Trimmer clutch. malfunctions, causes and solutions

1) Trimmer malfunction: At idle, the knife spins almost always, extraneous sounds are heard in front of the motor, while the trimmer mows normally. The mowing malfunction is the same as the trimmer.

Causes of malfunction: The trimmer clutch spring burst.

Do-it-yourself trimmer repair: Replace a broken clutch spring with a new one (for details, see “How to Remove Clutch on a Trimmer” below). Or, if I just cut off the hook on the spring, I can heat the spring with a burner, bend one ring to make a new hook and temper the spring (such a clutch spring can work even several years). Do-it-yourself lawnmower repair is similar to trimmer repair.

How to remove the clutch on a chainsaw

- Chainsaw device

- Chainsaw engine device

- Carburetor and fuel system

- Ignition system and starter for chainsaw powerplant

- Chainsaw Clutch

Often people using chainsaws in the process of servicing raises the question of how to remove the clutch on a chainsaw. The fact is that this node of the chainsaw mechanism requires constant monitoring of operability, which, in turn, requires periodic disassembly for preventive maintenance and repair.

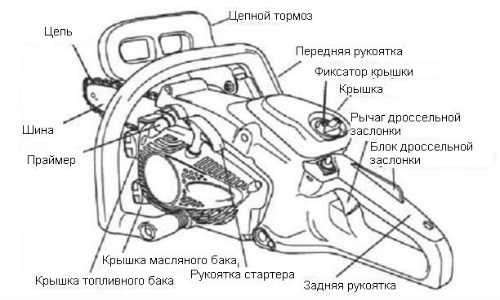

Chainsaw device diagram.

It is worth noting that all chainsaws are classic devices driven by gasoline ICE.

Chainsaw electronic ignition circuit.

Single-cylinder engines operating on high-octane gasoline have found application in the device of chainsaws. The power unit does not have a reducer. It acts as a single-stage transmission, which drives the chain. The simplicity of the design is the key to the reliability and reliability of the tool even in the presence of severe operating conditions.

In addition to these nodes, the design of the chainsaw includes an air purification system, which is fed to the engine to prepare the combustible mixture, a tire with a saw chain installed on it, a starter that starts the chainsaw power plant, a chain tension mechanism, an ignition system, and an exhaust silencing system. In addition, the design of the chainsaw includes the so-called emergency brake, the operation of which allows you to instantly disconnect the power unit of the chainsaw from the drive sprocket in an emergency to prevent injury to the person operating the device.

Back to the table of contents

Types of spark plugs for chainsaws.

In modern chainsaws, a two-stroke single-cylinder power plant of a carburetor type is installed.

The engine consists of several systems and components that make up a single whole. In the design of the engine, there are several elements that ensure its functioning:

- flywheel;

- clutch;

- ignition module;

- muffler;

- special sleeve for mounting a carburetor.

Engines mounted on chainsaws are high speed. The maximum number of revolutions of the power plant is 13,500 revolutions per minute. This requires the use of high-quality oil when lubricating the engine, which is added to the fuel mixture.

Since the operation of chainsaws is carried out, as a rule, in difficult conditions, the power plants of the device require good cooling. The engines used to install the chainsaw are power plants equipped with a forced cooling system. For this purpose, an impeller is installed in one of the semi-axes of the crankshaft in a closed housing. Due to the rotation of the impeller, air is supplied to cool the cylinder of the power plant through the corresponding duct.

Back to the table of contents

Chainsaw fuel system: 1. fuel filter, 2. carburetor, 3. manual pre-pump.

The carburetor in the power unit is designed to prepare and supply a combustible mixture to the cylinder. Most often, carburetors manufactured by manufacturers such as Walbro, Zama and some others are used in the device of chainsaws. A special filter is mounted on top of the carburetor to carry out the purification supplied to the air carburetor. The fuel system in the simplest version consists of a tank, a filter element, a hose for supplying fuel. As a rule, a fuel tank is enough to work for 30-40 minutes.

To fill the tank during operation of the device with air, its lid has a breather that lets air into the tank and prevents the flow of fuel. If the breather is clogged with debris, the engine stops working. A fuel filter is installed at the end of the freely dangling hose. Fuel injection occurs due to the operation of the pump located inside the carburetor.

When the power plant is operating, atmospheric air must be supplied to it to prepare a combustible mixture in the carburetor. The incoming air is cleaned with a special air filter. As a rule, two filters are installed in the chainsaw design: a coarse filter and a fine filter. The pre-filter has several elements and prevents large contaminants from entering the engine. The fine filter purifies the air from dust particles. In some models, a flywheel impeller is used as a cleaning element, which cleans the air stream from large impurities due to centrifugal forces. In the manufacture of fine filters, diffuse foam rubber, nylon mesh or some other materials are used as a filter element. The chainsaw filter requires regular cleaning.

Video: How To Remove A Fuel Filter On A Stihl Trimmer

Back to the table of contents

Scheme of a two-stroke engine of a chainsaw.

