How to choose the right type of hacksaw blade

Choosing the correct teeth per inch for a hacksaw blade depends on the size and type of cutting material.

14 teeth / 25 mm. cutting thin materials of all types, pipes, profiles, etc. 10 teeth / 25 mm. cutting all types of small and medium sized materials 6 teeth / 25 mm. cutting all types of materials with a greater thickness of 4 teeth / 25 mm. cutting thicker soft materials

RECOMMENDED TEETH FOR 25 MM (TPI) FOR EACH MATERIAL:

| Freehand steel Construction iron Structural steel | 14-8 | 8-6 | 6-4 |

| Heat treated steel Nitrided steel | 14-8 | 8-6 | 6-4 |

| Unalloyed tool steel Alloy tool steel | 10-8 | 6-4 | four |

| Spring steel | 14-8 | 8-6 | 6-4 |

| Heat resistant steel Stainless steel | 8-6 | 6-4 | 6-4 |

| Ductile iron up to 200HB Gray cast iron over 200HB | 8-6 | 6-4 | four |

| Cast iron | 10-8 | 8-6 | 6-4 |

| Dural Bronze Aluminum Brass | 6-4 | 6-4 | 6-4 |

Fewer teeth are better for cutting thicker material, while more teeth are better for cutting thin profiles.

Technical information for hacksaw blades: Pilana

How to use power saw blades correctly

- It is important to pay the same attention to power saw blades as you would any other tool.

- Keep the machine in good technical condition. It is especially necessary to check:

- the lifting arm and its functions are OK, the oil pump

- lifting arm clean and free of air bubbles.

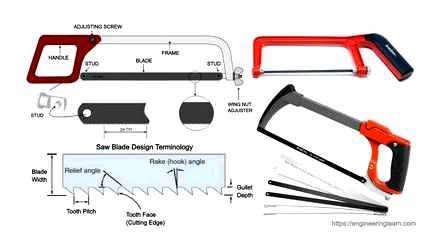

Tighten the wing nut

When the blade is in place, turn the wing nut clockwise to force the metal bar backward, pulling the blade tightly into the frame.

Types of hacksaw blades

GOST R 53411-2009 “Hacksaw blades for metal” establishes two types of such tools. for machine and manual cutting. We will not touch on the first ones, but the second ones are produced in three main standard sizes:

- Single, with a distance between the fixing holes 250 ± 2 mm, with a total blade length of no more than 265 mm;

- Single, with a distance between the fixing holes of 300 ± 2 mm, with a total blade length of no more than 315 mm;

- Double, with a distance between the fixing holes of 300 ± 2 mm, with a total blade length not exceeding 315 mm.

In this case, the thickness of the single-sided sheet s is 0.63 mm, and the double sheet is 0.80 mm. Height with a single row of tines is 12.5 mm, and with a double row is 20 mm.

GOST also regulates the values of the pitch of the teeth P, mm and their number z, which for the first type of blades are 0.80 / 32, 1.00 / 24 and 1.25 / 20, respectively. Owners of longer hacksaws, in addition to those listed above, can also use hacksaw blades with parameters 1.40 / 18 and 1.60 / 16.

According to the brand of material used for the manufacture of hacksaw blades for metal, they are made from tool steels:

- H6VF brands.

- В2Ф brands.

- High-speed, grades P6M5, P12 or P18.

The range of domestic hacksaw blades is exhausted by this, however, in specialized retail chains, so-called diamond blades are widespread, with surface spraying with titanium nitrides or other refractory metals. These canvases can be easily distinguished by their color: ordinary steel canvases are dark gray, and the sprayed ones can have different colors. from bright orange to blue (depending on the manufacturer).

There are also canvases with the so-called tungsten carbide spraying, however, with a very high hardness, they are extremely sensitive to bending stresses. Therefore, when cutting metal, their durability is negligible.

