How to properly remove the clutch on a chainsaw

Often, people who use chainsaws in their work, during the maintenance process, have a question about how to remove the clutch on a chainsaw. The fact is that this unit of the chainsaw mechanism requires constant monitoring of its operability, which, in turn, requires periodic disassembly for preventive maintenance and repair.

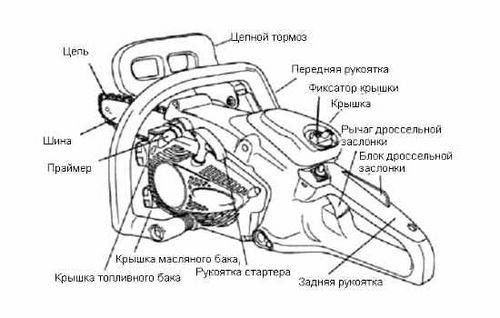

Chainsaw device diagram.

It should be noted that all chainsaws are classic devices, driven by a gasoline engine.

Chainsaw electronic ignition circuit.

In the device of chainsaws, single-cylinder engines running on high-octane gasoline are used. The power unit does not have a gearbox. It is a one-stage transmission that drives the chain. The simplicity of the design is the key to the reliability and trouble-free operation of the tool, even in the presence of severe operating conditions.

In addition to these units, the design of the chainsaw includes an air purification system that is supplied to the engine to prepare the combustible mixture, a tire with a saw chain installed on it, a starter that starts the power plant of the chainsaw, a chain tension mechanism, an ignition system, and an exhaust suppression system. In addition, the design of the chainsaw includes the so-called emergency brake, the actuation of which allows in an emergency to instantly disconnect the power plant of the chainsaw from the drive sprocket to prevent injury to the person operating the device.

Types of spark plugs for chainsaws.

In modern chainsaws, a two-stroke single-cylinder carburetor-type power plant is installed.

The engine consists of several systems and components, which make up a single whole. In the design of the engine, several elements can be distinguished that ensure its functioning:

- Flywheel;

- Clutch;

- Ignition module;

- Muffler;

- Special sleeve for mounting the carburetor.

Engines installed on chainsaws are high-speed. The maximum number of revolutions of the power plant is 13,500 rpm, which requires the use of high quality oil for engine lubrication, which is added to the fuel mixture.

Since the operation of chainsaws is carried out, as a rule, in difficult conditions, good cooling is required for the power plants of the device. The engines used to install the chainsaw are power plants equipped with a forced cooling system. For this purpose, an impeller in a closed casing is installed on one of the crankshaft axles. Due to the rotation of the impeller, air is supplied to cool the cylinder of the power plant along the corresponding air duct.

Chainsaw fuel system: 1. fuel filter, 2. carburetor, 3. manual pre-priming pump.

The carburetor in the power plant device is designed to prepare and feed the fuel mixture into the cylinder. Most often, carburetors manufactured by manufacturers such as Walbro, Zama and some others are used in chainsaws. A special filter is mounted on top of the carburetor for cleaning the air supplied to the carburetor. The fuel system in its simplest form consists of a tank, a filter element, and a fuel supply hose. Typically, a fuel tank is sufficient to operate for 30-40 minutes.

To fill the tank during operation of the device with air, its lid has a breather, which allows air to pass into the tank and prevents fuel from flowing. If the breather becomes clogged with debris, the engine stops working. A fuel filter is installed at the end of a loose hose. Fuel injection occurs due to the operation of the pump located inside the carburetor.

When the power plant is operating, atmospheric air must be supplied to it to prepare a combustible mixture in the carburetor. The incoming air is cleaned with a special air filter. As a rule, two filters are installed in the construction of a chainsaw: a coarse filter and a fine filter. The pre-filter has several elements and prevents large contaminants from entering the engine. A fine filter purifies the air from dust particles. Some models use a flywheel impeller as a cleaning element, which cleans the air stream from large impurities due to centrifugal forces. In the manufacture of fine filters, diffuse foam rubber, nylon mesh or some other materials are used as a filter element. Chainsaw filter requires regular cleaning.

Chainsaw two-stroke engine diagram.

