHL, Husqvarna or Oregon. By the way, when buying pay attention to the chain pitch, it is different for each chainsaw. There are also very expensive and efficient chains with tungsten carbide inserts.

The second step is to install it correctly on your chainsaw. This is a somewhat time-consuming process, but if you know how to install and adjust the chain on the saw bar yourself, then the good owner should not have any problems.

We hope that after reading this article you will succeed the first time. But in order to minimize the appearance of problems with the chainsaw and the chain in the future, remember the 3 basic rules:

Why the chain falls off, what’s the cause?

If you’re wondering why the chain on your chain saw is coming off, it could be a problem with the chain. There are three main reasons for this problem: the bar is not working properly, the chain is stretched and the sprocket is not properly fastened. Let’s look at each of the possible causes in more detail.

Tire problems

If there is a problem with the bar, the tensioning of the chain almost always loosens. this problem is usually at the bar mounting location.

This location is in the groove between the outer plate that is on the chain guard and the inner plate that is on the engine housing. The cover together with the busbar is secured with a bolt. This attachment is called the “engine node”. The drive sprocket and bar mount are protected by covers.

If the fastening screws come loose, the tire starts to move or vibrate. If the bar is good, the tensioning of the chain should be ok. Once it’s tightened, it’ll go at least five working days without tightening. So you have to tighten the bolts that hold the bar in place.

Did you know? In the town of Nora, which is in Canada, chainsaw wood carving is highly developed. All the streets and squares of this town are decorated with products made by the masters of chain saws.

To understand how to tension the chain on a chainsaw, you first need to find and lower the chain brake. The tensioning screw is next to the bar and is turned until the chain is tensioned on the bar. Then pull the chain back in a clockwise direction. If it does not move, it must be loosened a little by turning the tensioning screw in the opposite direction.

The chain has stretched

If you have a sagging chain on your chainsaw, it indicates a malfunction of some mechanism, one option is the wear of the chain itself.

Over time, the metal deforms and the chain becomes 0.5 to 1 cm longer. The best way to fix this problem is to buy a new chain, but there is a way to get the old one to work again. Experts say it is very difficult and almost impossible, but we will tell you how to do it at home.

For this we will need:

A regular chainsaw chain is made of strong steel, so it’s hard to disconnect. You must loosen the chain on the inside of the rivet, which serves as a connecting mechanism.

First of all you need to fix the rivet in a vice, and then gradually grind down the protruding part of the rivet. Grinding should be done with a file or file. an angle grinder is not recommended because of the risk of damaging the sides of the links. After grinding, the rivets are hammered out with a bead. A rivet that has been blown out should not be thrown away. You may not be able to find a replacement. Petrol saw manufacturers don’t make separate parts for the chain, because they don’t expect customers to be able to repair the chain themselves. You probably won’t be able to make a new rivet yourself, so you’ll have to install the old one.

In order to shorten the chain, it must be split in two places. But remember, the number of guide tabs on the inside of the chain and the distance between them should match the drive sprocket.

How to change a chain or replace a Black and decker chainsaw

Important! When welding a link, set the current to its minimum value. Use the smallest diameter electrode so you won’t hit the neighboring links.

After removing one or more links (depending on how stretched the chain is), the chain can be joined together. Rivet the old rivets together, pressing them firmly against the sides.

Next we need a welder. The rivet must be welded to the sides of the link. After that, use a file to grind off any excess that was created when welding. The chain can be considered as working again.

Drive sprocket is loose

One possibility for a sagging chain on your machine is a problem with the drive sprocket. Most often it happens because the star is not properly secured. Now we’ll tell you how to fix the sprocket correctly and then put the chain on the chain saw.

The first thing to do is to remove the engine cover. Next, remove the protective cover of the spark plug, pull out the air filter. Then with a special wrench to unscrew the candle. In its place is a special stopper, which fixes the piston in a certain position. Using a special wrench (you can use a universal wrench for angle grinder) turn clockwise the clutch disk until the piston reaches the extreme upper position. The piston should remain at the bottom, as viewed from the hole in the plug. A thick rope can be used as a stopper, it is better to fold it several times. After locking, you can clamp the drive sprocket by turning the clutch disc counterclockwise.

Did you know? Druzhba” chain saw was named in honor of the three-hundredth anniversary of the union of Ukraine and Russia in 1954.

After clamping you have to do everything in the reverse order, that is, reassemble the chainsaw. Put the chain on the bar and make sure it hits the drive sprocket that holds it in place. Put the tire in the designated mounting holes and bolt it down. Then the bar protector is fitted.

Operating Tips

Knowing how to tighten the chain on a chainsaw is not enough. Proper care of the chain saw is essential, not only for the chain itself, but also for the machine’s lifespan. Here are some operating tips:

- Clean the air filter regularly and lubricate it with oil. Replace the filter with a new one, if necessary.

- Always check that all nuts and bolts are securely tightened before operating the machine so that no malfunctions can occur during operation.

- Lubricate the bearings regularly, and do not forget to clean the candle from the sludge.

- Lubricate the drive sprocket. And after working with your chainsaw, don’t forget to clean it.

- Always keep the chain lubricated, sharpened and tightened in good time so you won’t have any problems with the bar and chain.

If you use all of the above tips, your machine will last much longer than the warranty period.