High strength of hacksaw blades for metal is ensured by appropriate heat treatment. On the surface of the blade, two zones with different values of hardness are distinguished: directly at the teeth, it ranges from HRC 64 67 for alloyed tool steels to HRC 73 78. for high-speed steels (for diamond blades this parameter reaches HRA 82 84), and in the rest zone. НRС 44 46. A significant difference in hardness confirms the high sensitivity of the product to bending stresses, therefore, the standard also limits the maximum force applied to the hand hacksaw. It should not exceed 60 kg when working with blades with a tooth pitch of less than 1.4 mm, and 10 kg for blades with a tooth pitch of more than 1.4 mm.

How to use a hacksaw safely

To install the blade, turn the adjuster on the handle or frame until there is slack and the holes on each end of the blade fit into the sleeves. Make sure the prongs are facing away from the handle.

For safe use of the hacksaw, place the material to be cut tightly in a vise (if possible). Place the center teeth of the saw on the line to be cut and press down on the saw with a short stroke to start the cut. Continue cutting, making sure the end of the object to be cut is held and will not crack due to unsupported weight. For safety, keep hands and other objects away from sharp teeth.

Hacksaw blade for metal. How to choose and install?

The blade for a hacksaw for metal is one of the most short-lived elements from the entire range of consumables for tools. Of course, a lot depends on the technology of working with metal and the skills of using a hacksaw, but first of all you need to be able to make the right choice of the blade. Today, we will talk about the choice and types, and also learn how to easily change the hacksaw blade.

Hacksaw design for metal

The most common and more common device for performing work with metal is a special hacksaw for metal, which differs from the outside from a hacksaw for wood. A hacksaw for metal is often used in construction and repair work, when it is necessary to accurately and neatly saw not too huge wood and iron workpieces.

The design of hacksaws for metal is quite common: a narrow hacksaw blade is stretched between 2 ends of an iron U-shaped bracket. The working part of a similar saw is the thinnest blade with teeth, and you only need to work with such equipment with 2 hands. The blade fastening system is of 2 types: threaded clamp. under such circumstances, the canvas is stretched and then fixed with a wing nut, the lever mechanism. when the blade is installed and removed using a special lever.

Hacksaws, in which the 2nd method of installing and stretching the blade is used, is more expensive than the first option due to its own versatility, in addition to the speed of installing and removing the blade. The main advantage of hacksaws for metal will be that, in contrast to a power tool, with the help of a hacksaw for metal, of course, work at the breakdown site, for the reason that an electrical network is not needed. Among other advantages of hacksaws for metal. simplicity in the boat, maintenance and low weight.

There are a lot of hacksaw blades on sale. And, this, the price of canvases is also different. The cost of a hacksaw for metal depends on the type of blade and the number of teeth per inch (bimetallic as it is also called with hardened teeth). Bimetallic blades occasionally break, more flexible and more expensive are hardened blades.

Application environment

Saw blades are used for cutting soft metals (bronze, copper, aluminum) and polymer products. The thickness of the hacksaw blade is selected based on the type of material being processed.

Hacksaw blade for metal. its types and principles of use

A hacksaw blade for metal is a consumable that quickly breaks down. The service life of the file depends on the way the metal is processed with a hacksaw and the skill of using the tool. Correct selection of replacement part plays an important role.

How to choose a tool and canvas

When choosing a saw, you should pay attention to the distance between the fasteners. It is necessary to purchase a tool into which replacement parts of various sizes can be inserted. When buying a hacksaw blade for metal, the following parameters are taken into account:

- The strength of the processed material. If the saw will be used for cutting soft sheets, use a blade with a minimum hardness, made of steel grade X6VF. A professional hacksaw is equipped with parts made of high-speed materials. High cutting quality is ensured by diamond or tungsten blades.

- The thickness of the processed sheet and the quality of the cuts. The selection criterion is the number of teeth per inch of material (PPI). For thin sheet metal cutting where smooth edges are required, it is recommended to select parts with a PPI greater than 24. If cutting speed is more important than quality, the index should be less than 24. The PPI increases as the tooth frequency increases.

