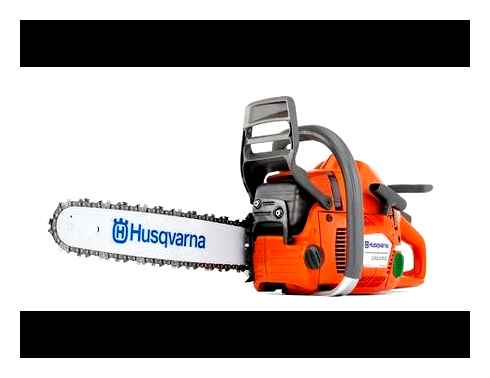

How to remove the carburetor on a Husqvarna 240

Husqvarna 240 chainsaw, carburetor adjustment, which you can do yourself. is a tool that cannot be repaired at home. However, the configuration of the mentioned node can be done independently, for this you need to learn how to distinguish the screws. Each has a letter designation, the first. For adjusting the low RPM, another for adjusting the upper RPM, and a third. for adjusting idle speed.

Despite the fact that the factory setting is considered optimal, with the help of screws you can adjust the operation of the engine. Sometimes it is necessary when climatic conditions differ from those recommended by the manufacturer. To increase the speed, the first two screws indicated must be turned clockwise. The sequence in which the screws are used corresponds to the above. If you have any doubts, it is better to contact an expert, because if the carbureted “Husqvarna 240” chain saw is not adjusted correctly, the engine can fail.

Factory equipment

Includes:

- Instruction manual, which describes all the possible nuances of its use, preparation for start-up, recommendations for use and troubleshooting, including.ч. and carburetor adjustment;

- the Husqvarna chain saw itself 135;

- Universal spark plug wrench;

- Busbar cover for safe transportation of your Husqvarna chain saw;

- cardboard packaging.

General characteristics of the Husqvar chain saws

Of course, this manufacturer, known for more than 300 years, has its own face. Husqvarna chain saws have a nice bright orange color.

By the way, color deviations, and also too glossy or matte cladding can be an evidence of counterfeit. As well as the saturated black color of the handles and the shield, the original products have more of a dark gray. And the sheer number of fakes is more evidence of the brand’s popularity.

Husqvarna 445 carb cleaning and chain sharpening

All brands of these saws are numerically marked with 3 or 4 digits, in which the first is the sequential number of the saw’s generation, and the two following it are the rounded volume of the gasoline two-stroke engine. There may also be letters after the numbers:

- e. indicates the presence of the SmartStart function;

- XP indicates the AirInjection pre-cleaning system;

- G. have heated grips and carburetor.

- more economical engine. X-Torq;

- of increased ability to work in bad weather conditions and on low-quality fuel. AutoTune is a professional saw;

- Improved vibration protection. Low Vib.

Despite the fact that more than 80% of all Husqvarna chainsaw users’ reviews are definitely positive, we have selected some problems, typical for generations 1 and 2, most often used by Russians in their households.

The first problem is a slight oil leak from the chain lubrication system, sometimes even when the saw is not running.

The second common, characteristic unpleasant peculiarity of the Husqvarna, owners call the starter motor much harder than in other chainsaws. This becomes especially noticeable if the saw has a habit of starting far from the first or second time, which happens in some cases if the owner has not checked this function when buying. This is most often due to poor quality factory carburetor tuning, which is a sin of quite a few domestic Husqvarna.

All users, who left unflattering reviews about these saws, mark disgusting Russian translation of this chainsaw instruction. Besides being written in incomprehensible language and in many cases requiring second-guessing and semantic corrections, it sometimes contains obvious inaccuracies.

Husqvarne chains are also sometimes criticized for needing frequent tightening during the initial period of use until they stretch.

Some models sometimes throttle when turning 90° when cutting down trees.

But the biggest reproaches are caused by the for the brand oil, the replacement of which by cheaper brands is the reason for refusal of warranty service and repair.

It must be said that such reviews about Husqvarna chain saws are not so numerous, and they are clearly outweighed by the overall positive impression of their work. All note:

- the excellent balance of the tools;

- Low vibration and low noise during operation;

- Sufficient power reserve to perform the functions provided for each particular model.

But if you saw thick oak trunks with a lopper, it might not have enough power.

Of the models listed above, only the semi-professional 365 can cope with such work, but even she needs to give a rest after 40-50 minutes of work.

Choosing a specific Husqvarna model, determine for what purpose you need it, and only then compare its price to your capabilities. The right chainsaw can easily provide 5 or more years of service under hard enough use, which lesser-known brands can hardly boast of.