Today, gasoline-powered saws are equipped with electronic ignition units, which do not require adjustment and cleaning. The ignition system includes a flywheel with magnets, a module with an electronic system, a spark plug and a high-voltage wire.

A starter mounted on the device is used to start the saw engine by turning the crankshaft. The starter mechanism includes the following elements:

- Drum;

- Cable with a handle;

- Body;

- Return spring.

When the cable is pulled sharply, the starter ratchet engages with the crankshaft teeth, which leads to its cranking. The return spring is designed to return the cable to its original position. To start the power plant, you need to apply a certain force, since the engine starts only at a certain speed of rotation of the crankshaft.

The design of the chainsaws is equipped with a centrifugal clutch, which works in automatic mode, depending on the amount of revolutions of the engine crankshaft.

At low revs, the elements installed in the clutch basket and having special overlays are attracted to the center of the shaft by springs. This position of the elements prevents the transmission of rotary motion from the crankshaft to the sprocket. When a certain number of revolutions of the power plant is reached, the elements from the special lining diverge and are pressed against the clutch drum, transferring the rotation to the chain. The main feature of such a clutch is that it starts to slip when the saw chain stops, which avoids damage to the power plant and mechanisms that transmit movement to the chain. Quite often, the clutch, as a result of intensive use, needs to be subjected to preventive maintenance and repair. For this purpose, the clutch is disassembled.

The clutch drum is also the driving sprocket.

This structural element is consumable, and this, in turn, requires regular replacement or repair.

File position when sharpening the chainsaw chain.

The main prerequisite for the failure of this unit is the wear of the sprocket teeth. If the drum is monolithic, then during operation the chain cuts the sprocket. This drum must be replaced. Some drum devices have a replaceable rim and during repairs it is replaced, and the drum, while maintaining its normal state, is operated further.

If it is necessary to repair a chainsaw, the question arises of how to disassemble the clutch. If you have a service center, it is better to contact specialists, but in the absence of the latter, the disassembly and repair procedure can be done with your own hands. This operation is uncomplicated and, with the appropriate tools, it can be performed by almost everyone. Almost every model of this tool has its own nuances in carrying out the dismantling of the clutch, however, the general sequence of actions is the same for all models.

The first step is to remove the chain brake cover. For this purpose, you need to pull the handle towards you. This is to ensure that the tape does NOT come into contact with the clutch cup. After that, the cover fastening nuts and the chain tensioner are loosened.

Loosening the tensioner will loosen the chain and bar. After that, the nuts securing the brake cover are unscrewed, after which the cover is completely dismantled.

At the second stage, the guide bar and chain are dismantled, dirt is removed.

The next disassembly step is to remove the cylinder head plug. Then the piston is fixed in the cylinder. For this purpose, the crankshaft is rotated and after closing the outlet, a piece of rope is lowered into the cylinder, which prevents further piston movement. After the repair, the rope is pulled out by the other end.

The fourth stage of disassembly is the direct dismantling of the clutch. First you need to Unscrew the nut on the clutch. It should be remembered that this one has a left-hand thread; when unscrewing it, you need to turn the key clockwise. A key is used for work, which is included in the chainsaw accessory kit.

After unscrewing the nut, you need to disassemble the clutch and inspect the drum with the drive sprocket for wear. Then, after inspecting the drum and sprocket, the condition of the needle bearing is inspected. If necessary, worn out elements must be replaced.

The assembly of the tool is carried out in reverse order.

There are several nuances that you need to know when repairing a clutch:

- On some modifications and models of chainsaws, a club is placed between the clutch and the drive sprocket cup. In the case of disassembling this element, it is required to install the washer in the position in which it was previously. This washer can sometimes be fitted between the motor and the cup.

- Some models of oil pump drives have a special spring. It transmits rotation from the sprocket to the oil pump drive. Correct installation of this spring is very important when assembling the device. If installed incorrectly, the oil pump stops supplying oil to lubricate the chain. Which can lead to costly repairs.

After carrying out repair work, before using the chainsaw for its intended purpose, it is required to check the operation of the oil pump and the supply of oil to them for lubricating the saw chain and the mechanisms of the guide bar.