- Coating type. Russian-made tools are coated with Chem.Ox.Prm. Less commonly, you can find files with an enamel coating. It must be remembered that with prolonged use, the enamel may crack. There are bimetallic products when a high-speed metal strip is applied to a steel strip.

- Uniform direction of the teeth. The points should not deviate from the axis by more than 45% of the pitch of the teeth.

Tooth pitch

The pitch of the teeth may also differ. This indicator of the hacksaw blade determines:

- Performance.

- Possible cut quality.

- Application area.

Fine pitch allows you to get a high-quality cut when working with various alloys.

Canvas dimensions, length, width

The dimensions of the file are determined by the fastening method.

For such products, canvases are produced in only 2 sizes: 300 and 150 mm.

The first option is considered standard, products of this size are made of all possible types and from all acceptable materials.

Saw blade with a length of 150 mm is made from carbon steel only.

Thickness depends on the purpose of the tool.

On professional models, the size varies from 0.63 to 1.25 mm.

Blades for electric saws have a large thickness. up to 2.5 mm.

The file height reaches 13 mm. They are made only of bimetallic alloy, since all other options are too fragile.

Made from bimetallic alloy only.

Fine-toothed products are suitable for sawing hard metals.

The large version is intended for processing soft.

Hacksaw Basics: How to buy and use a hacksaw.

Since when sawing soft metals with fine teeth, the saw is quickly clogged with shavings, and the cut is sloppy, ragged.

A hacksaw for metal is considered a fairly common hand tool, which is designed to divide a workpiece into several separate pieces of a certain size. Its design features are characterized by the fact that it is possible to periodically replace the worker. When processing metal, there is a very high probability of rapid wear of the cutting edge. Therefore, the function of changing the tape was provided, which requires a small amount of time. There is just a huge number of different canvases, we will consider the features of the choice and many other points in more detail.

How to install a blade on a hacksaw for metal

The design of the tool in question allows for quick replacement of the hacksaw blade. It should be borne in mind that if a mistake is made, the product in question will not serve for a long period. How to install a blade in a hacksaw for metal is a very common question, since this tool is found in almost all home workshops. The main recommendations include the following:

- The instruction largely depends on the fastening system used in a particular case.

- The threaded clamp is widespread, in which the hacksaw blade is installed and stretched. A sharp change in the applied load becomes the reason why you have to periodically check the degree of tension.

- There are lever-type tools. In this case, the installation is greatly simplified, since it is enough to pull the lever and install the hacksaw blade for cutting metal, and then tighten it in the opposite direction.

When considering how to correctly insert the blade into a hacksaw for metal, it should be borne in mind that after proper installation, it creates a slight ringing during operation and may vibrate slightly. However, at the time of sawing, the product should not change its position, as this may damage the fastening holes.

Tungsten filament

This is the same string, but made of steel and coated with tungsten carbide.

They produce both canvases from such material and strings.

The latter are more profitable because they are much cheaper.

The tungsten string reaches 300 mm in length and can be easily attached to a regular hacksaw.

Cuts made with thread are very accurate.

With a string, you can cut mowing line curves and circles, not just straight cuts.

Selection rules

Subject to certain rules, it is possible to choose a suitable canvas that can last for a long period. The main recommendations are the following:

- The surface should be free of cracks or other defects, as well as traces of corrosion. This is because even minor damage will cause increased wear.

- At the time of selection, you should make sure that the saw is elastic. To do this, bend it a little, then release it. A high-quality product regains its shape almost immediately, which indicates high flexibility.

- As previously noted, the allowable cutting speed is largely dependent on the number of teeth per inch.

- The determining factor in many cases is the type of material used. Often, preference is given to hardened steel or bimmetal products. Tungsten carbide-coated version is short-lived.

It is not recommended to use the price key figure as the main selection criterion. However, a too cheap version fails in a short period.

As practice shows, a low-quality version has to be changed several times, as a more expensive offer will last for a longer period.

