How to adjust the valves on the tiller: adjusting and adjusting the diesel Lifan and Neva MB-2 with an American engine How to adjust the tiller valves. What is the specificity of adjusting different models, and also how they are similar. Step by step instructions.

Cascade

Adjusting the valves on the cascade tiller:

- Remove the cover from the flywheel.

- Remove the valve cover.

- We turn the flywheel until the intake valve is compressed. Accordingly, the exhaust valve will be depressed.

- Next, you need to achieve the correct clearance for each of the valves. According to the instructions, for the inlet, this parameter is 0.15 mm, and for the outlet 0.20 mm.

- We check with a dipstick the existing gap between the valve and the piston. If the probe slips strongly, or it does not pass between them at all, then we need adjustment. If there is no dipstick, you can use a razor blade that is 0.1 mm thick.

- To adjust, we loosen the fastening nut, then insert the dipstick into the gap under the valve. Its optimal position will be a fairly tight movement between the piston and the valve, without slipping.

- If everything worked out, tighten the nuts back, after which we put the valve cover and the casing in place.

The scheme of work is arranged in an identical way, so you can use one algorithm of action, exactly the same as for adjusting the valves on the popular centaur tiller.

Lifan 6.5

Adjusting valves on the Lifan 6.5 tiller consists in setting the correct clearance under the valves. The sequence of actions will be as follows:

- Remove the cover to get to the flywheel.

- Remove the valve cover. Under it are two valves, an inlet and outlet.

- To check the inlet valve clearance, you need a 0.15 mm dipstick, and 0.2 mm for the outlet. When properly adjusted, the dipstick should pass freely under the valve.

- To adjust, loosen the fastening nuts with a wrench. We insert the dipstick between the valve and the piston so that it does not slip, but is tight enough in this position. We wrap the nut.

- We put in place the valve cover and flywheel housing.

How to properly adjust the Tiller Zip valve

What is the order of adjusting the valves on the popular zip tiller:

- We open the flywheel.

- Unscrew the valve cover clockwise.

- We check the gap with a probe in the same way as described above.

- Use a wrench to turn between the nuts and loosen them a little.

- We close the system and test it.

About the device of tillers and valves

Tillery Cayman, Patriot, Texas, Foreman, Crossser, Viking, Forza, Sadko, Don are a rather complex technical device, consisting of several main working units: engine, transmission, chassis and controls.

The very understanding of the tiller design is very important, because the correctness of the repair and adjustment work depends on it.

Let’s consider each node in more detail:

- Engine. Depending on the configuration, 2-stroke and 4-stroke motors can be used. At the moment, it is the 4-stroke that is most widely used, because they have higher performance.

- In addition, engines are divided into diesel and gasoline. The former are most suitable for large-sized units, and the latter for small and medium-sized units.

For more details on the operation of the tiller engine, see the following:

- Transmission. The torque that is transmitted from the engine to the wheels is carried out precisely by the transmission. It includes a gearbox, gearbox, clutch system and differential (for some models).

- Depending on the type of gearbox and clutch, not only the cost of the tiller is formed, but also the principle of operation of these components.

- Chassis. Most tillers have in their presence a pair of wheels of various types, pneumatic or metal, equipped with lugs. In addition, the chassis includes the frame itself, on which all the other elements of the tiller are located, the engine, gearbox, etc.

- Control system. All control of the tiller is located at the operator’s arm’s length, i.E. On the handle and in the immediate vicinity of it. This includes the clutch lever, shift and drive buttons, emergency engine stop, etc.

How to properly adjust the Tiller Zip valve

What is the order of adjusting the valves on the popular zip tiller:

- We open the flywheel.

- Unscrew the valve cover clockwise.

- We check the gap with a probe in the same way as described above.

- Use a wrench to turn between the nuts and loosen them a little.

- We close the system and test it.