Trimmer clutch. malfunctions, causes and remedies

1) Trimmer malfunction: At idle, the knife turns almost always, extraneous sounds are heard in the front of the engine, while the trimmer mows normally. The malfunction of the lawn mowers is the same as in the trimmer.

Cause of malfunction: Trimmer clutch spring burst.

DIY trimmer repair: Replace the broken clutch spring with a new one (for details, see below “How to remove the clutch on the trimmer”). Or, if only the edge of the hook breaks off on the spring, you can heat the spring with a torch, bend the ring equally to make a new hook and temper the spring (such a clutch spring can even work for several years). Do-it-yourself lawn mowers repair is similar to trimmer repair.

Chainsaw clutch. malfunctions, causes and remedies

1) Chainsaw malfunction: The chain rotates almost constantly (the engine, however, may NOT work stably). Causes of malfunction: The clutch spring burst. Do-it-yourself chainsaw repair: Replace the broken clutch spring with a new one (for details, see below “How to remove the chainsaw clutch”). In Husqvarna chainsaws. one clutch spring and two weights, in Stihl chainsaws. three clutch springs and three weights (cams, sectors). If you cannot find the clutch spring itself, you will have to change the entire clutch.

2) Chainsaw malfunction: The chain rotates almost constantly, sometimes extraneous sounds are heard in the clutch.

Causes of malfunction: The clutch cam broke off (due to overheating) and the clutch spring fell off. Overheating is indicated by blue clutch cams. Overheating before clutch breakage can occur if you operate the chainsaw with the chain brake or a dull chain on. Do-it-yourself chainsaw repair: Replace the clutch assembly (for details, see below “How to remove the chainsaw clutch”).

Removing the trimmer attachment

Receive one most read article by mail once a day. Join us on and .

So, in order to modernize the trimmer, it is necessary to select a suitable diamond saw blade from the TST series. These discs are designed for working with plywood and wood. The disc must have the following characteristics: outer diameter at the tops of the teeth. 216 mm, the number of teeth. 48, Bore. 30 mm. There must be three rings with the disc with the same outer and different inner diameters. They are needed to compensate for the difference between the bore and the counterpart on the pressure washer.

Fitting a diamond blade to a trimmer is not difficult at all. This operation is no different from installing any other nozzle, with the exception that you should show increased attention and accuracy. First you need to remove the spool with the line, block the gearbox shaft with a special pin. The line container should be rotated counterclockwise. Before installing the saw blade, make sure that its hole is larger than the diameter of the sedimentary band on the washer.

After that, you should alternately try on the expansion washers and choose the one that not only fits the width, but also completely selects the gap between the centering shoulder of the lower washer and the saw blade seat. First, the lower washer with the wear ring is installed on the gearbox shaft, then the diamond disc, after the upper club, and only after that the protective cup is put. Do not forget to tighten the entire package on the gearbox shaft with a nut.

Did you like the article? Then Support us, press:

The cord lengthens spontaneously

There are times when the trimmer user notices a very fast line flow. However, he never hit the ground with a button to lengthen the line. The reason that the line spontaneously lengthens, cutting into a special knife on the casing of the device, may be the absence of a spring in the mowing head. Often novice users of mowers, trying to load the line into the reel, forget to install the pressure spring in the head, or completely lose it when opening the lid, and in the future, they do not even suspect of its existence.

Major coil faults

Trimmer users and lawn mowers often face a problem with a semi-automatic mowing head. Coil malfunctions can be as follows:

- The line does NOT lengthen automatically;

- The cord spontaneously comes out of the reel.

What types of woods are there

A common type of line that fits virtually all reel types. round cord. Removing the spool from Assemble the mowing head. Before the trimmer attachment. This is an ordinary fishing line, suitable for mowing succulent grass, but it will be much more difficult to mow dead wood with it, and even more so It will not cope with shrubs.

Usually, the diameter, which can mow young grass, and does not exceed 1.6 mm. The thicker the thread, the more coarse grass it can overcome.

There are fishing lines with sharpened edges in the form of an asterisk or a square, this option is more adapted to mowing dry grass precisely due to the existing sharp edges, but its drawback is more wear and is inferior in strength to round cord.