How to use a hacksaw

Diamond string

There is also a more non-standard option for cutting metals. a string.

The latter is made of alloy steel, then diamond sputtering is applied to it with a thickness of 2 mm.

Loops are made at the ends of the strings so that the device can be fixed in a regular hacksaw.

A diamond string cuts literally any material: ceramics, stone, concrete and metal, and hard alloys.

At the same time, the thread is very cheap compared to professional hacksaws for metal.

Recommendations for use

Only with correct use can the possibility of damage to the hacksaw blade for metal be excluded. The main recommendations are as follows:

- It is necessary to carry out processing at the same speed and applied force. Even minor changes can cause a defect.

- Take breaks from time to time. The reasons are that too high a temperature causes an increase in ductility.

- At the time of the surface treatment, the entire hacksaw blade must pass. This ensures even wear.

You can often find a situation where, due to strong heating and applied force, the metal plate bursts. Low-quality versions wear out quickly and become practically unusable.

Types of hacksaw blades and their design

Do not forget that the production of a working hacksaw blade is carried out in accordance with the established standards in GOST 53411-2009. The specified information in this regulatory and technical documentation defines the allocation of two main groups: for machine and manual cutting. It should be borne in mind that a hacksaw blade for metal is purchased extremely rarely, since such equipment is used extremely rarely. For a hand hacksaw, the following versions are produced:

- Single hacksaw blade for metal with a distance between fasteners 250 mm. In this case, the total length is 265 mm. This version is suitable for a tool that is used when there is no need for high performance.

- Single versions with a distance of 300 mm between two fasteners. The total length is 315 mm.

- For greater productivity, a double hacksaw blade is installed. The length of this version, like the previous one.

When choosing, attention is also paid to the width indicator, which for a single version is 0.63 mm, for a double 0.8 mm. The height of the tooth in the first case is 12.5 mm, in the second 20 mm.

The value and pitch of the location is regulated, since such an indicator determines many operational characteristics.

In the manufacture of such a product, a variety of alloys can be used, on which the main operational characteristics largely depend. The most widespread are the following alloys:

- X6VF.

- В2Ф.

- High speed alloys, for example, P5M5 and P12.

A hacksaw blade with tungsten carbide spraying has recently been quite common, as it is characterized by increased wear resistance. It should be borne in mind that spraying can have a wide variety of colors, there are blue versions on sale, ordinary steel is dark gray.

The considered tungsten hacksaw blade is characterized by the fact that with a high hardness of the working surface, the structure is characterized by high sensitivity to bending load. That is why, if carelessly cutting metal, such a product will not be able to serve for a long time.

Manufacturers can achieve a high strength index through heat treatment. In this case, it is worth considering the following:

- The main part of the product is characterized by a hardness of the surface layer of about HRC 44-46.

- Depending on the type of material used in manufacturing, the hardness of the tooth varies in the HRC range from 64 to 67. This indicator is characteristic of alloyed alloys. High speed steel is characterized by having a hardness of HRC in the range of 73-78 units.

Do not forget that significant differences in hardness cause the product to be sensitive to bending. The tool is designed for various loads, it should not exceed 60 kg with a pitch of 1.4 mm, as well as 10 kg with a pitch of less than 1.4 mm.

A fairly large number of varieties of such a product determines that there are no serious problems with the selection of a suitable version.

How to properly saw with a hacksaw for metal

The general theory of sawing with a hacksaw for metal looks like this:

Looking at this picture, you can suddenly become sad, so the further presentation of the material will be based on solving those problems that have arisen in the course of the recent accidental practical application (in economic theory, this is called learning-by-doing) of this ancient tool and the corresponding technology for cutting metals.

So, let’s start with the fact that you need to cut with a hacksaw for metal horizontally, grabbing the tool with both hands. Why would it be good to use a hacksaw with a well-defined handle for gripping with the second hand.

In this video, the whole story about how to saw, in fact, is presented, but now a postscript will be presented with a number of additions and amendments (plus a short retelling of the content of the vidos).

