ways to cut metal pipes

One particular example of this situation is the need to cut a metal pipe at a 45-degree angle. Such cutting of the material is often required when laying plumbing or heating systems. In this case we have to deal with steel pipes.

For this purpose, the usual tubes of cylindrical cross-section are usually used. If we are talking about the installation of some metal structures, more often used profile pipes of rectangular or square cross-section.

The main problem here is that in order for the joined elements to coincide, the cut must be as even as possible, which means that particularly close attention should be paid to the marking of the material.

In the case where cutting at an angle is required, a simple square sheet of paper can be used as a marking template. It must be folded strictly diagonally, and then wrap the pipe with a template.

Care must be taken to ensure that the side of the sheet that is closest to the end of the pipe is perpendicular to its central axis. Then with the help of a marking material a number of dotted lines are applied and after the marking is made around the circumference the template can be removed.

Photo of a template for pipe cutting. from the side

A larger pipe blank

Marking a cut at 45 using a template

If you have to cut a profile pipe, then it is advisable to make a special template from the same pipe, but with a larger cross section. In this case it is necessary to use measuring tools only once. To make a mark you will need to use a protractor or a building angle.

After sawing the template, the pipe to be cut can simply be inserted into it and marked. This approach allows considerable time savings, and cutting the profile pipe under 45 degrees will be convenient.

As for what to use when carrying out the work, it is worth choosing the most appropriate and familiar. It can be a simple hacksaw for metal, or an angle grinder with a mounted cutting disc.

How to correctly cut pipes of different metals under 45 degrees and 90 degrees

How to cut a pipe at a certain angle? It has already been said about the straight cut. Next, let’s look at techniques for separating tubular workpieces made of different metals using a metal locksmith’s chair. In addition to the convenience of cutting, the jig minimizes the amount of sawdust, which is important if the work is done at home.

The locksmith’s jig consists of two assemblies:

- A handheld hacksaw, which has top tubular guides that allow you to hold the tool strictly perpendicular to the direction of cutting;

- A channel-like body in which holes. slots on both sides are made in advance to help the worker make precise angular cuts (usually 90° and 45°, but there are some chairs with an angle meter, which can perform angular cuts in the range of angles from 100 to 1150).

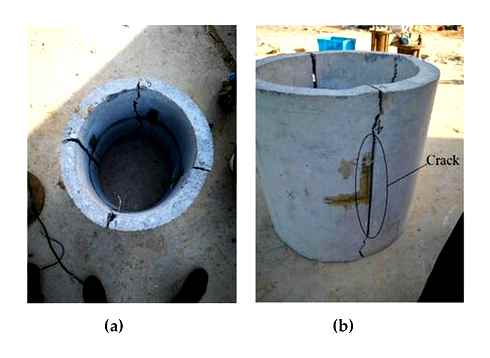

A distinction is made between cast and pressed wort. The first ones, although cheaper, but do not work well under the conditions of periodic bending stresses.

It is important to select the correct hacksaw for the job. Only high-precision tools with upper guides. additionally secured against bending by spring stops. are suitable for making angular cuts.

Selection of the size of the locksmith’s chair is made according to the following parameters:

- Width of the jigsaw, which determines the maximum diameter of the workpiece.

- Length of the jigsaw, with increasing accuracy of the cut increases.

- angular gauge available.

- Depth and width of through cuts in the side walls of the channel: the deeper they are, the less sensitive the jigsaw is to changes in cutting conditions. state of lubrication, increased temperature of the hacksaw blade and workpiece. On the other hand, when sawing large-diameter pipes the larger width of kerf requires less precision.

- Body material: steel (cast or forged) saws are clearly preferable to plastic saws, although the latter are lighter.

How to cut a pipe at a 45 degree angle? When working with a metalworker’s mitre saw, you must first file the material, and then, making sure the wall is perpendicular, gradually increase the pressure on the hacksaw blade.