The bobbins of the trimmers, the motor of which is located in the ground itself, have a different attachment to the axis of rotation, in them on the coil there are two buttons located at the edges, which must be wrung out, otherwise the substitution of whining could not differ from other cassettes.

The principle of correct winding of the fishing line is identical in all of the above cases, therefore, for example, we will consider the standard version with 2 Usyk.

To remove the spool with the fishing line, you need to Unscrew, located in the center, the screw, but Note that the thread is left there, therefore it will have to turn clockwise, this was made specially so that during operation It does not open under the influence of centrifugal force.

Next, using a screwdriver, disassemble the head and pull out the spool on which the fishing line is specifically wound. Having measured the desired length and folded it twice, it is necessary to tuck the fishing line into the spool.We will eventually bring its ends opposite each other (for this there are special slots for fixing).

Then you need to assemble the head in reverse order by threading the ends of the cord into two corresponding holes.

If you have any doubts or it is NOT completely clear how to load the line on the trimmer, we advise you to take a look: how to properly wind the line into the lawn mower. How to remove the head from the trimmer. In this clip, the instructor will carefully open the trimmer head step by step, measure the required amount of line, usually from 2 to 4 meters, and demonstrate assembly and installation on the trimmer.

To change the fishing line to a trimmer or lawn mowers (cord, strings), it is initially important to remember its thickness. If the remnants of the cord are not preserved, then we study the passport of our garden equipment. With the appropriate information, you will always find, by carefully examining the mowing reel, the range of diameters you will like best applied to its surface. If our search is NOT crowned with success, just estimate the diameter of the outlet on the coil. The line should move easily in the personal computer. I do not recommend widening the holes to use a thicker string to increase productivity and the ability of gardening equipment. Line thickness is calculated by the manufacturer based on motor power.

To change the cord on most models, you need to disassemble the mowing reel by pressing the latches. When you immediately press the latches, you also need to turn the upper part of the coil.

5-6 meters of narrow cutting line is loaded into a standard bobbin along the second up to 3 meters thick.

How to change line in each trimmer

What is needed, first unscrew the nozzle. This should be done by rotating the drum to the right. Here we have a drum with the remnants of an old fishing line in the palm of our hand. We open it. In most cases, the lid is locked with latches, which are opened with a screwdriver, threading it into the holes and pressing a little. Or it is necessary to squeeze the latch and turn the cover in the direction of the arrow. In this case, the lid itself must be held, because in drums with automatic line feed there is a spring, which, having straightened, can throw out the inner parts of the drum to our client. Gently took out the reel, removing the pieces of line from it.

Now you need to take 5 meters of the newest line and fold it in half (to find the middle). In the middle part of the coil there is a notch (in some structures. a hole), for which we need to hook our fishing line. There is also an arrow on the spool showing the direction of winding. A fundamental detail. if the reel has two compartments, then one half of the line should be wound.

#STALEX HB-40 is a small-sized but efficient hydraulic pipe bender. Thanks to the holes in the base of the structure, the machine is firmly fixed. The largest pipe diameter at work is 60 mm. Jack lifting capacity. 6 tons.

Advantages of the model:

– Expanded Capabilities. Includes rolls with 20, 40 and 60 mm grooves

– Small dimensions. your way for a small workshop;

– the pressure rollers are made of durable steel with bearings;

– The hydraulic jack greatly simplifies the work;

– Highest stability makes work very safe.

– Included.

The trimmer is the most common machine used for trimming grass and small bushes. This device is distinguished by its own simplicity in maintenance, easy control during its operation, and due to its low weight, even ladies can use it. It is NOT a secret that for high-quality performance of work on mowing grass, the correct selection of cutting tools is required. For the latter, special cutting attachments (discs, knives) or trimmer heads with a fishing line inside are used in trimmers. Nozzles and fishing line are a consumable tool, if there is an option to sharpen the knives, then when you use the fishing line, you need to change it. Here we will tell you very carefully how to correctly change the line.

The grass mowing head is a cylindrical body in which a spool (bobbin) is inserted with a fishing line (cord) tucked in here. This design can be installed both on gasoline.

