Chainsaw starter device

Not sure how to put a starter on your chainsaw? Start small by looking at the design features of this functional piece. What is its main goal? She is responsible for the easy start of the engine of the unit, the start of the device. It doesn’t matter what the quality of the chainsaw is, sooner or later you will have to adjust the starter, and possibly carry out repairs.

In some cases, this important unit will need to be replaced. This can happen even when the operator is using a professional chainsaw, adhering to the manufacturer’s recommendations for its use and equipment. Remember that the better you know the chainsaw starter device, the more chances that you will notice a minor malfunction on time and return the tool to working condition as soon as possible.

Chainsaw starter: device, principle of operation and DIY repair

A quick start of any chainsaw is not complete without a starter. During the operation of the tool, due to the accelerated cranking of the crankshaft, the fuel-air mixture is fed into the engine, compressed and ignited. Based on this, a well-chosen starter for a chainsaw is able to guarantee a long and trouble-free operation of the entire mechanism.!

How to put a spring on a chainsaw starter?

Fitting the starter spring into the correct groove is not easy, even for an experienced user. First, the spring should be twisted to the previous diameter and installed in the cavity of the drum hub.

The outer end of the spring is fixed by the restrictive protrusion, and the outer end with a screwdriver should be positioned opposite the hole in the lock. The loop at the inner end of the spring is aligned with the hole with a screwdriver, after which the disc is lowered.

Rotate the disc to check if the ratchet dog has come into place. Next, the ratchet itself is assembled.

After installing the spring, it is necessary to adjust its tension. To do this, a cable is inserted into the groove on the circumference, and a return spring is twisted around it. After removing the slack, it is better to wind the spring an additional few turns to ensure the required tension on the part.

Do-it-yourself chainsaw starter repair: how to put a spring, assemble, pull

If difficulties arise during starting the tool, power has disappeared or there are malfunctions in the fuel supply system, then it is necessary to repair the chainsaw starter with your own hands or return the tool to service.

Why does the starter break down: breakdowns and methods of their elimination

If the starter fails, starting the chainsaw becomes impossible. often the problem is as follows:

- the pulley of the starter system is damaged (it can crack or burst completely);

- the spring has deteriorated (sometimes the steel spring bursts);

- the system cable is torn.

To quickly fix the problem, you need to have a few screwdrivers and a starter in reserve.

Before you figure out how to put the spring on the chainsaw starter, replace the cable, eliminate other problems, you need to remove the starter system in order to study it more closely. To do this, we rely on the standard instructions.

- We start with the protective shield that needs to be dismantled. To do this, unscrew the screws. This will make it possible to get rid of the part covering the starter (it is attached to the screen).

- As soon as we dismantled the cover, we begin to unscrew the screw that fixes the position of the starter.

- Slowly and carefully start the starter, removing the spring clips.

- Removing the torso and coil to inspect.

Refit Stihl starter spring. FS 55 RC

During inspection, you are likely to notice common faults.

- The pulley is damaged (you can see not only cracks, but also tears, which are concentrated at the back). This prevents the starter from working fully.

- The spring is damaged (and not necessarily only it, so carefully inspect its vulnerable attachment point), which leads to a malfunction of the tool.

- Broken flywheel or its dog.

Sometimes it is difficult to repair a damaged part, so they replace the element with a new one that suits your model.

RicksDIY How To Rewind Recoil Pull Starter Spring Small Engine Coil Start

Device and principle of operation

Almost all well-known manufacturers of chainsaws supplement their products with starters of the same operating principle.

The work of the starter is as follows: on the body of the chainsaw there is a handle through which a special cable passes, pulling and engaging the drum of the ratchet mechanism when pulled sharply. In this case, the movement is transmitted to a drum with splines on the shaft.

The larger the volume of the chainsaw engine, the more fuel-air mixture will be required for further ignition. Therefore, to start high-powered saws, as a rule, more jerks are needed on the starter rope. For greater convenience of work and to speed up the return of the drum, manufacturers began to use unwinding return springs made of elastic steels.

The simplification of starting the chainsaw is achieved due to the following factors:

- The presence of a special pump in the design of some models of chainsaws (for example, in Maxcut, Partner models of the S line, etc.), which guarantees timely pumping of the fuel mixture.

- Installation of an additional spring, which provides easier unwinding of the crankshaft when the cable is displaced.

- Due to the preliminary enrichment of the mixture through the corresponding flap in the carburetor housing.

- Placement of an automatic decompression valve that will reduce the working pressure inside the cylinder.