To date, saws with a gasoline power plant are equipped with electronic ignition units, which does not require adjustment and cleaning. The ignition system includes a flywheel with magnets, a module having an electronic system, a spark plug and a high-voltage wire.

The starter installed on the device serves to start the saw engine by cranking the crankshaft. The starter mechanism includes the following elements:

- drum;

- cable with handle;

- housing;

- return spring.

When carrying out a sharp pulling of the cable, the starter ratchet engages with the crankshaft teeth, which leads to its turning. The return spring is designed to return the cable to its original position. To start the power plant you need to apply a certain force, since the engine starts only at a certain speed of rotation of the crankshaft.

Back to the table of contents

The design of chainsaws is equipped with a centrifugal clutch, which is activated automatically, in full dependence on the speed of rotation of the engine crankshaft.

At low revs, the elements installed in the clutch basket and having special pads are attracted to the center of the shaft by springs. This position of the elements prevents the transmission of rotational motion from the crankshaft to the sprocket. Upon reaching a certain number of revolutions of the power plant, elements with special overlays diverge and are pressed to the clutch drum, transmitting rotation to the chain. The main feature of such a clutch is that when the saw chain stops, it starts to slip, which avoids damage to the power plant and mechanisms that transmit movement to the chain. Quite often, clutch as a result of intensive use is required to be prevented and repaired. For this purpose, the clutch is disassembled.

Back to the table of contents

The clutch drum is simultaneously the drive sprocket.

This structural element is consumable, and this, in turn, requires regular replacement or repair.

File position when sharpening the chainsaw chain.

The main reason for the failure of this unit is the wear of the sprocket teeth. If the drum is monolithic, then in the process the chain cuts an asterisk. Such a drum must be replaced. On some drum devices there is a replaceable crown and during repair it is replaced, and the drum, while maintaining its normal state, is operated on.

If you need to repair the chainsaw, the question arises of how to disassemble the clutch. If there is a service center, it is better to contact specialists, but in the absence of the latter, the disassembly and repair procedure can be done with your own hands. This operation is simple and with the availability of appropriate tools it can be carried out by almost everyone. Almost every model of this tool has its own nuances in dismantling the clutch, however, the general sequence of actions is the same for any models.

The first step is to remove the chain brake cover. For this purpose, pull the handle towards you. This is done so that the tape does not come into contact with the clutch cup. After that, the nuts for securing the cover and the chain tensioner are loosened.

Loosening the tensioner loosens the chain and the bar. After that, the nuts for fastening the brake cover are unscrewed, after which the cover is completely dismantled.

At the second stage, the guide bar and chain are dismantled, and contaminants are removed.

The next stage of disassembly is the inversion of the cylinder head candles. Then the piston is fixed in the cylinder. For this purpose, the crankshaft is rotated and after the outlet is closed, a piece of rope is lowered into the cylinder, which prevents further movement of the piston. After the repair, the rope is pulled out at the other end.

The fourth stage of disassembly is the direct dismantling of the clutch. First you need to unscrew the nut on the clutch. It should be remembered that this one has a left-hand thread, when unscrewing it, you need to turn the key clockwise. For work, a key is used, which is included in the set of accessories for the chainsaw.

After unscrewing the nut, disengage the clutch and inspect the drum with the drive sprocket for wear. Then, after inspecting the drum and sprocket, the condition of the needle bearing is inspected. If necessary, worn items must be replaced.

The assembly of the tool is carried out in the reverse order.

There are several nuances that you need to know when repairing a clutch:

- On some modifications and models of chainsaws, a washer is placed between the clutch and the cup of the drive sprocket. In the case of disassembling this element, it is necessary to install the washer in the position in which it was previously. This washer can sometimes be installed between the engine and the cup.

- Some models of oil pump drives have a special spring. It transfers the rotation from the sprocket to the oil pump drive. The correct installation of this spring when assembling the device is very important. If installed incorrectly, the oil pump stops the oil supply to lubricate the chain. Which can lead to costly repairs.

After carrying out repair work, before starting the use of the chainsaw for its intended purpose, it is necessary to check the operation of the oil pump and its oil supply to lubricate the saw chain and guide rail mechanisms.

Chainsaw clutch. malfunctions, causes and solutions

1) Chainsaw malfunction: The chain rotates almost constantly (the engine, at the same time, may not work stably). Causes of malfunction: Clutch spring burst. Do-it-yourself chainsaw repair: Replace a broken clutch spring with a new one (for details, see below “How to remove the chainsaw clutch”). Husqvarna chainsaws have one clutch spring and two weights, Stihl chainsaws have three clutch springs and three weights (cam, sectors). If you cannot find the clutch spring itself, you will have to change the entire clutch.

2) Chainsaw malfunction: The chain spins almost constantly, sometimes extraneous sounds are heard in the clutch.

Causes of malfunction: The braid of the clutch cam broke off (due to overheating) and the clutch spring flew off. Blue clutch cams indicate overheating. Overheating even before the clutch breaks can occur if you work with a chainsaw with a chain brake or a dumb chain. Do-it-yourself chainsaw repair: Replace the clutch assembly (for details, see “How to Remove the Chainsaw Clutch” below).