Sawing horizontally is inconvenient, because this requires that the workpiece be fixed at chest level and sawing while standing. However, workbenches, as a rule, are tables at which you need to sit, and if sawing, then standing and from top to bottom. Therefore, hacksaws are often made with one hand and saw them at an angle of 45 °.

To regulate the pressure on the saw (the harder the metal, the more you need to load the blade, press on it so that the teeth bite into the flesh; and vice versa. if the teeth cut too hard, for example, into aluminum, then you need to reduce the pressure) you can: a) change angle of inclination when sawing, b) put your hand on top to increase the weight, c) unfold the blade with the teeth back.

The saw often gets stuck in the cut when it reaches the end of the bar. This is due to the fact that the blade has a wavy set of teeth (so that the cut is wider than the blade and it does not get stuck in the cut), but over time, in the center of the blade, the amplitude of this wave decreases, and at the ends it is almost not.

This misalignment has arisen on the basis of sawing with this blade, previously not all of its length. It is no longer possible to correct (increase the dilution in the center or decrease at the ends), due to the fact that the teeth are hardened. So the moral: from the very beginning of the operation of a new blade, you must always saw through its entire length.

Next problem: If you cut a thin sheet of metal that is thinner than the distance between the teeth, the saw gets stuck:

If the metal is hard (iron), you will move the horseradish, and if it is soft (aluminum), a huge piece of metal is torn out, torn edges are formed, the edge bends.

Saw at an angle to form a kerf so long that at least two teeth lie on the kerf at the same time (kerf length ≥ two tooth spacing).

Next topic: sawing a thin-walled aluminum pipe:

We install the blade with the teeth back, we twist the pipe in the direction of the teeth (otherwise the blade will get stuck at the near edge of the cut, and when force is applied, it will break).

Well, and even before the heap the hacksaw blade for metal can be restored, the teeth can be sharpened, for example, in this way:

Initially, this diamond disc was larger in diameter and this drill with this disc, being pressed in this way to the blade, was located strictly parallel to the mowing line of the blade teeth, and the disc, respectively, was perpendicular. And it was right. the front faces of the teeth of the new hacksaw are orthogonal to the blade. Now a small negative angle is formed. slightly less better, but also normal.

Principles for choosing a canvas

- A type of manual hacksaw for metal, more precisely, the distance between the mounting holes. It is better if it is variable, then a hacksaw blade of any standard size is suitable for work.

- Tensile strength of the cut metal. If the tool is supposed to be used to separate soft, ductile metals. copper, aluminum, etc., then it is advisable to have a hacksaw blade with the lowest hardness. H6VF steel can be adopted as a material; imported canvases have the HCS designation on the lateral plane. High-speed steel blades are suitable for cutting harder metals (corresponding import marking. HSS).

- The thickness of the cut metal and the quality of the separation surface. Foreign practice recommends using the PPI parameter as a selection criterion. the number of tooth vertices per inch of blade length. So, for thin metals, where a very smooth cut surface is required, the PPI24 value is considered correct. If for the user the main factor of productivity is more than quality, then there should be PPI

Hacksaw blade for metal. its types and principles of use

A hacksaw blade for metal is a consumable that quickly breaks down. The service life of the file depends on the way the metal is processed with a hacksaw and the skill of using the tool. Correct selection of replacement part plays an important role.

Principles for choosing a canvas

- A type of manual hacksaw for metal, more precisely, the distance between the mounting holes. It is better if it is variable, then a hacksaw blade of any standard size is suitable for work.

- Tensile strength of the cut metal. If the tool is supposed to be used to separate soft, ductile metals. copper, aluminum, etc., then it is advisable to have a hacksaw blade with the lowest hardness. H6VF steel can be adopted as a material; imported canvases have the HCS designation on the lateral plane. High-speed steel blades are suitable for cutting harder metals (corresponding import marking. HSS).

