How to sharpen a chain for chain saw and electric saw?

Symptoms of a dull chain.

Diagnose chain wear

The chain is considered worn if the tensioner does not provide the required chain tension (the chain is “stretched”).

A sharp chain is a must. never use a blunt chain! We recommend that you learn how to properly sharpen your chain. A chain should always be sharpened. That way your sawing is effective, safe and precise.

Professional woodcutters know that a sharpened chain is more important than a strong engine.

How often should the chain be sharpened?? There is no exact guideline for when to sharpen a chain. a professional sharpen the chain several times a day as it dulls. It depends on how often you use your saw. If you feel that the cutting is slower, it is time to sharpen the chain.

If the bar “moves”. the chain also needs to be sharpened. The cuttings are a good indication of the condition of the saw chain.

A well-sharpened (sharp) chain will produce a regular chip and approximately square sawdust; a worn chain will produce dusty chips and needle-like sawdust, as when sharpening a chain with a hacksaw.

Sharpening equipment for chains

Chain sharpening should be left to a chain sharpening specialist if you do not have a sharpening machine and certain chain sharpening skills. Sharpen the chain at home with a cylindrical file of appropriate diameter. Here’s how to straighten saw chains. For sharpening you need a round file, a flat file and the combination file that is right for your saw. Vise also makes your work easier. Clamp the guide bar in a vise and you have both hands free.

Sawing mechanics. How to saw a chain saw

First, a little bit of theory. Each link acts as a small planer in miniature. How well you cut is determined by the difference in height between your cutting tooth and the limiter tooth. The difference in height determines how deep the tooth will cut into the wood. The limiter tooth should be 0,5-0,8 mm below the cutting tooth.

Cutting teeth of a chain saw. Sharpening

Sharpening the cutting teeth first. Put a sharpening block on the chain.

Arrows on the bar should point in the direction of the chain.

Grind with a light, measured movement, pushing forward at an angle to the guide bar. The angle of inclination varies and depends on the pitch of the chain. There should be the same amount of movement per tooth. Sharpen one tooth on the right and one on the left. Tip: If you clamp the guide bar in a vice, it is easier to sharpen first every other tooth on one side and then every other tooth on the other side.

Sharpening the chain for the saw. Grinding the tooth stop

The guide bar is one of the defining components of the saw headset. The bar length influences the depth of cut: the longer the bar, the larger the diameter of the bar the chain saw can handle. Make sure, however, that the length of the guide bar is matched to the power of the saw. Insufficient engine power leads to increased cutting forces, which inevitably leads to premature wearing of saw headset and engine and increased fuel consumption.

Grinding the tooth. limiter.

Apply the jig for the jig tooth and use a flat file to file the jig tooth down to the level of the jig tooth. The jig has two positions: H or “hard” for hardwood, and S “soft” for softwood.

All teeth should be sharpened to the same length. Be guided by the length of the most blunted tooth.

So first measure the “visor” length of the blunted tooth. The angle between the flank and the visor must not be changed during sharpening. Although the peak is slightly tilted towards the bottom, it should be at an angle of 90°. Otherwise the sharpening will have no effect.

Since the inner bore of the tine expands more and more as you sharpen it, make sure that the base of the tine always stays in a horizontal position.

The width of the hole does not affect the performance of the saw.

Each tooth has a depth limiter that regulates the depth of penetration of the saw tooth into the wood.

The distance between the tip of the sprocket and the tip of the depth stop is 0.5. 1.2 mm. It must remain unchanged.

The sharpener grinds the tooth and limiter to the same material thickness in one stroke. In order to keep the original rounding of the depth limiter bore, it must be readjusted after every third grinding. This is to ensure that the saw does not “stumble.

Before you buy a file you need to know the size and parameters of the chain, because every saw needs a specific file. The most common file sizes are ¼”, 0.325″, 3/8″, 0.404″. Only the right file choice will produce the optimum results.

The chain, guide bar and drive sprocket are the main determinants of the quality of your chainsaw. When doing sawing work, they all act as a single saw and therefore must be maintained as a single unit. If used and maintained properly, the saw unit (chain, bar and drive sprocket) is what will provide the best cutting results. It is not the engine that saws on any chainsaw, it is the saw unit that saws.

Here are some basic rules to help you feel the joy of breaking wood of any hardness when you cut it.

Never use a new chain with an old sprocket or an old chain with a new sprocket.

Take a new drive sprocket and two new chains and wear them all at the same time in a rotating swap operation. Replace the drive sprocket with a new one after every two chainwheels are worn.

Rule Each new chain should run-in before use.