Ways of cutting pipes

To cut a profile pipe, including at a certain angle, you can use the following tool:

- angle grinder. angle grinder (picture above). This method is most often used for domestic purposes, as it is distinguished by the simplicity and accessibility of equipment;

- hacksaw for metal. Using a hacksaw is not difficult, but the process of doing the work is quite time consuming;

Using a hacksaw for metal to cut profiled pipes

Using an electric jigsaw and hacksaw is not possible for cutting thick-walled profile pipes or pipes with a large diameter.

- special machine for cutting pipes. The equipment is most often used by professionals, because it has a high cost. Currently, specialists use two types of machines:

- Equipment with mechanical cutting, which is performed by a cutting wheel or a special saw;

- equipment with a laser. Laser cutting is more precise compared to its mechanical counterparts.

Using a special laser cutting machine

When choosing any method, it is important to pay special attention to safety. During the cutting of profilpipe metal chips are formed, which can damage the hands and eyes of the master, so before you perform the work it is important to wear gloves and goggles.

How to cut a profiled pipe with an angle grinder

The most popular way of cutting in domestic conditions is the use of angle grinder. How to cut evenly an angle grinder profile tube? The main problem of doing the work is the correct marking.

For marking, you can use:

- A tape measure, a square, a marker (a pencil), a spirit level. The simplest tools allow you to accurately enough to mark the angle of the cut, but during the performance of angular grinding machine can deviate from the specified line (the equipment is not resting on a stand, and is on weight, that is, in the hands of the master), which will lead to an error. For this reason, this method is rarely used;

Marking the cut with an angle piece

Using a paper template

The easiest way to make an angled cut, such as for a greenhouse, is to use a template made of thick paper.

To make a cut at a right angle (90°), it is necessary:

- Wrap a thick sheet of paper around the pipe and achieve full alignment of the edges;

- Fix the sheet in this position;

- cut the profile tube along the edge of the paper.

To make a cut profil pipe at an angle of 45 °, you need to fold a sheet of paper in half (on the hypotenuse) and wrap the pipe so as to align the sharp ends of the resulting triangle.

Professional craftsmen use special computer programs that allow more accurate creation of a paper template for cutting profiled pipes at any angle.

Computer program for automatic creation of paper template

Using a chair

To cut profile pipe correctly at any angle you can use a construction plier. The fixture is used in the following order:

- Profile pipe is fixed inside the device and aligned at a certain angle;

- Using a built-in hacksaw, a preliminary cut is made;

Cutting at an angle with the construction diagonal cutter

the prefabricated measuring tool is expensive. To reduce the financial cost of construction work, you can make a counterpart of the construction chisel yourself. For this purpose a wooden frame with a pipe recess is made and, using the measuring tools, incisions are made at different angles.

Chisel to cut profil-pipe with their own hands

Watch this video to see what other methods are available for cutting angle bars.

Peculiarities of cutting pipes longitudinally

Not only can you use an angle grinder to make cross cuts, but also a longitudinal cut on a profile pipe. How to cut profile pipe longitudinally? The work is performed in the following order:

- as with cross cuts, the work starts with marking. It is important to determine as many anchor points as possible on the side surface of the pipe to get the smoothest line for the trimmer;

Marking the cut lengthwise

- to improve visibility and eliminate the possibility of obtaining an uneven cut, it is recommended to highlight the resulting line for the trimmer (with paint or masking tape);

- The pipe is fixed, for example, by clamps. If possible, you can also fix the angle grinder, as an option. with the help of a special stand;

- You gradually make the cut along the line you want to make.

Cutting the pipe lengthwise with an angle grinder, fixed on a stand

According to a similar technology makes the cut of thick-walled profile pipes. Before you perform the work it is required to fix the pipe, which eliminates the possibility of fracture of the workpiece under its own weight.