- The thickness of the cut metal and the quality of the separation surface. Foreign practice recommends using the PPI parameter as a selection criterion. the number of tooth vertices per inch of blade length. So, for thin metals, where a very smooth cut surface is required, the PPI24 value is considered correct. If for the user the main factor of productivity is more than quality, then there should be PPI

Application environment

Saw blades are used for cutting soft metals (bronze, copper, aluminum) and polymer products. The thickness of the hacksaw blade is selected based on the type of material being processed.

Types of hacksaw blades

GOST R 53411-2009 “Hacksaw blades for metal” establishes two types of such tools. for machine and manual cutting. We will not touch on the first ones, but the second ones are produced in three main standard sizes:

- Single, with a distance between the fixing holes 250 ± 2 mm, with a total blade length of no more than 265 mm;

- Single, with a distance between the fixing holes of 300 ± 2 mm, with a total blade length of no more than 315 mm;

- Double, with a distance between the fixing holes of 300 ± 2 mm, with a total blade length not exceeding 315 mm.

In this case, the thickness of the single-sided sheet s is 0.63 mm, and the double sheet is 0.80 mm. Height with a single row of tines is 12.5 mm, and with a double row is 20 mm.

GOST also regulates the values of the pitch of the teeth P, mm and their number z, which for the first type of blades are 0.80 / 32, 1.00 / 24 and 1.25 / 20, respectively. Owners of longer hacksaws, in addition to those listed above, can also use hacksaw blades with parameters 1.40 / 18 and 1.60 / 16.

According to the brand of material used for the manufacture of hacksaw blades for metal, they are made from tool steels:

- H6VF brands.

- В2Ф brands.

- High-speed, grades P6M5, P12 or P18.

The range of domestic hacksaw blades is exhausted by this, however, in specialized retail chains, so-called diamond blades are widespread, with surface spraying with titanium nitrides or other refractory metals. These canvases can be easily distinguished by their color: ordinary steel canvases are dark gray, and the sprayed ones can have different colors. from bright orange to blue (depending on the manufacturer).

There are also canvases with the so-called tungsten carbide spraying, however, with a very high hardness, they are extremely sensitive to bending stresses. Therefore, when cutting metal, their durability is negligible.

High strength of hacksaw blades for metal is ensured by appropriate heat treatment. On the surface of the blade, two zones with different values of hardness are distinguished: directly at the teeth, it ranges from HRC 64 67 for alloyed tool steels to HRC 73 78. for high-speed steels (for diamond blades this parameter reaches HRA 82 84), and in the rest zone. НRС 44 46. A significant difference in hardness confirms the high sensitivity of the product to bending stresses, therefore, the standard also limits the maximum force applied to the hand hacksaw. It should not exceed 60 kg when working with blades with a tooth pitch of less than 1.4 mm, and 10 kg for blades with a tooth pitch of more than 1.4 mm.

How to choose a tool and canvas

When choosing a saw, you should pay attention to the distance between the fasteners. It is necessary to purchase a tool into which replacement parts of various sizes can be inserted. When buying a hacksaw blade for metal, the following parameters are taken into account:

- The strength of the processed material. If the saw will be used for cutting soft sheets, use a blade with a minimum hardness, made of steel grade X6VF. A professional hacksaw is equipped with parts made of high-speed materials. High cutting quality is ensured by diamond or tungsten blades.

- The thickness of the processed sheet and the quality of the cuts. The selection criterion is the number of teeth per inch of material (PPI). For thin sheet metal cutting where smooth edges are required, it is recommended to select parts with a PPI greater than 24. If cutting speed is more important than quality, the index should be less than 24. The PPI increases as the tooth frequency increases.

- Coating type. Russian-made tools are coated with Chem.Ox.Prm. Less commonly, you can find files with an enamel coating. It must be remembered that with prolonged use, the enamel may crack. There are bimetallic products when a high-speed metal strip is applied to a steel strip.

- Uniform direction of the teeth. The points should not deviate from the axis by more than 45% of the pitch of the teeth.