Tiller adjustment: carburetor, valves, fuel system

This article describes the adjustment of the tiller, namely its main parts: the carburetor, valves and the fuel system. This process is not easy, so we have also attached some photos and. You can also read repair tips here.

Tiller Carburetor Adjustment

An unstable tiller engine speed indicates that the carburetor needs adjustment. The need to perform this procedure, as a rule, arises before the start of the agricultural season, when the equipment has not been used for a long time, or after it, when the cultivator has been subjected to significant loads for a long period of time.

Before proceeding with the adjustment, it is necessary to warm up the engine. The work process itself looks like this:

- The screws regulating low and maximum throttle are screwed in completely, after which they are loosened by about one and a half turns.

- The motor is started with a starting device or manually, and warms up for about 10 minutes.

- The lever that controls the operation of the power plant should be set to the minimum position, but the motor should not stop.

- The throttle throttle adjusting screw will help adjust the minimum idle speed so that the diesel engine is stable, without extraneous noise and stops.

- The rotation of the screws makes it possible to accurately set the amount of combustible mixture that enters the motor.

- Tightening the screw contributes to the enrichment of the mixture, while unscrewing it, on the contrary, increases the volume of air entering the engine;

Using the idle screw, adjust the maximum idle speed. Proceed in the same way with minimum speed, using the throttle stop screw. The essence of such an adjustment is that the shutter screw allows you to adjust the angle to which it is closed;

The lever responsible for controlling the motor should be moved to the "throttle" position. If the operation of the cultivator still cannot be called stable, the full throttle screw is adjusted until a perfect stroke is observed. However, the maximum permissible screw speed is 2.5.

The accuracy of carburetor adjustment can also be determined by how the spark plug looks after a short period of time under load. If the working mixture is ideal, then there will be no carbon deposits on the candle, no traces of fuel, which indicate too poor or, conversely, too rich combustible mixture. It should be noted, however, that carbon deposits or traces of fuel on the spark plug may indicate not only incorrect adjustment, but also more serious problems of the Chinese or domestic tiller, including faulty ignition or cooling system.

Tiller valve clearance adjustment

Over time, with significant loads, the valve clearance of the tiller engine changes. This may be due to wear on parts. Insufficient distance leads to the fact that the stages of gas distribution change significantly, as a result of which it is not possible to achieve a sufficient compression ratio, the power device works intermittently and does not reach the declared power. In particularly serious situations, even deformation of the valves can be observed. If the gap is too large, significant mechanical noises are recorded, the gas distribution phases also change significantly, the valves open for too short a time, due to which the cylinder does not fill up properly, the power drops, and failures occur. Clearance adjustment is necessary immediately as soon as the engine operation becomes incorrect or occurs with significant noise. Ideally, the engine being adjusted should be cool.

So, first you need to get to the flywheel. It is on this part that the value of the top dead center is marked. The flywheel is hidden under the cover, and therefore you have to remove it. Before removing the casing, the oil bath of the air filter is removed. It is possible to facilitate the task in the process of removing the casing if you fix all the latches with rubber bands. All bolted connections are unscrewed with a key, after which the cover can be removed without problems.

On the flywheel, you can see marks that indicate TDC, as well as values of 5, 10 and 20 degrees. The 20 degree mark indicates the injection of the combustible mixture. The flywheel should be brought under the top dead center, focusing on the appropriate division. The valve cover is unscrewed and removed.

In the process of adjustment, you need to use the following tools:

- Screwdriver;

- Box key for 10;

- The blade is 0.1 mm thick.

According to the technical data sheet, the valve clearance of the tiller engine is from 0.1 to 0.15 millimeters, and therefore it can be adjusted very accurately with the help of a blade. However, you need to pay attention to the fact that some blades are 0.8 mm thick, which is unacceptable. The exact value can be found with a micrometer or from the information on the manufacturer’s website. The adjustment is done as follows:

- Screwdriver;

- Relax the nut, insert the blade and start to tighten;

- You should focus on the blade, carefully tightening the nut;

- The adjustment is carried out until the valve free travel is eliminated. It should fit snugly enough.