Cutting at 45 degrees

Usually in order to turn the pipe by 45 degrees use fittings, bends with an angle of rotation of 45 degrees, made of the same material as the pipe itself, if the pipe is steel, then the turns are welded to steel. For HDPE pipes, there are electric welded or cast 45 degree bends (note that the compression fittings with such angle of rotation in Russia can not be found almost).

But, if you still need to cut a tube of circular section from steel or various types of plastics, then you need a line for cutting pipes at an angle, the shape of which is calculated by hand or machine. The task is greatly simplified if at an angle of forty-five degrees you need to cut a metal profile with a square cross-section.

For hasty trimming, you can use an ordinary sheet of paper folded diagonally, with which you mark the surface for the future cut. Applying the folded paper, proceed as follows:

- spend on a straight surface of a profile in a place where the cut is made, strictly perpendicular to a line for a trimmer;

- they put a sheet of paper folded on a diagonal to a lateral surface with the sharp end to a line so that the top edge of a paper triangle was flush with the top side of a metal profile.

- spend a pencil line for a trimmer on the side of the sheet at an angle of 45 degrees, then the paper corner is attached to the other side and trace it with a pencil (better to use a thin marker).

For sawing you can use an angle grinder with a disc for metal, first spending a thin line to trimmer on the markings, then gradually deepening it to complete separation of the edges.

When working with the angle grinder is necessary to consider the following factor. when fully cutting edges of the disk can be damaged on the sharp corner, which will lead to its failure, and in the absence of protection on the angle grinder even to injury to the employee. Therefore, it is desirable not to cut the corner edges all the way through, but to leave a narrow groove and then baste, sanding down the protrusion afterwards.

Making a template for trimming metal profile

If it is necessary to cut a large number of pipes, it is possible to make a template from metal profile of a larger diameter using a paper sheet in the above way. The angle of inclination is checked with a protractor or a construction angle piece. in this case the two edges of the cut parts of the template are joined.

At work on a detail in a necessary place is put on a template and tightly pressed, the marks are put by a sharply sharpened eraser at outlining of a template contour. The piece is cut in several steps with a gradual deepening of the groove.

Chisel for cutting pipes with their own hands

Using a template is not very convenient. you have to make a cut along the line, holding the angle grinder on weight, which leads to large errors. If you have a welder, you can make a simple plier. guides for the disc angle grinder, not allowing him to go sideways.

To do this, use the previously made template, in the side of which a hole is drilled and a nut is welded. When working with a homemade wire cutter put on a profile, screw a bolt into its nut and press the device to the profile surface. Angle grinder with a disc for metal make a cut, slightly pressing the disc to the side surface of the device. It is clear that with prolonged work, the edges in the chair gradually grind down, and although the process occurs simultaneously on all edges, over time there will be some inaccuracies. Therefore, it is better to make the device from hard, wear-resistant metal to increase its service life and obtain a more accurate tool.

Block: 2/9 | Number of characters: 3688

Cutting at 90 degrees

To cut evenly across a round pipeline or rectangular metal profile, use a sheet of ordinary paper. It is wrapped around the workpiece so that the edges of the sheet of paper coincide, then it is fixed on the part with tape or glue. an angle grinder guides a thin trimmer line near the edge of the paper sheet, and then it is gradually deepened until it is completely cut out.

Metal profile or a round tube can be sawn using a template, putting on them evenly cut element with a large inner diameter.

Collar punching

To obtain branching of metal pipe lines in the form of tees, a collar mortise is used, for which it is necessary to cut the edge of the round pipe adjacent to the walls of the other at right angles. To implement the method, proceed as follows:

- Cut off the edges of the workpiece at right angles in the manner described above.

- On the round end surface, a marker marks four equidistant points at angles of 90 and 180 degrees to each other.

- Measure the circumference, divide the resulting diameter by 3. From the two diametrically located points, the resulting distance is postponed, and then these points are connected to the other two by a smooth arc, conducting a line for the trimmer with a marker.