Chain arrangement in a chainsaw

The parts are the teeth and connecting pieces. The teeth are along the entire chain and alternate in right-hand and left-hand turns. The tangs are made of a special steel material, and the teeth have a hard chrome coating that makes them last longer.

STIHL has more success in producing quality products than any other company. STIHL chains are made in Switzerland and are individually tested and inductively hardened to increase the wear resistance of the entire support surface.

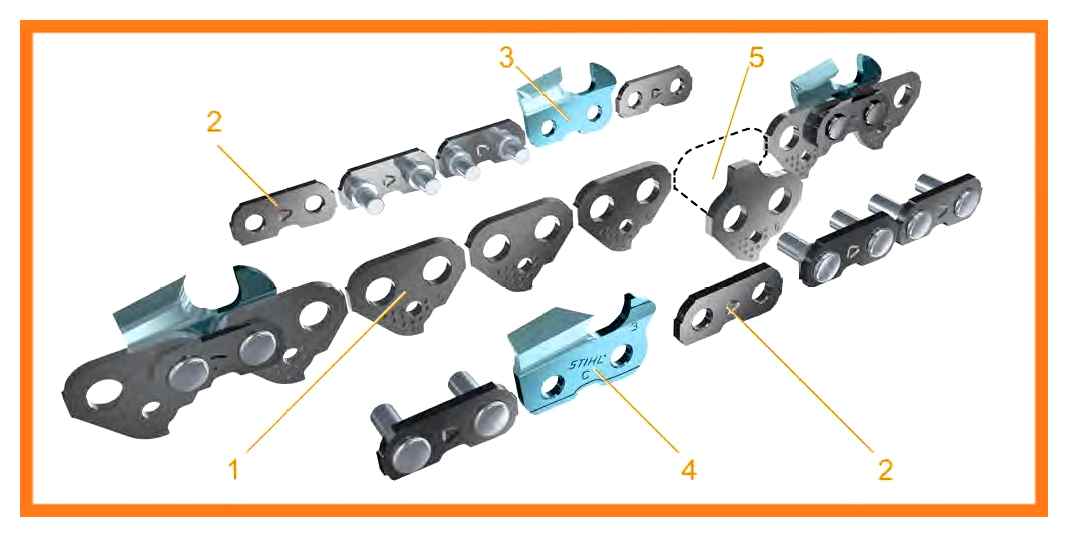

So, the chain consists of these elements:

- leading links (1);

- connecting links (2);

- left cutting teeth (3);

- of the right-hand cutting teeth (4);

- knobby drive links (5) for low kickback chains.

The cutting tooth itself also consists of separate areas:

The special thing about the tooth is that it is not sharpened on one side but on several sides at the same time and in doing so it is shaped:

- The angle for cutting the upper blade into the wood (1);

- Rear angle of the end blade (2);

- front angle of the end blade (3); different chains have 60-85 degrees;

- Back angle of the upper blade (4); the value varies between 50 and 60 degrees;

- sharpening angle (5); 25-35 degrees is optimal, the higher the angle. The softer the wood to be cut;

- depth stop distance (6);

- tooth pattern (8).

Mechanics of sawing, how a chainsaw saws

The principle of the teeth is similar to that of the planer. they plan the wood. The depth stop allows you to adjust the level of plunge cuts in the wood. The top blade lifts the chip away from the base of the kerf, and the end blade. sets it to the side. Tooth blade tapers at rear to form an end angle to the blade. This angle allows you to cut the chip on the side.

Saw chains are specially marked for easy sharpening and wear control:

- Sharpening angle. the upper blade is marked to determine the correct angle and the minimum tooth length. When reaching the mark. the chain is worth replacing.

- Front angle. for the correct angle and for the minimum length of the tooth.

- Depth stop. The correct angle for rebuilding is marked; rebuilding must run parallel to the marking line.

- The base of the tooth is marked to monitor the cutter’s working surface for wear. This is also an indicator of normal operation. if the wear is parallel to the marking.

Grinding chainsaw chain with your own hands with an angle grinder

Experts strongly recommend not to use this method for inexperienced craftsmen. It is rather dangerous.

But if there is no other solution, you must observe the safety rules. Place the angle grinder in a vice and clamp it securely. After switching on the tool, hold the edge to be sharpened against the rotating surface of the disk. Since it is impossible to hold a constant grinding angle with an angle grinder, the tooth ground with the angle grinder will be quite different from the one reached with the file. Also, there is a risk of the angle grinder disc notching the lug of the tooth.