How to remove the spool and replace the line

Trimmer owners, mostly beginners, find themselves in confusion, bordering on panic, when they need to change the cutting tool or line in the reel. Very often, when trying to unscrew the mowing head, users simply render it unusable, and not suspecting that it is unscrewed in the opposite direction. To prevent this from happening, if you need to change the tool, it is recommended to Read the Step-by-step instructions given below.

- Stop the mowers engine or power off the trimmer before threading the line into the spool to avoid personal injury that could result from accidentally starting the cutting tool.

- Unscrew the nozzle attached to the gearbox shaft. To do this, the shaft must be fixed by aligning the holes on the washer and on the axle, and inserted a metal rod or screwdriver into them.

- Unscrew the nozzle. You should be aware that the thread on the shaft is left-hand. Therefore, it turns the trimmer coil to the right, that is, clockwise.

- Let’s disassemble the mowing head. Most often, the head cover is attached to a latch. To remove it, you need to sink these clips into the case, squeeze the edges of the cover. If your trimmer has a Semi-automatic mowing head with a button on the bottom, then the disassembly of the nozzle should be done carefully, since you can lose the spring, which sometimes flies out when the cover is removed.

- Cut off the required amount of line. Usually its length is 5 meters. Use a cord of the same diameter as indicated in the instructions for the tool. It is not recommended to exceed the maximum line diameter as this will result in increased engine stress and higher gas mileage.

- Find the midpoint of the line by folding it in half. You will have a loop.

- Special grooves are cut inside the coil (there may be holes). Insert a loop of line into this groove.

- Wind the line around the spool by turning it counterclockwise. The cord should be tucked in as evenly as possible, the turns should lie down without overlap and with good tension. When the winding is finished, leave the free ends of the line about 20 cm long and fix them in the grooves on the sides of the reel.

- Assemble the mowing head. Remember to insert the spring and washer (if equipped) before final assembly of the accessory. Place the spool in the body and thread the ends of the cord through the holes or eyelets.

- Put on the cover and lock it latches.

- Screw the adapter back onto the gearbox shaft, also securing it with a screwdriver. You will need to twist the trimmer coil to the left (against the arrows).

How to replace, remove the cutter head of the Black Decker GL716 Electric Trimmer

How to change, remove the mowing head of the BlackDecker GL716 electronic trimmer for repair or replacement.

The line does NOT extend automatically

If the line is NOT lengthened by lightly hitting the trimmer button into the ground, the reasons for this may be the following.

Option 1. a bite has occurred, i.E. Clamping the cord between the turns. This problem usually appears if the user has been winding the line on the reel unevenly, with the intersection of turns, or winding it with insufficient tension. In the latter case, when the mowing head rotates at high speeds under the influence of centrifugal force, the cord begins to tighten, as a result of which inter-turn clamping of the fishing line is possible. To fix the problem, you will have to disassemble the coil into trimmers and rewind the cord correctly, that is, in even turns with good tension.

Option 2. too short ends protrude from the head. The fishing line may not come out when it hits the ground if its ends sticking out of the head are not long enough (short). In this case, the centrifugal force is not enough to stretch the line. Therefore, it is required to stop the unit (turn off the engine or disconnect the trimmer from the mains) and pull the line manually, after pressing the button.

Option 3. the line is soldered inside the mowing head. This causes the coil to lock and NOT spin when the button is pressed. Basically, this happens for several reasons: poor quality of the cord, overheating of the coil during prolonged operation of the unit, line hitting hard objects.

- In the first case, third-party cord can be made of low-quality and low-melting materials, which DO NOT withstand mechanical and temperature stress. Therefore, you should give preference to “branded” fishing line.

- But, if you nevertheless purchased a fishing line of unknown quality, and it is often soldered during operation, then you can follow the example of some users who, after filling the cord into the reel, moisten it with either silicone grease (from a can) or mineral oil. This procedure greatly reduces the likelihood of soldering the turns of the fishing line together.

- Also, the line can be welded if, during mowing, it hits a hard object (stone, fence, dry branch, etc.). As a result, it stretches slightly and is pulled back into the head at high speed. Here the friction of the cord heats up, and its turns stick together. The only thing that can be done to eliminate this malfunction is to open the trimmer spool and rewind the line.