- According to the markings make a cut with an angle grinder and separate semicircular segments, after which the part is ready for welding. For small inaccuracies in the mating, it can be sealed with a sledgehammer against the round surface of the other element.

Block: 3/9 | Number of characters: 1521

Other tools for cutting plastic pipe

These are rarely used when no pipe cutter is handy:

- angle grinder. for cutting pipes you will need a metal cutting disc. The main point when working with an angle grinder is to precisely regulate the force, too much pressure on the tool should not be.

- The electric jigsaw is the most convenient way in the absence of special scissors. Here there is a high probability of getting an oblique cut, so for greater accuracy during the work the pipe must be turned several times.

What is categorically not recommended to cut the pipe:

- The bandsaw blade moves too slow and if it is not sharp enough the possibility of damaging the inside diameter of the pipe is high and that can lead to chips and cracks.

- Circular saw. Because plastic pipes are flexible, pushing them into the machine often causes the pipe to shift and bump, which is dangerous for the person making the cut.

Cutting pipe at a 45 degree angle

Most often it has to be done when installing plumbing and heating and assembling frame structures. It is possible to cut the pipe under 45 degrees by the angle grinder according to the marking, which is made either by a sheet of paper of the same format of A4, or using a regular school (drawing) isosceles angle piece.

Use a sheet of paper or cardboard

You have to do several operations with the sheet to get the right angle. If you don’t want to get tangled up in the folds, just make it square and fold it diagonally to get the right angle. You can do the same with any sheet of paper, as long as its sides are equal to each other. The method is convenient because it can be applied to a pipe with a large diameter, and to [profiled pipes with a square and rectangular cross section].

IMPORTANT: Steel water and gas pipe

Marking with an angle piece

If there is an angle piece at hand, you must first determine the exact line for the trimmer end of the pipe, including the profile. Applying the tool and smoothly shifting it over the surface, we will get a line for the trimmer cut at 45 degrees. The same technique is used with a 30 degree angle.

How to perfectly mark the end of a pipe with a piece of paper for a 45-degree tapping

To weld one pipe into the second pipe at a 45 degree angle, you need to make a concave undercut of the end. The marking for it is very complex. The proposed method will allow you to make it evenly and as quickly as possible.

What will be needed:

Next, a rectangle is cut out of the paper with one side equal to the circumference of the pipe and the other equal to its diameter.

The paper is folded in half lengthwise and then again. As a result, it will have three folds after unrolling. They need to put marks on them with a marker.

The rectangle is wrapped around the pipe and aligned with its edge. Next, you need to mark the line for the joint trimmer, and transfer the marks from the paper to the end of the tube. On the opposite side, only the joint is marked.

After that, you must step back from the bottom to the edge of a couple of millimeters. Then it is necessary to attach the paper to this point and in turn to the side marks on the end. Using it as a ruler, you need to draw lines.

Then a wedge is cut in the marked pipe.

Now if you put it to weld, then the gap in the joint will be almost no. The angle will turn out exactly 45 degrees.

Cutting of large diameter pipes

When it is necessary to cut a pipe with a large diameter, you can use a number of special devices and tools. This may be necessary if, for example, a pipeline needs to be repaired.

- angle grinder. The use of angle grinder justified in terms of tool availability and comparative cheapness of the work. However, in this case, you should not count on high productivity, in addition, carrying out works in this way is associated with considerable risk.

- Rolling machine. Such devices are also often called pipe cutters. In fact, such a device is the same angle grinder, but more adapted for this type of work. The machine includes a special base, where the element to be cut off is fixed, and a cage with mounted cutting rollers, which perform the actual work. It is important to understand that each machine must be purchased for a specific purpose, i.e. the size of the pipe.

- Gas Cutting. This option is most commonly used when working with large diameters. Cutting is done through the action of the flame of high intensity, and the waste produced in the process is blown out by the pressure of the gas. This method can be considered the most practical and efficient.

