How to saw gas silicate blocks

The saber saw is an electric tool designed for cutting construction materials during repair and construction work. The design of the tool is closer to the device electric jigsaw, only the saw moves not perpendicular to the axis of rotation of the motor, and along it. In addition, the size of the tool is much larger. you can saw a gas silicate block with one pass and quite accurately. The plane of the cut is much cleaner than the factory edge of the block.

There are a large number of saws for saber saws. They are easy to change, with different kinds of tines, inclined forwards, backwards and sideways. There are tools with or without tungsten carbide inserts, with set or thickened teeth.

- accurate, clean cutting;

- High cutting speed;

- The ability to adjust the depth of cut, up to creating grooves for electrical wiring or reinforcement;

- easy and high-quality adjustment of the block to the desired configuration or dimensions.

The only disadvantage of the sabre saw is the price. it costs from 5,000 ₽, which many users consider too expensive for a single use. However, it is possible to buy such a saw in cooperation and use it as needed.

Why the chain is stretched and why it needs to be shortened

The chain, regardless of whether it came with the chainsaw as a package or was bought separately in the store, stretches. This is partly because of its composition, and partly because of the structure of the chainsaw itself. And in this case, the first derives from the second.

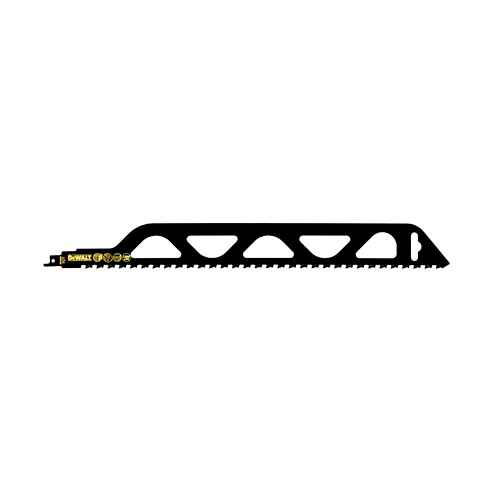

DeWALT DW392 cutting aerated concrete | beton komórkowy

But still, why does stretching occur?? The sprocket and the chain have a value called the pitch. When the tool is new, these pitches are the same for both elements. As it works, the sprocket begins to wear and the chain begins to stretch under, so to speak, its new pitch. By the way, there is also a sprocket on the bar that has the same problem over time.

Other causes that affect the chain length in one way or another:

- Metal stretches when heated. This, in turn, is caused by a broken oil pump, when the oil supply either stops altogether or in insufficient quantities. That is why it is essential to check how much oil reaches the work surface after each filling. To do this, when the tool is running, you need to bring a blank piece of paper, on which the oil traces should remain.

- Low-quality lubricant, which some owners replace with waste material, can not only lead to stretching of the material through overheating, but also dull the cutting teeth at all.

- Earth, dirt, dust. all of these things have a direct effect on pulling because of rubbing of the link joints.

Nevertheless, even if all the rules are followed and the lubricants are of the highest quality, chain stretching is a natural and inevitable process, the only difference being that it occurs later if the chain is used properly. Shortening the chain is therefore also a kind of unavoidable. And it is only necessary to do this if it does not make sense to adjust the chain saw. Shortening the chain increases the tool’s service life.

What to cut aerated concrete blocks: plunge cutter, planer, saws

Aerated concrete is a popular material in the construction world. Buildings and structures made of aerated concrete products are warm, fireproof and environmentally friendly. The material is not expensive, has high strength and easy to cut. Aerated concrete blocks are made from a mixture of cement, sand, water and aluminum shavings. The mixed solution is then poured into containers and left to dry for several hours. Shapes of blocks are ready for use. Pouring mortar into large containers produces appropriately sized slabs, which are subsequently sawn.

Types of equipment

When sawing aerated concrete blocks different equipment is used:

The equipment is manual and mechanical. It is possible to cut the aerated concrete material to any width and length, to give any angle of inclination. For small jobs, manual equipment is used, if the volume of materials is large, electric tools are used. It is not recommended to use a cutting unit. a chain saw.

It is possible to cut aerated concrete blocks into desired parts with a cutting tool. a hand saw. It is used for small amounts of work and if it is difficult to saw with a hacksaw. If there is no possibility to buy a special cutting tool, a self-made hacksaw is sufficient. To make the wood saw suitable for aerated concrete blocks, make teeth on it with an angle grinder and divide it with a pair of pliers. Such a cutting tool is suitable for cutting several blocks and will last a short time. This is a great option, so as not to spend money on buying cutting tools.

However, it is better to cut aerated concrete slabs with a special tool, then the cut edges will be smooth and even. Use in the form of special cutting tools:

Hand saw

For small amounts of work use a hand saw. With its help, finish the openings of windows and doors, and without it you can not cope when installing the initial layers of walls. To ensure that the device, which cuts the products, performed its function well, use auxiliary tools:

- Metal angle, with which to control the correct angle of cut.