Husqvarna 135 chainsaw

The Husqvarna 135 chainsaw is a relatively new modification, developed by engineers of the Swedish Husqvarna brand, but manufactured in the American factory.

Husqvarna 135 chain saw

Husqvarna was once (since its introduction in 1689) a company that specialized in making firearms, but since 1970 it has sharply changed its specialization and shown itself as a reliable manufacturer of gardening, construction and power tools. The direction successfully chosen, in just a few years the international market has been conquered, representative offices and plants opened on different continents.

video on how to rebuild and tune your chainsaw’s carburetor

Every chainsaw is equipped with a two-stroke single-cylinder carburetor engine. Earlier chainsaw models were equipped with contact ignition, but now almost all manufacturers use electronic ignition, which means that it is not necessary to constantly clean the contacts and adjust the gap between them.

The fuel-air mixture is mixed in the carburetor. With a special flap, you can manually deplete or enrich the fuel mixture for a specific purpose. for example, for sawing hard wood.

The carburetor’s good technical condition directly affects both the engine’s performance and the chainsaw’s performance. Let’s take a closer look at how the chainsaw carburetor is built.

Repair of the carburetor of a chainsaw with their own hands: the device, malfunctions, etc.

A chainsaw is needed in construction, and in gardening, and in landscaping. its presence greatly simplifies the performance of a number of tasks for processing wood. The main component of this tool is the engine, the operation of which depends largely on the condition and settings of the carburetor. This is where the fuel mixture is prepared. So, if the saw won’t start, stops, or doesn’t provide the power it deserves, it’s very likely that the carburetor isn’t working properly. Fortunately, in many cases you can do it yourself. Only for this you need to know and understand the structure and principle of the unit and, of course, the chainsaw itself.

How the chainsaw carburetor works?

The main purpose of the carburetor is to mix fuel with air in the required proportions. If the latter is disturbed, it has an almost immediate effect on engine operation.

STIHL MS 181 C BE chain saw carburetor

Chainsaw carburetors can differ in design. Their basic elements and principle of operation, however, remain more or less the same.

It is an aerodynamic tube with an air damper across which the intensity of the air supply is regulated.

This part is where the base tube is constricted. here the airflow rate increases, i.e.е. the air is always supplied to the carburetor under some pressure.

This is where the fuel comes in contact with the air stream. Fuel enters the atomizer from the float chamber through the nozzle.

It is a container that allows to keep the fuel mixture in a stable state.

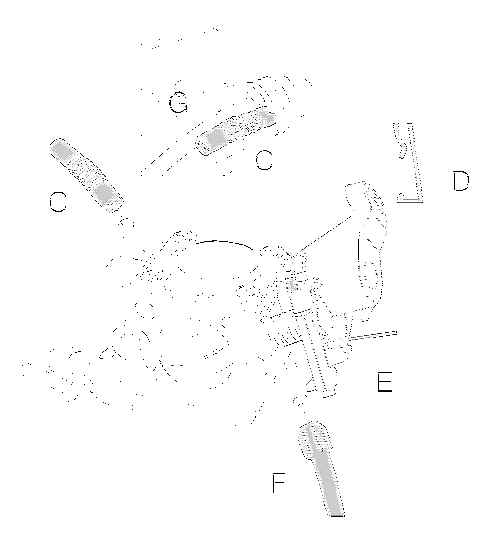

Constructional diagram of a chainsaw carburetor

The chainsaw carburetor works according to the following principle:

- when starting the engine, the main flap opens and a jet of air is blown into the air duct at a certain speed;

- the speed of airflow and the float level in the chamber are controlled by the position of the choke, namely by the difference in pressure in the float chamber and the air duct;

- fuel from the float chamber is sucked into the nozzle and from there into the diffuser;

- passing through the diffuser, the air picks up the fuel that is going in;

- the resulting mixture is fed into the cylinder cavities through the intake ducts.

the pressure in the float chamber is approximately equal to atmospheric pressure, but in the carburetor air ducts rarefaction occurs when starting the chainsaw engine. When the choke is opened, the air flow increases. as a result, more fuel is fed to the carburettor and the engine rpm increases.

What is the first adjustment for??

During the first hours of operation the 2-stroke chainsaw engine requires a running-in period, on which the quality of its further operation depends. Initial carburetor adjustment: Adjusts the optimum fuel mixture and delivery parameters during the test run.

The initial running-in of a chainsaw: finer material

Most modern chain saws come on sale tuned. Nevertheless, it does not hurt to check the quality of the factory settings. after all, you will have to work with the tool.

