How to change bits on an electric screwdriver?

bit in power tool chuck with magnetic clamp or magnet, you just push it into hexagonal slot and you’re ready to go. To change the nozzle on the magnet it is necessary to pull it with a small effort and take it out of the tool.

To remove the drill bit or bit, you need to reverse the electric screwdriver, lock the chuck and turn the electric screwdriver on: the cams open and release the drill bit or bit. The torque limiter clutch, which has become standard in most screwdrivers. On the top of the body, opposite the chuck, there is an arrow that indicates the number.

Direction of rotation of the chuck

The drill is equipped with a pusher type switch that can be used to change the direction of the chuck rotation for tightening or unscrewing fasteners.

There is a direction symbol on either side of the tool next to this switch. You can reverse by pushing the switch.

Remember that the direction of rotation can only be reversed when the motor comes to a complete stop.

The chuck of the electric drill/driver can be changed if necessary. It should be borne in mind that it is fixed with a screw with a left-hand thread, which means that it must be unscrewed in a clockwise direction.

This screw can be accessed through the front of the chuck.

Настолько ли это удобно? Обзор, сравнение xiaomi mijia electric screwdriver

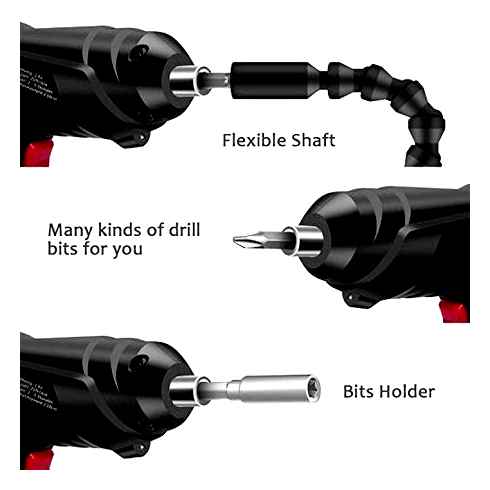

The tool kit also includes a set of drill bits of different diameters. They are all designed for relatively soft materials.

The drills are inserted into the chuck in the same way as with the bit.(cf. photo above)

Do not freeze the battery pack.

Can I drill?

The tool may only be used in place of a drill if this is stated in the machine’s data sheet.

However, even low-powered electric screwdrivers can be used to drill in soft materials like drywall.

To do this, instead of the bit, you need to insert a drill bit for working with gypsum board into the chuck.

To pull out the drill bit or other attachments, you must unscrew the chuck by hand or with a wrench. It is also necessary to move the socket to the appropriate position, usually this mode has a drill symbol on it. Attach the bit to the marked surface at a right angle. It is not recommended to deviate. it will hamper the stroke of the drill, increasing the diameter of the hole to be made.

To drill a concrete or brick wall, tile, you need a tool with high rotational speed (from 1200 rpm) and high torque. Impact screwdrivers are more efficient and faster.

Important! An electric screwdriver differs from a drill and a torch in power and should not be used for drilling a large number of holes. You have to take breaks in your work so the tool does not break down because of overheating.

How to remove the bit from an electric screwdriver

Those who work with the tool, it is essential to know how to remove the bit from an electric screwdriver. To remove the bit or drill bit, the electric screwdriver has to be reversed. Lock the chuck and start the tool. The jaws open, the bit is released and can be removed.

Any model of an electric screwdriver Metabo, Interskol, Hitachi, DeWALT and others can jam the clamping device. A bit can jam for a number of reasons, one of which is the use of the largest sized drill bit. The jaws of the chuck have to be pushed to the limit. and then there is no way to squeeze them. If they are not squeezed evenly, they cannot be unclamped to pull out the jammed drill bit or bit.

If the jaws jam, the bit may jam due to a free play during clamping and unclamping. This happens if you get under the shaped parts of the cams:

When these situations occur, it is impossible to work with the tool, even if it is in good working order. You can try to fix it yourself, or if you can’t, you can call in a specialist. Almost all screwdriver models are the same, so the ways to remove a jammed bit are the same.

The first thing to do is to add lubricant to the jammed chuck to make it open. WD-40 is a great grease for this purpose. It is poured so much that the liquid flows over each cam. Leave the grease in for 15 minutes. then gently tap the cams through the cloth. Most often after such a procedure, the problem can be solved. But in case the chuck has not loosened, you can warm it up a little with a hair dryer.

Some remove the bit with adjustable wrenches. after the chuck is lubricated, one clamps the base, the other gently twists its top. Once you can get the jammed bit, you need to clean the electric screwdriver.

The bit is magnetized for convenience

Magnetizing and hardening the bit

The bits on sale are mostly made in China. They are made of soft material, which causes rapid loss of their original shape. It cannot be regenerated, so these types of bit are characterized by a short service life.

To avoid having to buy new bits all the time, it is recommended to harden them. To perform the procedure, a piece is wound onto the nozzle, and it is heated to red over a gas burner. After the tooling has become reddish, it is lowered into a tin can, previously filled with machine oil for 5-6 seconds. This operation should be repeated several times, with pauses for 2-3 seconds. The element is considered to be hardened after blackening.

The magnetizing procedure will make the work more comfortable. There are several methods:

- The bit is placed with its working ends between 2 neodymium magnets, which are placed so that they repel each other. To hold them in place, they are joined with plasticine. You will have to wait at least 10 hours for the effect.

- Insert the bit in a special device to magnetize and demagnetize screwdrivers. The desired effect is achieved by placing the element in a square window.

- Wrap the copper wire, which has been previously stripped of insulation, in 3 layers on a plastic tube. They put a nozzle inside. Connect the ends of the wire to the battery terminals or the battery. To enhance the effect, connect 2-3 batteries in series. After a minute they evaluate the result of magnetization.