Grinding chain with angle grinder

How to correctly sharpen a chainsaw chain on a chain sharpening machine

It is much faster and more accurate to sharpen a chain on a chain sharpening machine than by hand. Many different electric chain sharpeners are available. Household units are compact and operate from 220 V mains. Abrasive wheels can be easily changed and can be easily adjusted for different chain parameters: tooth pitch, top edge thickness, grinding angle. All finished cutting edges are identical. Fast sharpening process.

Electric chain sharpener for chainsaws

The main part of the machine is an electric motor, the shaft is installed on the sharpening disc. There are controls on the handle of the sharpening machine. A clamping base is provided for securing the machine to the chain. A spring clip adjusts the amount of pressure on the item to be sharpened. Differentiated clamping allows for self-centering of the workpiece in the machine. For safety work a folding safety guard is available.

Electric chain sharpening machine

The saw chain is set into a special guide plate mounted on a turntable. A clamp holds the tooth to be sharpened and an electric emery is mounted at a preset angle. Operator switches on the motor and controls the plunging of the disk

Machines with manual drive

There are devices designed for sharpening, but without electric drive. These are manual machines for straightening saw chains. A regular file is used as a sharpening tool. The machine is mounted directly on the bar. Special stop that holds the tooth to be sharpened. The sharpening angle is adjustable.

Stationary machine shown here with sharpening disk rotated by hand via gearbox. The saw chain is clamped in a bench vice. The machine has a base that can be bolted to a table.

Hand-operated chain saw sharpener

Machine for sharpening chainsaw chains: selection criteria, design features, technical and operational characteristics of the equipment, the principle of operation of manual and automatic devices, review of popular models of sharpening machines.

How to sharpen a chainsaw chain

The chain blunts the most when sawing hard, wet, frozen wood. Less dull. when sawing dry conifers that have already spent some time in the cold.

There are two types of sharpening in total: manual and machine.

When sharpening manually, the cutting teeth are ground with a file, which is selected according to the size and pitch of the tooth. A number of conditions must be observed:

- it is necessary to sharpen teeth at an angle of 25°-35° (that means the angle of a cutting edge of a tooth concerning the perpendicular axis to a chain link). A smaller angle ensures smoother running and is needed for hard and frozen wood. Bigger angle. for soft wood, dry wood, quick cuts;

- the depth limiter is trimmed once in 5-10 sharpening of teeth to keep 0,5-0,8 mm difference between its height and the height of the cutting edge of the tooth (otherwise the saw can cut unproductively, give fine chips, give more bounce);

- hold the file at 30° horizontally and 90° vertically;

- to ensure that the top of the circular file is optimally out of the cutting tooth edge by about 20% of its total diameter.

In order to meet all of these difficult conditions a special tool is manufactured with nozzles that limit the depth of cut to the optimum cutting depth and with tips for the optimum angle of the file during operation.

As you can imagine, if the saw is used frequently and intensively, manual sharpening of the teeth is quite a waste of time. Machines are used to optimize. Manual machines are either attached to the chain blade to enable manual sharpening, or involve removing the chain. electric machines are the most productive. By setting the sharpening parameters once, the chain can be sharpened in minutes.

HOW TO DETERMINE IF IT’S TIME TO SHARPEN A CHAINSAW CHAIN

Frequent work with a chain saw leads to rapid blunting of the cutting teeth, and when abrasive particles (e.g., earth) get in contact with this process is accelerated. Sometimes the cutting ability of the saw has to be restored several times in one working day: with timely sharpening, less steel will have to be removed each time, which increases the life of the entire cutting set as a whole. Let’s list the most common signs of a dull chain:

- – the saw does not cut into the wood itself, requiring considerable pressure on the motor unit;

- – Fine chips are ejected by the saw chain instead of coarse chips;

- – Smoke and a smell of burning when you are sawing. despite perfect functioning of the oil pump and sufficient tensioning of the chain;

- – The saw “runs” sideways due to uneven wear of the cutting teeth;

- – The chain “bounces” and “jumps” when sawing, which can be caused by the small distance between the tips of the depth stopper and their respective cutting edges.

In addition, STIHL chains have special wear lines on the cutting links. If chain is worn to these lines, it is necessary to change the chain.

PRACTICAL TIPS FOR SHARPENING A STIHL CHAINSAW CHAIN

Sharpening a saw chain with the appropriate knowledge and skills is not difficult, but requires following certain rules. Consider the most useful and necessary.

If you run the chain saw continuously for a long time, you have to sharpen it from time to time during the day, because all cutting teeth have to have the same length, sharpening angle and depth limiter position in the first place.