- Ruler, marker or pencil, which are needed to determine the place of cutting.

- A planer for aerated concrete products, which flattens the surface layer of the masonry.

Aircrete is one of the hardest materials, which means that the choice of cutting tools must be based on the quality of the cutting blade. It is not right to saw aerated concrete panels with a hand saw, which is designed for wood material. It takes a lot of time and effort. The cutting element of a hand hacksaw should consist of carbide components with larger teeth. Hand saw is available with one handle and with two handles. The cost of the cutting tool is influenced by the distinctive properties of the tool and the manufacturer.

Sabre saw

A sabre hacksaw, which is similar to an electric jigsaw or electric drill, is an electric hand hacksaw. It requires a mains power supply. It can easily cut aerated concrete products. The cutting component is a blade. The sawing process looks like a translational and rotational motion, with movement in a straight line. Making a reciprocating motion, the blades go up. The construction of the saber saw tool consists of three parts, two sides are movable, and one, the middle part, is idle and serves as a lock on the place of cutting. The plus side of the sabre saw is the cleanliness and fineness of the cut. The sabre saw is distinguished by the following indicators:

The sabre saw differs in the way it is cut; it can be sabre and straight. Such a unit can be used directly at the place of work. The sabre saw unit is used to precisely cut aerated concrete blocks, and is perfect for grooving or adjusting boards to size. To work on an aerated concrete block accurately, a marking is made before sawing. Tool depend on unit capacity and power.

Band saw

The band saw mechanism is used for sawing aerated concrete in large productions. Is a closed steel band with teeth on one edge. Cutting with a band saw provides a smooth cut and produces twenty times more blanks than with a hand-held electric tool. The speed of work lies in the ability to saw aerated concrete structures at once 2-3 pieces. Mechanism teeth are made of hard alloy and multi-layer coating. The cost of the cutting structure is not everyone can afford, and reaches five thousand dollars.

electric saw

The cut in aerated concrete blocks can be made with an electric saw. Cutting blades make precise cuts and approximate. Often the electric mechanism with sawing property is used in domestic construction. electric saw is an inexpensive tool, therefore every second man adds to his luggage of building materials. Cutting tool has high technological characteristics and durable materials.

Plunge-cutting saw

The cutting attachment. a groove cutter designed for cutting grooves in the block and making grooves. It is necessary to work with a stitch cutter at the construction site. They can be electric or manual. The advantages of the tool include:

The planer consists of a double-sided cutter that is fixed to the handle. To accelerate the work, a tool with two holders is used. Before sawing, mark the places of future holes with a pencil and ruler.

Planer

Sawing aerated concrete blocks, they try to give them a smooth surface, but it does not always succeed. A planer can cope with this task, which aligns the surface of the aerated concrete and makes it perfectly smooth. The planer consists of a wooden base with embedded fine teeth that are angled.

Tips for choosing

Choosing a tool for cutting aerated concrete, pay attention to: power, price, factory-manufacturer and other criteria. To choose a stroborezor, which is designed for making grooves in the aerated concrete block, consider the power, rotational frequency and disk diameter. Also important are the weight of the unit, the space required and the amount of work.

What and how to saw aerated concrete

Aerated concrete blocks are often used in private housing construction because of their good thermal properties, their low weight and their ease of machining.

The main benefits of working with this building material. easy processing and masonry due to the low weight and large size. Aerated concrete is easy to drill, saw, chisel, plan, screw through and form complex geometries with hand tools such as an aerated concrete saw, planer or chisel.

Основные ошибки при возведении перегородок из газобетона #5

The basics of machining aerated concrete blocks with saws

Masters who have more experience with construction electrical equipment and devices, as well as the need to work with them more often, prefer to cut aerated concrete bricks with an electric saber saw or saw-alligator, rather than hand tools. But when one-time use of aerated concrete (for example, in the construction of outbuildings, garage or cottage. they do not need more than one on one site) hand saw for aerated concrete will be more economical and reliable.

- Electric sabre saw for aerated concrete. it is a powerful electric jigsaw, which gives the cutting blade in the form of a saber a horizontal reciprocating motion. Saw blades are available with two blades and many models are battery-powered. Sabre saw blades are available in various tooth sizes and shapes.

- Saws-alligator works on the principle of the crankshaft. the rotation of the electric motor rotor turns into reciprocating motion of the two cutting blades. Blade blades move in opposite directions to each other, but horizontally, so the cut edge is always clean and level. The price of such electric tool is much higher than that of a reciprocating saw, and the alligator saw is justified only when constantly in use, that is. in professional construction. So before such a highly specialized purchase, think about where this tool will work after construction is complete.