Repair of the cable

If the cable bursts, the ratchet teeth (not necessarily all) will crumble. This slows down the speed of rotation of the crankshaft. But why does the cable break? Do not forget about its friction, about the body of the starter system, over time this leads to damage to the cable.

- We disassemble the case, that is, remove the cover;

- We carefully lift the drum of the ratchet system, make sure that the return spring does not jump off the socket (ask someone to help you, the assistant will hold the spring until you change the cable);

- We fix a new cable inside the handle, do not forget to wind it on a roller located in the drum grooves;

- Assembling the case.

Spring repair

If the material of the starter spring is found to be of poor quality, the spring will burst (usually at the point of its attachment to the drum, where it forms a loop). In this case, it is not worth replacing the spring. Thoroughly clean its surface from dirt and traces of grease, gently grind the place of destruction, and then release the spring at 600 650 ° C (the steel of the spring should acquire a crimson color). It is necessary to cool the spring slowly, and at 100 150 ° C it is already possible to gently wrap its end in the shape of a restrictive protrusion on the inner surface of the drum (steel will acquire the necessary plasticity) and insert it into place. The elastic properties of the spring will not change.

Chainsaw starter repair

With frequent starts of the chainsaw, some parts of the starter are constantly subjected to dynamic loads. As a result, the cable may burst, several ratchet teeth may crumble, and the shaft will turn at a much lower speed. Therefore, the revision and even repair of the starter are operations that are sometimes carried out several times per season.

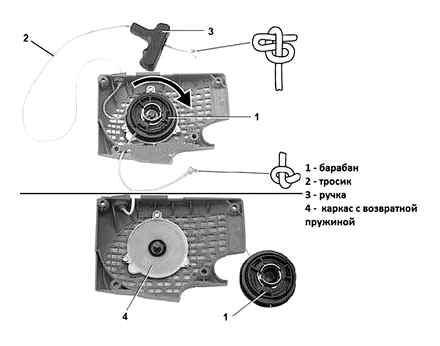

Chainsaw starter device

The principle of operation of a starter for a chainsaw is as follows. A handle is installed in the groove of the body, through which a cable is passed. If the handle is lifted sharply, the cable is pulled out and engages the drum of the ratchet mechanism, which transfers the movement to the drum with splines provided on the shaft. In this case, the crankshaft makes several revolutions, and the working mixture in the space between the piston and the cylinder head is compressed. Accordingly, when the handle is lowered, the contact between the ratchet and the splines is lost, and the shaft stops.

With an increase in engine volume, the required amount of the fuel-air mixture required for its subsequent ignition also increases, so the number of jerks for the starting cable for high-power saws increases. Therefore, in order to accelerate the return of the drum, unwanted return springs are used, made of steels with high elastic properties.

Facilitation of starting the chainsaw is implemented in the following ways:

How To Assemble A Recoil Starter System. TreeStuff.com Chainsaw Maintenance Video

- By preliminary enrichment of the working mixture, for which there is a special damper in the carburetor design.

- Installation of an automatic decompression valve, which reduces the working pressure in the cylinder of the chainsaw.

- Installing an additional spring, which, during the movement of the cable, facilitates the unwinding of the crankshaft.

- The presence in the design of some chainsaws (for example, Partner S series, Maxcut, etc.) a primer. a pump that provides preliminary fuel pumping.

Replacing the cord

When pulling it out, there is a constant friction of the cable against the starter housing. To replace, disassemble the body of the unit, and carefully raise the ratchet drum so as to prevent the return spring from jumping off its seats. It is better to do this work together: the assistant fixes the spring while the cable is being replaced. After fixing the cable in the handle and in the grooves of the drum, the cable is wound around the roller, and the body is assembled.

Chainsaw starter. Learning to self-repair

Any chainsaw requires a starter to quickly start. With accelerated scrolling of the crankshaft of the tool, the fuel-air mixture supplied to the engine is compressed and subsequently ignited. Therefore, the normal operation of the starter for the chainsaw determines the performance of the entire mechanism.

How to put a spring on a chainsaw starter?

Fitting the starter spring into the correct groove is not easy, even for an experienced user. First, the spring should be twisted to the previous diameter and installed in the cavity of the drum hub. The outer end of the spring is fixed by the restrictive protrusion, and the outer end with a screwdriver should be positioned opposite the hole in the lock. The loop at the inner end of the spring is aligned with the hole with a screwdriver, after which the disc is lowered. Rotate the disc to check if the ratchet dog has come into place. Next, the ratchet itself is assembled.

After installing the spring, it is necessary to adjust its tension. To do this, a cable is inserted into the groove on the circumference, and a return spring is twisted around it. After removing the slack, it is better to wind the spring an additional few turns to ensure the required tension on the part.