At the first start-up the chainsaw should run sparingly. For several hours after starting it is recommended not to overload the engine and only cut small branches and trunks up to 10 cm thick.

To insure against malfunctions in the chainsaw carburetor will help simple rules:

Fuel mix proportions for chainsaw engine

The chainsaw must start up correctly, have a consistent chainwheel speed and a smooth increase/decrease in power. The engine shouldn’t make any knocking, squealing or noise.

Professional chainsaw in operation

The most important thing when running the tool for the first time is to make sure that the fuel consumption is in line with the power used, t.е. in practice, the saw should not go out, “sneeze”, smoke and work jerkily.

How to recognize a carburetor malfunction?

Typical carburetor malfunctions are easy to recognize. They are expressed in that the chainsaw engine starts and immediately stops, or shows no signs of life at all. Or it is wasting fuel at full speed, producing puffs of black smoke and loud vibrations instead of the power it should.

Diagram of a chainsaw carburetor

The carburetor settings may be disturbed when:

chainsaw air filter with a capron insert

Any faults detected should be corrected immediately. But how do you know if it’s the carburetor?? To do this, keep an eye on how your lawn mower works.

A list of typical signs that the carburetor settings have gone off include:

Husqvarna 240 Chain Saw. Carb Rebuild and Dissassembly

This is usually caused by using the wrong (lean) fuel mixture.

Expressed by increased exhaust emissions that turn black. This means that the fuel is not completely consumed, t.е. the mixture is oversaturated.

Carburetor is set correctly. chain saw starts on the first try

Could be due to damaged fasteners of adjustment screws or protective cap.

Indicates critical wear of the piston group, so the adjustment of the carburetor will postpone the overhaul only for a while.

This pattern occurs when the carburetor channels are clogged or its filters are malfunctioning. In this case, adjustment should be carried out only after thoroughly flushing the unit.

How to remove a jammed tree. Husqvarna Chainsaw Academy

Last edited on 12 November 2020.

If you accidentally fall a tree on another. always start with a break and think calmly about the situation.Removing a stuck tree is always a risky endeavor, and there is no need to rush. Choose the safest solution to the problem, even if it takes longer. There are several options. Don’t be afraid to call for help. your safety comes first.

Here are two methods you can use to easily destroy a hanged tree. provided it’s not too big and not too tangled up in a second tree. But first, let’s take a brief look at the recommended tools and some very important safety rules.

Tools

These are the tools that will come in handy when removing a suspended tree: Pivot strap Pivot hook. Often comes with a brake bar. Winch (extended, not covered in this section) Forwarders or tractors equipped with a grapple loader or winch (extended, not covered in this section)

Safety first!

Working with or near suspended trees can be very dangerous.Never leave a captured tree unmarked. Mark the area with highly visible marking tape if you need to leave the area to get other tools or help. Follow these rules and never endanger yourself or others:

Tree twisting method

Slightly tilted hangers usually roll easily.Use a twist hook or twist strap if you don’t think the tree is too stuck. Here’s how to do it.

Inspecting the tree

2.Adjust the hinge

The hinges need to be adjusted so that you can roll the wood down. Start by sawing off the middle of the hinge to keep the two corners. Then cut a corner on the opposite side from the direction you are going to roll off the tree. Cut this corner with repeated cuts diagonally from the top. Be sure to leave a corner on the side from which you are going to roll the tree.

3.Roll up the tree

Take a pivot hook (or use a pivot strap to attach a branch as leverage) and roll the tree away from you. Lift straight with straight back and bent knees. If the tree is big or hanging very tight, the rolling force can be increased by using a pivoting hook or a pivoting strap with a longer piece of thin wood.

Lowering method

Hanging trees with a strong tilt can be difficult to roll down and need to be lifted or pulled back up.The method is based on removing the tree from the stump or where the tree is stuck with its end in the ground. The trunk should have a good sliding surface and fall off neatly.

Be aware that the barrel may break too soon. never stand in the direction of travel or under the barrel.

It is important that the two cuts are not made too high on the trunk, as it may “bend” at the breaking point.If the tree is too heavily suspended, use a tractor, winch or other machine.

Sawing the front side kerf

6.The suspended tree moves backwards

A lever with a rod, if necessary

Repeat the process if necessary

1.Create a slider bed

Place branches and a pole on the ground in front of the trunk to form a surface/crawlspace.

2.Make the back cut

Cut about half the diameter of the back of the trunk. Continue cutting on the other side if the guide bar is shorter than the diameter of the tree.

3.Place the wedge

Insert a wedge to prevent the back cut from getting pinched.