- Hand saws with carbide tipped teeth last much longer than conventional hand saws that have to be resharpened after a few cuts. With pobedite tips you can build a house without replacing the saw, and it will last even longer. When choosing such a tool it is recommended to pay attention to the thickness of the blade. a thin saw will be led aside, the cut will be uneven and slanted. Thick-blade saw makes a precise, accurate, and even cut.

So when choosing what to saw aerated concrete, pay attention to the accuracy and reliability of the tool, not to its price: many people think that expensive power tools are a guarantee of successful construction, but this is not always true. Try to saw the foam block with an ordinary hand saw first, and only if the results are not satisfactory buy more expensive aerated concrete saws.

Sawing by hand

A common misconception that sawing aerated concrete by hand is a long and thankless task with poor results (uneven cuts, torn edges, tedious and unproductive). But for an individual builder cut blocks by hand is possible and necessary, as with a fairly thick blade the cut will always be flat, and the porosity of the material does not make a lot of pressure on the hands. It’s all in the technique of cutting, in the material and in the brand of foam block. If you are going to saw an aerated block or a foam brick of class B 2.0 and density (grade) D 400 with a hand saw, you will like the result. But a block of grade B 3,5 D 600 will make you think about buying an electric cutting tool.

The right hand saw can make several thousand cuts, and these can be complex lines in the form of a trapezoid or hemisphere. The conclusion suggests itself: in addition to the brand of foam block, it is important to work out the right technique of the process:

- Do not put too much pressure on the saw to prevent the blade from bending sideways. Aerated concrete should not be cut in the same way as boards or slats. the material is not cut, and crumbles, so pressure is not needed here in principle.

- Before sawing aerated concrete blocks, make sure they are well dried. wet crumb will stick in the kerf and complicate the cutting process.

- A smooth cut will be obtained if the block is pre-marked on three sides. Make shallow cuts of 20-30 mm in the markings.

- The blade must follow the kerf so that there is no deflection in the planes. Hold the saw at a 45° angle and do not apply pressure to the blade. The block must rest on the base with its whole body to avoid dropping off at the end of sawing and breaking away with jagged edges.

- The hacksaw must be long enough so that the blade overlaps the brick completely and with a reserve on the length.

- To make the work easier, you can make a tuslo from boards or plywood.

How to saw a block with power tools

Sawing gas or foam concrete with electric saws speeds up the process and increases the amount of work, and also allows you to saw complex architectural elements. The method justifies itself in the construction of large objects or a house of two or three stories. The optimal choice for such work would be an alligator saw or a sabre saw for aerated concrete with electric power of about 1000 W and a blade length of 365 mm.

Important: When sawing with an electric saw of any type, you must take only dry foam blocks, otherwise the saw may bite in the sawing and tear out of his hands.

- Before you cut, it is recommended to practice the movements with the tool turned off: the saw blade should not put a hard stop in the block. Before cutting, hold the tool at some distance from the place of cutting, while rocking the saw up, down, and back in the center, as if it were a hand saw. Do not saw through the whole block but with the central part of the blade and with a length of the cutting surface of approx. 250 mm.

- When working with a saber saw, resting it against the end of the product can cause dust to build up and the blade to bite, especially on a wet block. That’s why it is recommended to make cuts from two sides towards each other.

- “Alligator” is a professional tool, and working with it will be justified only for large volumes. However, no one will saw a large number of gas blocks with a manual saw, as it is quite a slow process, and if there is a lot of material, it is also tedious. Sawing with an alligator saw speeds up the work.

- Practice with this power tool has shown that it is not necessary to lubricate the sawing surfaces, as the instructions say, because the grease will immediately adhere to the solid dust, which just throws the grease away, after which the saw works on dry material and the blade often jams. If the grease was factory-made, it must be removed immediately, but to do this, you will have to disassemble the saw. This unusual approach with the correction of the factory instruction allows you to dissolve 50-70 blocks up to 1 meter long for 2-3 hours, with a cutting length of 500-600 mm. If the product is long, the cut is made double-sided, with a preliminary marking of the sides.

How to cut with electric chainsaw

Many people, after purchasing an electric saw and using it for a while, find it difficult to cut wood for firewood. These difficulties arise because the owner simply does not know how to use the saw correctly. And the secret is quite simple. it is necessary to have a good stop, to watch the sharpening and the correct tension of the chain. Regularly change the position of the working area from side to side so that the cutting is even. Always make sure the lubrication tank is full.

The sequence of actions when working is as follows:

- Putting the chainsaw against the wood;

- Start the saw;

- Saw with a smooth motion, lifting the handle up and then down;

- If it becomes awkward to cut, the saw has to be lowered and resumed.

Operating principle

The saber saw works on the same principle as an electric jigsaw. The hacksaw blade moves back and forth and the teeth cut through the material.