Cutting with gas is the fastest way

SEE A gas cutter on AliExpress

There are other options for the task, such as plasma, waterjet or laser cutting, but they are practically never used in private practice.

Proper tooling

When you begin to saw any piece with an angle grinder, the following rules must be observed.

- Hold the angle grinder when cutting metal should be firmly, with two hands.

- You can change the wheel only after the complete cessation of rotation, not cooled to an acceptable temperature by disconnecting the power tool from the mains.

- Do not rest the working tool on the ground or, in other words, on the table (do not let it out of your hands).

- It is necessary to stop for about five minutes to rest and not to let the disc cool down.

- Always take care of the cutting disk and do not let it get jammed by the edges of the workpiece to be sawn.

- Do not leave the power tool unattended when plugged in.

- Use only discs of the appropriate size, as specified in the operating instructions of the device in use.

- It is better to work on a flat surface so that the body position is stable.

- Keep power cord away from rotating wheel, sharp edges, objects hotter than 100 degrees.

- Perform non-cutting movements only with the power tool turned off.

- It is necessary to sit at the side or otherwise behind the tool, doing the work yourself so that the body parts are not in the plane of the cut.

It is inadmissible to work with the angle grinder when you are strongly tired, or under the influence of alcohol, psychotropic or narcotic substances.

As for the question of whether the disk of the angle grinder should rotate toward you or away from you, there is no unambiguous answer. The operating instructions indicate that the first option is correct. This is because the resulting sparks fly away in the opposite direction from the operator, causing no harm. Also, fragments of the wheel will fly in this direction if it breaks into pieces.

However, if the passage, when the disk rotating “on itself” happens to jam, the tool will fly into the working. That’s why some experts prefer to cut metal so that the wheel rotates “away from you”. The power tool ripped out of your hands will fly in the opposite direction. This reduces the chance of injury, and the user will be protected from flying sparks by men’s clothing, shoes, and gloves.

How to cut a pipe at an angle

Sometimes it is necessary to cut the pipe to a certain angle. In this article, the master plumber will tell you how such operations are performed and what methods of cutting exist.

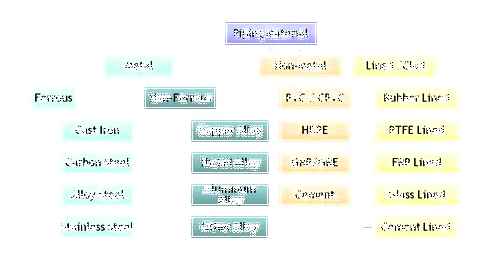

Considering the methods of work. cutting straight or at an angle. it is necessary to take into account the different material of products to be processed. Thus, hoses made of polypropylene or thin copper are easier and easier to cut than thick-walled steel pipes.

Plastic products of small diameters are cut at the right angle with special scissors. It is possible to control the angle with an ordinary protractor. Plastic pipe can also be cut with a fine-toothed hacksaw.

In the process of installation, it is very often necessary to cut metal pipes. Popular tool for such cases. the so-called angle grinder. Use this tool to cut straight and at an angle.

Let’s find out what fixtures can be used for cutting at different angles.

For execution of rather precise cut it is possible to apply a simple technique, where an ordinary sheet of paper acts as a kind of template. For example, printer’s paper of A4 format is well suited for creating a mold.

The sheet is preliminarily marked under the square using a ruler. The size of the diagonal of the square should be equal to the length of the circumference of the tube to be cut. Trim the excess sheet parts.

- Fold the sheet diagonally, aligning the opposite corners;

- Turn the resulting triangle so that the line for the hypotenuse trimmer is perpendicular to the axis of the pipe;

- In this position, wrap the paper around the pipe surface, aligning the extreme points of the hypotenuse together;

- Use a marker to mark the cut along the line of any of the triangle’s cathetuses;

- Trim the pipe along the marked line.