To do it, first find the shortest tooth, set it as a reference point and, while sharpening, adjust all other chain teeth to its length. If it is in the right tooth row, engage the guide bar in a vise with the end sprocket to the left, if it is in the left tooth row, engage the bar with the end sprocket to the right. Then put this tooth in the sharpening zone and engage the chain brake. Sharpen with a round file of a certain diameter depending on the pitch of the chain

For this reason two kinds of saw chains are produced, cross and longitudinal, with different sharpening angles.

The file should have about 20-25% of its diameter protruding over the top edge of the cutting tooth. NOTE: remember, the file only cuts metal as it moves away from you, but it needs to be lifted as you move backward. Also, the file should periodically be rotated slightly around its axis to prevent uneven wear. Check after going forward two or three passes to see if the steel is evenly removed from the cut tooth. If you are pulling off in places you are either using the wrong file or your file is too high or too deep. Grind the cutting edge until the light bar has disappeared.

After obtaining a quality cutting edge on the tooth to be sharpened, first disengage the brake, move the chain to the next tooth on the same side of the bar and reinstall the brake before sharpening. Grind the remaining cutters to the same length on this side, then turn the tool 180° and sharpen all cutters on the other side in the same way. Recall that they all have to be ground to the starting tooth length. If one set of cutters is longer than the other, sharpen them in one or two sharpening motions.

Observance of the above recommendations contributes to obtaining correct and identical values of the rake angle and sharpening angle at the same height of all chain cutting links.

Now the depth limiters need to be adjusted, because the height differences between the upper points of the cutting edge and the plunge stop as the teeth are being ground have decreased, and unevenly, because the teeth had to be aligned.

To check this value, it is convenient to use a filing gauge that corresponds to the chain pitch and determines the cutting depth (see “Depth of cut” on page 24). table 1). It is a template to control the position of the depth gauge, it is placed on the cutting tooth, and if the depth gauge protrudes over the upper plane of the gauge, this surplus must be removed with a flat file. Do not touch a sharpened cutting tooth with a file. Calculate the number of pitches you need to file on the first depth stop and grind the depth stops on the remaining cutters about the same number of times, remembering to round the leading edge of the stop to reduce vibrations and reduce the risk of kickback.

a manual chain saw sharpening justifies itself in maintaining the cutting performance of the machine if it is used intensively during the working day. STIHL also offers a wide range of accessories to make sharpening easier and more efficient. These include special guides, various sharpening devices, proof gauges, etc.д. After 3-4 manual sharpening cycles we recommend that you have your saw chain professionally sharpened mechanically by a qualified sharpening service to guarantee high cutting performance and excellent cut quality.

How to sharpen a chain using a file?

The cutting attachments are made of steel, so overheating is not allowed. When working with an emery wheel, the angle grinder heats the surface to high temperatures, which can disrupt the structure of the alloy, making it more brittle and prone to abrasion. Overheating can be avoided by continuous cooling of the cutting area.

Sharpening with an angle grinder has another disadvantage. The abrasive wheel is quite thick and large, and it is very difficult to get under the tooth to maintain the sharpening angle. Most of the chainsaw manufacturer’s manuals give recommendations on how to file using the guide.

The manual method is the most popular method for sharpening. Manual sharpening steps:

- The chain saw blade is held in a vise or clamp.

- Mark the shortest tooth with chalk or paint.

- The file is filed under the blade, pressing the blade firmly against the edge line. At the same time, the tool holder is pressed down, which will help it take an optimal position.

- Maintaining the angle, work with the file in a back-and-forth motion, using 2 to 3 strokes on the beveled surface of the blade. Reverse movement of the tool without pressure.

- Rotate the file to evenly grind. Repeat the operation until the tooth is sharpened.

- Check the position of the stop on the jig. A flat file is used to correct an element.

- Start sharpening the next tooth separated by one from the marked one.

- After completing a lap, turn the bar over and sharpen the remaining teeth. That is, first work elements of one direction, and then the opposite.

- Do not sharpen the stop every time, but after 2-3 sharpenings.

Each tooth has a factory-made notch. This mark indicates the maximum angle of the edges and determines the direction of the sharpening motion.

Some craftsmen insert the file into the chuck of an electric screwdriver or drill. You get a mechanized device. Quality and safety of work with the tool is not guaranteed, but the speed of processing the chain will be higher.

How to keep a chainsaw chain sharp for longer?

Deciding to sharpen the tool chain on your own, be careful. Safety of the master in the first place. Attention during work will save you from injury and ensure the correct sharpening angle.

In our catalog you can choose and order tools, chainsaw accessories, files and other tools for your work. If you have any questions, call 7870.