The higher the stroke frequency, or strokes per minute, the higher the cutting speed. This speed is required for machining hard materials: metal, stone, ceramics.

Selected models have a pendulum function. Why it is needed? If you look closely at the design of the saw, you will notice that the cutters only have a cutting edge at the front. The other edge is not sharpened and, during the return stroke of the saw, causes resistance, increasing the load on the slide, not working in any way on the depth of cut. When the pendulum mode is on, the blade tilts slightly upward during the reciprocating motion, sawdust is removed, and the cutting process is accelerated. The pendulum stroke is not always required, with shaped cuts this function is not needed.

Sawing techniques

There are a few methods that can simplify the use of the machine. Among them:

- Long-length flexible blades suitable for cutting in line with anything. And it will turn out neat. Such blades are suitable for materials that are in hard-to-reach areas. When you need to cut a pipe from the wall flush with it, it is enough to bend the edge of the blade a little and turn on the machine.

- Sometimes the saber model is compared to an electric jigsaw, but it is rougher. It has been noted that when the tool is functioning, it causes strong vibrations, and the support may deform the face of the object being worked on. To avoid this, it is enough to fix a soft material on the bottom of the unit, reducing the vibration vibration. Then you can not fear that there will be scratches.

- The base of the tool presses firmly against the work surface during the sawing operation to minimize vibration and make the cut more accurately. But because of the close proximity of the teeth to the stop, they are more likely to rub off. It is better to use models with adjustable sole height. This will allow to achieve a more even wear and tear.

- To speed up the work process, the machine is held at a small angle to the surface. This reduces the contact between the material and the equipment, reducing friction and speeding up the process. The main thing is to keep the soleplate firmly pressed to the surface.

- Sometimes the blade can bend in the process. You can correct the situation with a hammer. The blade is placed on a flat piece of wood and tapped. It is necessary to knock along the entire length, without hitting the teeth, so they do not become blunt.

Sabre saws have a lot of additional features. The stroke of its blade can be both straight and pendulum-like. Some models have a tine that can be adjusted up or down. A special wheel allows you to limit the speed. This is a useful tool that is sure to come in handy in everyday life.

Sabre saw Pros and cons of sabre saws Is it worth buying a sabre saw?

The video examines the disadvantages of sabre saws, telling about the pros and cons of sabre saws on the example of the saw

Sabre saw. is the most controversial tool. For most Russians engaged in construction

Cutting blocks was a pleasure at all. At first, the length of the blade (27 cm) was not long enough for a one-pass cutting of a 40 cm block. But then I noticed that even on the narrower areas it is smoother if you saw with 2-3 cuts towards each other. It’s easy to cut with a sabre saw, how often with such a saw one gets tired. And the long blade would be useful for cutting out chute blocks. If you saw with a sabre saw, as in the threads on the forumhouse you can learn how and what to saw with. But here I only needed to make 2 counter-cutting angled cuts (guide bar is not possible because of the chain saw design) and the subsequent small final cut with the standard hand saw. As a result screwed up (cracked) only one U-block. I could have glued it that way, but I decided not to “mold” and saw a new one in 10 minutes. At the end of the season I took my DeWALT to the service station for a preventive measure (gas block dust was flying. horrible). To clean and get the assessment of the master. Lubricated, cleaned, issued a paper saying it was ok (53k.)

Cons: 1. Flimsy accidental start lock button (already floppy). 2. Consumables are expensive and the saw itself costs a pretty penny.

Don’t regret the purchase, t.к. was looking for a universal tool (wood gas concrete) for a completely self contained construction. In addition I also got the ability to saw hard materials (I have to try thin metal. Maybe for a composite MH will do as well). Maybe someone sawed with a saber saw? 8122 11 how to saw with a jigsaw? Ahead of the 2nd floor, rafters, roof. Then the porch and redoing the old house. the saw has enough work yet. That’s why I hope for its reliability and return on investment.

Bevels

Connection of two wooden details under a right angle, for example at picture frames, is often carried out with the help of glue joint with an angle of 45 degrees to the edge. A cut at such an angle has to be made very precisely. Even a slight deviation will not allow the parts to fit together tightly.

If you need to saw the slat exactly and accurately at a 45-degree angle the jigsaw is a good guide. Made of hardwood, this is a block with two parallel flanks and oblique slots in the flanks to keep the saw in position. And in three positions, i.e. the saw can split the strip either diagonally to the left, right or at right angles.

The block must be held firmly in the jigsaw: any relocation of the block could cause a change in the angle of cut. It’s best to secure the workpiece with a clamp. Sawing is done with a back or fret saw. If you use the jigsaw frequently, the jigsaw rims can get damaged, which inevitably leads to a distorted sawing angle. You have to replace the jigsaw.