This method is quite convenient for marking and cutting pipes at an angle of 45º in the diameter range from 32 to 63 mm. It is recommended to take thick, but soft paper for more convenience of marking. You can also use paronite and similar materials.

Competently made templates for shaped cutting of pipe allow for extremely accurate cuts. However, the gap between the prepared blanks is not excluded. In the connection of metal pipes it is “closed” by a welded seam, when connecting plastic parts, a specialized cord for soldering is used.

The technology of cutting on templates allows obtaining different angles of cut. But to form the template for angles other than 45º, you will already need to perform mathematical calculations and according to the calculated data to cut the template from paper or similar materials.

It is true there are computer programs designed to save the master from making calculations. Templates for cutting pipes such programs print out on a printer.

A simple calculation program, based on MS Excel application, allows you to calculate and create a template for almost any value of pipe diameters and required angles of cut.

All the user has to do is to enter the appropriate values in the cells “Outer diameter” and “Cut angle”. According to these parameters the drawing will be formed and you can send it for printing.

Note! Calculation of the points of the curve is based on only two given parameters. the diameter of the pipe and the required angle of cut. A disadvantage of the program is that it does not take into account the thickness of the template sheet, which leads to small inaccuracies

There is a simple tool, often used in everyday life, mainly for work with wood. It is called the jigsaw. So, the same device is suitable for cutting pipes, and at different angles.

The chisel is available for sale, but if you want, you can always make it with your own hands and adjust the design to the desired diameter of the pipe:

- Take a wooden board of width equal to the diameter of the pipe, length 400-500 mm;

- Take two more boards of the same dimensions, but increased in width by the thickness of the first board;

- From the three boards assemble a construction in the form of an inverted letter “U”, with the first board as the base;

- In the central part of the structure to mark a rectangle, two sides of which run along the inner boundaries of the side boards;

- Divide the rectangle by diagonals and along the lines obtained on the upper faces of the side boards, make cuts down to the base.

This is the way to make a template for cutting at a 45º angle. But using a protractor, it is possible to mark almost any angle and make cuts under the pipe cut for a particular angle.

How to make a bend in the profile pipe at any angle

When you want to make an element with a 45-degree angle from a profile pipe, then usually two blanks are faced at 22.5 degrees, and then welded together. This is a very simple and quick method, but not the most beautiful. If you need to make a smooth bend in a one-piece pipe without forming a sharp outside corner, you can use the following method.

Tools needed:

In the center of the future bend of the profile pipe a cross line for the trimmer is drawn with a marker under the angle. Such a mark is made on all 4 sides of the pipe.Further on one of the parties it is necessary to make 4 more cross lines on the left and on the right from the central one. They are drawn under the angle at an indentation of half of the pipe cross section. For example, if it is 40×40 mm, then you must indent with a step of 20 mm, and if it is 50×50 mm, then 25 mm. The same lines should be drawn on the opposite side of the pipe.

Then between these lines the diagonals are drawn, as on the photo. As a result they must make the letter “M”. Similar diagonals are made on the opposite side of the pipe. It is important that they were in the same direction.

Then the tube is rotated so that the sides with diagonals are on the sides, and then you should draw the extreme lines with a marker, both on the top side and the back.Now it is necessary to make diagonal cuts on both sides using an angle grinder. It is most convenient to use a worn cutting wheel for this, as it has a small diameter, which allows you to work finely, without undercutting unnecessary.

After cutting diagonals, it is necessary to lay the pipe in such a way that it is formed or the letter “M” is inverted. In the next step, the outermost marks on top are cut through, and the pipe‘s revolution must remain intact. As a result of undercutting, the unnecessary fragment with two teeth is separated.

If its walls are thick, you will have to use a vise. Next you need to weld and grind the joints.

The result is a perfect 45-degree bend without a sharp outer corner, which looks like a factory one. This is the way pipes can be bent when making various frameworks and frames, where safety is important. Accidental collision with a hand or foot on such a bend is less traumatic than on a conventional bend with a sharp outside angle.