4.Cut the front side

The next cut in the front is parallel to the previous one, but 3 to 5 cm lower. Cut the trunk to about half the diameter. Narrow the front of the trunk.

5.Knock out the wedge

Drive the wedge until the wood fibers separate between the two cuts. Be alert. the trunk usually slips off the stump.

6.Suspended tree slides backwards

Done correctly, this is the result of the lowering method. The tree breaks away from the stump, slides backwards on the sliding surface, is removed from the tree it is caught on, and falls to the ground.

7.Use a pole lever if necessary

If the suspended tree does not come off due to the wedge: Lift the tree with a 2-3 m long pole/stick in the direction of travel until the tree breaks off and slides down.

8.Repeat the process if necessary

If the tree does not come off, repeat the process from step 1. Remember: Safety first. If in doubt, ask a tree-hanging specialist for help.

Minimize all steps Your browser does not support the video tag.

Husqvarna carburetor design and operating principle

To successfully set up and adjust a Husqvarna chainsaw carburetor you’ll need to understand the setup and how it works. It’s really not as complicated as it sounds.

The saw’s carburetor has a built-in fuel pump, which is responsible for transporting the gasoline-oil mixture, as well as a diaphragm, a needle valve with a yoke. Their work together allows you to dose the fuel supply to the main chamber and the two chokes.

One of the throttle valves is used to regulate the fuel flow into the cylinder when the throttle is depressed, and a second valve is used to restrict the air inlet from the air cleaner for easy starting of a Husqvarna cold chain saw.

At the moment when the operator closes the air supply to the carburetor by means of the choke, the fuel mixture is depleted and its supply to the cylinder is increased, which makes the chainsaw much easier to start than when the cold start is carried out in normal mode.

The Husqvarna carburetor involves a nozzle valve that atomizes fuel and prevents air from entering the main chamber. It is often the faulty part that causes the chain saw to malfunction.

For example, the valve, if improperly stored the chainsaw can stick, the fuel supply will stop, making the engine impossible to operate. Also, malfunctions of the injector can cause air leakage into the carburetor’s main fuel chamber. In such cases adjustment of adjusting screw positions will not correct the situation, you need to repair or replace the unit.

Three adjustment screws in the carburetor case are responsible for adjusting mixture quality and quantity, and also the crankshaft idle speed:

- screw (L). adjusts the amount of fuel in low and medium speed mode;

- (H). responsible for traction at high revolutions and their quantity;

- (T). changes position of throttle slide, thus regulating quantity of fuel mixture entering a cylinder and engine operation in idle mode.

Attention! screws (L) and (H) should not be adjusted without specific knowledge and experience. Incorrect adjustment of the quality and quantity of the fuel mixture can cause the engine to stop working or to run incorrectly, leading to rapid wear or even jamming.

structure and principle of carburetor operation

Carburetor serves to prepare a combustible mixture in a proportion determined by the operator from gasoline and air.

correct adjustment and setting is essential for proper operation of the device.

And for this you need to know the principles of the carburetor of a Husqvarna chainsaw.

Its construction consists of the following elements:

- body with clamping bolts and a set of gaskets;

- The fuel pump is a device that pumps the gasoline-oil mixture into the carburetor;

- diaphragm. designed to limit the flow of the combustible mixture into the engine;

- Float chamber. fuel is accumulated in it, the level is regulated by the float, the mixture is supplied to the main chamber for mixing with air, as required;

- Main chamber. the air flows through it, and the fuel is injected there as well, the amount of mixture fed into the engine is regulated by the throttle valve located here;

- diffuser. section of the narrowing of the air supply tube at the place of fuel injection;

- The needle valve is the device that regulates the fuel supply;

- Jet injector. the screws that regulate the mixture at high and low speeds, as well as the idle speed screw.

Also in the carburetor device, in addition to the throttle, there is a damper located at the inlet from the air filter. It artificially lowers the air supply, making the mixture richer for easier starting in a cold engine.

The nozzle valve is responsible for fuel injection into the main chamber, and it also prevents the ingress of air

When adjusting the carburetor on a Husqvarna chainsaw special attention should be paid to this valve, because. к

its condition has a direct effect on engine operation. The nozzle can jam if stored for too long. This will restrict the fuel supply and prevent the engine from starting.

Also due to long-term use or a factory defect, the valve may let air into the main chamber. In this case, the only way to fix the problem is to replace it.

The work of the carburetor is as follows: the air flow falling into the diffuser, mixed with injected fuel, the resulting mixture is fed into the engine. Throttle-controlled mixture quantity. The more mixture, the higher the engine speed.