Craftsmen also offer a simple variant. the tool is rubbed against a magnet from all sides. Trying to hold the fastener. If necessary manipulation repeats.

Top 5 best mini electric screwdriver 2022

The chuck of the Bosch GSR 12 V electric screwdriver is stuck

Forum / Tools and equipment / jammed chuck of an electric screwdriver Bosch GSR 12 V

Ask your question on our forum without registration and you will soon receive an answer and consultation from our experts and forum visitors! Why are we so sure?? Because we’re paying them to do it!

Rodion

Tell us how to fix the problem: when the clamping mechanism expands to the maximum, it jams, it can not be adjusted.

How to use a screwdriver correctly

It often happens that there is no way to do without an electric screwdriver. Electric screwdriver. it is an indispensable assistant in the manufacture of suspended ceilings, installation of drywall. Repair work is complicated if there is no electric screwdriver at hand, with which you can easily screw self-tapping screws and fasteners. In the domestic sphere, it is in demand no less than in professional activities.

But not all tool owners know how to properly use an electric screwdriver. There is nothing difficult about it, the main thing is to adhere to some rules and recommendations for beginners.

Types of the tool: characteristic features

The electric screwdriver can be classified into the following varieties:

The principle of operation of the tools is similar to each other, but there are differences in functionality.

Electric screwdriver is able not only to screw in a screw, but also to drill a hole. The nutrunner specializes in bolts and nuts. The third representative is a cordless screwdriver, designed exclusively for screwing/unscrewing fasteners with a Phillips head. The last type is characterized by low power, unlike the above.

What an electric screwdriver consists of? Setting up the device.

The plastic housing contains the engine and gear mechanism that drives the bit, which is installed in the end of the electric screwdriver. The device is equipped with a start switch, a direction switch and a speed switch, an LED backlight and a tightening time regulator.

The principle of operation of the tool is very simple. The nozzle, pre-fixed in the chuck, moves with the help of a shaft, which comes from the work of the motor by means of a reducer. Before using an electric screwdriver, you should find out whether the battery is charged, and whether the correct attachment is installed.

Just before you start working, make sure you have the nozzle adjusted to the size of the flat of the screw or screw.

In order to set the bit, it must be adapted to the size of the fastener’s flat and fastened in the magnetic base of the chuck. First the chuck with the sleeve must be removed from the device, and after fixing the bit, the chuck must be reattached to the housing of the electric screwdriver.

Then you need to set a suitable speed for the bit. Adjustment is carried out using a special knob. Set the required mode when the tool is off.

Before using the power tool, the screw depth of the fastening element must be corrected. After a short time it may be necessary to change the magnetic holder. To change it, the chuck, the magnetic mount and the socket must be removed. Then the socket chuck is inserted back into the housing of the electric screwdriver.

How to change/insert/remove the bit, drill bit

Once the suitable bit has been selected, taking into account the size of the screw head and the configuration of the cavities (straight edge, cross edge), it must be inserted centrally between the opened jaws and secured in the chuck by turning the sleeve clockwise. If a key-type chuck is selected, the key is inserted in the recess in the chuck and then turned clockwise until the bit is fastened. The bit end fits in the slot in the screwdriver. Before starting the machine, check that the direction of rotation is set correctly and that it is the same as the screw’s twist.

Increasing the pressure on the trigger adjusts the optimum rotation speed. When the screw is fully plunged, the force limiting mechanics are activated and then the drill stops.

How to work with a screwdriver

After completing all adjustments, you can start using the power tool. By studying the operating instructions for your electric screwdriver, you can prevent possible malfunctions in the handling of the machine, thereby increasing the life of the tool.

It is not allowed to adjust the frequency and direction of the speed of the nozzle while the appliance is on. Do not touch grounded objects with the power tool, otherwise you might get an electric shock. Do not use the tool for a long period of time, as it may burn out.

The room in which it is best to use the electric screwdriver should be well lit and the power supply network should be constant, without surges, this will avoid equipment malfunction. Wear proper protective clothing and only use tools that are in good working order.

Can the drill be used as a screwdriver

An electric screwdriver can also be used as a drill. The chuck mechanism enables the drill bit with a cylindrical tail to be firmly locked. To start working, you will need to install a drill bit in the chuck.

Be careful, because the design is not provided for making holes, especially in hard wood, metal or concrete, because there is a high probability of failure of the planetary gear.

Screwdriver maintenance

There is nothing remarkable about maintenance, because today’s modern models are more robust and can even withstand being dropped from a low height. The chuck should be regularly lubricated and cleaned. Do not allow any moisture, dirt, or sand into the middle of the tool. Watch out for overloading of the electric screwdriver, if you feel that the electric screwdriver begins to work with difficulty, lower the speed of rotation.

What to do if the chuck of the electric screwdriver jams?

If the bit jams in the chuck of an electric screwdriver Bosch, Texas, Practice, etc., after greasing the chuck the problem is solved by the use of two adjustable wrenches. Clamp the base of the chuck with one and gently rotate the upper part of the chuck with the other.

It is designed for screwing or unscrewing bolts or nuts. Unlike an electric screwdriver, there is no chuck attached to the nutrunner. It is good to use drill bits when carrying out drilling.

Can the drill be used as a screwdriver

The electric screwdriver can also be used as a drill. The chuck mechanism enables a drill bit with a cylindrical tail to be firmly fixed. To start working, a drill bit must be inserted in the chuck.

Be careful, because the design is not intended for making holes, especially in hard wood, metal or concrete, because there is a high probability of breakage of the planetary gear.