- In the reverse order, we assemble the casing, put the oil bath in place with our hands.

If all manipulations are carried out without errors, then the engine will run smoothly and without unnecessary noise.

Tiller fuel system adjustment

If the fuel is not supplied to the cylinder, then, first of all, it is necessary to check if there is enough fuel in the tank. You also need to check whether it goes to the carburetor. For this, a hose is removed from the inlet connection of the device. If we are talking about a K45 carburetor, press on its quench so that fuel begins to pour out through the drain hole.

If fuel does not enter the carburetor, then you need to turn off the fuel supply valve, completely disassemble it and remove accumulations of dirt from the mechanical filter. To achieve maximum cleanliness, all components must be treated with gasoline. The fuel cock is assembled and returned to its original location.

If fuel enters the carburetor, but is not supplied to the cylinders, it is necessary to check the correct operation of the fuel valve, as well as the presence of dirt on the jets.

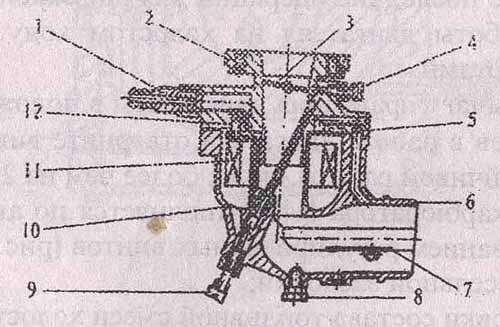

To deal with the carburetor of a gasoline tiller of the KMB-5 type, you need to remove it from the engine and pour the fuel out of the float chamber. Through the fitting (see figure), with the help of which the gasoline is supplied, it is necessary to supply the air mixture, having previously set the carburetor in the operating position. The passage of air should go unhindered, and when the carburetor is turned over, stop completely. These features indicate the complete performance of the part.

Details in the picture: 1 fuel supply connection; 2 upper body; 3 throttle valve; 4 idle needle; 5 jet; 6 lower body; 7 air damper; 8 screw fixing the tie; 9 needle of maximum gas; 10 spray element; 11 float; 12 fuel supply valve.

The fuel level inside the float chamber can be adjusted using the float tab. Ideally, it should range from 3 to 3.5 centimeters.

To purge the jets, the full and idle screws must be unscrewed.

Cleaning the carburetor parts begins by loosening the screws holding the upper body. The lower body is removed, the fuel supply valve is flushed with gasoline, and the dirt from the nozzles is blown out by a pump. It is necessary to check if the float is intact. It is categorically impossible to use rags in the cleaning process.

After completing the cleaning, the housings are connected. It is necessary to check that the spray tube is clearly inserted into the hole located on the upper body. Open the throttle valve and check how well the assembly is done. The screws that secure the upper case are tight. After the assembly process is completely completed, the carburetor should be adjusted. This will significantly improve the performance of a heavy tiller with attachments, since perfect adjustment of all its parts is required for correct operation.

If the carburetor DM 1.08.100 is installed on the engine of the cultivator, then the procedure for adjusting it will be as follows:

- Screw in screw 10 (Fig. 3) at idle until it stops and unscrew it half a turn.

- Then you need to tighten the full throttle screw 9 and unscrew it completely by 2 turns.

- Unscrew the screw 4 (Fig. 4) of the minimum engine speed right up to the stop of the lever against the bore of the carburetor body and turn it 2 turns.

- Start the tiller engine, then adjust stable operation at maximum rpm after warming up with screw 9.

Do not allow the engine control lever to be turned off, move it to the minimum throttle (rpm) position and by unscrewing screw 10 set stable idle rpm. This completes the setup.

That, in principle, is the whole repair. The main points of adjusting the main parts of the tiller are considered. Use our manual (instruction) and prevent faults. Enjoy adjusting your tiller or cultivator!